Content Menu

● Introduction to SMT Stencils

>> Types of SMT Stencils

● Latest Innovations in SMT Stencil Technology

>> Advanced Coating Technologies

>> Laser Cutting and Additive Manufacturing

>> Automation and Sustainability

● Market Trends and Challenges

>> Competitive Landscape

>> Emerging Technologies and Applications

● Future Outlook

● Conclusion

● Frequently Asked Questions

>> 1. What is the role of SMT stencils in electronics manufacturing?

>> 2. What are the main types of SMT stencils?

>> 3. How do advanced coatings like CVD and PVD improve stencil performance?

>> 4. What impact does automation have on SMT stencil production?

>> 5. How is sustainability influencing the SMT stencil market?

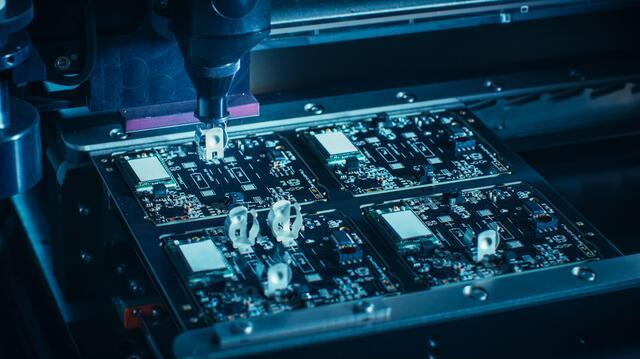

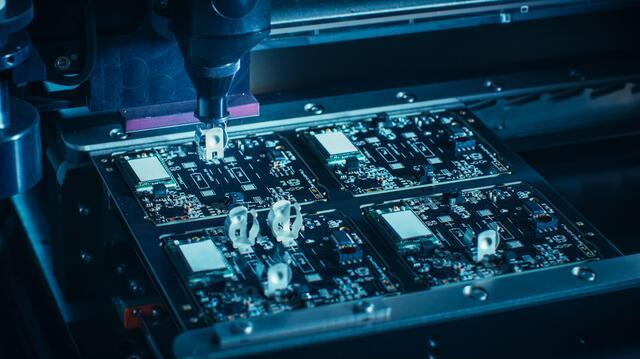

The Surface Mount Technology (SMT) industry has witnessed significant advancements in recent years, driven by the increasing demand for sophisticated electronic devices and the miniaturization of components. One crucial element in SMT is the stencil, which plays a pivotal role in the precise deposition of solder paste onto Printed Circuit Boards (PCBs). This article explores the latest innovations in SMT stencil technology, focusing on advancements that enhance precision, efficiency, and sustainability.

Introduction to SMT Stencils

SMT stencils are essential tools in the electronics manufacturing process. They are used to apply solder paste onto PCBs, ensuring accurate component placement and reliable connections. The quality and precision of these stencils directly impact the performance and reliability of the final electronic product. Traditional stencils are made from materials like stainless steel or nickel, but recent innovations have introduced new materials and technologies to improve stencil performance.

Types of SMT Stencils

- Framed vs. Frameless Stencils: Framed stencils are widely used due to their cost-effectiveness and ease of handling. However, frameless stencils are gaining popularity for their superior precision and adaptability to complex PCB designs.

- Single-Sided vs. Double-Sided SMT Stencils: While single-sided stencils are common, double-sided stencils are used for more complex PCBs that require solder paste application on both sides. However, the term "sided smt stencil" is not commonly used in the industry; instead, the focus is on the type of stencil (framed or frameless) and its application (single-sided or double-sided).

Latest Innovations in SMT Stencil Technology

Advanced Coating Technologies

1. StenTech BluPrint CVD and PVD Coatings: StenTech has introduced the BluPrint CVD (Chemical Vapor Deposited) and PVD (Physical Vapor Deposited) surface treatments. These coatings enhance stencil performance by improving surface smoothness, corrosion resistance, and solder paste transfer efficiency. The PVD stencils, in particular, offer a transfer efficiency of 98%, making them ideal for high-performance PCBs.

2. Nano-Coatings: Nano-coatings applied to stencil surfaces improve paste release characteristics and reduce blocking, enhancing overall stencil efficiency. These coatings are especially beneficial for stencils used in high-volume production environments where maintaining consistency is crucial.

Laser Cutting and Additive Manufacturing

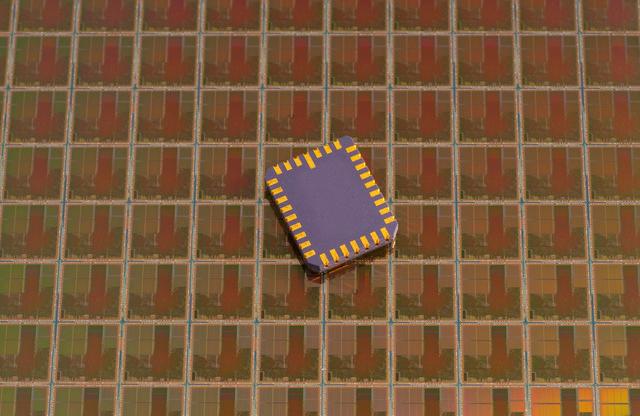

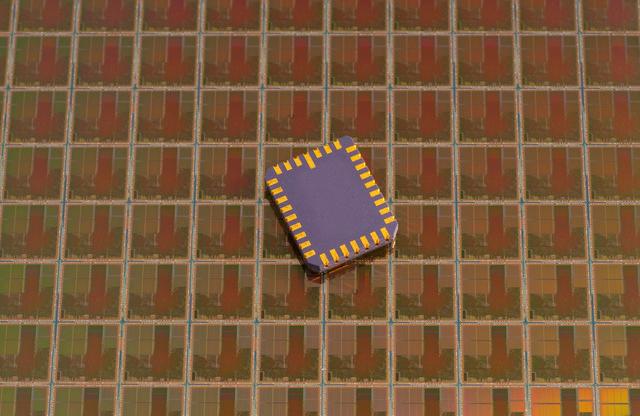

- Laser Etching: Advances in laser cutting technology allow for the creation of stencils with finer features, supporting ultra-fine-pitch component designs. This technology enables the production of stencils with apertures as small as 0.05mm, catering to the increasing demand for miniaturization. Laser etching also provides precise control over stencil aperture shapes, which is essential for optimizing solder paste deposition.

- Additive Manufacturing (3D Printing): Although still in its early stages, additive manufacturing holds potential for creating custom-made stencils for unique PCB designs. This technology could disrupt the traditional stencil market by offering tailored solutions for specialized applications, such as prototyping or small-batch production.

Automation and Sustainability

- Automated Systems: The integration of automated under-stencil cleaning systems and in-line stencil inspection technologies maintains stencil quality over long production runs, enhancing efficiency and reducing downtime. These systems ensure that stencils remain clean and free from debris, which is critical for maintaining consistent solder paste application.

- Eco-Friendly Materials: There is a growing demand for eco-friendly stencil materials and manufacturing processes. Biodegradable and lower-toxicity solder pastes are becoming more prevalent, aligning with the industry's shift towards more sustainable practices. Additionally, efforts to reduce waste and energy consumption during stencil production are gaining traction.

Market Trends and Challenges

The global SMT stencil market is experiencing robust growth, driven by the increasing demand for sophisticated electronic devices and advancements in SMT technologies. North America and Asia-Pacific dominate the market due to their high concentration of electronics manufacturing hubs. However, challenges include managing fluctuating raw material costs and ensuring consistent quality across large-scale production runs.

Competitive Landscape

The market is highly competitive, with both large multinational corporations and specialized smaller firms vying for market share. Companies are focusing on technological innovation, cost optimization, and strategic partnerships to enhance their market position. Collaborations between stencil manufacturers and electronics companies are becoming more common, as they work together to develop tailored solutions for specific applications.

Emerging Technologies and Applications

Emerging technologies like the Internet of Things (IoT) and 5G are driving the demand for more complex and miniaturized electronic devices. This trend necessitates the development of stencils capable of handling finer pitches and more precise solder paste deposition. Additionally, advancements in stencil technology are also influencing the automotive and aerospace industries, where reliability and precision are paramount.

Future Outlook

The future of SMT stencil technology looks promising, with ongoing advancements in materials, manufacturing techniques, and the increasing demand for high-precision electronics driving growth. As the electronics industry continues to evolve, the need for precise and efficient PCB assembly techniques will remain paramount. Innovations in stencil technology will play a crucial role in meeting these demands, ensuring that electronic devices continue to become smaller, faster, and more reliable.

Conclusion

In conclusion, the latest innovations in SMT stencil technology are transforming the electronics manufacturing landscape by enhancing precision, efficiency, and sustainability. From advanced coating technologies to the integration of automation and additive manufacturing, these developments are crucial for meeting the increasing demand for sophisticated electronic devices. As the industry continues to evolve, the focus on technological innovation and strategic partnerships will remain key to success.

Frequently Asked Questions

1. What is the role of SMT stencils in electronics manufacturing?

SMT stencils are used to apply solder paste onto PCBs, ensuring accurate component placement and reliable connections. They are crucial for the performance and reliability of electronic devices.

2. What are the main types of SMT stencils?

The main types include framed and frameless stencils. Framed stencils are cost-effective and easy to handle, while frameless stencils offer superior precision and adaptability to complex PCB designs.

3. How do advanced coatings like CVD and PVD improve stencil performance?

Advanced coatings like CVD and PVD enhance stencil performance by improving surface smoothness, corrosion resistance, and solder paste transfer efficiency. This leads to improved stencil longevity and overall quality of the SMT assembly process.

4. What impact does automation have on SMT stencil production?

Automation, such as automated under-stencil cleaning systems and in-line inspection, maintains stencil quality over long production runs, enhancing efficiency and reducing downtime.

5. How is sustainability influencing the SMT stencil market?

There is a growing demand for eco-friendly stencil materials and manufacturing processes. Biodegradable and lower-toxicity solder pastes are becoming more prevalent, aligning with the industry's shift towards more sustainable practices.