Content Menu

● Introduction

● Key Innovations in SMT Line Equipment

>> Automation and Robotics

>> Dual-Lane Manufacturing

>> Artificial Intelligence and Big Data

>> Sustainability in SMT Processes

>> Flexible and High-Mix Equipment

>> Advanced Inspection Technologies

>> Enhanced Software Capabilities

>> High-Speed Pick-and-Place Machines

>> The Rise of Microelectronics

>> Smart Manufacturing Practices

>> Customization Capabilities

>> Sustainability Initiatives

● Conclusion

● FAQ

>> 1. What is SMT line equipment?

>> 2. How does dual-lane manufacturing improve productivity?

>> 3. What role does AI play in SMT line equipment?

>> 4. Why is sustainability important in SMT processes?

>> 5. What are the benefits of flexible SMT equipment?

Introduction

Surface Mount Technology (SMT) line equipment is crucial in the modern electronics manufacturing landscape. It enables the efficient assembly of electronic components onto printed circuit boards (PCBs), which are integral to a wide range of devices, from smartphones to industrial machinery. As technology evolves, so does the equipment used in SMT lines, leading to significant innovations that enhance productivity, efficiency, and sustainability. This article explores the latest innovations in SMT line equipment, highlighting key advancements that are shaping the future of electronics manufacturing.

Key Innovations in SMT Line Equipment

Automation and Robotics

Automation has become a cornerstone of SMT line equipment, significantly enhancing efficiency and reducing human error. Advanced robotics are now integrated into various stages of the SMT process, from component placement to inspection. These systems can operate continuously without fatigue, allowing for higher throughput and consistent quality.

- Collaborative Robots (Cobots): Cobots work alongside human operators, assisting in tasks that require precision and speed. They are designed to be safe and easy to program, making them ideal for small to medium-sized enterprises looking to automate their processes.

- Automated Guided Vehicles (AGVs): AGVs transport materials and components between different stages of production without human intervention. This not only streamlines operations but also reduces the risk of accidents in busy manufacturing environments.

Dual-Lane Manufacturing

Dual-lane manufacturing is an innovative approach that allows for simultaneous processing of different products on separate lanes within the same SMT line. This flexibility is particularly beneficial for manufacturers facing high mix-low volume production demands.

- Increased Throughput: By utilizing dual lanes, manufacturers can optimize space and increase overall throughput. This setup minimizes downtime associated with changeovers between different product types.

- Independent Operation: Each lane can operate independently, allowing for tailored settings based on specific product requirements. This adaptability is crucial for meeting diverse customer needs efficiently.

Artificial Intelligence and Big Data

The integration of artificial intelligence (AI) and big data analytics into SMT line equipment is revolutionizing decision-making processes and operational efficiency.

- Predictive Maintenance: AI algorithms analyze data from machinery to predict potential failures before they occur, allowing for proactive maintenance. This reduces downtime and maintenance costs while ensuring continuous operation.

- Process Optimization: Big data analytics enables manufacturers to gather insights from production data, leading to improved process control and quality assurance. By analyzing trends and patterns, companies can make informed decisions that enhance productivity.

Sustainability in SMT Processes

As environmental concerns grow, sustainability has become a focal point in the development of SMT line equipment. Manufacturers are increasingly adopting eco-friendly practices that comply with global regulations.

- Lead-Free Soldering: The shift towards lead-free soldering materials not only meets regulatory requirements but also promotes environmental sustainability. New soldering technologies ensure high-quality joints while minimizing environmental impact.

- Energy-Efficient Equipment: Innovations such as energy-efficient reflow ovens and soldering machines reduce energy consumption during production. These advancements contribute to lower operational costs and a smaller carbon footprint.

Flexible and High-Mix Equipment

The demand for customization in electronics manufacturing has led to the development of flexible SMT line equipment capable of handling diverse product types.

- Modular Systems: Modern SMT lines feature modular equipment that can be reconfigured quickly to accommodate different products. This flexibility allows manufacturers to respond swiftly to market changes without significant downtime or investment.

- Shorter Production Cycles: With the capability to switch between various product configurations rapidly, manufacturers can meet the increasing demand for shorter production cycles while maintaining high quality standards.

Advanced Inspection Technologies

Quality control is paramount in electronics manufacturing, and recent innovations in inspection technologies have significantly improved defect detection rates.

- 2D and 3D Automated Optical Inspection (AOI): These systems utilize advanced imaging technologies to inspect PCBs for defects at high speeds. The 3D AOI systems provide more detailed analysis by capturing depth information, allowing for better detection of issues such as lifted leads or misaligned components.

- X-ray Inspection Systems (AXI): X-ray inspection allows manufacturers to see inside components and connections in 3D, detecting defects like voids or lack of wetting that traditional visual inspections might miss. This technology is essential for ensuring the reliability of complex assemblies.

Enhanced Software Capabilities

The software used in conjunction with SMT line equipment has evolved significantly, enabling smarter manufacturing processes.

- Industry 4.0 Integration: Many new machines come equipped with software that supports Industry 4.0 principles, including real-time monitoring, predictive analytics, and machine learning capabilities. This integration allows manufacturers to optimize their operations continuously based on live data inputs.

- MES Systems: Manufacturing Execution Systems (MES) provide comprehensive control over production processes by tracking materials, managing workflows, and ensuring traceability throughout the manufacturing cycle. These systems help streamline operations and improve overall efficiency.

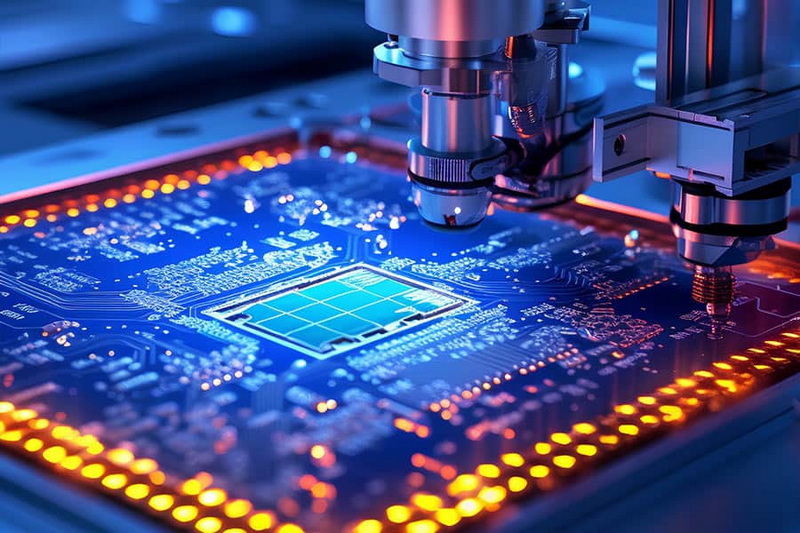

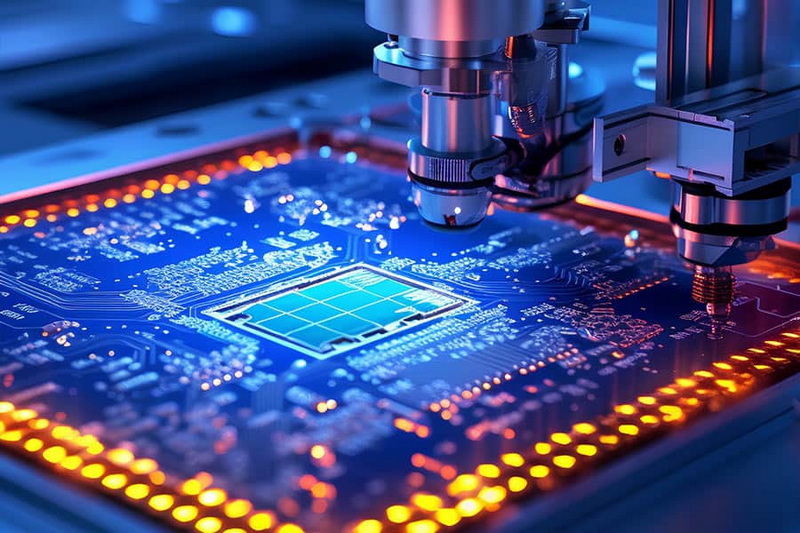

High-Speed Pick-and-Place Machines

Pick-and-place machines are at the heart of any SMT line, responsible for placing components accurately onto PCBs at high speeds.

- Speed and Accuracy: New generations of pick-and-place machines boast placement speeds exceeding 100,000 components per hour while maintaining micron-level placement precision. This capability is crucial as electronic devices continue to shrink in size while increasing in complexity.

- Component Versatility: Modern machines can handle a wide range of components—from tiny 01005 chips to large BGAs—making them suitable for various applications across industries such as automotive, consumer electronics, and telecommunications.

The Rise of Microelectronics

Microelectronics is a significant trend influencing SMT line equipment design as devices become smaller yet more powerful. The demand for micro-sized components—such as those found in wearables or IoT devices—has led manufacturers to develop specialized machinery capable of handling these tiny parts efficiently.

- Micro-SMT Technologies: Innovations like microBGAs (Ball Grid Arrays) enable higher component density on PCBs without sacrificing performance or reliability. As a result, new pick-and-place machines are being designed specifically for handling these minute components with precision placement capabilities down to microns.

Smart Manufacturing Practices

Smart manufacturing practices are becoming increasingly prevalent within electronics assembly lines due to their ability to enhance productivity through connectivity and data analysis.

- IoT Integration: The Internet of Things (IoT) facilitates communication between machines on the production floor allowing real-time adjustments based on performance metrics collected from various stages of assembly lines—leading towards fully automated factories where human intervention is minimized or entirely removed from routine tasks.

- Data Analytics: Advanced analytics tools allow manufacturers not only to monitor machine performance but also predict future needs based on historical data trends—enabling better resource allocation across production lines which can lead directly toward cost savings over time through optimized operations.

Customization Capabilities

As consumer preferences shift towards personalized products across industries—from smartphones tailored specifically for individual users' needs—to unique automotive features—SMT lines must adapt accordingly by providing customizable solutions without compromising speed or quality assurance standards.

- Flexible Production Lines: Manufacturers are increasingly investing in flexible production lines that can easily switch between different product configurations with minimal setup time required—this flexibility allows companies greater responsiveness when responding quickly towards changing market demands while still maintaining high levels of efficiency throughout each stage involved within their respective supply chains.

Sustainability Initiatives

Sustainability remains at the forefront as companies strive towards reducing their environmental impact through improved practices across all aspects related directly back towards electronics manufacturing processes including:

- Eco-Friendly Materials: The use of biodegradable materials during PCB fabrication processes contributes positively towards reducing waste generated throughout typical assembly operations; additionally utilizing recycled substrates helps minimize reliance upon virgin resources thereby promoting circular economy principles within this industry sector.

- Waste Reduction Strategies: Implementing waste reduction strategies such as optimizing material usage during component placement ensures minimal excess material ends up discarded post-production—this not only benefits profitability margins but also aligns closely with corporate social responsibility goals aimed at fostering sustainable growth over time across global markets served by these organizations involved within this field.

Conclusion

In conclusion; staying abreast with emerging technologies will prove vital if organizations wish not only remain competitive but also thrive amidst rapid changes occurring within global markets influenced heavily by technological advancements shaping modern-day society today—particularly those centered around surface mount technology where innovations continue transforming traditional methods employed historically into cutting-edge solutions designed specifically cater needs arising from evolving consumer demands seen across various sectors worldwide!

FAQ

1. What is SMT line equipment?

SMT line equipment refers to the machinery used in surface mount technology for assembling electronic components onto PCBs. It includes various machines such as pick-and-place systems, reflow ovens, inspection units, and more.

2. How does dual-lane manufacturing improve productivity?

Dual-lane manufacturing allows simultaneous processing of different products on separate lanes within the same SMT line. This optimizes space usage and increases throughput while minimizing downtime associated with changeovers between products.

3. What role does AI play in SMT line equipment?

AI enhances decision-making by analyzing production data for predictive maintenance and process optimization. It helps manufacturers reduce downtime and improve overall operational efficiency through data-driven insights.

4. Why is sustainability important in SMT processes?

Sustainability ensures compliance with environmental regulations while promoting eco-friendly manufacturing practices. It helps manufacturers reduce their carbon footprint and meet consumer demand for environmentally responsible products.

5. What are the benefits of flexible SMT equipment?

Flexible SMT equipment can adapt quickly to handle diverse product types and shorter production cycles. This capability enables manufacturers to meet modern market demands efficiently without significant downtime or reconfiguration costs.