Content Menu

● Understanding Surface Mount Technology (SMT)

● Recent Innovations in SMT for LED Assembly

>> 1. Micro SMT Technology

>> 2. 3D Packaging Techniques

>> 3. Advanced Soldering Techniques

>> 4. AI-Driven Inspection Systems

>> 5. Direct Attach and Flip Chip Technologies

● Additional Innovations Impacting SMT for LED Assembly

>> Flexible PCB Technology

>> Enhanced Thermal Management Solutions

>> Integration with Smart Technologies

● Challenges in SMT for LED Assembly

● Future Trends in SMT for LED Assembly

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does micro SMT benefit LED assembly?

>> 3. What role does AI play in SMT?

>> 4. What are some challenges faced in LED assembly using SMT?

>> 5. What future trends can we expect in SMT for LED assembly?

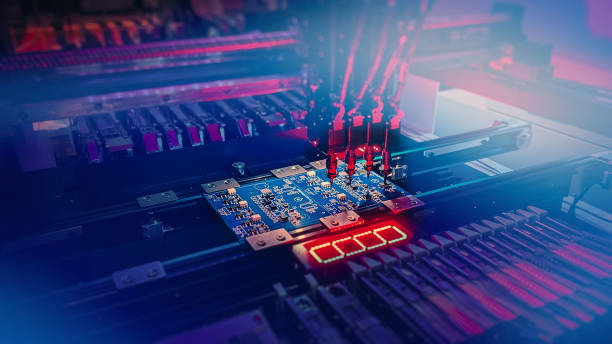

Surface Mount Technology (SMT) has revolutionized the assembly of electronic components, particularly in the context of LED manufacturing. As the demand for compact, efficient, and high-performance lighting solutions continues to grow, innovations in SMT are becoming increasingly critical. This article explores the latest advancements in SMT specifically tailored for LED assembly, highlighting key technologies, processes, and trends shaping the industry.

Understanding Surface Mount Technology (SMT)

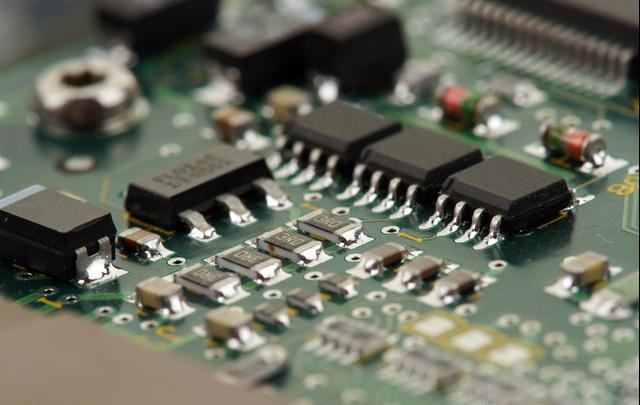

SMT is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This approach contrasts with traditional through-hole technology, which requires components to be inserted into drilled holes on the PCB. The benefits of SMT include:

- Higher Component Density: SMT allows for more components to be placed on a smaller area of the PCB, which is essential for modern electronic devices that require miniaturization.

- Improved Electrical Performance: Shorter lead lengths reduce inductance and capacitance, leading to better performance in high-frequency applications.

- Cost Efficiency: The automation of SMT processes reduces labor costs and increases production speed.

- Flexibility: SMT accommodates a wide variety of component types and sizes, making it suitable for diverse applications.

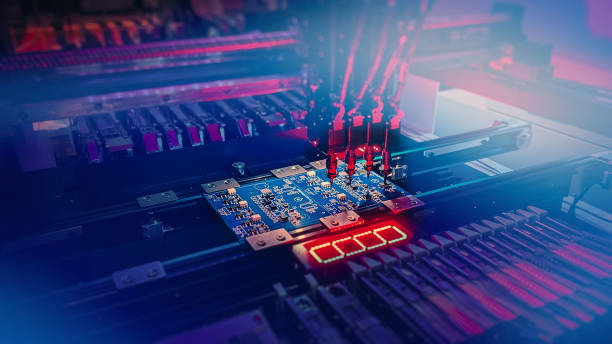

Recent Innovations in SMT for LED Assembly

The integration of LEDs into various applications has necessitated advancements in SMT processes. Here are some of the latest innovations:

1. Micro SMT Technology

Micro SMT enables the use of ultra-small components such as 0201 passives and microBGAs. This technology is crucial for producing compact LED assemblies that fit into modern devices like smartphones and wearables. The ability to handle smaller components allows manufacturers to create more intricate designs without compromising performance.

Micro SMT technology also facilitates higher packing density on PCBs, which is particularly beneficial in applications where space is at a premium. As consumer electronics continue to trend towards slimmer profiles and lighter weights, micro SMT will play an essential role in meeting these demands.

2. 3D Packaging Techniques

3D packaging involves stacking multiple layers of components vertically rather than spreading them out horizontally. This method enhances space efficiency and allows for better thermal management—an essential factor in LED applications where heat dissipation is critical.

Additionally, 3D packaging can improve signal integrity by reducing the length of interconnections between components. This reduction not only minimizes potential interference but also contributes to faster signal transmission speeds, which is vital for high-performance LED applications.

3. Advanced Soldering Techniques

Innovations in soldering techniques, such as selective soldering and reflow soldering with controlled vacuum environments, have improved the reliability of solder joints in LED assemblies. These methods minimize defects such as voids, ensuring stronger connections that can withstand thermal cycling.

Selective soldering allows manufacturers to apply solder only where it is needed, reducing waste and improving overall efficiency. Furthermore, advancements in solder materials have led to the development of low-temperature solders that can be used with sensitive components without risking damage from excessive heat.

4. AI-Driven Inspection Systems

Automated Optical Inspection (AOI) systems equipped with artificial intelligence (AI) capabilities are now used to inspect LED assemblies more efficiently. These systems can quickly identify misaligned components and defects, significantly reducing setup times and enhancing quality control. The integration of AI helps streamline the inspection process by learning from previous data, thus improving accuracy over time.

Moreover, AI-driven systems can adapt to new product designs without extensive reprogramming, allowing manufacturers to rapidly introduce new LED products into their production lines while maintaining high-quality standards.

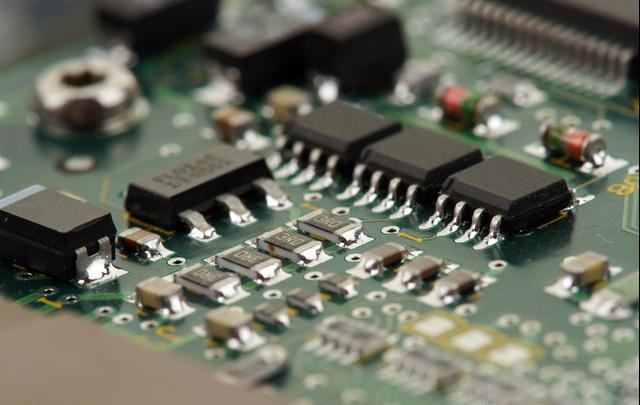

5. Direct Attach and Flip Chip Technologies

These advanced assembly methods eliminate the need for wire bonding by directly attaching die to substrates using eutectic bonding or solder paste. This results in lower profiles and improved thermal performance for LEDs, making them ideal for compact applications.

Direct attach technology enhances thermal conductivity between the LED chip and substrate, which is crucial for maintaining optimal operating temperatures. Flip chip technology further reduces thermal resistance by placing the active area of the chip directly against the substrate, allowing for efficient heat dissipation.

Additional Innovations Impacting SMT for LED Assembly

In addition to the above innovations, several other trends are shaping SMT processes in LED assembly:

Flexible PCB Technology

Flexible PCBs are gaining traction in LED assembly due to their lightweight nature and ability to conform to various shapes. This flexibility allows manufacturers to design innovative lighting solutions that can be integrated into unconventional spaces or products.

Flexible PCBs also facilitate unique lighting designs such as bendable or foldable light strips that can be used in creative installations or portable devices. As consumer preferences shift towards customizable lighting options, flexible PCB technology will become increasingly important.

Enhanced Thermal Management Solutions

As LEDs generate heat during operation, effective thermal management solutions are crucial for maintaining performance and longevity. Recent innovations include advanced thermal interface materials (TIMs) that improve heat transfer between LEDs and heat sinks.

Manufacturers are also exploring new materials such as graphene and ceramic composites that offer superior thermal conductivity while remaining lightweight. These materials can help dissipate heat more effectively than traditional metals like aluminum or copper.

Integration with Smart Technologies

The rise of smart lighting solutions has led to increased integration between LEDs and IoT technologies. Manufacturers are developing smart drivers that allow LEDs to communicate with other devices within a network.

This integration enables features such as remote control via smartphone apps or automated adjustments based on environmental conditions (e.g., dimming lights based on natural light levels). As smart home technologies continue to grow in popularity, this trend will likely expand further.

Challenges in SMT for LED Assembly

Despite these innovations, several challenges persist in the SMT assembly process for LEDs:

- Thermal Management: As LED assemblies become more compact, managing heat dissipation without compromising performance is increasingly difficult.

- Component Miniaturization: The trend toward smaller components complicates handling and placement processes, requiring more advanced machinery and techniques.

- Quality Control: Ensuring consistent quality across high-volume production runs remains a challenge, necessitating robust inspection systems.

- Supply Chain Issues: The global semiconductor shortage has impacted many industries, including LED manufacturing. Accessing high-quality components consistently is essential for maintaining production schedules and meeting customer demands.

Future Trends in SMT for LED Assembly

Looking ahead, several trends are likely to shape the future of SMT in LED assembly:

- Increased Automation: The push towards fully automated production lines will continue as manufacturers seek to improve efficiency and reduce labor costs. Automation not only speeds up production but also minimizes human error during assembly processes.

- Integration with IoT: As more devices become connected through the Internet of Things (IoT), there will be a greater need for smart lighting solutions that integrate seamlessly with other technologies. This integration will drive demand for advanced communication protocols within LED assemblies.

- Sustainability Initiatives: With growing environmental concerns, there will be an emphasis on developing lead-free soldering processes and energy-efficient manufacturing practices. Companies will need to adopt sustainable practices throughout their supply chains while still delivering high-quality products.

- Customization Capabilities: As consumer preferences shift towards personalized products, manufacturers will need to develop flexible production processes that allow customization without sacrificing efficiency or quality.

Conclusion

The landscape of SMT for LED assembly is rapidly evolving due to technological advancements aimed at improving efficiency, performance, and sustainability. Innovations such as micro SMT technology, AI-driven inspection systems, advanced soldering techniques, flexible PCB technology, and enhanced thermal management solutions are paving the way for more compact and reliable lighting solutions.

As manufacturers continue to adapt to market demands and technological changes while facing challenges like supply chain issues and quality control needs, we can expect further enhancements that will redefine what is possible in electronics assembly. The future promises even greater integration with smart technologies while emphasizing sustainability—ensuring that LED lighting remains at the forefront of innovation within electronics manufacturing.

FAQ

1. What is Surface Mount Technology (SMT)?

SMT is a method used to mount electronic components directly onto the surface of a PCB instead of inserting them through holes.

2. How does micro SMT benefit LED assembly?

Micro SMT allows manufacturers to use smaller components like 0201 passives, enabling more compact designs essential for modern electronic devices.

3. What role does AI play in SMT?

AI enhances automated optical inspection systems by improving defect detection accuracy and reducing inspection times through machine learning algorithms.

4. What are some challenges faced in LED assembly using SMT?

Challenges include effective thermal management, handling miniaturized components, maintaining consistent quality across production runs, and navigating supply chain issues due to global shortages.

5. What future trends can we expect in SMT for LED assembly?

Future trends include increased automation within production lines, greater integration with IoT technologies for smart lighting solutions, sustainability initiatives focusing on eco-friendly practices, and customization capabilities catering to consumer preferences.