Content Menu

● Introduction to SMD LED Making Machines

● Key Innovations in SMD LED Making Machines

>> 1. Enhanced Precision and Placement Speed

>> 2. Multi-Head and Multi-Feeder Systems

>> 3. Flying Vision and Automated Correction

>> 4. Continuous Placement and Conveyor Integration

>> 5. Advanced Thermal and Optical Management in LED Packaging

>> 6. Miniaturization and High-Density Mounting

>> 7. Energy Efficiency and Environmental Resistance

>> 8. Integration of Proprietary Technologies

>> 9. Intelligent Software and Automation

>> 10. Environmental and Safety Enhancements

● Impact of Innovations on Manufacturing

● Conclusion

● FAQ

>> 1. What is an SMD LED making machine?

>> 2. How do flying vision systems improve SMD LED making machines?

>> 3. What are the benefits of multi-head placement in SMD LED making machines?

>> 4. How do recent innovations affect the size of SMD LEDs that can be handled?

>> 5. What role does thermal management play in SMD LED manufacturing?

Surface-Mount Device (SMD) LED technology has revolutionized the lighting and display industries, offering compact, energy-efficient, and versatile solutions. Central to the production of these LEDs are SMD LED making machines, which have seen significant innovations to enhance precision, speed, and quality. This article explores the latest advancements in SMD LED making machines, highlighting their features, technological breakthroughs, and the impact on manufacturing efficiency and product performance.

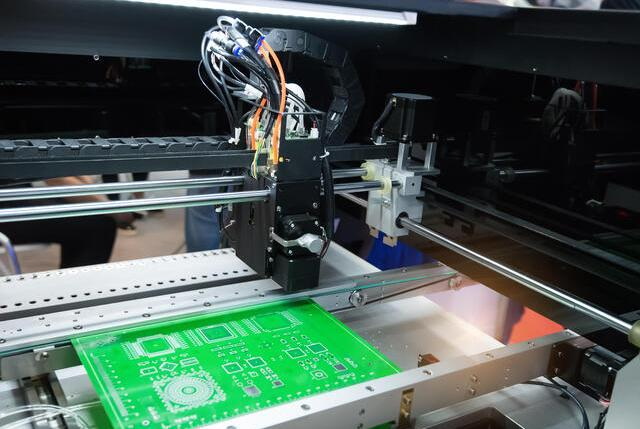

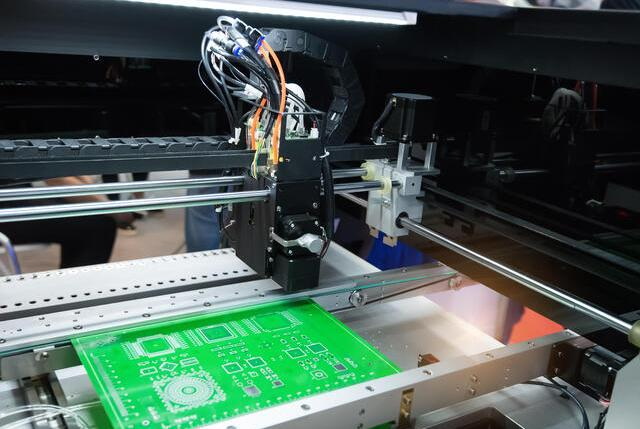

Introduction to SMD LED Making Machines

SMD LED making machines are specialized equipment designed to automate the assembly of SMD LEDs onto printed circuit boards (PCBs). These machines perform tasks such as component placement, soldering, and inspection with high precision and speed. The adoption of these machines has enabled manufacturers to achieve higher yields, better product consistency, and reduced labor costs compared to manual assembly methods.

The importance of SMD LED making machines cannot be overstated in today's fast-paced electronics manufacturing environment. As the demand for smaller, brighter, and more energy-efficient LEDs grows, manufacturers require machines that can keep up with these evolving requirements while maintaining high quality and throughput.

Key Innovations in SMD LED Making Machines

1. Enhanced Precision and Placement Speed

One of the most significant advancements in SMD LED making machines is the improvement in placement precision and speed. Modern machines incorporate advanced full-color vision systems combined with precision ball screw X-Y head positioning technology. For example, the NeoDen10 SMT LED making machine boasts a placement accuracy of 0.01mm and can place up to 18,000 components per hour. This level of precision ensures accurate mounting of tiny components, including those as small as 0201 reels and fine pitch ICs up to 40mm x 40mm.

The ability to place components with such accuracy is crucial, especially as LEDs and other electronic components continue to shrink in size. The high speed of placement also allows manufacturers to meet increasing production demands without sacrificing quality.

2. Multi-Head and Multi-Feeder Systems

To further boost productivity, SMD LED making machines now commonly feature multi-head placement systems. Machines like the NeoDen5 come equipped with four heads, each capable of ±180° rotation. This flexibility allows the machine to handle components in tight spaces and complex layouts with ease. The multi-head design also enables simultaneous placement of different components, significantly reducing cycle time.

In addition to multi-head systems, the number and variety of feeders have increased. Machines can now accommodate up to 66 feeder slots, including patented tape reel feeders and vibration feeders that handle various packaging types such as tubes and trays. This versatility allows manufacturers to work with a wide range of components without frequent machine reconfiguration, improving efficiency.

3. Flying Vision and Automated Correction

Flying vision systems represent a breakthrough in real-time component recognition and placement correction. These systems use multiple CCD cameras to capture images of components and PCB pads during the placement process. The machine's software then analyzes these images to detect any misalignment or orientation errors and automatically adjusts the placement position.

This technology dramatically reduces errors caused by component misfeeds or PCB warping, improving overall yield and reducing waste. Flying vision also speeds up the setup process, as the machine can quickly calibrate itself for new components or board designs.

4. Continuous Placement and Conveyor Integration

Another innovation in SMD LED making machines is the integration of continuous placement capabilities through conveyor and rail systems. Auto rails of various lengths (0.6m, 1.2m, 1.5m) can be connected with universal conveyors to create a seamless SMT production line. This integration reduces downtime between PCB placements, allowing for uninterrupted production flow.

The continuous placement feature is particularly beneficial for large-scale manufacturing, where minimizing idle time directly translates to higher throughput and lower operational costs. It also simplifies the automation of the entire assembly process by linking placement machines with other SMT equipment such as solder paste printers and reflow ovens.

5. Advanced Thermal and Optical Management in LED Packaging

While not directly part of the machine hardware, innovations in the LED packaging process are closely tied to the capabilities of SMD LED making machines. New encapsulation materials, such as fast-curing, low-stress epoxy resins, have been developed to improve the thermal and optical performance of SMD LEDs.

These materials help reduce internal stresses during curing, preventing damage to the LED chip and enhancing reliability. Additionally, advanced encapsulation techniques now incorporate optical lens structures within the resin to improve light extraction and beam shaping. This results in brighter LEDs with more uniform light distribution, meeting the demands of high-end display and lighting applications.

6. Miniaturization and High-Density Mounting

The trend toward miniaturization in electronics has pushed SMD LED making machines to handle smaller and more densely packed components. The machines now support the placement of ultra-small LEDs, such as 0201 size and even smaller, with high precision. This capability enables the production of compact LED modules used in applications like ultra HD displays, wearable devices, and automotive lighting.

High-density mounting also requires machines to place components closer together without causing damage or misalignment. Innovations in nozzle design, component handling, and placement algorithms have made this possible, allowing manufacturers to produce more complex and feature-rich LED assemblies.

7. Energy Efficiency and Environmental Resistance

Newer SMD LED making machines support the production of LEDs that consume significantly less power—up to 30% less—while maintaining brightness and clarity. This is achieved through precise placement and packaging techniques that optimize the LED's electrical and thermal properties.

In addition, innovations in encapsulation materials and thermal design contribute to improved moisture resistance, heat dissipation, and durability. These improvements enable LEDs to perform reliably in outdoor and harsh environments, expanding their application range to include street lighting, automotive headlights, and industrial displays.

8. Integration of Proprietary Technologies

Leading LED manufacturers have introduced proprietary technologies that influence the design and operation of SMD LED making machines. For example, SiliconCore's Common Cathode IQ technology reduces power consumption and heat generation by sharing a common cathode among multiple LEDs. Similarly, their LISA encapsulation technology enhances durability and optical performance.

These innovations require machines capable of handling more complex assembly and packaging processes, including precise alignment and multi-layer encapsulation. As a result, SMD LED making machines have evolved to meet these demands, incorporating advanced software and hardware features to support proprietary LED designs.

9. Intelligent Software and Automation

Modern SMD LED making machines are increasingly equipped with intelligent software systems that enable automation beyond simple placement tasks. Features such as automated feeder calibration, real-time process monitoring, and predictive maintenance help optimize machine uptime and reduce human intervention.

Machine learning algorithms are also being integrated to improve component recognition and placement strategies, adapting to variations in component shape, size, and orientation. This level of automation reduces setup time and enhances overall production efficiency.

10. Environmental and Safety Enhancements

With growing emphasis on sustainable manufacturing, newer SMD LED making machines incorporate energy-saving features and environmentally friendly materials handling. For example, machines are designed to minimize solder paste waste and reduce power consumption during idle periods.

Safety features such as enclosed working areas, emergency stop systems, and dust extraction units protect operators and maintain clean production environments, which is critical for high-quality LED assembly.

Impact of Innovations on Manufacturing

The latest innovations in SMD LED making machines have transformed LED manufacturing by:

- Increasing Productivity: High-speed placement and multi-head systems drastically reduce production time.

- Improving Quality: Enhanced vision systems and precision placement minimize defects and improve yield.

- Reducing Costs: Automation reduces labor dependency and material waste.

- Enabling New Designs: Support for smaller components and complex packaging allows for cutting-edge LED products.

- Enhancing Reliability: Better thermal and environmental management extends product lifespan and performance.

- Supporting Sustainability: Energy-efficient machine designs and processes contribute to greener manufacturing.

These advancements not only improve the efficiency of LED production lines but also enable manufacturers to innovate in LED design, meeting the evolving demands of markets such as automotive, consumer electronics, and large-format displays.

Conclusion

The evolution of SMD LED making machines continues to drive the advancement of LED technology. Innovations such as high-precision placement, multi-head systems, flying vision, and integration with conveyor lines have significantly boosted manufacturing efficiency and product quality. Coupled with improvements in LED packaging materials and thermal management, these machines enable the production of smaller, brighter, more durable, and energy-efficient SMD LEDs.

As the demand for advanced lighting and display solutions grows, the role of sophisticated SMD LED making machines will become increasingly critical in meeting industry needs. Manufacturers who adopt these latest technologies will be better positioned to deliver high-quality products at competitive prices, fostering innovation and growth in the LED market.

FAQ

1. What is an SMD LED making machine?

An SMD LED making machine is an automated device used to place and solder surface-mount device LEDs onto printed circuit boards with high precision and speed, facilitating mass production of LED modules.

2. How do flying vision systems improve SMD LED making machines?

Flying vision systems use multiple cameras to recognize and correct the position of components in real-time during placement, enhancing accuracy and reducing errors in the assembly process.

3. What are the benefits of multi-head placement in SMD LED making machines?

Multi-head placement allows simultaneous mounting of multiple components, increasing throughput and enabling more complex assembly tasks with higher precision and flexibility.

4. How do recent innovations affect the size of SMD LEDs that can be handled?

Advances in machine precision and feeder technology allow handling of very small components, such as 0201 size LEDs, supporting miniaturization trends in LED lighting and display applications.

5. What role does thermal management play in SMD LED manufacturing?

Effective thermal management in LED packaging improves heat dissipation, enhancing LED lifespan and performance. Innovations in materials and encapsulation processes are critical to achieving this and are supported by precise assembly methods in SMD LED making machines.