Content Menu

● Introduction to SMD Component Machines

● Key Innovations in SMD Component Machines

>> 1. Micro SMT and Miniaturization

>> 2. 3D Packaging and Advanced Component Integration

>> 3. Automation and Smart Data Analytics

>> 4. Additive Manufacturing and Innovative Soldering Techniques

>> 5. Flexible and Hybrid Electronics

● Applications of SMD Components and Machines

● Benefits of Latest SMD Component Machines

● Challenges and Future Directions

● Conclusion

● FAQ

>> 1. What is an SMD component machine?

>> 2. How does micro SMT improve electronics manufacturing?

>> 3. What role does automation play in modern SMD machines?

>> 4. What are the benefits of 3D packaging in SMT?

>> 5. How are SMD machines adapting to flexible electronics?

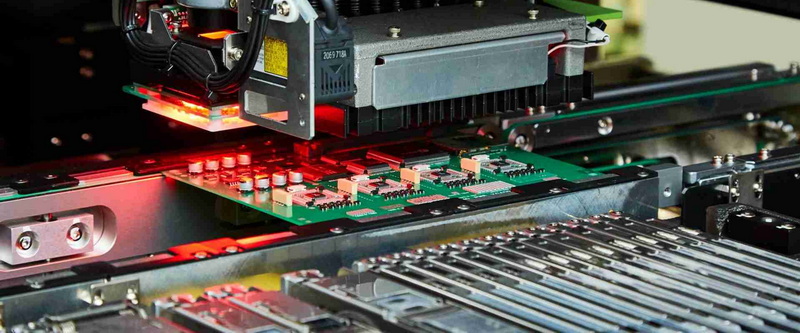

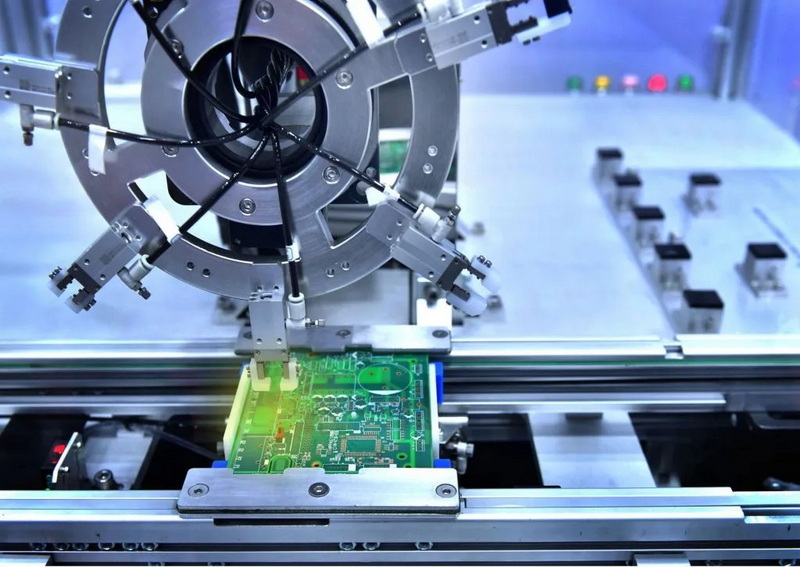

Surface Mount Device (SMD) component machines are at the heart of modern electronics manufacturing, enabling the precise and rapid assembly of electronic components onto printed circuit boards (PCBs). With the continuous evolution of electronics demanding smaller, faster, and more reliable devices, innovations in SMD component machines have become crucial to meet these challenges. This article explores the latest advancements in SMD component machines, highlighting how these innovations are shaping the future of PCB assembly and electronics manufacturing.

Introduction to SMD Component Machines

SMD component machines, commonly known as Surface Mount Technology (SMT) machines, automate the placement of surface mount devices onto PCBs. These machines are critical for assembling components like resistors, capacitors, integrated circuits, and LEDs with high precision and speed. The automation introduced by SMT machines has revolutionized electronics manufacturing by reducing assembly time, minimizing errors, and enabling miniaturization of components and devices.

The core function of an SMD component machine is to pick components from feeders or trays and accurately place them on the PCB at designated locations. This process requires extremely high precision, often in the micrometer range, to ensure proper electrical connections and mechanical stability. The speed of these machines is also a key factor, with modern high-end models capable of placing tens of thousands of components per hour.

Key Innovations in SMD Component Machines

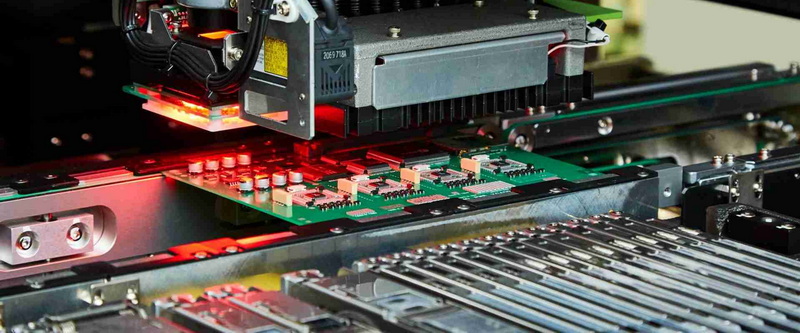

1. Micro SMT and Miniaturization

One of the most significant trends in SMD component machines is the capability to handle ultra-small components, such as 0201 passives (measuring 0.6 mm x 0.3 mm) and micro Ball Grid Arrays (microBGAs). These micro SMT machines allow manufacturers to place components that are only fractions of a millimeter in size, facilitating the development of highly compact and complex electronics.

Miniaturization is driven by the demand for smaller devices with higher functionality. Smartphones, wearables, and medical implants require dense PCB layouts with tiny components. To meet these demands, SMD component machines now incorporate ultra-precise pick-and-place heads, capable of sub-micron accuracy, and advanced vision systems that use high-resolution cameras and AI algorithms to detect component orientation and placement position.

Additionally, the development of new nozzle designs and vacuum systems allows these machines to handle fragile and tiny components without damage. The ability to place micro components reliably ensures higher PCB density and better performance in modern electronics.

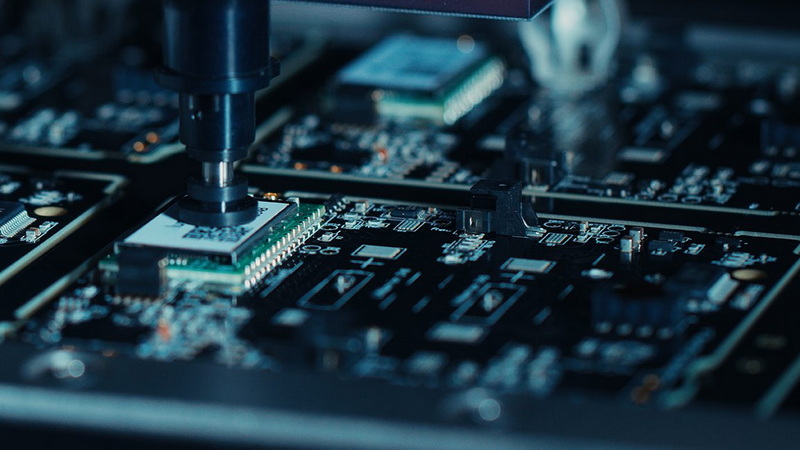

2. 3D Packaging and Advanced Component Integration

3D packaging techniques, including System-in-Package (SiP) and Package-on-Package (PoP), are becoming more prevalent in the electronics industry. These packaging methods stack multiple chips vertically to save space and improve electrical performance by shortening interconnect lengths.

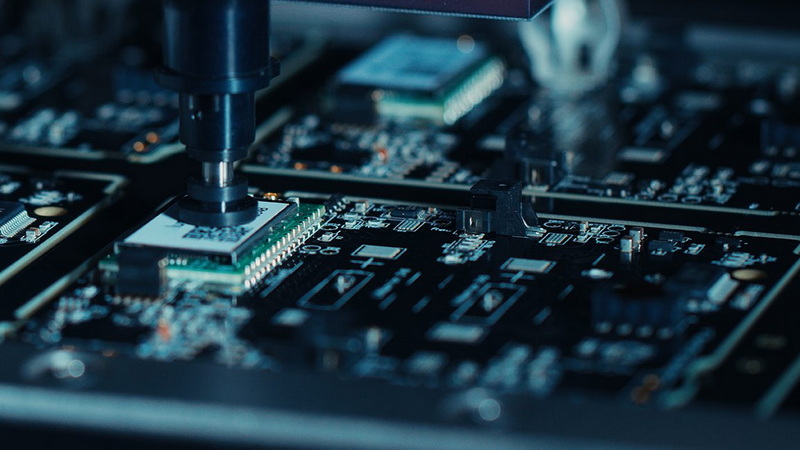

SMD component machines are evolving to handle these complex packages, which require precise vertical alignment and placement accuracy. Advanced machines support direct integration methods such as flip-chip bonding, where components are mounted directly onto the substrate without traditional leads. This technique reduces parasitic inductance and capacitance, enhancing signal integrity and device speed.

Moreover, some SMD machines now feature multi-axis movement systems, allowing for placement on uneven or 3D surfaces, which is critical for 3D packaging. These innovations enable manufacturers to produce smaller, faster, and more power-efficient devices.

3. Automation and Smart Data Analytics

Automation continues to advance with faster, more precise pick-and-place machines integrated into fully automated SMT production lines. Modern SMD component machines are equipped with AI-powered inspection systems that detect defects such as misalignment, missing components, and solder paste issues in real-time.

These intelligent systems use machine learning algorithms to improve defect detection accuracy over time, reducing false positives and minimizing production stoppages. Integration with Manufacturing Execution Systems (MES) allows seamless data exchange, enabling real-time monitoring and control of the assembly process.

Smart data analytics plays a vital role in predictive maintenance. By continuously monitoring machine parameters such as vibration, temperature, and motor currents, the system can predict potential failures before they occur. This proactive approach minimizes downtime and maintenance costs, improving overall equipment effectiveness (OEE).

4. Additive Manufacturing and Innovative Soldering Techniques

Emerging additive manufacturing processes, such as inkjet solder printing and aerosol jetting, are being integrated with SMD component machines. These methods allow for the precise deposition of solder paste and conductive materials at a micro scale, improving solder joint quality and enabling new design possibilities.

Traditional solder paste printing using stencils can be limiting for complex or fine-pitch components. Additive soldering techniques provide flexibility in depositing solder exactly where needed, reducing material waste and enabling rapid prototyping.

Advanced soldering techniques also include lead-free soldering and enhanced thermal management. Lead-free solders comply with environmental regulations such as RoHS, but require precise temperature control to avoid defects. Modern SMD machines incorporate advanced thermal profiling and controlled heating zones to ensure reliable solder joints.

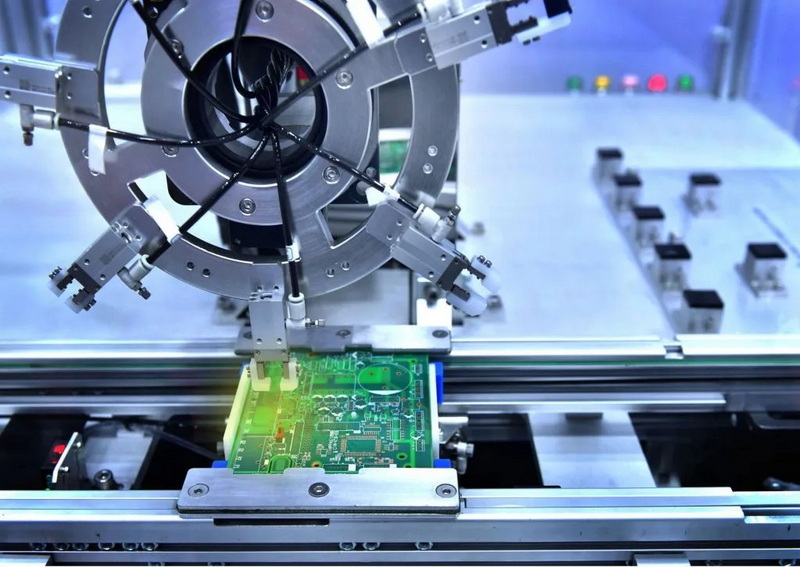

5. Flexible and Hybrid Electronics

SMD component machines are adapting to produce flexible hybrid electronics by enabling the printing and placement of electronic circuits onto flexible substrates such as polyimide films or stretchable materials. This innovation supports the growing market for wearable technology, flexible displays, and Internet of Things (IoT) devices, where traditional rigid PCBs are unsuitable.

Flexible electronics require specialized handling to avoid damage to delicate substrates. New SMD machines feature gentle component placement mechanisms and adjustable pressure controls to accommodate these materials. Additionally, hybrid electronics combine printed electronics with conventional SMT components, requiring machines capable of handling both additive and subtractive manufacturing processes.

This convergence of technologies expands the possibilities for innovative product designs, such as foldable smartphones, smart textiles, and medical sensors that conform to the human body.

Applications of SMD Components and Machines

SMD component machines are widely used across various industries due to their versatility and efficiency:

- Consumer Electronics: Smartphones, tablets, LED lighting, and household appliances rely heavily on SMT for compact and reliable circuit assembly. The demand for high-density PCBs in consumer devices drives continuous innovation in SMD machines.

- Automotive Industry: Automotive electronics require high reliability and durability. SMD machines assemble components for control systems, infotainment, advanced driver-assistance systems (ADAS), and LED lighting, often under harsh environmental conditions.

- Medical Devices: Medical equipment demands precision and reliability. SMT assembly is critical for devices such as diagnostic instruments, implantable devices, and wearable health monitors.

- Telecommunications: Network infrastructure, routers, and wireless communication devices benefit from the high-speed, high-precision assembly capabilities of modern SMD machines, supporting ever-increasing data transfer rates and connectivity.

- Industrial Electronics: Automation, robotics, and control systems utilize SMT technology for robust and scalable electronics manufacturing.

Benefits of Latest SMD Component Machines

| Feature | Benefit |

| Micro SMT capability | Enables placement of ultra-small components |

| 3D packaging support | Allows vertical stacking for space-saving |

| AI-powered inspection | Improves defect detection and quality control |

| Additive soldering techniques | Enhances solder joint precision and reliability |

| Flexible electronics assembly | Supports wearable and IoT device manufacturing |

| Automation and predictive maintenance | Increases throughput and reduces downtime |

| Multi-axis placement systems | Enables complex 3D and uneven surface assembly |

| Environmental compliance | Supports lead-free soldering and green manufacturing |

Challenges and Future Directions

Despite rapid advancements, SMD component machines face ongoing challenges. The increasing complexity of PCBs and components requires continuous improvements in machine precision and speed. Handling new materials and substrates, such as flexible and stretchable electronics, demands further innovation in machine design.

Future directions include deeper integration of AI for autonomous decision-making during assembly, enhanced collaboration between machines and humans (cobots), and development of modular machines that can be quickly reconfigured for different production needs.

Moreover, sustainability is becoming a key focus, with efforts to reduce energy consumption, minimize waste, and enable recycling of electronic components and materials.

Conclusion

The latest innovations in SMD component machines are transforming the electronics manufacturing landscape by enabling greater miniaturization, higher assembly speeds, improved reliability, and enhanced automation. Advances such as micro SMT, 3D packaging, AI-driven inspection, and additive manufacturing are pushing the boundaries of what is possible in PCB assembly. These developments not only meet the growing demands of modern electronics but also open new opportunities in emerging fields like flexible electronics and IoT. As SMD component machines continue to evolve, they will remain fundamental to producing the next generation of high-performance, compact, and reliable electronic devices.

FAQ

1. What is an SMD component machine?

An SMD component machine is an automated device used in surface mount technology to place surface mount devices (SMDs) onto printed circuit boards with high precision and speed.

2. How does micro SMT improve electronics manufacturing?

Micro SMT enables the placement of extremely small components, such as 0201 passives and microBGAs, allowing for more compact and complex PCB designs with higher functionality.

3. What role does automation play in modern SMD machines?

Automation enhances production efficiency by integrating AI-powered inspection, real-time analytics, and predictive maintenance, which reduce errors and downtime in SMT assembly lines.

4. What are the benefits of 3D packaging in SMT?

3D packaging allows vertical stacking of components, saving PCB space and improving electrical performance by reducing parasitic effects, which is supported by advanced SMD machines.

5. How are SMD machines adapting to flexible electronics?

SMD machines are incorporating printing technologies that enable the assembly of circuits on flexible substrates, facilitating the production of wearable devices and flexible displays.