Content Menu

● Introduction to SMD Assembly Machines

>> Key Components of Modern SMD Assembly Machines

● Latest Innovations in SMD Assembly Machines

>> Intelligentization and Automation

>> High Precision and High Speed

>> Multifunctionality and High Integration

>> Flexible Production Capabilities

>> Green and Environmental Protection

● Impact of Innovations on the Electronics Industry

>> Role of IoT in SMD Assembly

>> Future of PCB Assembly

● Emerging Trends in Electronics Manufacturing

>> High-Density Interconnects (HDI) and Miniaturization

>> Smart Factories and Automation

>> Sustainability in Electronics Manufacturing

● Future Outlook

● Conclusion

● FAQs

>> 1. What are the key technologies driving innovation in SMD assembly machines?

>> 2. How do SMD assembly machines contribute to sustainability in electronics manufacturing?

>> 3. What role does automation play in SMD assembly?

>> 4. How do flexible manufacturing systems benefit SMD assembly?

>> 5. What are the future trends expected in SMD assembly machines?

● Citations:

The landscape of electronics manufacturing is rapidly evolving, driven by advancements in technology and the increasing demand for smaller, more complex electronic devices. At the heart of this evolution are SMD (Surface Mount Device) assembly machines, which play a crucial role in the production of printed circuit boards (PCBs). These machines are integral to the Surface Mount Technology (SMT) process, enabling the efficient and precise placement of components onto PCBs. In this article, we will explore the latest innovations in SMD assembly machines, highlighting how these advancements are transforming the electronics manufacturing industry.

Introduction to SMD Assembly Machines

SMD assembly machines are designed to automate the process of placing surface mount devices onto PCBs. These machines have evolved significantly over the years, incorporating cutting-edge technologies such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT) to enhance efficiency, precision, and adaptability.

Key Components of Modern SMD Assembly Machines

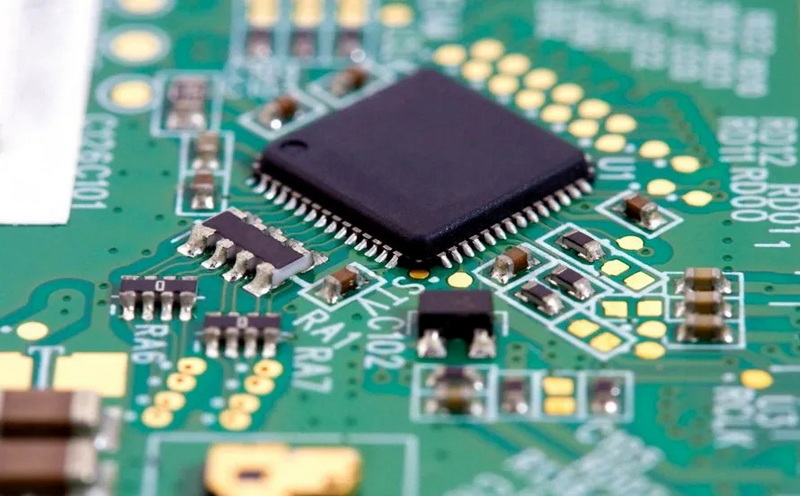

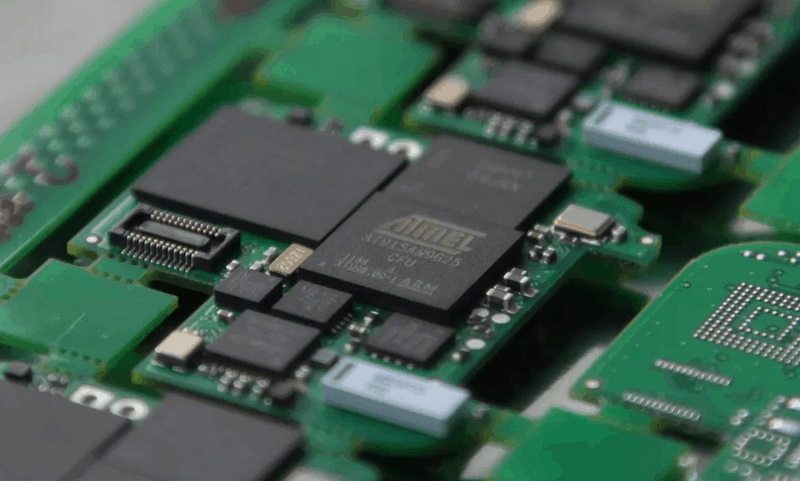

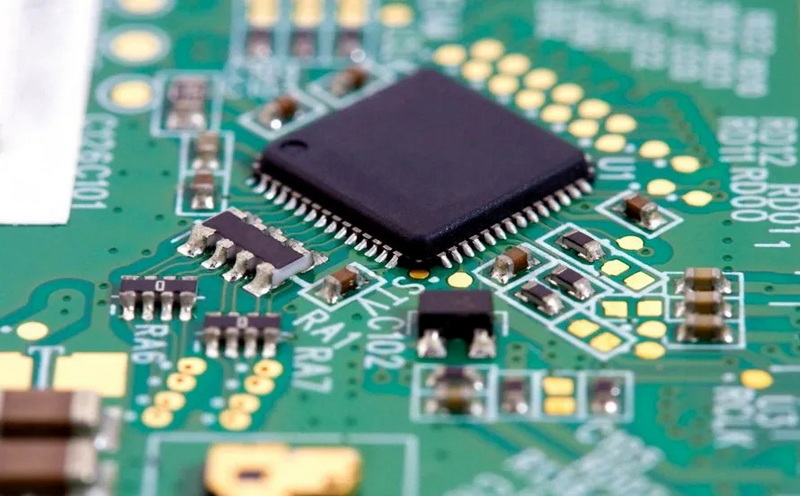

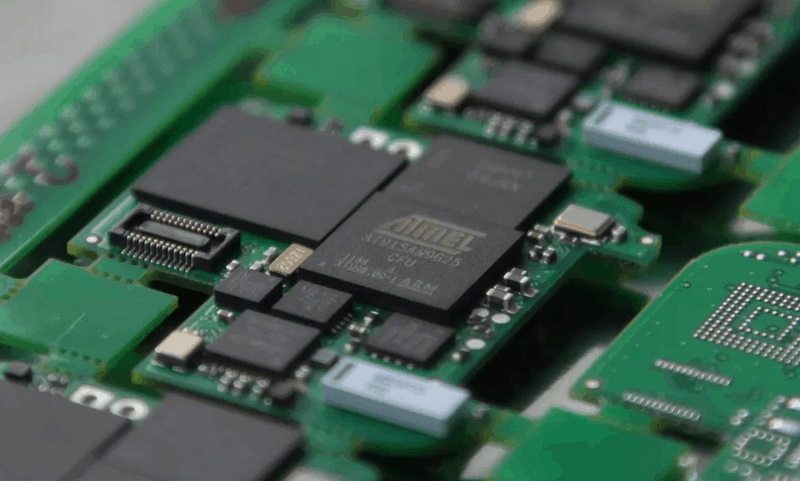

1. Advanced Placement Systems: Modern SMD assembly machines feature high-speed pick-and-place mechanisms that can handle a wide range of components, from small passive devices like resistors and capacitors to complex active components like BGAs (Ball Grid Arrays) and QFPs (Quad Flat Packages). These systems ensure that components are placed with micron-level precision, significantly reducing errors and improving production quality.

2. Automated Optical Inspection (AOI): AOI systems are integrated into SMD assembly lines to provide real-time monitoring and defect detection. These systems use advanced algorithms and machine learning to assess the quality of solder joints and component placement, reducing the need for manual inspection and improving overall accuracy.

3. Flexible Manufacturing Systems: To meet the demands of multi-variety and small-batch production, SMD assembly machines are designed with flexibility in mind. Modular equipment and customizable software allow manufacturers to quickly adapt production lines to different product configurations without significant downtime.

4. Green and Sustainable Technologies: As environmental concerns grow, SMD assembly machines are being designed with sustainability in mind. This includes the use of environmentally friendly materials, reduced energy consumption, and minimized waste emissions, contributing to a more sustainable manufacturing process.

Latest Innovations in SMD Assembly Machines

Intelligentization and Automation

The integration of AI and machine learning into SMD assembly machines enables real-time monitoring and adaptive learning. These technologies facilitate predictive maintenance, allowing manufacturers to address potential issues before they cause downtime. Additionally, AI-driven systems can optimize production processes, improving efficiency and product quality. For instance, AI can analyze production data to identify bottlenecks and suggest improvements in workflow, thereby enhancing overall production efficiency[1][2].

High Precision and High Speed

The miniaturization of electronic components requires SMD assembly machines to achieve higher placement precision and speed. Modern machines employ advanced visual recognition systems and high-precision servo control systems to achieve micron-level placement accuracy. This capability is crucial for handling complex components like BGAs and CSPs (Chip Scale Packages). The use of advanced materials and designs, such as those required for 5G devices, further necessitates high-speed and precise assembly processes[1][5].

Multifunctionality and High Integration

Future SMD assembly machines are moving towards multifunctionality and high integration. Modular designs and multi-functional placement heads enable these machines to handle a variety of components with different package forms. This flexibility improves the adaptability of the equipment to diverse production needs, allowing manufacturers to efficiently produce a wide range of electronic devices[1][3].

Flexible Production Capabilities

With the rise of multi-variety and small-batch production models, SMD assembly machines need to be highly flexible. By incorporating flexible manufacturing systems and customized services, manufacturers can quickly respond to market demands and adapt to frequent product changes without significant downtime. This flexibility is essential for meeting the dynamic needs of modern electronics manufacturing[1][4].

Green and Environmental Protection

Environmental sustainability is becoming a key focus in the electronics manufacturing industry. SMD assembly machines are being developed with green technologies, including the use of eco-friendly materials and energy-efficient designs. These measures help reduce the environmental footprint of manufacturing processes, aligning with global sustainability goals[1][5].

Impact of Innovations on the Electronics Industry

The latest innovations in SMD assembly machines are transforming the electronics manufacturing landscape in several ways:

- Enhanced Efficiency: Automation and AI-driven technologies streamline production processes, reducing human error and increasing throughput.

- Improved Quality: Advanced inspection systems and precision placement mechanisms ensure higher quality products with fewer defects.

- Increased Flexibility: Modular designs and flexible manufacturing systems allow for quick adaptation to changing production requirements.

- Sustainability: Green technologies and sustainable practices contribute to environmentally friendly manufacturing processes.

Role of IoT in SMD Assembly

The integration of the Internet of Things (IoT) into SMD assembly processes is revolutionizing the industry. IoT enables real-time monitoring and predictive maintenance, allowing manufacturers to identify potential equipment failures before they occur. This reduces downtime, boosts productivity, and cuts operational costs. IoT-driven smart factories are leading the charge toward Industry 4.0, where interconnected systems deliver unparalleled agility and adaptability[2][4].

Future of PCB Assembly

In the future, PCB assembly will continue to evolve with advancements in automation and precision. The use of flexible PCBs, which are lightweight and durable, will become more prevalent, especially in wearable technology and IoT devices. Innovations like vapor phase soldering and conformal coating will enhance the reliability and longevity of electronic products. Additionally, the integration of AI and machine learning into PCB assembly processes will further optimize workflows and detect anomalies, ensuring every circuit board meets the highest standards of quality and performance[2][4].

Emerging Trends in Electronics Manufacturing

High-Density Interconnects (HDI) and Miniaturization

The trend towards miniaturization is driving the adoption of High-Density Interconnect (HDI) technology. HDI PCBs are crucial for high-speed applications, offering improved signal integrity, reduced component spacing, and shorter trace lengths. This technology is expected to significantly impact the PCB manufacturing market, with the HDI PCB market projected to reach nearly $40 billion by 2032[4][8].

Smart Factories and Automation

The push towards Industry 4.0 is transforming electronics manufacturing into a faster, smarter, and more efficient process. AI and machine learning are integral to this transformation, enabling real-time monitoring, predictive maintenance, and adaptive manufacturing processes. Robotic soldering and pick-and-place robots are becoming essential for fast and accurate component installation, ensuring high-quality products with minimal defects[4][7].

Sustainability in Electronics Manufacturing

Sustainability is increasingly important in the electronics industry, with manufacturers adopting greener practices to meet environmental regulations and consumer demands. This includes the use of recyclable materials, reduced energy consumption, and effective waste management. As the industry moves forward, sustainable manufacturing will become a critical component of electronics production[5][8].

Future Outlook

As technology continues to evolve, we can expect SMD assembly machines to become even more sophisticated. The integration of emerging technologies like 3D printing and advanced materials will further enhance production capabilities. Additionally, the emphasis on sustainability will continue to grow, driving innovations in eco-friendly manufacturing practices.

The future of SMT will be shaped by advancements in automation, precision, and sustainability. With the launch of new high-speed placement machines and the integration of AI-driven systems, SMT is poised to address the challenges of rising production volumes and complexity, making it an essential part of the electronics manufacturing ecosystem[6].

Conclusion

In conclusion, the latest innovations in SMD assembly machines are revolutionizing the electronics manufacturing industry. With advancements in automation, precision, flexibility, and sustainability, these machines are poised to meet the growing demands for complex and high-quality electronic devices. As technology continues to evolve, we can expect even more significant improvements in efficiency, quality, and environmental sustainability.

FAQs

1. What are the key technologies driving innovation in SMD assembly machines?

The key technologies driving innovation in SMD assembly machines include artificial intelligence (AI), machine learning, the Internet of Things (IoT), and advanced visual recognition systems. These technologies enhance efficiency, precision, and adaptability in production processes[1][2].

2. How do SMD assembly machines contribute to sustainability in electronics manufacturing?

SMD assembly machines contribute to sustainability by incorporating green technologies, such as environmentally friendly materials, reduced energy consumption, and minimized waste emissions. These measures help reduce the environmental footprint of manufacturing processes[1][5].

3. What role does automation play in SMD assembly?

Automation plays a critical role in SMD assembly by streamlining production processes, reducing human error, and increasing throughput. Automated systems, including pick-and-place machines and AOI systems, enhance efficiency and quality in PCB assembly[3][7].

4. How do flexible manufacturing systems benefit SMD assembly?

Flexible manufacturing systems allow SMD assembly machines to quickly adapt to different production configurations, enabling manufacturers to respond swiftly to market demands and adapt to frequent product changes without significant downtime[1][4].

5. What are the future trends expected in SMD assembly machines?

Future trends in SMD assembly machines include further integration of AI and IoT technologies, increased use of advanced materials, and a greater emphasis on sustainability. Additionally, innovations in 3D printing and modular design will continue to enhance production capabilities and flexibility[6][7].

Citations:

[1] https://www.hwgcsmt.com/news/new-technological-trends-in-the-smt-machine-in-84515003.html

[2] https://rootsems.com/future-of-electronics-manufacturing-emerging-trends-in-2025/

[3] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[4] https://www.pcbpower.us/blog/top-trends-pcb-assembly

[5] https://www.kinghelm.net/industry-news/2025-The-Future-of-PCB-PCBA-Trends.html

[6] https://www.cognitivemarketresearch.com/articles/surface-mount-technology-smt-market-trends-and-future-opportunities

[7] https://arshon.com/blog/pick-and-place-machines-revolutionizing-pcb-assembly/

[8] https://www.linkedin.com/pulse/pcb-assembly-trends-2025-faster-smaller-greener-pcb-power-inc-cgq4f

[9] https://www.pcbcart.com/article/content/smt-assembly-development-trend.html

[10] https://novaenginc.com/future-of-circuit-board-assembly/

[11] https://highpcb.com/top-5-emerging-trends-in-pcb-technology-for-2025/

[12] https://www.pcbpower.us/blog/the-future-of-pcb-assembly-trends-challenges-and-opportunities

[13] https://global.iteschina.com/en/news/details/2640

[14] https://www.wnie.online/pemtron-to-exhibit-at-smart-smt-pcb-assembly-sspa-2025-showcasing-advanced-inspection-and-automation-systems/

[15] https://www.circuits-central.com/blog/pcb-assembly-in-2024-and-beyond-what-does-the-future-hold/

[16] https://aaloktronix.com/the-future-of-pcb-manufacturing-trends-innovations-2025/

[17] https://www.pcbasic.com/blog/top_pcb_assembly.html

[18] https://www.tronstol.com/the-three-major-development-trends-of-the-pick-and-place-machine-in-the-future.html

[19] https://www.circuits-central.com/blog/advancements-in-pcb-manufacturing-new-developments-in-2025-and-beyond/

[20] https://www.allsmt.com/electronic-manufacturing-innovations-2025