Content Menu

● Introduction to DIY SMD Technology

>> Key Components of DIY SMD Technology

● Latest Innovations in DIY SMD Machines

>> 1. Automated Pick-and-Place Machines

>> 2. Reflow Ovens

>> 3. DIY SMD Resistor Cutting Machines

● Trends in DIY SMD Technology

>> 1. Integration of Smart Features

>> 2. Miniaturization and Precision

>> 3. Sustainable Practices

● Applications of DIY SMD Technology

>> 1. Custom Lighting Projects

>> 2. IoT Devices

>> 3. Educational Projects

● Challenges and Future Directions

>> Future Directions

● DIY SMD Machines: A Closer Look

>> Building a DIY SMT Pick-and-Place Machine

>> Components of a DIY Pick-and-Place Machine

● The Role of SMD Technology Beyond DIY

>> Advancements in SMD Screens

● The Growing Demand for DIY Tools

>> Impact on DIY SMD Technology

● Conclusion

● FAQ

>> 1. What is DIY SMD Technology?

>> 2. What are the Key Components of DIY SMD Technology?

>> 3. What are the Latest Innovations in DIY SMD Machines?

>> 4. What are the Trends in DIY SMD Technology?

>> 5. What are the Applications of DIY SMD Technology?

● Citations:

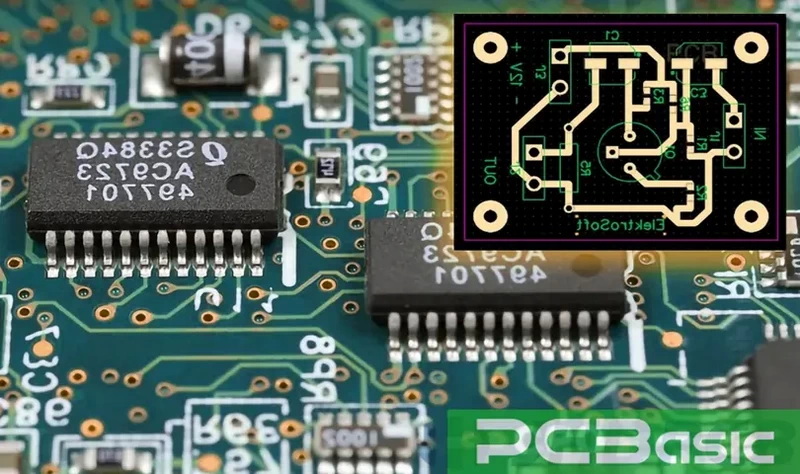

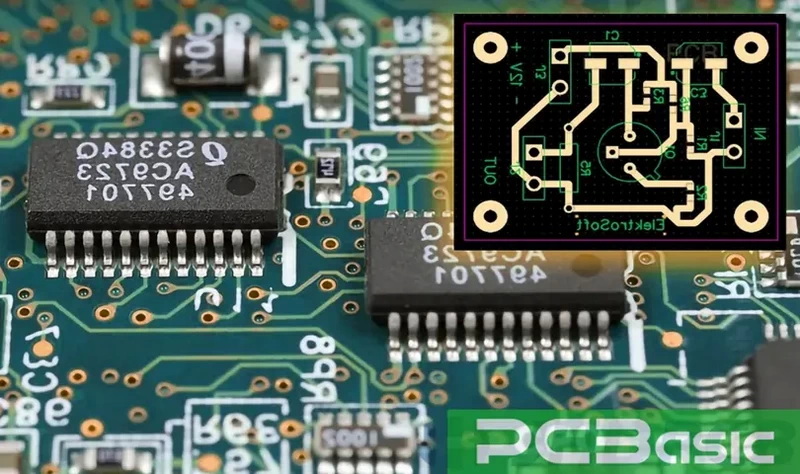

The world of DIY (Do-It-Yourself) SMD (Surface Mount Device) technology has seen significant advancements in recent years, transforming the way enthusiasts and professionals work with electronic components. SMD technology involves mounting components directly onto the surface of a printed circuit board (PCB), which has become a cornerstone in modern electronics due to its compactness and efficiency. This article explores the latest innovations in DIY SMD technology, focusing on tools, techniques, and applications that are shaping the future of electronics assembly.

Introduction to DIY SMD Technology

DIY SMD technology empowers individuals to create and assemble electronic circuits without relying on large-scale manufacturing facilities. This democratization of electronics manufacturing has led to a proliferation of innovative projects and products, from simple LED lighting to complex IoT devices. The core of DIY SMD involves using surface mount components, which are smaller and more efficient than their through-hole counterparts, allowing for more compact and sophisticated designs.

Key Components of DIY SMD Technology

1. SMD Components: These include resistors, capacitors, LEDs, and ICs that are mounted directly onto the PCB. Their small size and low profile make them ideal for compact devices.

2. PCB Design Software: Tools like KiCad and Eagle allow users to design PCB layouts, which are then used to fabricate the boards.

3. DIY SMD Machines: These are specialized tools designed to handle the assembly process, including pick-and-place machines and reflow ovens.

Latest Innovations in DIY SMD Machines

1. Automated Pick-and-Place Machines

Automated pick-and-place machines are revolutionizing the DIY SMD landscape by streamlining the component placement process. These machines can accurately place components onto PCBs, significantly reducing assembly time and improving accuracy. For instance, the TVM926 model can handle components as small as 0.5 mm pitch ICs and 0402 passive components, making it suitable for a wide range of DIY projects.

2. Reflow Ovens

Reflow ovens are essential for soldering SMD components onto PCBs. Recent innovations include more precise temperature control and compact designs, making them accessible for home use. DIY enthusiasts can even repurpose household appliances like toaster ovens for reflow soldering, though dedicated reflow ovens offer better results and safety.

3. DIY SMD Resistor Cutting Machines

For those working with SMD resistors, a DIY SMD resistor cutting machine can be a valuable tool. This machine automates the process of cutting resistors to specific lengths, which can be tedious and error-prone when done manually. Projects like the one featured on Hackaday demonstrate how DIY solutions can simplify tasks in electronics assembly.

Trends in DIY SMD Technology

1. Integration of Smart Features

The integration of smart technologies into DIY tools is becoming more prevalent. This includes IoT connectivity, AI-powered optimization, and automation, which enhance the efficiency and precision of DIY projects. For example, smart reflow ovens can adjust temperature profiles based on the specific components being soldered.

2. Miniaturization and Precision

The trend towards miniaturization continues to drive innovation in DIY SMD technology. As devices become smaller and more complex, the need for precise assembly techniques grows. This has led to the development of more sophisticated DIY tools capable of handling tiny components with high accuracy.

3. Sustainable Practices

There is an increasing focus on sustainability in DIY electronics. This includes using eco-friendly materials, reducing waste, and designing projects with energy efficiency in mind. For instance, using 3535 LED SMD technology for lighting projects offers both high efficiency and longevity, reducing the environmental impact of DIY projects.

Applications of DIY SMD Technology

1. Custom Lighting Projects

DIY SMD technology is widely used in custom lighting projects, such as LED strip lights and ambient wall art. The versatility of SMD LEDs allows for creative designs that are both visually appealing and energy-efficient.

2. IoT Devices

The compactness and efficiency of SMD components make them ideal for IoT devices. DIY enthusiasts can create smart home devices, wearables, and other connected products using SMD technology.

3. Educational Projects

DIY SMD technology is also used in educational settings to teach electronics and engineering principles. Students can design and assemble their own circuits, fostering hands-on learning and innovation.

Challenges and Future Directions

Despite the advancements, DIY SMD technology faces challenges such as the complexity of handling small components and the need for specialized equipment. However, innovations in automation and smart tools are addressing these issues, making DIY SMD more accessible and efficient.

Future Directions

The future of DIY SMD technology is promising, with trends pointing towards more automation, miniaturization, and sustainability. As tools become more affordable and user-friendly, we can expect to see a wider range of innovative projects and applications emerge.

DIY SMD Machines: A Closer Look

Building a DIY SMT Pick-and-Place Machine

Building a DIY SMT pick-and-place machine is an exciting project that can significantly enhance the efficiency of DIY electronics assembly. Using open-source software like OpenPnP, enthusiasts can create machines that accurately place SMD components onto PCBs. These machines typically use stepper motors for precise movement and may include features like vision support for manual placement and nozzle changers for different components[2].

Components of a DIY Pick-and-Place Machine

- Frame and Rails: The frame is often constructed from aluminum extrusions, providing a sturdy base for the machine. Linear rails are attached to the frame to support the movement of the pick-and-place head.

- Motors and Control: Stepper motors are used for X, Y, and Z axis movement. The machine is controlled by a microcontroller, such as the NXP LPC1769, which manages all motor operations and sensor inputs.

- Vision System: A down-looking camera is integrated into the machine to assist with component placement accuracy.

The Role of SMD Technology Beyond DIY

SMD technology is not limited to DIY projects; it is also transforming the display industry. SMD screens, which consist of LED chips attached directly to PCBs, offer superior image quality and energy efficiency. These screens are widely used in digital displays and large-stage screens due to their reliability and performance[1].

Advancements in SMD Screens

- Higher Pixel Density: Modern SMD screens achieve higher pixel densities, resulting in sharper images. This is particularly evident in outdoor LED displays like the P6 SMD, which delivers ultra HD visuals[1].

- Energy Efficiency: SMD LED technology uses significantly less energy than previous models, making it more eco-friendly and cost-effective[1].

- Durability: SMD screens are now more weather-resistant, with IP65 ratings that allow them to withstand harsh outdoor conditions[1].

The Growing Demand for DIY Tools

In 2025, the DIY tools industry is experiencing a surge in demand, driven by the desire for self-sufficiency and creativity. Manufacturers are responding by integrating smart features, improving cordless technology, and focusing on sustainability[3][4]. This trend is not limited to general DIY tools but also affects the development of specialized tools like those used in SMD assembly.

Impact on DIY SMD Technology

The growing demand for DIY tools, combined with technological advancements, is making DIY SMD technology more accessible. Smart tools and automation are reducing the complexity of SMD assembly, allowing more people to engage in DIY electronics projects.

Conclusion

In conclusion, DIY SMD technology is rapidly evolving, driven by innovations in tools, techniques, and applications. As the electronics landscape continues to shift towards smaller, smarter, and more efficient devices, DIY enthusiasts and professionals alike are leveraging SMD technology to create innovative projects. Whether it's custom lighting, IoT devices, or educational projects, DIY SMD technology offers endless possibilities for creativity and innovation.

FAQ

1. What is DIY SMD Technology?

DIY SMD technology refers to the practice of designing and assembling electronic circuits using surface mount components without relying on large-scale manufacturing facilities. It empowers individuals to create complex electronic devices at home.

2. What are the Key Components of DIY SMD Technology?

The key components include SMD components (resistors, capacitors, LEDs, ICs), PCB design software (KiCad, Eagle), and DIY SMD machines (pick-and-place machines, reflow ovens).

3. What are the Latest Innovations in DIY SMD Machines?

Recent innovations include automated pick-and-place machines, advanced reflow ovens with precise temperature control, and DIY SMD resistor cutting machines.

4. What are the Trends in DIY SMD Technology?

Trends include the integration of smart features, miniaturization and precision, and a focus on sustainable practices.

5. What are the Applications of DIY SMD Technology?

Applications include custom lighting projects, IoT devices, educational projects, and more.

Citations:

[1] https://ledsino.com/blog/evolution-of-smd-screens/

[2] https://mcuoneclipse.com/2018/06/26/building-a-diy-smt-pickplace-machine-with-openpnp/

[3] https://www.diversitech-global.com/post/the-growing-demand-for-diy-tools-in-2025

[4] https://www.diversitech-global.com/post/diy-tool-manufacturing-2025-latest-trends-innovations

[5] https://www.pcb-hero.com/blogs/lickys-column/types-and-features-of-excellent-smt-machines

[6] https://rootsems.com/future-of-electronics-manufacturing-emerging-trends-in-2025/

[7] https://smdled.pk/top-trends-in-smd-screen-technology-for-2025/

[8] https://www.datainsightsmarket.com/reports/smd-rework-tools-28283

[9] https://www.youtube.com/watch?v=0uKgPR0gQ24

[10] https://www.womenontop.co.za/homelife/diy-in-2025-bold-colours-smart-tech-and-sustainable-choices/

[11] https://www.manufacturingtomorrow.com/news/2024/06/24/choosing-the-right-smt-pick-and-place-machine-a-comprehensive-guide-for-different-buyers/22957/

[12] https://www.circuits-central.com/blog/advancements-in-pcb-manufacturing-new-developments-in-2025-and-beyond/

[13] https://highpcb.com/top-5-emerging-trends-in-pcb-technology-for-2025/

[14] https://www.aliexpress.com/i/1005006855736370.html

[15] https://en.ekinglux.com/news_Detail/1877561077246672896.html

[16] https://www.youtube.com/watch?v=kylBD4sCJUI

[17] https://github.com/PixiePlacer/PixiePlacer

[18] https://www.kinghelm.net/industry-news/2025-The-Future-of-PCB-PCBA-Trends.html

[19] https://www.linkedin.com/pulse/top-10-trends-shape-electronics-manufacturing-2025-peakingtech-kmfge

[20] https://www.pcbdirectory.com/news/vitrox-to-showcase-smt-pcb-assembly-solutions-at-ipc-apex-expo-2025