Content Menu

● Introduction to Automatic SMD Pick and Place Machines

● Latest Innovations in Automatic SMD Pick and Place Technology

>> Intelligentization and Automation

>> High Precision and High Speed

>> Multifunctionality and High Integration

>> Flexible Production

>> Green and Environmental Protection

● Impact of Automation in PCB Assembly

● Challenges and Innovations

● Future Trends in Pick-and-Place Machines

● Role of Vision Systems and Optical Inspection

● Integration with Industry 4.0 and Smart Manufacturing

● Advanced Feeding Systems

● Enhanced Traceability and Quality Control

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary function of an automatic SMD pick and place machine?

>> 2. How do automatic SMD pick and place machines enhance production efficiency?

>> 3. What are the key innovations in automatic SMD pick and place technology?

>> 4. What challenges do automatic SMD pick and place machines face, and how are they addressed?

>> 5. What future trends can we expect in automatic SMD pick and place machines?

● Citations:

The field of electronics manufacturing has witnessed significant advancements in recent years, with automatic SMD pick and place machines playing a pivotal role in enhancing efficiency and precision in Printed Circuit Board (PCB) assembly. These machines are crucial for the surface-mount technology (SMT) process, which involves mounting electronic components directly onto the surface of PCBs. This article explores the latest innovations in automatic SMD pick and place technology, highlighting trends, benefits, and future directions.

Introduction to Automatic SMD Pick and Place Machines

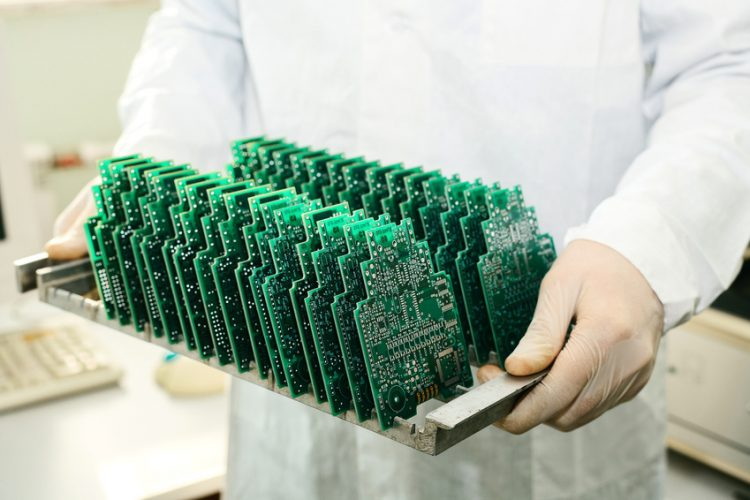

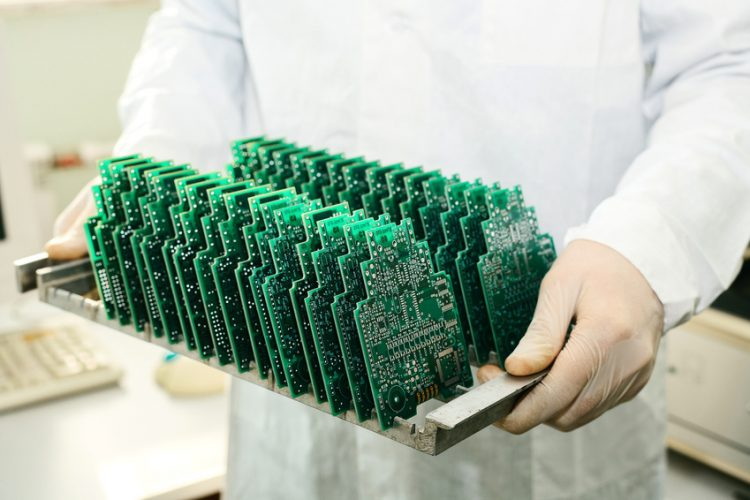

Automatic SMD pick and place machines are sophisticated robotic systems designed to accurately place electronic components onto PCBs. These machines are equipped with advanced vision systems, precision control mechanisms, and high-speed robotic arms, enabling them to handle a wide range of components, from small resistors and capacitors to complex integrated circuits (ICs).

The process involves several key steps:

- Component Feeding: Components are fed into the machine through tape feeders, tray feeders, or bulk feeders.

- Component Recognition: Vision systems and sensors identify and locate components, determining their position, orientation, and dimensions.

- PCB Alignment: The PCB is precisely positioned using fiducial marks or optical sensors.

- Component Pickup and Placement: A robotic arm picks up components and places them onto the PCB with high accuracy.

- Verification: Vision systems verify the accuracy of component placement in real-time.

Latest Innovations in Automatic SMD Pick and Place Technology

Intelligentization and Automation

The integration of artificial intelligence (AI) and machine learning (ML) is revolutionizing automatic SMD pick and place machines. AI algorithms optimize component placement paths, predict maintenance needs, and enable machines to adapt to new components and PCB designs without extensive reprogramming. This intelligentization enhances production efficiency, reduces downtime, and improves product quality. For instance, AI can analyze production data to identify bottlenecks and optimize workflows, ensuring that machines operate at peak performance levels[1][2].

High Precision and High Speed

Future automatic SMD pick and place machines will focus on achieving micron-level placement precision and speeds of tens of thousands of components per minute. Advanced visual recognition systems, high-precision servo control systems, and precision mechanical structures are being developed to meet these demands. The miniaturization of electronic components necessitates machines that can handle smaller parts with increased accuracy, ensuring that high-density PCBs are assembled efficiently[1][2].

Multifunctionality and High Integration

To handle diverse component types, such as BGA, CSP, and FC, machines are evolving towards multifunctionality and high integration. Modular designs and multi-functional placement heads allow for greater flexibility and adaptability, enabling the efficient placement of various components. This versatility is crucial for manufacturers who need to produce a wide range of products with different component requirements[1][7].

Flexible Production

With the rise of multi-variety and small-batch production models, automatic SMD pick and place machines need to be highly flexible. By incorporating flexible manufacturing systems and customized services, these machines can quickly adapt to changing market demands and frequent product switching. This flexibility allows manufacturers to respond rapidly to market changes and maintain competitiveness in a dynamic environment[1][2].

Green and Environmental Protection

Environmental sustainability is becoming increasingly important. Future machines will focus on using environmentally friendly materials, reducing energy consumption, and minimizing waste emissions to achieve sustainable development. This includes implementing energy-efficient designs and reducing the ecological footprint of electronics manufacturing[1][2].

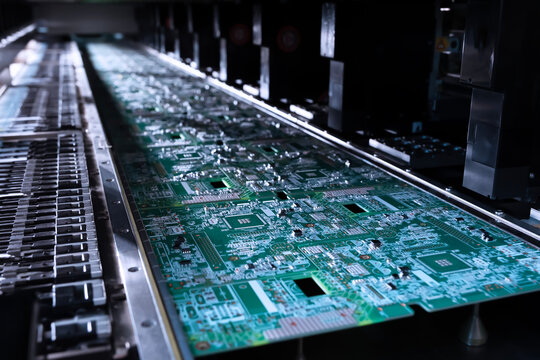

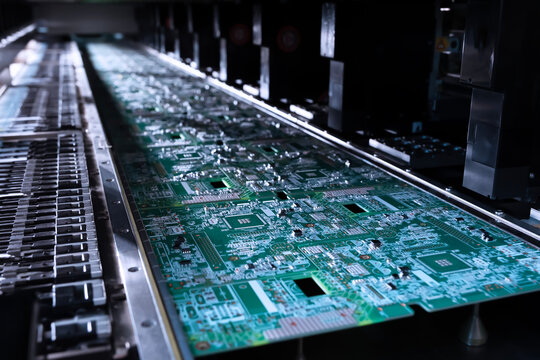

Impact of Automation in PCB Assembly

Automation, led by automatic SMD pick and place machines, is transforming the PCB assembly landscape by:

- Increasing Efficiency: Reducing assembly time and boosting production throughput.

- Enhancing Quality: Minimizing defects through advanced vision systems.

- Saving Costs: Long-term savings from reduced labor costs and improved yield.

Challenges and Innovations

Despite the advantages, automatic SMD pick and place machines face challenges such as miniaturization and complex PCB designs. To address these, manufacturers are incorporating cutting-edge technologies like modular designs, AI, and machine learning. The integration of these technologies enables machines to adapt to smaller components and more complex assembly requirements[2][3].

Future Trends in Pick-and-Place Machines

The future of automatic SMD pick and place machines involves integration with the Internet of Things (IoT), 3D printing, and sustainability. Machines will become part of smart factories, communicating with other equipment to optimize production processes. Combining pick-and-place machines with 3D printing could revolutionize PCB prototyping by enabling on-demand, fully assembled boards. This integration will allow for rapid prototyping and customization, significantly reducing the time-to-market for new electronic devices[6].

Role of Vision Systems and Optical Inspection

Vision systems play a crucial role in automatic SMD pick and place machines by enabling accurate component recognition and alignment. Ongoing developments in vision technology are enhancing the speed, accuracy, and reliability of optical inspection systems. These advancements ensure that components are correctly identified and placed, reducing errors and improving overall product quality[2][5].

Integration with Industry 4.0 and Smart Manufacturing

Automatic SMD pick and place machines are becoming integral to the smart manufacturing ecosystem. Integration with other machines and systems, such as automated storage and retrieval systems (AS/RS) and manufacturing execution systems (MES), enables seamless data exchange and intelligent decision-making for enhanced productivity. This integration facilitates real-time monitoring and optimization of production processes, ensuring that manufacturing operations are highly efficient and responsive to market demands[2][4].

Advanced Feeding Systems

Feeder technology is a critical aspect of automatic SMD pick and place machines. Innovations in feeder design and control mechanisms are improving the efficiency, reliability, and versatility of component feeding, reducing setup times, and enabling faster changeovers. These advancements allow manufacturers to quickly switch between different components and production runs, enhancing flexibility and reducing downtime[2].

Enhanced Traceability and Quality Control

Traceability and quality control are vital in modern electronics manufacturing. Automatic SMD pick and place machines are incorporating advanced tracking and tracing capabilities, such as barcode scanning, laser marking, and real-time data monitoring, to ensure component and process traceability and enhance overall quality control. This ensures that every component can be tracked throughout the production process, improving accountability and reducing defects[2].

Conclusion

In conclusion, automatic SMD pick and place machines are at the forefront of innovation in the electronics manufacturing industry. With advancements in intelligentization, precision, multifunctionality, flexibility, and sustainability, these machines are set to play an even more critical role in the future of PCB assembly. As technology continues to evolve, we can expect to see further enhancements in efficiency, accuracy, and environmental responsibility.

Frequently Asked Questions

1. What is the primary function of an automatic SMD pick and place machine?

- The primary function of an automatic SMD pick and place machine is to accurately place electronic components onto a PCB using advanced vision systems and robotic arms.

2. How do automatic SMD pick and place machines enhance production efficiency?

- These machines enhance production efficiency by automating the component placement process, reducing labor costs, and improving accuracy through advanced vision systems.

3. What are the key innovations in automatic SMD pick and place technology?

- Key innovations include the integration of AI and ML for intelligentization, advancements in precision and speed, multifunctionality, flexible production capabilities, and a focus on environmental sustainability.

4. What challenges do automatic SMD pick and place machines face, and how are they addressed?

- Challenges include component miniaturization and complex PCB designs. These are addressed through the use of modular designs, AI, and machine learning technologies.

5. What future trends can we expect in automatic SMD pick and place machines?

- Future trends include integration with IoT, the use of 3D printing for PCB prototyping, and a greater emphasis on sustainability and energy efficiency.

Citations:

[1] https://www.hwgcsmt.com/news/new-technological-trends-in-the-smt-machine-in-84515003.html

[2] https://www.itechsmt.com/blogs/news/10-hot-topics-about-smt-pick-and-place-machine

[3] https://www.hwgcsmt.com/info/future-trends-and-challenges-of-the-pick-and-p-102769305.html

[4] https://www.linkedin.com/pulse/evolution-smt-pick-place-systems-xalten-xxcdc

[5] https://arshon.com/blog/pick-and-place-machines-revolutionizing-pcb-assembly/

[6] https://www.reportsnreports.com/semiconductor-and-electronics/the-future-of-surface-mount-technology-innovations-and-opportunities-in-the-smt-market/

[7] https://www.hct-smt.com/blog/multifunctional-smt-pick-and-place-machines

[8] https://www.cognitivemarketresearch.com/articles/surface-mount-technology-smt-market-trends-and-future-opportunities

[9] https://neodenusa.com/smt-pick-and-place/neoden9

[10] https://www.zjyingxing.com/info/what-is-the-future-of-smt-machine-82208106.html

[11] https://www.tronstol.com/the-three-major-development-trends-of-the-pick-and-place-machine-in-the-future.html

[12] https://www.youtube.com/watch?v=0uKgPR0gQ24

[13] https://www.pivotint.com/blog/advanced-pick-and-place-smt-automation/

[14] https://blog.tbrc.info/2025/03/pick-and-place-machines-market-analysis-2/

[15] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[16] https://www.pcbasic.com/blog/pick-and-place_machinesH.html

[17] https://smt.fuji.co.jp/en/topics/2858

[18] https://www.neodensmt.com/news/semicon-korea-84115829.html

[19] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[20] https://www.postharvest.biz/news/purchase-of-a-new-fully-automated-smd-assembly-line-25203