Content Menu

● Introduction

● Technological Advancements

>> Miniaturization of Components

>> Enhanced Manufacturing Processes

● Increasing Demand for Consumer Electronics

>> Smart Devices and IoT

>> Automotive Electronics

● Globalization and Market Expansion

>> Emerging Markets

>> Supply Chain Optimization

● Sustainability and Environmental Concerns

>> Lead-Free Soldering

>> Energy-Efficient Manufacturing

● Market Consolidation and Strategic Partnerships

>> Mergers and Acquisitions

>> Collaborative Innovation

● Conclusion

● Related Questions

>> 1. What are the main advantages of surface mount technology over traditional through-hole technology?

>> 2. How does the rise of electric vehicles impact the surface mount technology market?

>> 3. What role does automation play in the surface mount technology market?

>> 4. How are sustainability concerns influencing the surface mount technology market?

>> 5. What are the future growth prospects for the surface mount technology market?

Introduction

The surface mount technology market has witnessed significant growth over the past few decades, driven by advancements in electronics manufacturing and the increasing demand for compact and efficient electronic devices. As industries evolve and consumer preferences shift, understanding the key trends that influence this market is essential for stakeholders, including manufacturers, suppliers, and investors. This article explores the primary trends driving growth in the surface mount technology market, examining technological advancements, market dynamics, and future projections.

Technological Advancements

One of the most significant factors contributing to the growth of the surface mount technology market is the rapid pace of technological advancements. Innovations in materials, processes, and equipment have enhanced the efficiency and reliability of surface mount technology (SMT).

Miniaturization of Components

The trend towards miniaturization has been a game-changer in the electronics industry. As devices become smaller and more powerful, the demand for compact components that can be mounted directly onto printed circuit boards (PCBs) has surged. SMT allows for a higher density of components on a PCB, enabling manufacturers to create smaller, lighter, and more efficient products. This trend is particularly evident in consumer electronics, where smartphones, tablets, and wearables are designed to be as compact as possible.

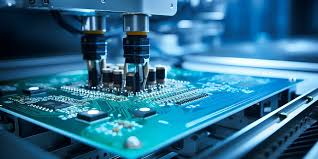

Enhanced Manufacturing Processes

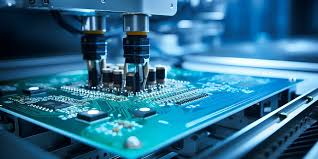

Advancements in manufacturing processes, such as automated assembly and improved soldering techniques, have also played a crucial role in the growth of the surface mount technology market. Automation reduces labor costs and increases production speed, allowing manufacturers to meet the rising demand for electronic devices. Additionally, innovations in soldering materials and techniques, such as lead-free soldering, have improved the reliability and performance of SMT assemblies.

Increasing Demand for Consumer Electronics

The proliferation of consumer electronics is another key trend driving the growth of the surface mount technology market. With the rise of the Internet of Things (IoT), smart home devices, and wearable technology, the demand for advanced electronic components has skyrocketed.

Smart Devices and IoT

Smart devices, which are equipped with sensors and connectivity features, rely heavily on SMT for their compact design and functionality. The IoT ecosystem, which connects various devices to the internet, requires efficient and reliable electronic components that can be easily integrated into a wide range of applications. As more consumers adopt smart devices, the demand for surface mount technology continues to grow.

Automotive Electronics

The automotive industry is also experiencing a shift towards more electronic components, particularly with the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS). These technologies require sophisticated electronic systems that utilize SMT for their compact and efficient design. As the automotive sector increasingly embraces electrification and automation, the surface mount technology market is poised for significant growth.

Globalization and Market Expansion

Globalization has opened new markets for surface mount technology, allowing manufacturers to expand their reach and tap into emerging economies. As countries invest in technology and infrastructure, the demand for electronic devices and components is expected to rise.

Emerging Markets

Countries in Asia-Pacific, Latin America, and Africa are experiencing rapid economic growth, leading to increased investments in technology and electronics manufacturing. The surface mount technology market is benefiting from this trend, as manufacturers seek to establish production facilities in these regions to meet local demand.

Supply Chain Optimization

Globalization has also led to the optimization of supply chains, enabling manufacturers to source materials and components more efficiently. This optimization reduces costs and improves the overall competitiveness of SMT products in the global market.

Sustainability and Environmental Concerns

As environmental awareness grows, the surface mount technology market is also adapting to meet sustainability goals. Manufacturers are increasingly focusing on eco-friendly materials and processes to reduce their environmental impact.

Lead-Free Soldering

The transition to lead-free soldering is a significant trend in the SMT industry. Lead is a hazardous material that poses environmental and health risks, prompting regulatory changes and consumer demand for safer alternatives. The adoption of lead-free soldering materials not only complies with regulations but also enhances the sustainability of electronic products.

Energy-Efficient Manufacturing

Energy-efficient manufacturing processes are becoming a priority for SMT manufacturers. By implementing energy-saving technologies and practices, companies can reduce their carbon footprint and operational costs. This trend aligns with the broader movement towards sustainability in the electronics industry.

Market Consolidation and Strategic Partnerships

The surface mount technology market is witnessing consolidation as companies seek to enhance their competitive edge through mergers and acquisitions. Strategic partnerships are also becoming more common, allowing companies to leverage each other's strengths and capabilities.

Mergers and Acquisitions

Mergers and acquisitions enable companies to expand their product offerings, enter new markets, and achieve economies of scale. This trend is particularly evident in the SMT industry, where companies are acquiring smaller firms with specialized technologies or market access.

Collaborative Innovation

Strategic partnerships between manufacturers, suppliers, and research institutions are fostering innovation in the surface mount technology market. Collaborative efforts can lead to the development of new materials, processes, and technologies that enhance the performance and reliability of SMT products.

Conclusion

The surface mount technology market is poised for continued growth, driven by technological advancements, increasing demand for consumer electronics, globalization, sustainability efforts, and market consolidation. As industries evolve and consumer preferences shift, stakeholders must stay informed about these key trends to remain competitive in the dynamic electronics landscape. By embracing innovation and adapting to market changes, companies can capitalize on the opportunities presented by the growing surface mount technology market.

Related Questions

1. What are the main advantages of surface mount technology over traditional through-hole technology?

Surface mount technology offers several advantages, including smaller component sizes, higher component density on PCBs, improved performance, and reduced manufacturing costs due to automation.

2. How does the rise of electric vehicles impact the surface mount technology market?

The rise of electric vehicles increases the demand for advanced electronic components, which rely on surface mount technology for their compact and efficient design, driving growth in the SMT market.

3. What role does automation play in the surface mount technology market?

Automation enhances production efficiency, reduces labor costs, and improves the consistency and quality of SMT assemblies, making it a critical factor in the growth of the market.

4. How are sustainability concerns influencing the surface mount technology market?

Sustainability concerns are prompting manufacturers to adopt eco-friendly materials and processes, such as lead-free soldering and energy-efficient manufacturing, to reduce their environmental impact.

5. What are the future growth prospects for the surface mount technology market?

The future growth prospects for the surface mount technology market are promising, driven by ongoing technological advancements, increasing demand for consumer electronics, and the expansion of emerging markets.