Content Menu

● Introduction to Surface Mount Technology (SMT)

>> Advantages of Surface Mount Assembly

● Key Steps in the Surface Mount Assembly Process

>> PCB Design and Fabrication

>> Solder Paste Application

>> Component Placement

>> Reflow Soldering

>> Inspection and Testing

>> Repair and Rework

>> Final Assembly and Packaging

● Conclusion

● Related Questions

>> 1. What is the difference between surface mount technology and through-hole technology?

>> 2. How does solder paste application affect the assembly process?

>> 3. What are the common defects in surface mount assembly?

>> 4. How can quality control be maintained in the SMT process?

>> 5. What advancements are being made in surface mount technology?

The surface mount assembly process is a critical aspect of modern electronics manufacturing, enabling the efficient and precise placement of electronic components onto printed circuit boards (PCBs). This article will delve into the key steps involved in this process, providing a comprehensive overview that highlights its significance in the electronics industry.

Introduction to Surface Mount Technology (SMT)

Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled onto PCBs. Unlike traditional through-hole technology, where components are inserted into holes drilled in the PCB, SMT allows components to be mounted directly onto the surface of the board. This method not only saves space but also enhances the performance and reliability of electronic devices.

Advantages of Surface Mount Assembly

1. Compact Design: SMT components are generally smaller than their through-hole counterparts, allowing for more compact PCB designs.

2. Higher Component Density: More components can be placed on a single board, which is essential for modern electronic devices that require miniaturization.

3. Improved Performance: The shorter electrical paths in SMT can lead to better performance and reduced signal interference.

4. Automated Assembly: The process is highly compatible with automated assembly techniques, increasing production speed and reducing labor costs.

Key Steps in the Surface Mount Assembly Process

The surface mount assembly process can be broken down into several key steps, each crucial for ensuring the quality and reliability of the final product. Below are the main stages involved:

PCB Design and Fabrication

Before any assembly can take place, the PCB must be designed and fabricated. This involves:

- Schematic Design: Engineers create a schematic diagram that outlines the electrical connections between components.

- Layout Design: The physical layout of the PCB is designed, taking into account the placement of SMT components.

- Fabrication: The PCB is manufactured using processes such as etching and drilling to create the necessary pathways for electrical connections.

Solder Paste Application

Once the PCB is ready, the next step is to apply solder paste, which is a mixture of solder and flux. This is typically done using a stencil to ensure precise application. The solder paste serves two main purposes:

- Adhesion: It holds the components in place during the assembly process.

- Electrical Connection: It provides the necessary solder for creating electrical connections when the components are soldered.

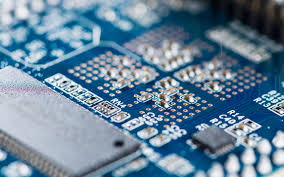

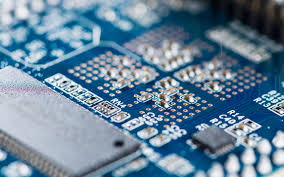

Component Placement

After the solder paste is applied, the next step is to place the SMT components onto the PCB. This is usually done using automated pick-and-place machines, which can accurately position thousands of components per hour. Key considerations during this step include:

- Alignment: Ensuring that components are correctly aligned with the solder paste.

- Placement Accuracy: High precision is required to avoid misalignment, which can lead to soldering defects.

Reflow Soldering

Once all components are placed, the PCB undergoes reflow soldering. This process involves heating the board to melt the solder paste, creating a strong electrical connection between the components and the PCB. The reflow process typically includes:

- Preheating: Gradually raising the temperature to prepare the solder paste.

- Reflow: Heating the board to the melting point of the solder, allowing it to flow and form connections.

- Cooling: Gradually cooling the board to solidify the solder joints.

Inspection and Testing

After soldering, the assembled PCB must be inspected and tested to ensure quality. This can involve several methods:

- Visual Inspection: Checking for obvious defects such as misaligned components or solder bridges.

- Automated Optical Inspection (AOI): Using cameras and software to detect defects that may not be visible to the naked eye.

- Functional Testing: Verifying that the assembled PCB operates as intended.

Repair and Rework

If defects are found during inspection, the PCB may require repair or rework. This can involve:

- Desoldering: Removing defective components using specialized tools.

- Re-soldering: Replacing components and re-soldering them to ensure proper connections.

Final Assembly and Packaging

Once the PCBs pass inspection, they are ready for final assembly into the end product. This may involve:

- Integration: Combining the PCB with other components such as enclosures, connectors, and displays.

- Packaging: Preparing the final product for shipping, ensuring it is protected during transport.

Conclusion

The surface mount assembly process is a complex but essential part of modern electronics manufacturing. By understanding the key steps involved—from PCB design to final assembly—manufacturers can ensure high-quality products that meet the demands of today's technology-driven world. As the industry continues to evolve, advancements in SMT will likely lead to even more efficient and reliable assembly processes.

Related Questions

1. What is the difference between surface mount technology and through-hole technology?

Surface mount technology (SMT) involves mounting components directly onto the surface of a PCB, while through-hole technology requires components to be inserted into holes drilled in the PCB. SMT allows for smaller, more compact designs and is generally more suitable for automated assembly.

2. How does solder paste application affect the assembly process?

Solder paste application is critical as it holds components in place and provides the necessary solder for electrical connections. Inaccurate application can lead to defects such as insufficient solder or solder bridges.

3. What are the common defects in surface mount assembly?

Common defects include misalignment of components, solder bridges, insufficient solder, and cold solder joints. Regular inspection and testing can help identify and rectify these issues.

4. How can quality control be maintained in the SMT process?

Quality control can be maintained through rigorous inspection methods, including visual checks, automated optical inspection (AOI), and functional testing to ensure that all components are correctly placed and soldered.

5. What advancements are being made in surface mount technology?

Advancements in surface mount technology include improved automation, better solder materials, and enhanced inspection techniques, all aimed at increasing efficiency and reliability in the assembly process.