Content Menu

● Material Preparation and Inspection

● Solder Paste Printing

● Component Placement

● Reflow Soldering

● Cleaning

● Inspection

● Rework (if necessary)

● Final Assembly and Packaging

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. Why is solder paste printing important?

>> 3. What role does inspection play in SMT?

>> 4. How does reflow soldering work?

>> 5. What happens if defects are found during inspection?

● Citations:

Surface Mount Technology (SMT) has become a cornerstone in the electronics manufacturing industry, enabling the efficient assembly of printed circuit boards (PCBs). This innovative process involves mounting electronic components directly onto the surface of PCBs, which significantly enhances production speed and reduces costs compared to traditional methods. In this article, we will delve deeper into the key steps involved in the SMT line process, elaborating on each stage's significance and methodology.

Material Preparation and Inspection

The SMT process begins with material preparation, a crucial step that ensures all components meet quality standards before they are utilized in production.

- Incoming Material Inspection: Electronic components must undergo rigorous inspection to verify their quality and compatibility with design specifications. This includes checking for physical damage, verifying part numbers, and ensuring that the correct quantities are available. Quality Control (QC) inspectors play a vital role at this stage, as they are responsible for identifying unqualified materials that could compromise the final product.

- PCB Preparation: The printed circuit boards are prepared by ensuring they are clean and free from contaminants that could affect soldering quality. This often involves baking the boards to remove moisture. Additionally, PCBs typically contain flat solder pads made of materials such as tin-lead or gold-plated copper, which are designed to facilitate optimal soldering.

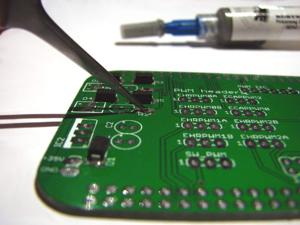

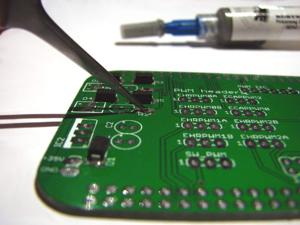

Solder Paste Printing

Solder paste printing is a critical phase where solder paste is applied to the PCB pads using a stencil.

- Stencil Application: A stencil is aligned over the PCB, allowing solder paste to be deposited only on designated areas. This precise application is vital for ensuring that each pad receives the correct amount of solder paste.

- Squeegee Action: A squeegee spreads the solder paste across the stencil at an angle ranging from 45° to 60°. Solder paste is a putty-like mixture of powdered metal solder and sticky flux, which serves as a temporary adhesive to hold surface mount components in place while also cleansing the soldering surfaces of impurities.

- Inspection of Solder Paste Application: After printing, a Solder Paste Inspection (SPI) system checks for defects such as misalignment or insufficient paste coverage. This step is essential to prevent issues during subsequent assembly stages.

Component Placement

Once solder paste has been applied and inspected, the next step involves placing surface mount components onto the PCB.

- Pick and Place Machines: Automated machines known as pick-and-place machines accurately position components on the PCB pads. These machines utilize advanced vision systems to ensure precise placement according to design files.

- Component Feeding: Components are fed into these machines from reels or trays, allowing for quick and efficient handling of various component types. This automation significantly reduces labor costs and increases production speed.

Reflow Soldering

After components are placed on the PCB, they must be soldered to secure them in place. This is achieved through reflow soldering.

- Reflow Oven: The assembled PCB is passed through a reflow oven where it undergoes several temperature zones:

- Preheat Zone: Gradually raises the temperature of both the PCB and components to prevent thermal shock, typically reaching 140°C-160°C.

- Soak Zone: Maintains a steady temperature for about 60-90 seconds to allow for even heating.

- Reflow Zone: The temperature peaks between 210°C and 230°C, melting the solder paste and creating strong electrical connections.

- Cooling Zone: Rapidly cools down the assembly to solidify the solder joints.

This controlled heating process ensures that all components are securely bonded to their respective pads without causing damage due to excessive heat exposure.

Cleaning

Post-soldering, PCBs may require cleaning to remove any residual flux or contaminants that could affect performance.

- Cleaning Methods: Depending on whether no-clean or water-soluble flux was used, cleaning may or may not be necessary. If required, cleaning agents are applied to remove any unwanted residues. This step is crucial for ensuring long-term reliability and performance of the electronic assemblies.

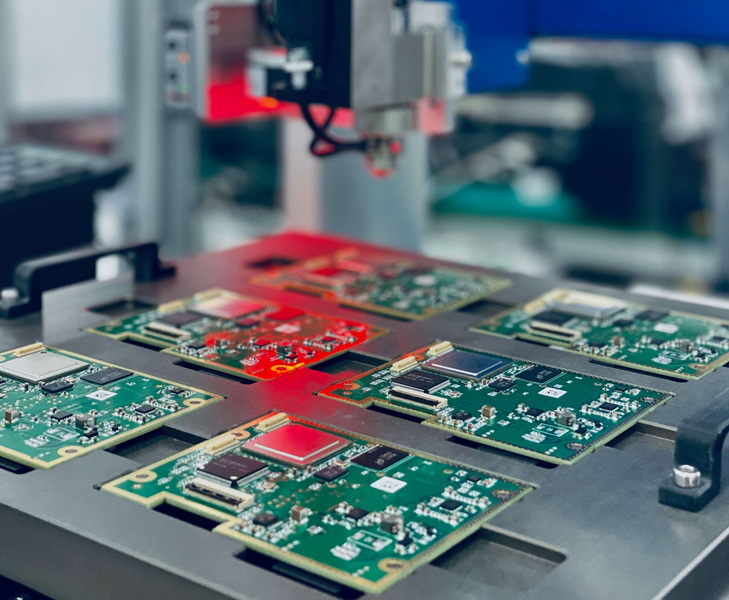

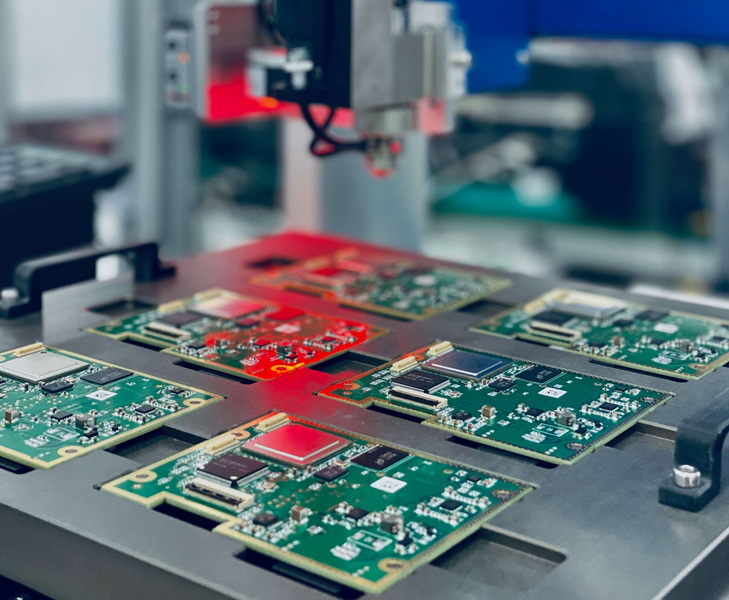

Inspection

Quality control is paramount in SMT processes; therefore, inspection occurs at multiple stages.

- Automated Optical Inspection (AOI): After reflow soldering, AOI systems scan PCBs for defects such as misaligned components or insufficient solder joints. This automated process helps identify issues early on, preventing defective products from proceeding further down the line.

- Functional Testing: Final testing ensures that all components function correctly within their specified parameters before products are shipped out. This may involve various testing methods such as In-Circuit Testing (ICT) or functional testing based on product specifications.

Rework (if necessary)

If defects are identified during inspection, rework processes may be initiated.

- Defect Resolution: Components may be removed and replaced as needed, followed by re-soldering and additional inspections to ensure quality standards are met. Rework stations equipped with specialized tools allow operators to address these issues efficiently while minimizing disruption to production flow.

Final Assembly and Packaging

Once all inspections have been completed and any necessary rework has been performed, the final assembly stage involves preparing products for shipment.

- Final Assembly: Any additional components that need to be added (such as through-hole components) are integrated into the assembly at this stage if required by design specifications.

- Packaging: Finished products are carefully packaged to protect them during transportation and storage. Proper packaging ensures that products remain intact until they reach their final destination.

Conclusion

The SMT line process encompasses several critical steps that work together to ensure high-quality electronic assemblies. From material preparation through inspection and potential rework, each phase plays a vital role in producing reliable PCBs efficiently. As technology continues to advance, SMT processes will likely evolve further, enhancing production capabilities while maintaining high standards in electronic manufacturing.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) refers to a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for faster production and more compact designs compared to traditional methods like through-hole technology.

2. Why is solder paste printing important?

Solder paste printing is essential because it ensures that each pad on the PCB receives an appropriate amount of solder paste for effective component attachment during reflow soldering.

3. What role does inspection play in SMT?

Inspection is crucial at various stages of SMT production to identify defects early on, ensuring that only high-quality assemblies proceed through the manufacturing process.

4. How does reflow soldering work?

Reflow soldering involves passing assembled PCBs through a reflow oven where temperature zones gradually heat up and then cool down, melting and solidifying solder paste to create strong electrical connections between components and pads.

5. What happens if defects are found during inspection?

If defects are found during inspection, a rework process may be initiated where faulty components are removed, replaced, and then subjected to additional inspections before final approval for shipment.

Citations:

[1] https://www.wevolver.com/article/smt-process

[2] https://www.hayawin.com/resources/what-is-the-smt-line-process-and-what-are-the-precautions.html

[3] https://www.electronicspecifier.com/news/surface-mount-technology-best-practice-guide

[4] https://www.pcbonline.com/blog/smt-manufacturing-process.html

[5] https://www.pcbasic.com/blog/smt_production_line.html

[6] https://www.lioncircuits.com/blog/posts/what-is-surface-mount-technology

[7] https://www.pcbcart.com/article/content/smt-process-to-cost-reduction.html

[8] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[9] https://www.ablcircuits.co.uk/blog/what-is-the-smt-process-and-why-should-oems-care/

[10] https://insightsolutionsglobal.com/smt-surface-mount-technology-manufacturing-process/