Content Menu

● Introduction

● Key Metrics in SMT Line Data

>> 1. Overall Equipment Effectiveness (OEE)

>> 2. Line Efficiency

>> 3. Defects Per Million Opportunities (DPMO)

>> 4. Cycle Time and Throughput

>> 5. Component Usage and Wastage

>> 6. First Pass Yield (FPY)

>> 7. Machine Downtime

● Best Practices for Data Collection and Analysis

● Technological Tools for SMT Analytics

● Challenges in Tracking SMT Line Metrics

● Conclusion

● FAQ

>> 1. What is OEE and why is it important?

>> 2. How can I improve line efficiency?

>> 3. What tools are available for SMT data analysis?

>> 4. Why is tracking component usage important?

>> 5. How does AI enhance SMT analytics?

● Citations:

Introduction

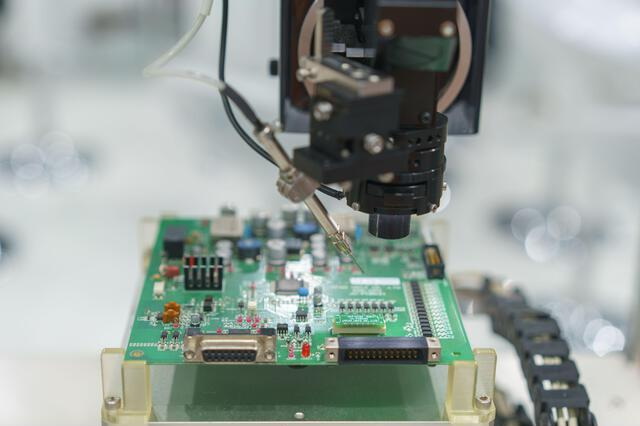

Surface Mount Technology (SMT) lines are crucial in modern electronics manufacturing, enabling the efficient assembly of circuit boards. As the demand for high-quality electronic devices continues to grow, manufacturers must optimize their production processes. Tracking key metrics is essential for improving efficiency, quality, and cost-effectiveness in SMT lines. This article explores the critical metrics that should be monitored in SMT line data and how they contribute to optimizing production processes.

Key Metrics in SMT Line Data

1. Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness (OEE) is a comprehensive metric that evaluates the efficiency of an SMT line by combining three factors: availability, performance, and quality.

- Availability measures the percentage of scheduled production time that the equipment is available for production.

- Performance assesses how well the equipment performs compared to its maximum potential output during the available time.

- Quality indicates the proportion of good units produced compared to the total units manufactured.

OEE provides a holistic view of how well the production line operates and highlights areas needing improvement. A high OEE score indicates an efficient and effective production process. For example, if an SMT line has an OEE of 85%, it means that 85% of its potential output is being realized in terms of availability, performance, and quality combined.

2. Line Efficiency

Line efficiency measures the ratio of actual production time to total staffed time. It is a straightforward yet powerful indicator of how effectively the SMT line is utilized.

For example, if an SMT line operates for 80% of the staffed hours, it indicates a line efficiency of 80%. This metric helps identify areas where downtime can be reduced and productivity can be enhanced.

Moreover, line efficiency can be influenced by various factors such as machine setup times, operator skills, and maintenance schedules. Therefore, continuous monitoring and analysis are crucial to improving this metric.

3. Defects Per Million Opportunities (DPMO)

Defects Per Million Opportunities (DPMO) is a quality metric that quantifies the number of defects in a production process per million opportunities. It helps manufacturers identify quality issues and implement corrective actions to reduce waste and improve customer satisfaction.

By tracking DPMO, manufacturers can focus on continuous improvement initiatives to enhance product quality and minimize defects. A lower DPMO indicates a more effective manufacturing process, leading to higher customer satisfaction and reduced costs associated with rework or returns.

4. Cycle Time and Throughput

Cycle time refers to the time taken to complete one production cycle, while throughput measures the number of units produced within a specific time frame.

Monitoring these metrics is crucial for identifying bottlenecks in the production process and optimizing workflow. Reducing cycle time while increasing throughput can significantly enhance overall productivity. For instance, if an SMT line's cycle time is reduced from 30 seconds to 25 seconds per unit while maintaining throughput, it can lead to substantial increases in overall production capacity.

5. Component Usage and Wastage

Tracking component usage and wastage is vital for cost management in SMT lines. By analyzing this data, manufacturers can identify inefficiencies and implement measures to minimize waste, thereby reducing overall production costs.

Understanding which components are frequently wasted allows manufacturers to adjust their purchasing strategies and improve inventory management. This not only leads to cost savings but also contributes to more sustainable manufacturing practices by reducing excess material usage.

6. First Pass Yield (FPY)

First Pass Yield (FPY) measures the percentage of products that meet quality standards without requiring rework or repair after initial assembly. It is a critical indicator of process effectiveness and product quality.

A high FPY indicates that most products are produced correctly on the first attempt, which reduces waste and increases efficiency. Conversely, a low FPY suggests that there are significant issues within the manufacturing process that need addressing.

7. Machine Downtime

Machine downtime refers to periods when machines are not operational due to maintenance or unexpected failures. Tracking this metric helps identify patterns or recurring issues that may need attention.

By minimizing machine downtime through preventive maintenance strategies or quick response protocols for repairs, manufacturers can significantly improve overall productivity on their SMT lines.

Best Practices for Data Collection and Analysis

Effective data collection and analysis are cornerstones of successful SMT line management. Here are some best practices:

- Integrate Data from All Machines: Collect data from every machine in the SMT line to gain a comprehensive view of performance.

- Standardize Metrics: Use standardized metrics across all machines to ensure consistency and comparability.

- Employ Real-Time Monitoring Tools: Utilize tools that provide real-time insights into machine performance, allowing for quick identification and resolution of issues.

- Utilize Automated Data Logging Systems: Implementing automated data logging systems captures critical parameters such as temperature, humidity, and machine settings throughout various stages of the SMT process. This data is invaluable for traceability and process optimization.

Technological Tools for SMT Analytics

Several advanced tools are available for analyzing SMT data:

- BoostSMT Analytics provides a self-contained data collection system that calculates assembly line efficiency across different machine types.

- QualityLine uses AI technology to continuously collect and analyze SMT assembly data from various factories in real-time, identifying inefficiencies and suggesting improvements.

These tools enable manufacturers to make data-driven decisions that lead to improved operational efficiency.

Challenges in Tracking SMT Line Metrics

While tracking these metrics provides valuable insights into production efficiency, several challenges may arise:

- Data Integration: Many SMT lines consist of machines from different vendors with varying data formats. Integrating these disparate systems requires specialized software or middleware solutions.

- Identifying Relevant Metrics: With numerous potential metrics available for tracking, it can be challenging to determine which are most relevant for specific goals or objectives.

- Change Management: Implementing changes based on metric analysis often requires buy-in from multiple stakeholders within an organization. Effective communication is essential for successful implementation.

Conclusion

Tracking key metrics in SMT line data is essential for optimizing production processes, improving quality, and reducing costs. By leveraging advanced analytics tools and adhering to best practices for data collection and analysis, manufacturers can achieve significant improvements in efficiency and productivity. Continuous monitoring of these metrics allows organizations to adapt quickly to changing market demands while maintaining high standards of quality.

FAQ

1. What is OEE and why is it important?

OEE measures the overall efficiency of an SMT line by combining availability, performance, and quality metrics. It helps identify areas for improvement and optimize production processes.

2. How can I improve line efficiency?

Improving line efficiency involves reducing downtime, optimizing staffing levels, addressing bottlenecks in the production process, and ensuring proper training for operators.

3. What tools are available for SMT data analysis?

Tools like BoostSMT Analytics and QualityLine provide comprehensive data analysis capabilities including real-time monitoring, predictive analytics, and actionable insights for improving efficiency.

4. Why is tracking component usage important?

Tracking component usage helps identify wastage, reduce costs associated with excess inventory or rework, and ensure that the production process remains cost-effective.

5. How does AI enhance SMT analytics?

AI enhances SMT analytics by predicting failures based on historical data patterns, optimizing processes through real-time adjustments, improving overall efficiency, reducing waste loss, and providing actionable recommendations based on comprehensive analysis.

Citations:

[1] https://www.linkedin.com/pulse/from-paper-automation-evolution-impact-oee-data-collection-iliev

[2] https://blog.matric.com/smt-production-for-pcbs-matric

[3] https://kantanmtblog.com/2014/01/28/essential-kpis-for-your-smt-engines/

[4] https://quality-line.com/smt-analytics/

[5] https://www.pcbcart.com/article/content/essential-facts-about-SMT.html

[6] https://quality-line.com/smt-quality/

[7] https://itchronicles.com/manufacturing/why-is-line-efficiency-a-vital-business-metric-in-the-pcb-manufacturing-industry/

[8] https://www.jycircuitboard.com/news/smt-pcb-assembly-quality-influencing-factors-and-analysis-277.html

[9] https://help.archsys.io/hc/en-us/articles/360052554391-How-SMT-Manufacturers-Analyze-Time-and-Productivity-with-Line-Utilization

[10] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[11] https://blog.intraratio.com/traceability-for-surface-mount-technology-process

[12] https://www.pcbcart.com/article/content/measures-to-improve-smt-assembly-quality.html

[13] https://insightsoftware.com/blog/30-manufacturing-kpis-and-metric-examples/

[14] https://help.archsys.io/hc/en-us/articles/360052054332-How-Global-KPIs-Solution-Calculates-SMT-Manufacturing-KPIs-for-Line-Utilization-Bottom-Up-Explanation

[15] https://cogiscan.com/smt-manufacturing-analytics-software-placement-factory-intelligence

[16] https://help.archsys.io/hc/en-us/articles/360052502731-Global-KPIs-Solution-Formulas-Quick-Reference-for-SMT-Line-Utilization

[17] https://archsys.io/blog/strategic-uses-of-machine-data/

[18] https://smt.asmpt.com/en/products/software-solutions/works/works-monitoring/