Content Menu

● Introduction

● Understanding SMT Technology

>> Advantages of Surface Mount Technology

● Key Features of SMT PCB Machines

>> 1. Pick-and-Place Machines

>> 2. Solder Paste Printers

>> 3. Reflow Ovens

>> 4. Inspection Machines

>> 5. Flexibility and Automation

● Additional Features to Consider

>> 6. Component Handling Capabilities

>> 7. Software Integration

>> 8. Maintenance and Support

>> 9. Environmental Compliance

● Factors to Consider When Choosing an SMT Machine

● The Future of SMT Technology

● Conclusion

● FAQs

>> 1. What is an SMT machine?

>> 2. How does a pick-and-place machine work?

>> 3. What are the advantages of SMT over traditional methods?

>> 4. How to maintain SMT machines?

>> 5. What is the typical cost of an SMT machine?

● Citations:

Introduction

Surface Mount Technology (SMT) has fundamentally transformed the landscape of electronic manufacturing, enabling the assembly of compact and efficient printed circuit boards (PCBs). As the demand for high-quality electronics increases, selecting the right SMT PCB machine becomes critical for manufacturers aiming to optimize their production processes. This article delves into SMT PCB machine, providing insights that can help businesses enhance productivity and maintain quality.

Understanding SMT Technology

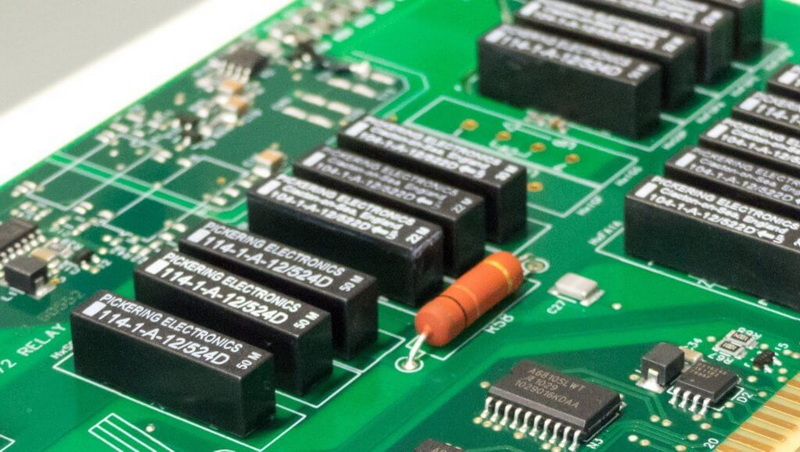

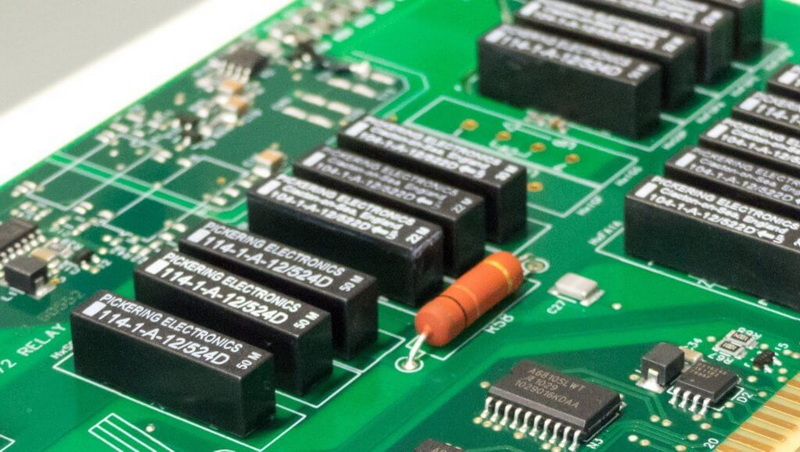

SMT is a technique where electronic components are mounted directly onto the surface of PCBs. This method offers several advantages over traditional through-hole technology, including reduced size and weight of components, increased component density, and improved electrical performance. SMT machines automate the assembly process, significantly decreasing production time while enhancing accuracy and reliability.

Advantages of Surface Mount Technology

SMT has largely replaced through-hole technology due to its numerous benefits:

- Faster Automated Assembly: Some placement machines can place over 136,000 components per hour.

- Higher Component Density: SMT allows more components to fit into a smaller area, improving functionality without increasing board size.

- Dual-Sided Assembly: Components can be mounted on both sides of a PCB, maximizing space utilization.

- Improved Electrical Performance: Shorter connections reduce resistance and inductance, enhancing signal integrity.

- Cost Efficiency: Reduced material costs and faster production lead to lower overall manufacturing expenses.

Key Features of SMT PCB Machines

When evaluating SMT PCB machines, several key features should be prioritized:

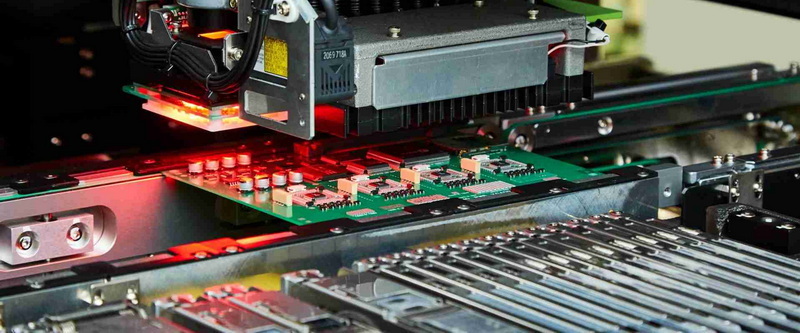

1. Pick-and-Place Machines

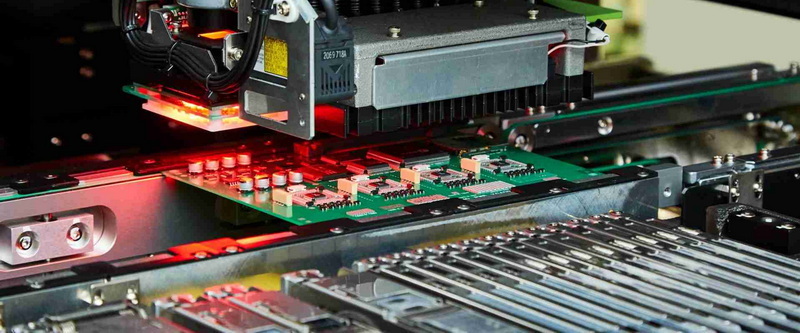

Pick-and-place machines are integral to the SMT assembly process. They are responsible for accurately positioning components on PCBs. These machines vary from manual to fully automated systems, with capabilities ranging from low to high-speed operations. High-speed pick-and-place machines can place thousands of components per hour, making them ideal for high-volume production environments.

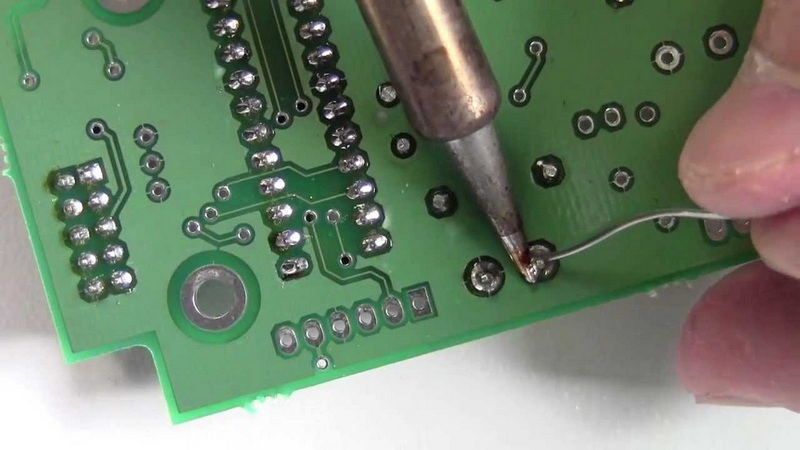

2. Solder Paste Printers

Solder paste printers apply solder paste to designated areas on the PCB before component placement. The precision of this application is crucial for ensuring strong solder joints. Advanced models utilize automated systems to maintain consistent paste thickness and alignment, which minimizes defects during assembly.

3. Reflow Ovens

Reflow ovens are essential for melting solder paste after components have been placed on the PCB. These ovens must provide precise temperature control to accommodate various component types and solder materials. A quality reflow oven ensures uniform heating and cooling, which is vital for preventing damage to sensitive components.

4. Inspection Machines

Automated Optical Inspection (AOI) machines are critical for maintaining quality control in the SMT process. They detect defects such as misaligned components or solder bridges, which could compromise PCB performance. Incorporating inspection machines into the production line allows manufacturers to identify errors early, reducing waste and rework.

5. Flexibility and Automation

Modern SMT machines should offer flexibility in handling different component sizes and types. The ability to quickly switch between production runs without extensive retooling is a significant advantage. Additionally, automation features like intelligent feeders and integrated software can streamline operations and enhance overall efficiency.

Additional Features to Consider

While the above features are essential, there are other factors that can significantly impact the performance of an SMT machine:

6. Component Handling Capabilities

The ability of an SMT machine to handle various types of components—including small passive devices and complex integrated circuits—is crucial. Machines should be equipped with adaptable feeders that can accommodate different packaging styles such as tape, tray, or tube feeders.

7. Software Integration

Advanced software solutions can optimize production processes by providing real-time data on machine performance, component placement accuracy, and production speed. This integration allows manufacturers to make informed decisions quickly and adjust settings as needed for different production runs.

8. Maintenance and Support

Selecting a machine from a reputable manufacturer that offers comprehensive support and maintenance services is essential for minimizing downtime. Regular maintenance schedules help ensure that machines operate at peak efficiency over their lifespan.

9. Environmental Compliance

As sustainability becomes increasingly important in manufacturing processes, it is crucial that SMT machines comply with environmental regulations such as RoHS (Restriction of Hazardous Substances). This compliance ensures that manufacturers can produce environmentally friendly products without compromising quality or performance.

Factors to Consider When Choosing an SMT Machine

Selecting an appropriate SMT machine involves considering several factors:

- Production Volume: Assess your expected production volume to ensure you select a machine that meets your needs.

- Component Types: Verify that the machine can accommodate the specific types of components you plan to use.

- Budget: Balance desired features with your budget constraints; higher-end machines often come with additional capabilities.

- Space Requirements: Evaluate the physical space available for the machine and its operation.

- Support and Maintenance: Choose manufacturers that provide robust support and maintenance services.

The Future of SMT Technology

The evolution of SMT technology continues as manufacturers seek ways to improve efficiency and reduce costs further. Innovations such as micro-soldering techniques allow for even smaller components and denser board layouts. Additionally, advancements in AI-driven automation promise to enhance precision in component placement while minimizing human intervention.

As industries increasingly demand miniaturized electronic devices with enhanced functionality, SMT will remain at the forefront of PCB manufacturing technology. The integration of robotics in assembly lines also presents opportunities for greater flexibility in production processes, allowing manufacturers to adapt quickly to changing market demands.

Conclusion

Choosing the right SMT PCB machine is essential for manufacturers looking to enhance their production capabilities. By understanding key features such as pick-and-place technology, solder paste application, reflow processes, inspection systems, and overall flexibility, businesses can make informed decisions that lead to improved efficiency and quality in their PCB assembly processes.

FAQs

1. What is an SMT machine?

An SMT machine is a device used in the assembly of surface mount technology components onto printed circuit boards (PCBs). It automates placement and soldering processes, enhancing efficiency and accuracy.

2. How does a pick-and-place machine work?

A pick-and-place machine employs robotic arms to pick components from feeders and place them onto PCBs at precise locations based on design data.

3. What are the advantages of SMT over traditional methods?

SMT offers numerous benefits including higher component density, reduced manufacturing costs, faster production times, and smaller component sizes essential for modern electronics.

4. How to maintain SMT machines?

Regular maintenance includes cleaning, calibration, and software updates according to manufacturer guidelines to ensure optimal performance.

5. What is the typical cost of an SMT machine?

The cost varies widely based on features and automation levels; entry-level machines may start at a few thousand dollars while high-end models can exceed hundreds of thousands.

Citations:

[1] https://en.wikipedia.org/wiki/Surface_mount

[2] https://www.greencircuits.com/pcb-assembly-capabilities-and-equipment/

[3] https://morepcb.com/smt/

[4] https://vectorbluehub.com/smt-assembly

[5] https://alimco.in/WriteReadData/UserFiles/file/Specification3MR3.pdf

[6] https://www.altestcorp.com/surface-mount-technology/

[7] https://www.odyssey-oei.com/pcb-assembly-process/surface-mount-technology-smt.html

[8] https://www.raypcb.com/surface-mount-technology/

[9] https://www.mpe-electronics.co.uk/2024/10/22/advantages-and-disadvantages-of-surface-mount-technology

[10] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[11] https://www.unmannedsystemstechnology.com/feature/mpl-explains-the-evolution-of-smt-technology/

[12] https://levisonenterprises.com/5-advantages-to-using-smt/

[13] https://www.neodensmt.com/other-products/dual-camera-small-desktop-smt-assembly.html

[14] https://www.hayawin.com/news-smt-machine-types-and-features-of-excellent-smt-machines.html

[15] https://www.pcbgogo.com/knowledge-center/SMT_Assembly_capabilities.html

[16] https://blog.matric.com/robotics-current-pcb-manufacturing-techniques-the-latest

[17] https://lenalea.com/the-advantages-of-smt-assembly-in-electronics-manufacturing/

[18] https://www.sunzontech.com/product/smt-spi-machine-sunzontech-refine-x/

[19] https://www.linkedin.com/pulse/comprehensive-guide-smt-machines-what-how-choose-%E6%97%AD%E4%B8%9C-%E8%A2%81-wm4hc

[20] https://www.nextpcb.com/pcb-vocabulary/smt-assembly-capabilities

[21] https://auroraboardworks.com/manufacturing/smt-assembly/

[22] https://www.zjyingxing.com/info/what-role-does-smt-machine-play-in-modern-indu-102642276.html

[23] https://www.charmhigh-tech.com/sale-14039556-pcb-conveyor-4-heads-desktop-smt-pick-and-place-machine-chm-650-auto-nozzle-change.html

[24] https://www.wevolver.com/article/smt-process

[25] https://www.pcbway.com/pcb_prototype/SMT_Assembly_Capabilities.html

[26] https://jlcpcb.com/blog/the-characteristics-of-surface-mount-technology

[27] https://www.ourpcb.com/smt-machine.html

[28] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[29] https://www.pcbcart.com/article/content/PCB-design-elements-effect-smt-mfg.html

[30] https://www.pcbasic.com/blog/surface_mount_technology_smt.html

[31] https://shenzhenshengdian.en.made-in-china.com/product/NOsTbaMvGCkH/China-SMT-Machine-PCB-Printer-Semi-Automatic-1-2m-Specification-PCB-Solder-Paste-Printing-Machine.html

[32] https://www.venture-pcba.com/smt-assembly-capabilities/