Content Menu

● Understanding the Role of an SMD Stencil Machine

● Key Features to Consider in an SMD Stencil Machine

>> 1. Precision Printing Mechanism

>> 2. Automated PCB and Stencil Alignment

>> 3. Stencil Clamping and Tension Control

>> 4. Automatic Cleaning System

>> 5. User-Friendly Interface and Programmability

>> 6. Squeegee Pressure Feedback System

>> 7. PCB Size and Handling Capacity

>> 8. Robust Frame and Build Quality

>> 9. Integration with SMT Production Line

>> 10. Environmental and Safety Features

● Additional Considerations When Choosing an SMD Stencil Machine

>> Maintenance and Support

>> Cost vs. Performance Balance

>> Flexibility for Future Needs

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the primary function of an SMD stencil machine?

>> 2. How does automated alignment improve the performance of an SMD stencil machine?

>> 3. Why is stencil tension important in solder paste printing?

>> 4. Can an SMD stencil machine handle different PCB sizes?

>> 5. What role does the automatic cleaning system play in an SMD stencil machine?

In the realm of electronics manufacturing, the Surface Mount Device (SMD) stencil machine is a vital piece of equipment that ensures precision and efficiency in the solder paste printing process. Choosing the right SMD stencil machine can significantly impact the quality of printed circuit boards (PCBs) and the overall productivity of the assembly line. This comprehensive article explores the key features to look for in an SMD stencil machine, helping manufacturers and engineers make informed decisions for their SMT (Surface Mount Technology) production needs.

Understanding the Role of an SMD Stencil Machine

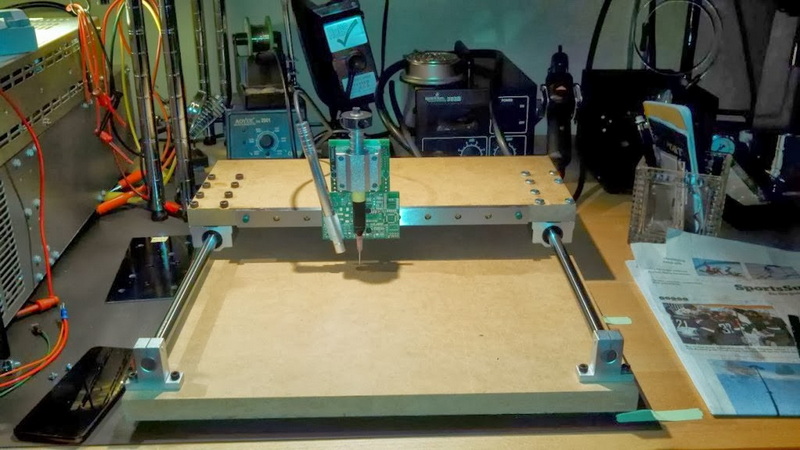

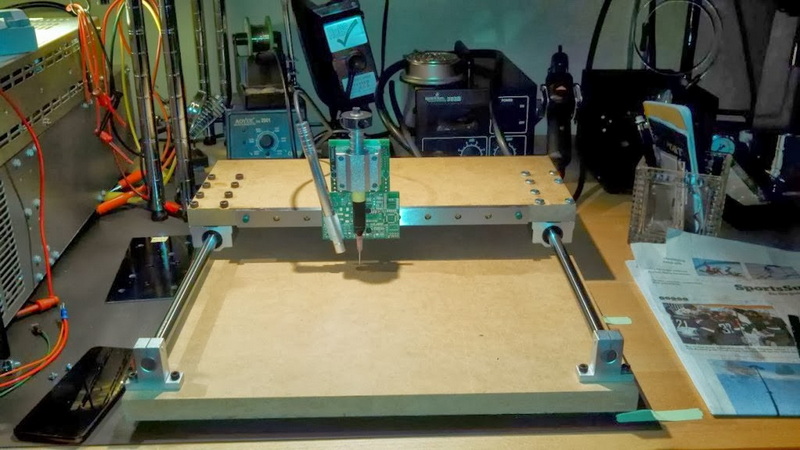

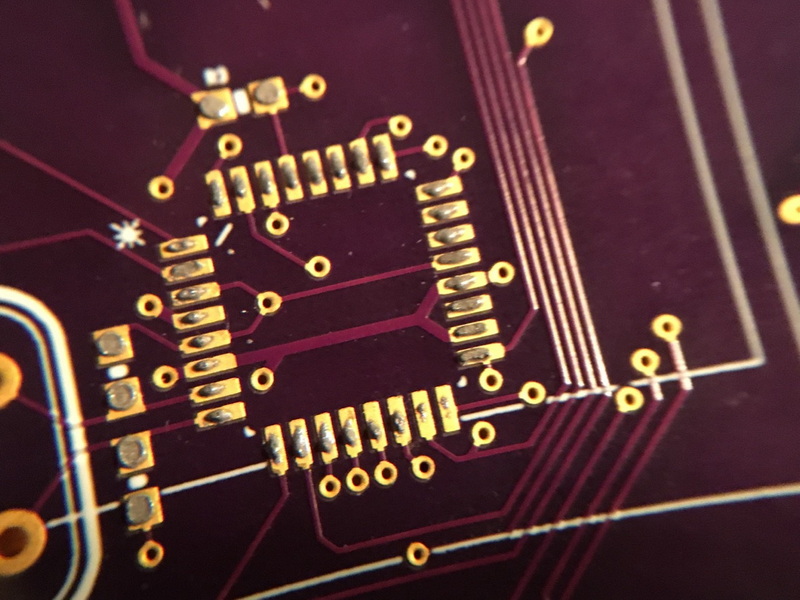

An SMD stencil machine, often referred to as a solder paste stencil printer, is designed to apply solder paste accurately onto the PCB pads through a stencil template. This process is critical because the solder paste acts as the adhesive and conductive medium for mounting surface-mount components onto the PCB. The stencil ensures that solder paste is deposited only where needed, in precise amounts, to avoid defects such as solder bridging, insufficient solder, or misalignment.

The machine's primary function is to align the stencil with the PCB and apply solder paste uniformly across the stencil apertures using a squeegee mechanism. The quality of this step directly influences the reliability of the final electronic assembly. Without a high-quality SMD stencil machine, manufacturers risk inconsistent solder paste deposits that can lead to costly defects and rework.

Key Features to Consider in an SMD Stencil Machine

1. Precision Printing Mechanism

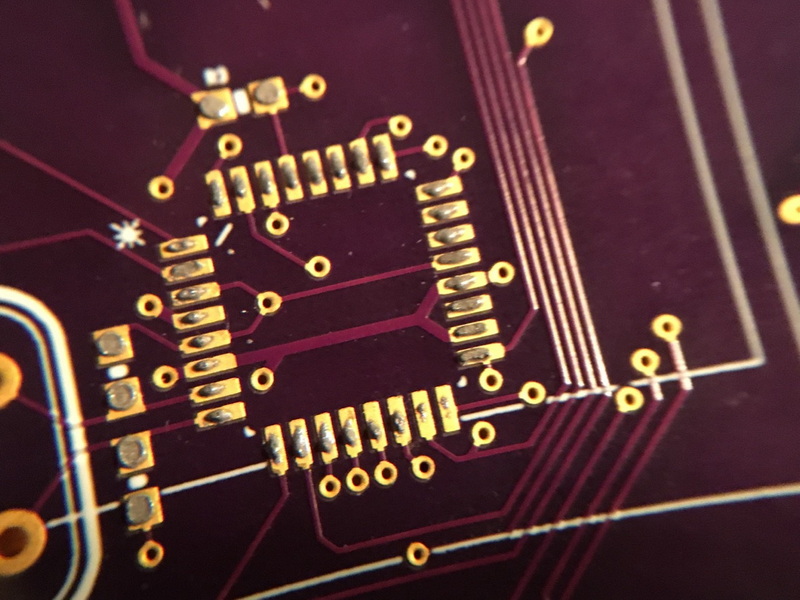

The core feature of any SMD stencil machine is its printing mechanism. It must provide highly accurate alignment between the stencil apertures and the PCB pads. This is typically achieved through advanced vision systems or mechanical alignment tools that ensure the stencil is positioned with micron-level accuracy.

The squeegee system, which spreads the solder paste over the stencil, should allow for adjustable pressure and speed. Proper control of these parameters ensures even distribution of solder paste and prevents defects caused by over- or under-printing. Machines with programmable squeegee pressure and speed offer greater flexibility to handle different PCB designs and solder paste viscosities.

Moreover, some advanced SMD stencil machines feature dual squeegee systems that can print from both sides or provide enhanced pressure control, which is especially useful for complex or fine-pitch components. The ability to fine-tune the printing parameters directly affects the quality of solder joints and reduces the risk of solder bridging or insufficient solder.

2. Automated PCB and Stencil Alignment

For high-volume and high-mix production environments, automated alignment systems are essential. These systems use cameras and sensors to detect fiducial marks on the PCB and stencil, aligning them precisely without manual intervention. Automated alignment reduces setup time, increases throughput, and enhances repeatability.

Some machines offer automatic calibration features that adjust the stencil and PCB positions dynamically during the printing process, further improving accuracy and minimizing errors. The integration of AI and machine learning algorithms in newer models can even predict and compensate for minor deviations caused by thermal expansion or mechanical wear, ensuring consistent print quality over time.

3. Stencil Clamping and Tension Control

Proper clamping and tensioning of the stencil are critical to maintain flatness and prevent movement during printing. An SMD stencil machine should have a robust clamping mechanism that holds the stencil securely without causing deformation.

Tension control systems ensure the stencil maintains optimal tension throughout the printing cycle. Consistent stencil tension prevents solder paste smearing and ensures uniform paste thickness. Some machines provide real-time tension feedback and automatic adjustments to maintain ideal conditions.

In addition, the ability to quickly change stencils and adjust tension settings is beneficial for production lines that handle multiple product types or frequent design changes. This flexibility reduces downtime and improves overall line efficiency.

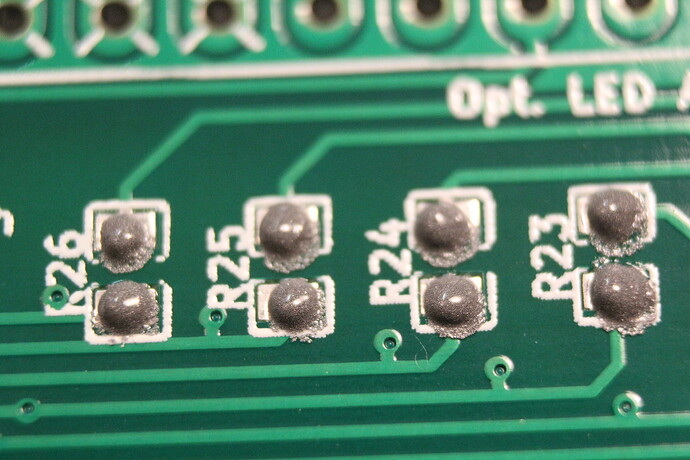

4. Automatic Cleaning System

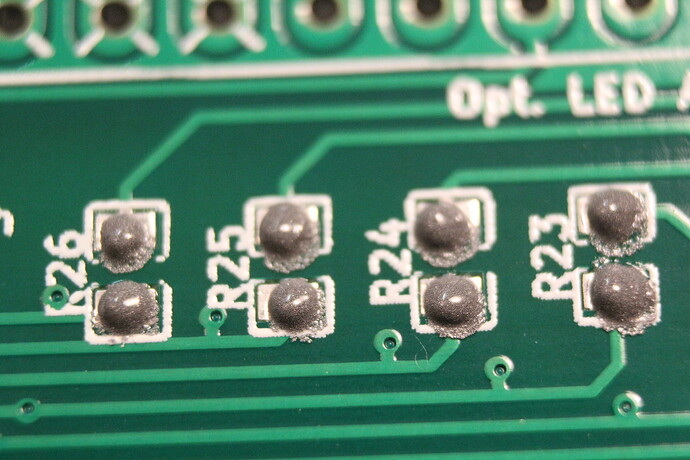

Solder paste residues can clog stencil apertures, leading to printing defects. An automatic cleaning system integrated into the SMD stencil machine is a valuable feature that enhances productivity and print quality.

This system cleans the stencil at preset intervals or after a specific number of prints, removing excess solder paste without manual intervention. Automated cleaning reduces downtime and maintains consistent stencil aperture clarity, which is crucial for fine-pitch components.

Advanced cleaning systems use ultrasonic or brush-based cleaning methods combined with solvent sprays to ensure thorough removal of solder paste. Some machines also feature stencil drying mechanisms to prepare the stencil for immediate reuse, further minimizing production interruptions.

5. User-Friendly Interface and Programmability

Modern SMD stencil machines come equipped with intuitive touch-screen interfaces that simplify operation and setup. Programmable settings for stencil positioning, squeegee pressure, printing speed, and cleaning cycles allow operators to customize the machine for different PCB designs and production requirements.

The ability to save and recall printing programs improves efficiency, especially in facilities handling multiple product types. Some machines also offer remote monitoring and diagnostics, enabling proactive maintenance and minimizing unexpected downtime.

User-friendly software can include features such as guided setup wizards, error diagnostics, and real-time process feedback. This reduces the learning curve for new operators and helps maintain consistent print quality even with less experienced staff.

6. Squeegee Pressure Feedback System

A feedback system that monitors and adjusts the squeegee pressure in real time is a significant advantage. This feature ensures the pressure applied during solder paste spreading remains consistent, preventing variations that could affect print quality.

Such systems detect anomalies like excessive pressure or insufficient contact and automatically correct them or alert the operator, thereby reducing defects and rework. This level of control is especially important when printing on PCBs with uneven surfaces or varying pad sizes.

7. PCB Size and Handling Capacity

Depending on the production scale, the machine's capacity to handle various PCB sizes is important. Some SMD stencil machines are designed for small to medium-sized boards, while others can accommodate large or long PCBs up to 1.2 meters or more.

The machine should support easy loading and unloading of PCBs, either manually or through automated feeders, to streamline workflow and reduce handling errors. Features like adjustable conveyor widths, vacuum hold-down systems, and anti-static handling mechanisms protect delicate PCBs during printing.

Additionally, some machines offer modular designs that allow expansion of handling capacity or integration with robotic arms for automated material handling, further enhancing production flexibility.

8. Robust Frame and Build Quality

The mechanical stability of the SMD stencil machine affects printing accuracy and longevity. A robust frame minimizes vibrations and mechanical drift during operation, ensuring consistent print quality over time.

High-quality components and precise manufacturing tolerances contribute to the machine's reliability and reduce maintenance needs. Machines built with corrosion-resistant materials and sealed components also perform better in environments where solder paste fumes and dust are present.

Durability is particularly important for manufacturers with continuous production schedules, as it reduces downtime and repair costs.

9. Integration with SMT Production Line

For seamless SMT assembly, the stencil machine should be compatible with other line equipment such as pick-and-place machines and reflow ovens. Features like automated conveyor interfaces and communication protocols enable smooth material flow and synchronization.

Integration capabilities improve overall line efficiency and allow for real-time process monitoring and control. Some advanced SMD stencil machines support Industry 4.0 standards, enabling data exchange with Manufacturing Execution Systems (MES) and allowing for predictive maintenance and quality control analytics.

This connectivity helps manufacturers optimize their production processes and respond quickly to any issues that arise.

10. Environmental and Safety Features

Some machines include humidity monitoring systems and temperature controls to maintain optimal printing conditions. Solder paste properties can be sensitive to environmental factors, and controlling these helps maintain consistent print quality.

Safety features such as emergency stops, protective covers, and user access controls are also important to protect operators and equipment. Ergonomic designs that reduce operator strain and noise reduction technologies contribute to a safer and more comfortable working environment.

Manufacturers should also consider machines with low power consumption and environmentally friendly cleaning systems to support sustainability goals.

Additional Considerations When Choosing an SMD Stencil Machine

Maintenance and Support

Choosing an SMD stencil machine from a reputable manufacturer that offers comprehensive after-sales support is crucial. Regular maintenance is necessary to keep the machine operating at peak performance, and access to spare parts, technical support, and training can minimize downtime.

Some manufacturers provide remote diagnostics and software updates that help maintain machine reliability and extend its service life.

Cost vs. Performance Balance

While it is tempting to opt for the most advanced SMD stencil machine available, manufacturers must balance cost with the features they truly need. High-end machines with extensive automation and advanced features are ideal for large-scale production but may not be cost-effective for smaller operations.

Evaluating production volume, product complexity, and budget constraints will help determine the best fit.

Flexibility for Future Needs

The electronics industry evolves rapidly, with new PCB designs and component types emerging frequently. Investing in an SMD stencil machine that offers upgrade paths or modular expansions can protect against obsolescence and allow manufacturers to adapt to future production requirements.

Conclusion

Selecting the right SMD stencil machine involves careful consideration of multiple features that impact print quality, production efficiency, and operational flexibility. Key aspects include precision printing mechanisms, automated alignment, stencil tension control, automatic cleaning, and user-friendly programmability. A robust and well-integrated machine not only enhances solder paste application accuracy but also contributes to smoother SMT assembly workflows and higher overall product quality. Investing in an advanced SMD stencil machine is essential for manufacturers aiming to maintain competitive advantages in the fast-evolving electronics industry.

Frequently Asked Questions (FAQ)

1. What is the primary function of an SMD stencil machine?

The primary function of an SMD stencil machine is to accurately apply solder paste onto the PCB pads through a stencil template, ensuring precise placement for surface mount components during the SMT assembly process.

2. How does automated alignment improve the performance of an SMD stencil machine?

Automated alignment uses vision systems to precisely position the stencil over the PCB, reducing setup time, minimizing human error, and ensuring consistent solder paste application across production batches.

3. Why is stencil tension important in solder paste printing?

Proper stencil tension maintains the flatness and stability of the stencil during printing, preventing smearing or uneven solder paste deposits, which can lead to defects in the solder joints.

4. Can an SMD stencil machine handle different PCB sizes?

Yes, many SMD stencil machines are designed to accommodate a range of PCB sizes, from small to large boards, with some models capable of handling PCBs up to 1.2 meters in length or more.

5. What role does the automatic cleaning system play in an SMD stencil machine?

The automatic cleaning system removes excess solder paste from the stencil apertures at regular intervals, preventing clogging and ensuring consistent print quality without manual cleaning interruptions.