Content Menu

● Understanding SMD Pick & Place Machines

>> Main Components of an SMD Pick & Place Machine

● Key Features to Consider When Selecting an SMD Pick & Place Machine

>> 1. Production Volume and Speed

>> 2. Placement Accuracy

>> 3. Versatility and Component Handling

>> 4. Ease of Use and Programming

>> 5. Reliability and Maintenance

>> 6. Vision and Inspection Systems

>> 7. Placement Head and Nozzle Configuration

>> 8. Conveyor and Board Handling

● Additional Considerations

>> Cost vs. Performance

>> Future Expansion and Upgradability

>> Software Integration

>> Environmental and Physical Factors

● Conclusion

● FAQ

>> 1. What is the importance of the feeder system in an SMD pick & place machine?

>> 2. How does the vision system improve placement accuracy?

>> 3. What factors affect the speed of an SMD pick & place machine?

>> 4. How can maintenance impact the performance of a pick & place machine?

>> 5. Can SMD pick & place machines handle different component sizes and types?

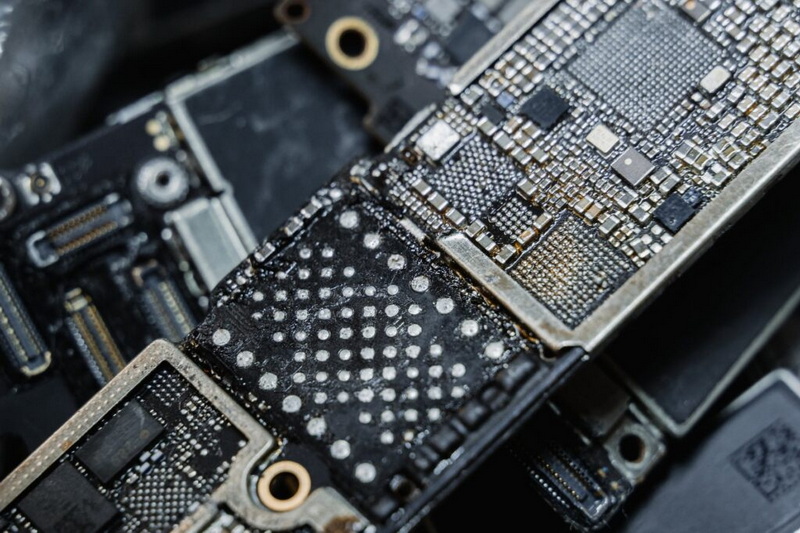

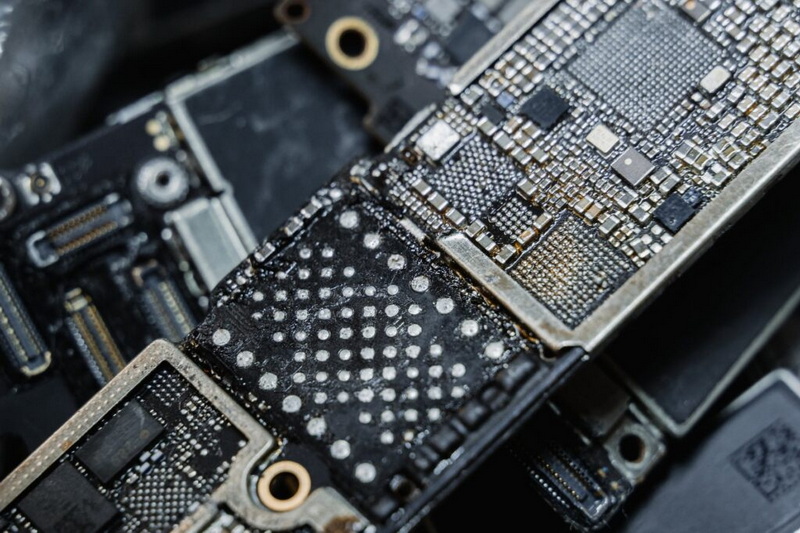

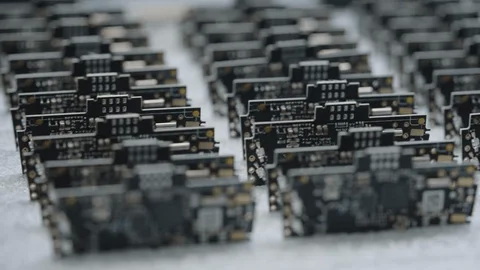

Surface Mount Device (SMD) pick & place machines are critical in modern electronics manufacturing, automating the precise placement of tiny components onto printed circuit boards (PCBs). Selecting the right SMD pick & place machine can greatly impact production efficiency, product quality, and operational costs. This comprehensive article explores the key features to look for in an SMD pick & place machine, helping manufacturers make informed decisions tailored to their specific needs.

Understanding SMD Pick & Place Machines

An SMD pick & place machine automates the process of picking up electronic components and placing them accurately on PCBs. These machines are indispensable in producing devices such as smartphones, computers, and televisions due to their speed and precision compared to manual assembly.

Main Components of an SMD Pick & Place Machine

- Feeder System: Supplies components continuously to the machine, using tape and reel feeders for small parts and bulk feeders for larger ones.

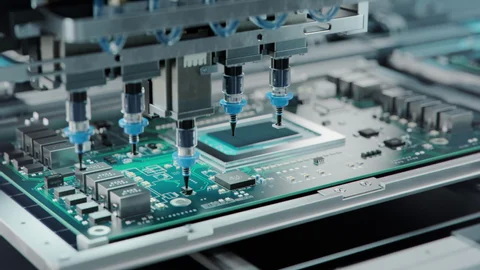

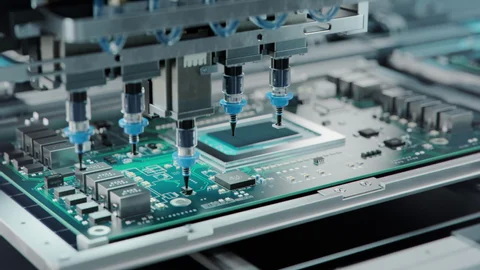

- Placement Head: Equipped with multiple vacuum nozzles to pick components and place them precisely on the PCB.

- Vision System: Uses cameras and software to verify component position, orientation, and PCB alignment.

- Control System: Computer and software that coordinate machine operations and programming.

- Conveyor System: Moves PCBs through the machine in sync with placement operations.

Key Features to Consider When Selecting an SMD Pick & Place Machine

Choosing the right SMD pick & place machine requires a thorough understanding of your manufacturing requirements and the machine's capabilities. Below are the essential features to consider:

1. Production Volume and Speed

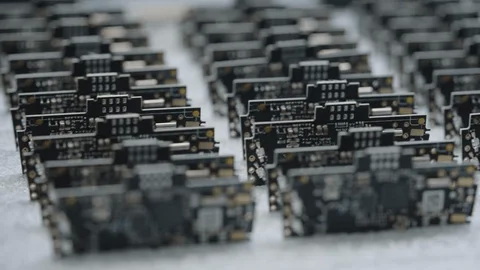

The required production volume is a primary consideration. High-volume manufacturers need high-speed machines capable of placing thousands of components per hour (CPH), while low-volume or prototype production may prioritize flexibility over speed.

- High-speed machines can place upwards of 30,000 to 60,000 components per hour, ideal for mass production.

- Medium to low-speed machines offer placement speeds between 5,000 to 20,000 CPH, providing versatility for various component types and smaller production runs.

Speed is not just about raw numbers; it also depends on the machine's ability to handle complex PCB layouts without sacrificing accuracy. Some machines incorporate multi-head placement systems that allow simultaneous placement of multiple components, significantly boosting throughput.

2. Placement Accuracy

Accuracy is crucial to ensure components are placed correctly, minimizing defects and rework. Factors influencing accuracy include:

- Precision of the placement head's X, Y, and rotational movements.

- Resolution and calibration of the vision system.

- Quality of the mechanical frame, preferably an all-welded steel frame for stability.

Modern SMD pick & place machines achieve placement accuracy within ±0.02 mm or better, which is essential for fine-pitch components and high-density boards. Advanced vision systems with high-resolution cameras and intelligent algorithms help identify fiducial marks and component orientation, ensuring precise placement even on complex boards.

3. Versatility and Component Handling

The machine should accommodate a wide range of component sizes, shapes, and packaging types (tape, tray, tube). Features to look for include:

- Multiple nozzle types and sizes to handle different components, from tiny 01005 resistors to large connectors.

- Ability to manage various feeders and trays simultaneously, allowing mixed component placement without manual intervention.

- Capability to place components with different heights and shapes, including odd-shaped and 3D components.

Versatility is especially important for manufacturers producing multiple product lines or prototypes, where component diversity is high. Machines with flexible feeder systems and adaptable placement heads reduce changeover time and increase operational efficiency.

4. Ease of Use and Programming

User-friendly software and intuitive controls reduce setup time and training costs. Features include:

- Support for native language programming and graphical user interfaces (GUI).

- Easy import of BOM (Bill of Materials) and CPL (Component Placement List) files from common CAD and CAM software.

- Automated calibration and setup routines that minimize manual adjustments.

- Clear interface for feeder management, component library creation, and real-time monitoring.

Some advanced SMD pick & place machines offer offline programming capabilities, allowing operators to prepare and simulate placement programs without halting production. This feature is invaluable for reducing downtime during product changeovers.

5. Reliability and Maintenance

A robust machine with minimal downtime is essential for continuous production. Consider:

- Durable construction materials, such as welded steel frames, to reduce vibration and maintain alignment.

- Availability of technical support, spare parts, and comprehensive service agreements.

- Maintenance schedules and ease of access to components like nozzles, feeders, and belts.

- Software tools for diagnostics and predictive maintenance to detect issues before they cause breakdowns.

Reliability also depends on the quality of consumables such as vacuum nozzles and feeder tapes. Choosing a machine with widely available parts reduces operational risks and maintenance costs.

6. Vision and Inspection Systems

Integrated vision systems enhance placement accuracy and quality control by:

- Capturing images of components and PCBs for alignment and fiducial recognition.

- Detecting component presence, orientation, and polarity before placement.

- Verifying component placement post-placement to reduce defects.

- Some machines also incorporate 3D inspection and height measurement for components with varying thickness.

Vision systems reduce manual inspection requirements and enable real-time error correction, improving overall yield and reducing scrap.

7. Placement Head and Nozzle Configuration

The placement head's design affects speed and flexibility:

- Multi-head machines can pick multiple components simultaneously, increasing throughput.

- Vacuum nozzles must be adaptable, easy to replace, and compatible with a variety of component sizes.

- Rotation and multi-axis movement capabilities enable precise placement on complex boards and odd-shaped components.

Some machines offer interchangeable heads or modular designs that allow upgrading or customizing the placement system based on production needs.

8. Conveyor and Board Handling

Efficient PCB transport through the machine ensures smooth operation:

- Conveyor speed synchronization with placement head to maintain continuous flow.

- Capability to handle different PCB sizes, thicknesses, and materials.

- Reliable board clamping and positioning mechanisms to prevent movement during placement.

- Optional features like board marking, barcode scanning, and automated loading/unloading systems.

Proper board handling reduces misalignment and damage, contributing to higher production quality and less downtime.

Additional Considerations

Cost vs. Performance

Balancing cost with required features is critical. High-speed, high-accuracy machines come with a premium price tag but deliver significant productivity gains in large-scale manufacturing. Conversely, budget-friendly machines may suffice for small-scale or prototype production but might lack advanced features and speed.

Future Expansion and Upgradability

Investing in machines that offer upgrade paths-such as adding more feeders, placement heads, or advanced vision modules-ensures your equipment can grow with your business needs. This flexibility protects your investment and reduces the need for frequent capital expenditures.

Software Integration

Compatibility with existing manufacturing execution systems (MES), enterprise resource planning (ERP) systems, and other automation software streamlines production workflows and data management. Look for machines that support industry-standard communication protocols and offer APIs for custom integration.

Environmental and Physical Factors

Consider the machine's footprint, noise levels, and power consumption, especially if operating in space-constrained or noise-sensitive environments. Energy-efficient machines reduce operational costs and support sustainability goals.

Conclusion

Choosing the right SMD pick & place machine involves evaluating multiple factors including production volume, placement speed and accuracy, component versatility, ease of use, and machine reliability. A well-chosen machine will enhance manufacturing efficiency, reduce defects, and support your business growth. Investing in advanced vision systems, robust mechanical design, and user-friendly software ensures long-term operational success. By carefully considering these key features, manufacturers can select an SMD pick & place machine that meets their current needs and adapts to future demands.

FAQ

1. What is the importance of the feeder system in an SMD pick & place machine?

The feeder system supplies components to the machine continuously and accurately. It includes tape and reel feeders for small components and bulk feeders for larger parts, ensuring uninterrupted production and correct component presentation for pickup.

2. How does the vision system improve placement accuracy?

The vision system uses cameras to capture images of the PCB and components, analyzing position, orientation, and rotation. This data allows the machine to adjust the placement head for precise component placement, reducing errors and improving product quality.

3. What factors affect the speed of an SMD pick & place machine?

Speed depends on machine design, number of placement heads, component size, and complexity of the PCB layout. High-speed machines use multi-head configurations and optimized motion control to increase throughput, while slower machines may offer greater versatility.

4. How can maintenance impact the performance of a pick & place machine?

Regular maintenance ensures optimal vacuum pressure, nozzle condition, and calibration. Neglecting maintenance can cause placement errors, component damage, and machine downtime, negatively affecting production quality and efficiency.

5. Can SMD pick & place machines handle different component sizes and types?

Yes, modern machines are designed with multiple nozzle types and feeder options to handle a wide range of components from tiny 01005 chips to larger parts. This versatility supports diverse product lines and manufacturing flexibility.