Content Menu

● Introduction to SMT Reel Storage Systems

>> Importance of SMT Reel Storage

● Key Features of High-Quality SMT Reel Storage Systems

>> 1. Modular and Scalable Design

>> 2. Advanced Inventory Management

>> 3. Automation and Efficiency

>> 4. Integration with Manufacturing Systems

>> 5. Environmental Protection

>> 6. Security and Ergonomics

● Benefits of Automated SMT Reel Storage Systems

● Case Studies and Examples

● Emerging Trends in SMT Reel Storage

● Technological Innovations in SMT Reel Storage

● Future Trends in SMT Reel Storage

● Conclusion

● FAQs

>> 1. What are the primary benefits of using automated SMT reel storage systems?

>> 2. How do SMT reel storage systems protect electronic components?

>> 3. What types of integration do high-quality SMT reel storage systems support?

>> 4. Can SMT reel storage systems accommodate different reel sizes?

>> 5. How do SMT reel storage systems enhance traceability and quality control?

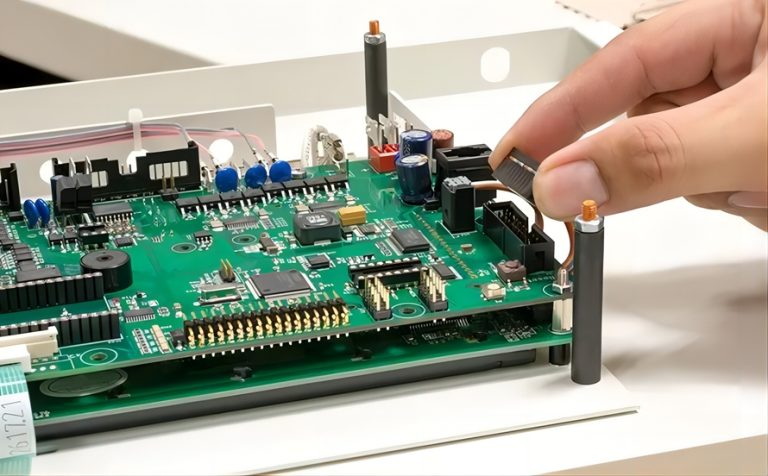

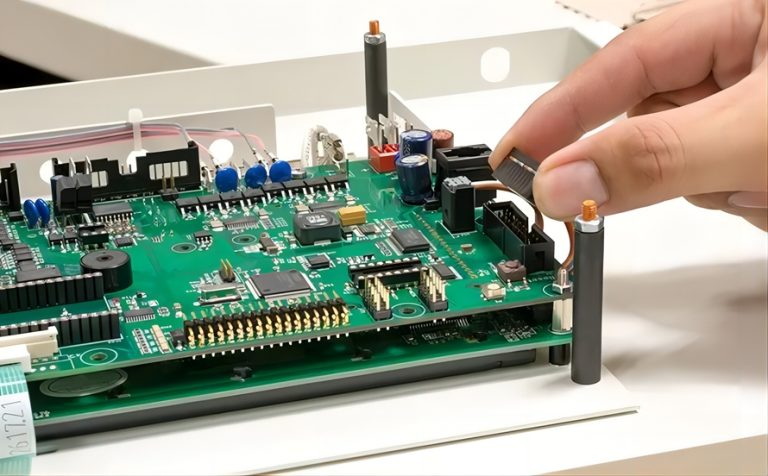

In the realm of electronics manufacturing, particularly in surface mount technology (SMT), efficient storage and management of component reels are crucial for maintaining production efficiency and quality. SMT reel storage systems are designed to optimize space, enhance inventory management, and protect sensitive electronic components from environmental damage. This article delves into the key features of high-quality SMT reel storage systems, highlighting their importance in modern manufacturing environments.

Introduction to SMT Reel Storage Systems

SMT reel storage systems are specialized solutions for storing and managing reels of electronic components used in surface mount technology. These systems are essential for electronics manufacturing facilities, as they help streamline production processes by ensuring quick access to components, reducing errors, and maintaining component integrity.

Importance of SMT Reel Storage

1. Space Optimization: In most manufacturing environments, floor space is limited. High-quality SMT reel storage systems, such as Vertical Carousel Modules (VCMs) and Vertical Lift Modules (VLMs), maximize vertical space utilization, potentially saving up to 85% of floor space compared to traditional shelving systems. For instance, advanced smart storage systems can store up to 720 reels in just 0.45 m², significantly enhancing storage density.

2. Efficient Inventory Management: These systems often integrate with inventory management software, providing real-time tracking of component quantities, locations, and usage history. This ensures accurate stock levels, reduces the risk of production delays due to component shortages, and enhances traceability throughout the manufacturing process.

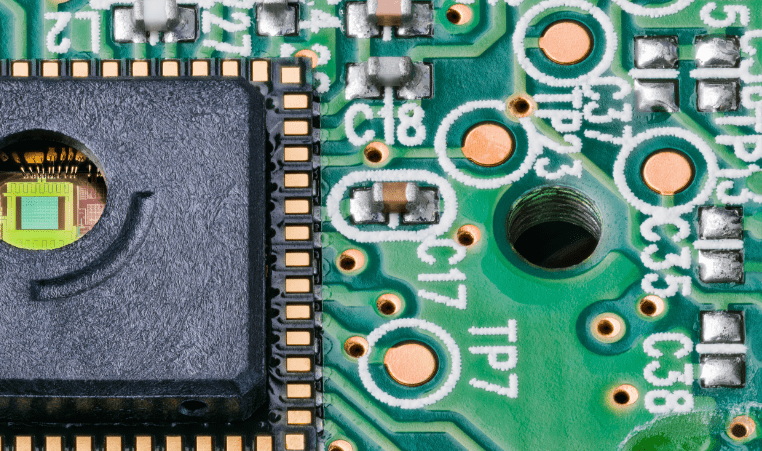

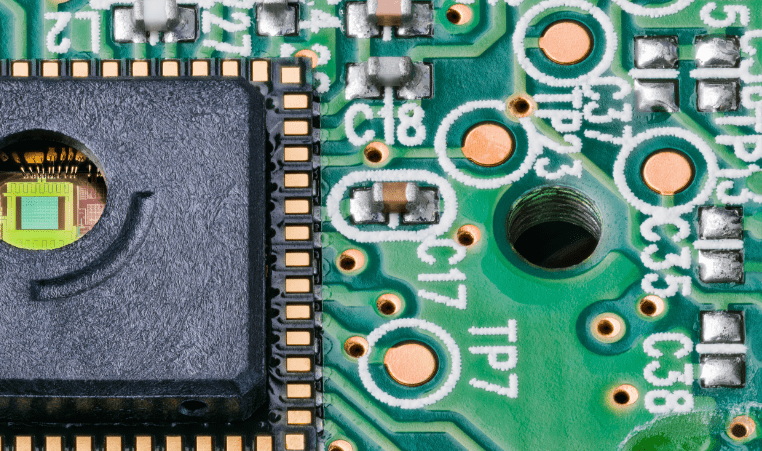

3. Protection of Components: SMT reel storage systems often include features like temperature control, humidity regulation, and ESD (Electrostatic Discharge) protection to maintain the integrity and longevity of stored components. This is crucial for preventing damage from environmental factors that could compromise component quality.

Key Features of High-Quality SMT Reel Storage Systems

1. Modular and Scalable Design

High-quality SMT reel storage systems are modular and scalable, allowing for easy expansion as storage needs increase. This scalability is a cost-effective solution in the long run, as it eliminates the need for complete system replacements as the business grows.

2. Advanced Inventory Management

These systems typically include integrated inventory management software that provides real-time updates, supports barcode or RFID scanning for accurate tracking, and follows the First-in, First-out (FIFO) inventory management principle. This ensures that older components are used before newer ones, which is crucial for industries where component aging or expiration is a concern.

3. Automation and Efficiency

Advanced SMT reel storage systems offer automated carousel or lift mechanisms for quick access to stored reels. Features like guided retrieval systems using LEDs or laser pointers enhance efficiency by reducing kitting time from hours to minutes. For example, some systems can store and retrieve reels in as little as 3 seconds, significantly improving production setup times.

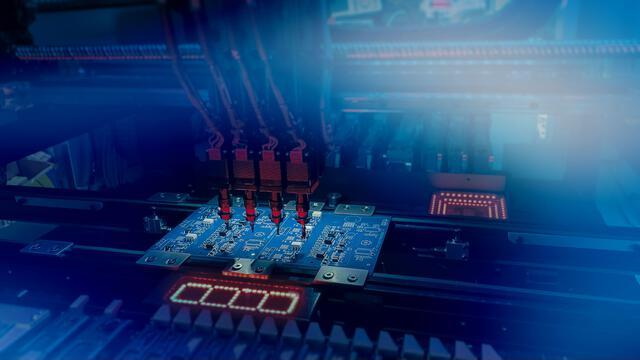

4. Integration with Manufacturing Systems

High-quality systems integrate seamlessly with other manufacturing systems, including Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP) systems, and automated guided vehicles (AGVs). This integration enhances overall factory automation and efficiency.

5. Environmental Protection

These systems often include climate control features that regulate temperature and humidity levels, ensuring that components remain in optimal condition. Additionally, they provide ESD protection measures to safeguard sensitive electronic components.

6. Security and Ergonomics

SMT reel storage systems can include access control features to restrict unauthorized access to valuable components. They also eliminate the need for manual lifting and carrying of heavy reels, reducing the risk of worker injuries and fatigue.

Benefits of Automated SMT Reel Storage Systems

Automated storage systems offer numerous benefits, including:

- Space Optimization: They make efficient use of available space, which is particularly important in facilities with limited floor space.

- Improved Inventory Management: Automated systems provide accurate tracking of component quantities and locations, reducing errors and ensuring that components are used in the correct order.

- Enhanced Productivity: Automated retrieval and storage processes are much faster and more reliable than manual handling, reducing downtime and increasing production efficiency.

- Cost Savings: While requiring an initial investment, automated systems can lead to long-term cost savings through reduced labor costs and less component waste.

Case Studies and Examples

Companies like Kardex have successfully implemented Automated Storage and Retrieval Systems (ASRS) in various electronics manufacturing facilities, enhancing storage efficiency and component protection. Similarly, Inovaxe's Smart Storage Solutions have been praised for their ability to store hundreds of reels per square foot and access parts in seconds, significantly reducing kitting time.

For instance, a medium-sized electronics manufacturer implemented a vertical carousel SMT reel storage system, achieving a 70% reduction in floor space used for component storage and a 50% decrease in time spent retrieving components. Additionally, they achieved 99.9% inventory accuracy. A large electronics production facility invested in a fully automated AS/RS for SMT reel storage, resulting in a 90% reduction in manual handling of components, a 30% increase in overall production efficiency, and zero incidents of component mix-ups or losses.

Emerging Trends in SMT Reel Storage

The SMT reel storage market is witnessing significant growth driven by trends such as automation, sustainability, and Industry 4.0 integration. Manufacturers are increasingly adopting intelligent storage solutions that optimize space, reduce waste, and enhance operational efficiency. The integration of AI and IoT technologies into these systems is revolutionizing inventory management by providing real-time tracking and predictive analytics, which help in optimizing production cycles and reducing downtime.

Technological Innovations in SMT Reel Storage

Technological innovations are transforming the landscape of SMT reel inventory management. Automated storage and retrieval systems (AS/RS) equipped with robotics and AI algorithms are streamlining the process of storing and retrieving reels, minimizing human error and optimizing space. The use of cloud-based inventory management systems allows for centralized data access, enabling seamless collaboration across different locations and facilitating agile manufacturing practices.

Future Trends in SMT Reel Storage

As manufacturing moves towards greater automation and Industry 4.0 principles, choosing an SMT reel storage system that aligns with these trends is crucial. Systems that integrate with AGVs for material transport and are compatible with robotic picking systems will future-proof investments and enhance factory efficiency. The integration of IoT devices into storage systems facilitates real-time tracking and predictive maintenance, ensuring that potential issues are identified before they disrupt production.

Moreover, the emphasis on sustainability is driving the adoption of eco-friendly storage solutions. Manufacturers are increasingly focusing on systems that optimize space, reduce waste, and use energy-efficient technologies, aligning their operations with global sustainability goals. This shift towards intelligent storage solutions not only enhances operational efficiency but also supports environmental stewardship.

Conclusion

High-quality SMT reel storage systems are indispensable for modern electronics manufacturing, offering benefits such as space optimization, efficient inventory management, and protection of sensitive components. By integrating advanced automation and inventory management features, these systems significantly enhance production efficiency and reduce costs. As the electronics industry continues to evolve, the importance of these systems will only grow.

FAQs

1. What are the primary benefits of using automated SMT reel storage systems?

Automated SMT reel storage systems offer several key benefits, including space optimization, improved inventory management, enhanced productivity, and reduced risk of component damage. They also provide real-time tracking and integration with manufacturing systems, which can lead to cost savings and improved efficiency.

2. How do SMT reel storage systems protect electronic components?

SMT reel storage systems protect electronic components through features like temperature control, humidity regulation, and ESD protection. These measures ensure that components remain in optimal condition, reducing the risk of damage from environmental factors.

3. What types of integration do high-quality SMT reel storage systems support?

High-quality SMT reel storage systems support integration with various manufacturing systems, including MES, ERP, and AGVs. This integration enhances automation and efficiency by enabling seamless data exchange and workflow automation.

4. Can SMT reel storage systems accommodate different reel sizes?

Yes, many SMT reel storage systems are designed to accommodate various reel sizes, often ranging from 7" to 15" in diameter and 8-56mm in width. They also offer customizable storage options for other component types.

5. How do SMT reel storage systems enhance traceability and quality control?

SMT reel storage systems enhance traceability and quality control by providing real-time tracking of component locations, usage history, and remaining quantities. This level of detail ensures that components can be traced throughout the production process, meeting quality control standards and facilitating easier audits.