Content Menu

● Introduction

● Key Features of Advanced PCB SMT Machines

>> High-Speed and Precision Placement Capabilities

>> Automation and Reduced Labor Costs

>> Compact Design and High-Density Component Placement

>> Improved Electrical Performance and Signal Integrity

>> Flexibility in Design and Manufacturing

>> Advanced Monitoring and Recognition Systems

● Benefits of Using Advanced PCB SMT Machines

● Applications of Advanced PCB SMT Machines

● Innovations Driving Advanced PCB SMT Machines

>> Additive Processes

>> Smart Data Analytics

>> Flexible Hybrid Electronics

>> 3D Packaging Technologies

● Enhanced Thermal Management

● Environmental Considerations

● Customization Capabilities

● Future Trends in Advanced PCB Manufacturing

● Challenges and Considerations

● Conclusion

● FAQ

>> 1. What is the primary function of an SMT machine?

>> 2. How does SMT differ from through-hole technology?

>> 3. What industries benefit most from SMT machines?

>> 4. What are the cost implications of using SMT machines?

>> 5. How do SMT machines ensure quality?

Introduction

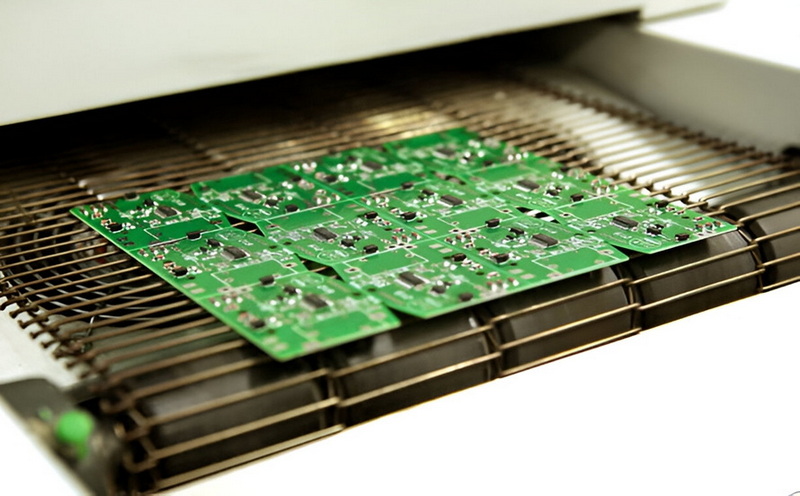

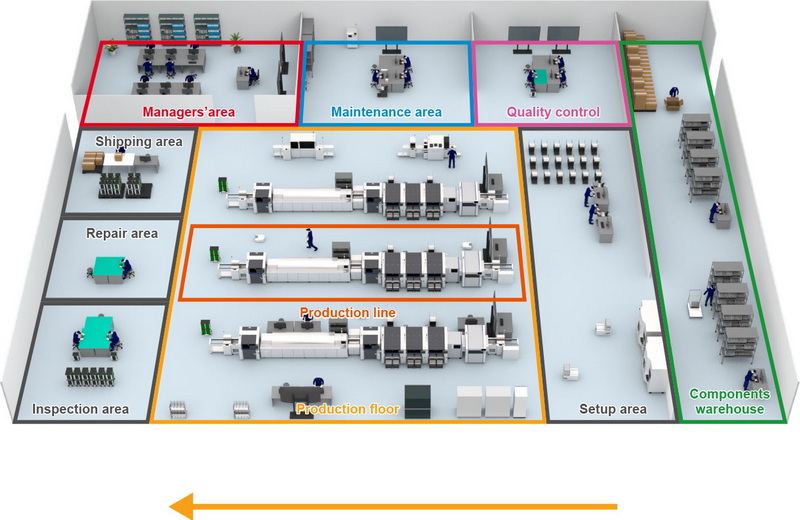

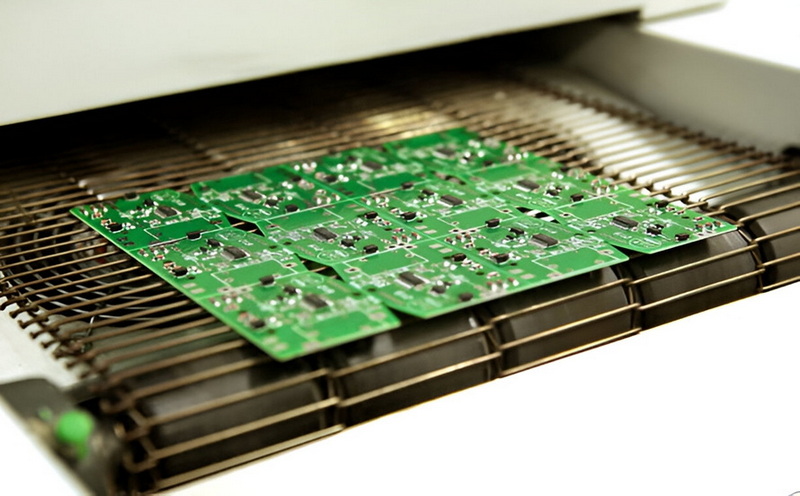

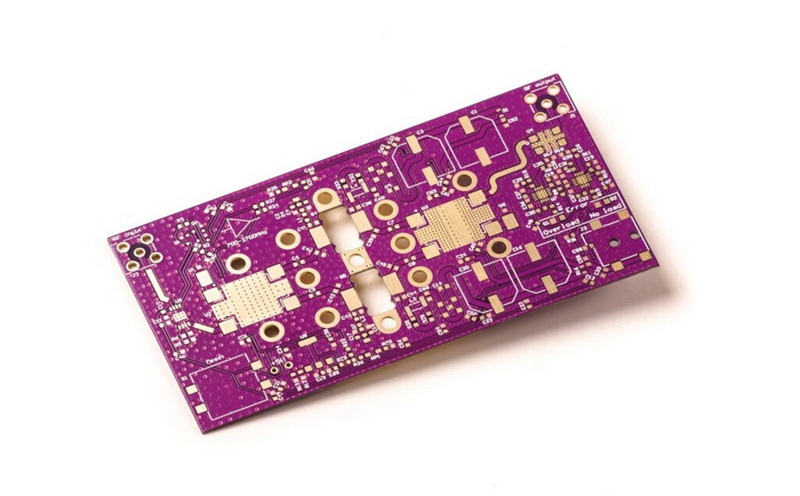

Surface Mount Technology (SMT) has transformed the landscape of electronics manufacturing, offering significant advantages over traditional methods such as Through-Hole Technology (THT). This article delves into the key features of advanced PCB SMT machines, highlighting their importance in modern electronic assembly processes. As the demand for compact, efficient, and high-performance electronic devices continues to rise, understanding these features becomes crucial for manufacturers aiming to stay competitive in the industry.

Key Features of Advanced PCB SMT Machines

Advanced PCB SMT machines are equipped with a variety of features that enhance their performance, efficiency, and flexibility. Here are some of the most notable features:

High-Speed and Precision Placement Capabilities

One of the standout features of advanced SMT machines is their ability to place components with high speed and precision. Modern pick-and-place machines can achieve placement rates of up to 80,000 components per hour, significantly reducing assembly time compared to manual processes. This high throughput is essential for meeting the demands of large-scale production runs while maintaining accuracy in component positioning.

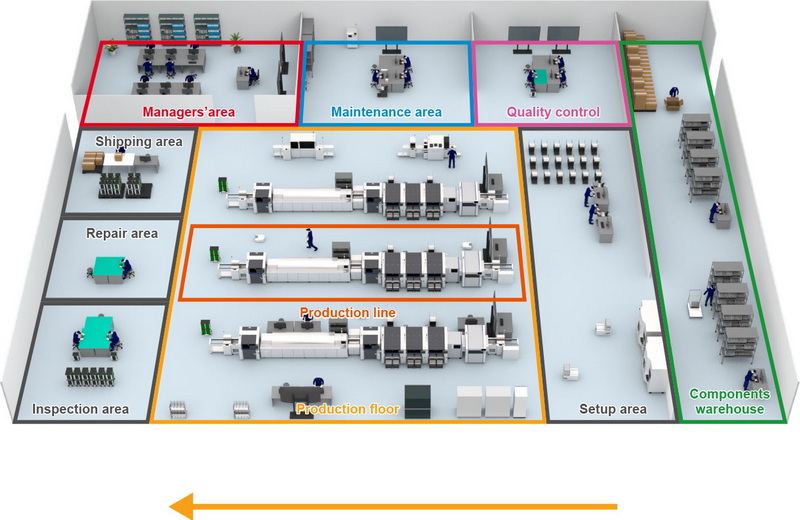

Automation and Reduced Labor Costs

Automation is a cornerstone of advanced SMT machines. By minimizing human intervention in the assembly process, these machines not only enhance efficiency but also reduce labor costs. Automated systems can operate continuously, leading to higher output rates and lower chances of human error. This shift towards automation allows manufacturers to allocate resources more effectively and focus on quality control and innovation.

Compact Design and High-Density Component Placement

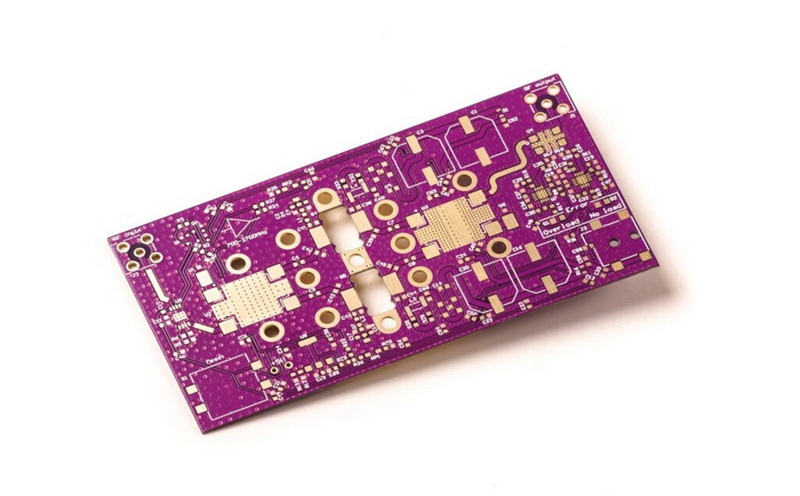

Advanced SMT machines are designed to accommodate high-density component placement on PCBs. The compact nature of SMT components allows for more efficient use of board space, enabling manufacturers to create smaller and more complex electronic devices. This feature is particularly advantageous in industries such as consumer electronics, where miniaturization is essential.

Improved Electrical Performance and Signal Integrity

The design of SMT components contributes to improved electrical performance compared to traditional through-hole components. SMT devices have shorter lead lengths, which reduces parasitic inductance and capacitance. This enhancement leads to better signal integrity and performance in high-frequency applications, making SMT an ideal choice for modern electronic circuits.

Flexibility in Design and Manufacturing

Advanced SMT machines offer flexibility in both design and manufacturing processes. They can handle a wide range of component types, from simple passive components to complex integrated circuits. This versatility allows manufacturers to adapt quickly to changing market demands and incorporate new technologies into their products without extensive retooling.

Advanced Monitoring and Recognition Systems

Modern SMT machines are equipped with sophisticated monitoring and recognition systems that ensure optimal performance throughout the assembly process. These systems utilize sensors and cameras to monitor component placement accuracy in real-time, allowing for immediate corrections if misalignments occur. Such features enhance overall quality assurance by reducing defects in the final product.

Benefits of Using Advanced PCB SMT Machines

The adoption of advanced PCB SMT machines brings numerous benefits that impact production efficiency, cost-effectiveness, and product reliability:

- Enhanced Production Efficiency: The combination of high-speed placement and automation results in significantly increased production rates.

- Cost-Effectiveness for Large-Scale Production: While initial investments in SMT machinery can be high, the long-term savings from reduced labor costs and increased throughput make these machines economically viable for large-scale operations.

- Improved Reliability and Reduced Defects: Automated processes minimize human error, leading to higher quality products with fewer defects.

- Support for Complex and High-Speed Circuits: The capabilities of advanced SMT machines make them suitable for assembling intricate circuits required in today's fast-paced technological environment.

Applications of Advanced PCB SMT Machines

Advanced PCB SMT machines find applications across various industries due to their efficiency and versatility:

- Consumer Electronics: Smartphones, tablets, and wearable devices benefit from the compact design enabled by SMT technology.

- Medical Devices: High reliability and precision are crucial in medical applications where device failure can have serious consequences.

- Telecommunications: The demand for high-speed data transmission drives the need for advanced circuit designs that SMT can accommodate.

- Automotive Industry: As vehicles become more technologically advanced, the need for reliable electronic systems increases.

- Aerospace and Defense: The stringent requirements for reliability and performance make SMT an ideal choice for aerospace applications.

Innovations Driving Advanced PCB SMT Machines

The evolution of technology continues to push the boundaries of what advanced PCB SMT machines can achieve. Several innovations are shaping the future of these machines:

Additive Processes

Recent advancements include additive manufacturing techniques such as inkjet solder printing and aerosol jetting. These processes allow for precise application of solder paste directly onto the PCB without traditional stenciling methods. This innovation enhances flexibility in design while reducing waste during production.

Smart Data Analytics

The integration of smart data analytics into SMT processes enables manufacturers to optimize production lines by analyzing real-time data from machine operations. Machine learning algorithms can predict maintenance needs, thereby minimizing downtime and improving overall efficiency.

Flexible Hybrid Electronics

The development of flexible hybrid electronics is made possible through advanced SMT techniques that allow components to be printed onto flexible substrates. This innovation opens up new possibilities for wearable technology and other applications where traditional rigid PCBs may not be suitable.

3D Packaging Technologies

3D packaging technologies enable manufacturers to stack multiple layers of components vertically within a single package. This approach not only saves space but also improves performance by shortening signal paths between components.

Enhanced Thermal Management

Effective thermal management is vital for maintaining optimal performance in electronic devices. Advanced PCB designs using SMT technology allow for better heat dissipation due to closely packed components that minimize thermal resistance. The proximity of components on a single layer reduces thermal gradients across the board while allowing heat sinks or thermal vias to be integrated efficiently into designs without compromising space or layout integrity.

Environmental Considerations

With increasing awareness regarding environmental sustainability in manufacturing processes, many companies are adopting eco-friendly practices within their operations involving advanced PCB SMT machines. These practices include utilizing lead-free solder materials compliant with RoHS (Restriction of Hazardous Substances) directives while optimizing energy consumption during production cycles through improved machine efficiencies or implementing recycling programs for electronic waste generated during assembly processes.

Customization Capabilities

Customization has become an essential aspect when designing PCBs tailored specifically according to client specifications or market trends requiring unique functionalities embedded within devices produced using advanced PCB technologies like those offered by modernized SMTS machinery setups today! Manufacturers can easily modify layouts based on customer feedback or emerging trends while ensuring compliance with industry standards without sacrificing quality assurance protocols established throughout production lines!

Future Trends in Advanced PCB Manufacturing

Looking ahead towards future developments within this sector reveals exciting prospects driven largely by advancements made possible through AI integration alongside IoT connectivity among various stages involved throughout entire workflows associated with producing sophisticated electronics! As smart factories emerge equipped with interconnected systems capable of real-time data exchange between different types/makes/models used across diverse applications ranging from consumer goods all way up heavy industrial machinery—this transformation promises enhanced operational efficiencies along with greater flexibility when responding quickly changing market demands!

Challenges and Considerations

While advanced PCB SMT machines offer numerous advantages, there are challenges that manufacturers must consider:

- High Initial Investment Costs: The upfront costs associated with purchasing advanced SMT machinery can be significant.

- Requirement for Skilled Operators: Operating sophisticated SMT equipment requires skilled personnel who understand both the technology and the manufacturing process.

- Maintenance and Calibration Needs: Regular maintenance is essential to ensure optimal performance over time. Calibration may also be necessary to maintain precision in component placement.

Conclusion

In conclusion, advanced PCB SMT machines play a pivotal role in modern electronics manufacturing by providing high-speed placement capabilities, automation, compact design options, improved electrical performance, flexibility in manufacturing processes, and sophisticated monitoring systems. As industries continue to push for smaller, faster, and more reliable electronic devices, these machines will remain at the forefront of technological advancement in PCB assembly.

FAQ

1. What is the primary function of an SMT machine?

The primary function of an SMT machine is to place and solder components onto a PCB with high precision.

2. How does SMT differ from through-hole technology?

SMT mounts components directly onto the PCB surface without drilling holes, while through-hole technology requires leads to pass through drilled holes on the board.

3. What industries benefit most from SMT machines?

Industries such as consumer electronics, automotive, telecommunications, medical devices, and aerospace benefit significantly from SMT technology.

4. What are the cost implications of using SMT machines?

While initial costs can be high due to equipment investment, they lead to reduced labor costs and increased production efficiency over time.

5. How do SMT machines ensure quality?

SMT machines utilize advanced monitoring systems and automated inspections throughout the assembly process to maintain high quality standards.