Content Menu

● Overview of SMT Production Lines

● Key Machines in an SMT Production Line

>> Solder Paste Printer

>> Pick and Place Machine

>> Reflow Oven

>> Automated Optical Inspection (AOI)

>> Solder Paste Inspection (SPI)

● Advantages of Using an SMT Production Line

● Layout Configurations of SMT Production Lines

>> In-line Layout

>> U-Shaped Layout

>> Modular Layout

● Quality Control Measures in SMT Lines

● Future Trends in SMT Production Lines

● Challenges Facing SMT Production Lines

● Conclusion

● FAQ

>> Q1: What is Surface Mount Technology (SMT)?

>> Q2: What are the main components of an SMT production line?

>> Q3: How does an AOI machine work?

>> Q4: Why is an SMT production line more efficient than traditional methods?

>> Q5: What future trends are influencing SMT production lines?

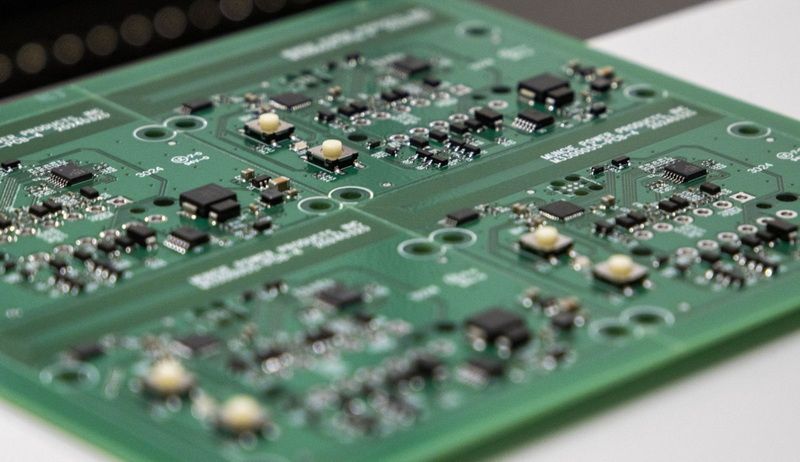

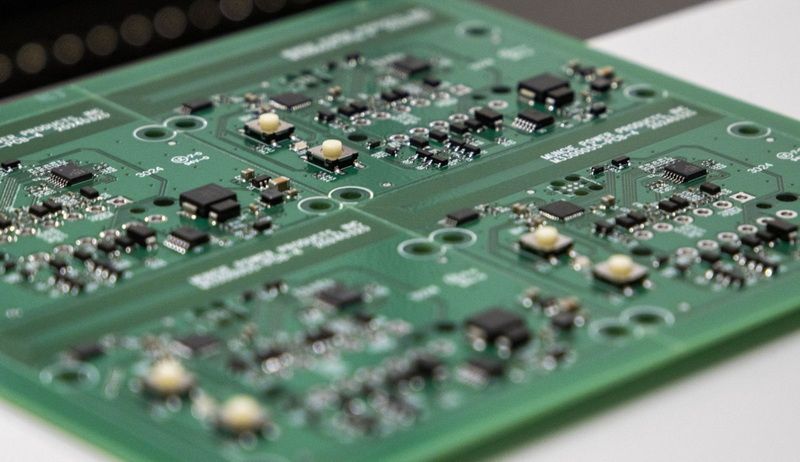

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for the efficient assembly of electronic components onto printed circuit boards (PCBs). An SMT production line is a sophisticated setup that integrates various machines and processes to ensure high-quality assembly with minimal manual intervention. This article explores the key features of a UI SMT production line, its components, advantages, and overall significance in modern electronics manufacturing.

Overview of SMT Production Lines

SMT production lines are designed to automate the process of placing surface mount components on PCBs. These lines typically consist of several key machines that work in tandem to ensure efficient and accurate assembly. The primary stages of an SMT production line include:

- Solder Paste Printing: Applying solder paste onto the PCB pads.

- Component Placement: Accurately placing components onto the solder paste.

- Reflow Soldering: Melting the solder paste to create reliable electrical connections.

- Inspection: Verifying the quality of solder joints and component placement.

The efficiency of an SMT production line is critical for meeting the demands of modern electronics manufacturing, where speed, precision, and quality are paramount.

Key Machines in an SMT Production Line

The efficiency and effectiveness of an SMT production line depend on various specialized machines, each serving a unique purpose:

Solder Paste Printer

The solder paste printer is crucial for applying solder paste onto the PCB pads. It uses stencils to ensure that the right amount of paste is deposited accurately.

- Key Features:

- High precision in paste application

- Adjustable speed settings for different production volumes

- Compatibility with various PCB sizes

- Advanced cleaning systems to maintain stencil integrity

Solder paste printers can be equipped with automated alignment systems that ensure precise registration between the stencil and PCB, minimizing defects during the printing process.

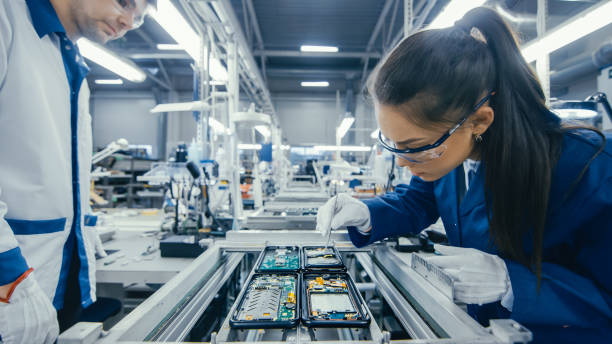

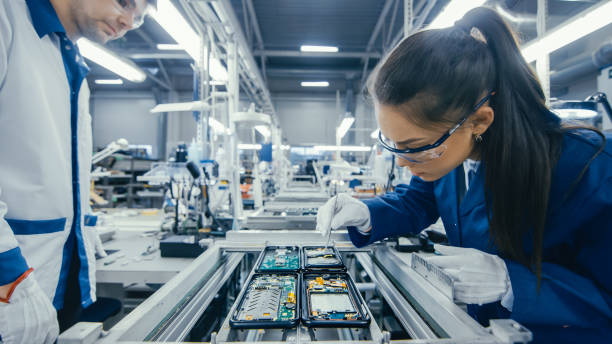

Pick and Place Machine

Often regarded as the heart of an SMT line, the pick and place machine is responsible for accurately placing components onto the PCB.

- Key Features:

- Multiple placement heads for simultaneous operation

- Advanced vision systems for component recognition and alignment

- Capability to handle a wide range of component types and sizes

- High-speed operation with real-time feedback mechanisms

Modern pick and place machines are designed to accommodate various component shapes, including odd-form components, which enhances their versatility in manufacturing different products.

Reflow Oven

The reflow oven is where soldering occurs. It heats the assembled PCB to melt the solder paste, creating reliable electrical connections.

- Key Features:

- Controlled heating profiles to suit different types of solder

- Multiple temperature zones for optimal soldering conditions

- High throughput capabilities

- Advanced cooling systems for quick temperature drop post-soldering

Reflow ovens can be configured for different production needs, allowing manufacturers to optimize their processes based on specific product requirements.

Automated Optical Inspection (AOI)

AOI machines are used to inspect PCBs before and after soldering, ensuring that components are correctly placed and that solder joints are of high quality.

- Key Features:

- High-resolution cameras for detailed inspections

- Real-time feedback on defects detected

- Integration with production data systems for continuous monitoring

- Capability to perform both pre-reflow and post-reflow inspections

By employing advanced algorithms, AOI systems can identify common defects such as misalignment, missing components, or insufficient solder joints, significantly reducing the risk of faulty products reaching customers.

Solder Paste Inspection (SPI)

SPI machines check the quality of solder paste application before component placement, identifying issues like insufficient or excessive paste.

- Key Features:

- 3D inspection technology for accurate measurement

- Automated reporting features

- Integration with other inspection processes

SPI helps maintain consistent quality by ensuring that only PCBs with optimal solder paste application proceed to component placement.

Advantages of Using an SMT Production Line

Implementing an SMT production line offers numerous benefits over traditional through-hole technology:

- Higher Component Density: SMT allows more components to be placed closer together on a PCB, enabling more compact designs.

- Reduced Manufacturing Costs: Automation reduces labor costs and minimizes material wastage.

- Improved Reliability: The direct mounting of components enhances mechanical stability and reliability under various conditions.

- Faster Production Cycles: Automated processes significantly shorten assembly times compared to manual methods.

- Enhanced Design Flexibility: Designers can create more complex circuit layouts without worrying about space constraints associated with through-hole components.

These advantages make SMT technology particularly appealing in industries where space is at a premium, such as mobile devices and consumer electronics.

Layout Configurations of SMT Production Lines

The layout of an SMT production line can greatly influence its efficiency:

In-line Layout

This straightforward configuration places machines in a linear sequence, facilitating easy navigation and management. It allows for smooth transitions between processes but may require longer distances between some operations.

U-Shaped Layout

This design reduces operator walking distances and enhances communication among team members. It allows operators to oversee multiple machines from a central point while maintaining a compact footprint.

Modular Layout

Utilizing standardized units allows for easy reconfiguration based on changing production needs. Manufacturers can add or remove machines as necessary without significant downtime or disruption.

Quality Control Measures in SMT Lines

Quality control is paramount in SMT production lines to ensure that each assembled PCB meets stringent standards:

- Regular inspections at various stages, including SPI and AOI.

- Implementation of statistical process control (SPC) techniques to monitor quality metrics continuously.

- Use of automated feedback systems to adjust processes in real-time based on inspection results.

Additionally, manufacturers often conduct reliability testing on finished products to ensure they meet industry standards before shipping them out.

Future Trends in SMT Production Lines

As technology advances, several trends are shaping the future of SMT production lines:

- Increased automation with AI-driven systems for predictive maintenance and quality control. These systems can analyze data from various stages of production to predict potential failures before they occur.

- Greater emphasis on sustainability, including eco-friendly materials and processes. Manufacturers are increasingly adopting lead-free solders and recyclable materials to minimize environmental impact.

- Enhanced flexibility to accommodate rapid changes in product designs and volumes. This adaptability is crucial as consumer electronics trends shift quickly, requiring manufacturers to respond promptly without extensive retooling.

Challenges Facing SMT Production Lines

Despite their many advantages, SMT production lines also face several challenges:

- Component Variability: The wide variety of surface mount components can lead to challenges in handling and placement accuracy.

- Process Complexity: As technology evolves, so do the processes involved in PCB assembly. Keeping up with these changes requires continuous training and investment in new equipment.

- Supply Chain Issues: Global supply chain disruptions can affect the availability of essential materials needed for PCB assembly, leading to delays in production schedules.

Manufacturers must remain vigilant about these challenges while continuously seeking improvements in their processes.

Conclusion

In summary, a UI SMT production line is a complex but highly efficient system that plays a crucial role in modern electronics manufacturing. By integrating advanced machinery and automation, these lines facilitate high-density assembly while ensuring quality and reliability. As technology continues to evolve, so too will the capabilities and configurations of SMT production lines, making them indispensable in the ever-growing electronics industry.

FAQ

Q1: What is Surface Mount Technology (SMT)?

A1: Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs and automated assembly processes.

Q2: What are the main components of an SMT production line?

A2: The main components include solder paste printers, pick-and-place machines, reflow ovens, automated optical inspection (AOI) systems, and solder paste inspection (SPI) machines.

Q3: How does an AOI machine work?

A3: An AOI machine uses high-resolution cameras to inspect PCBs before and after soldering, checking for correct component placement and quality of solder joints.

Q4: Why is an SMT production line more efficient than traditional methods?

A4: An SMT production line automates many processes, reducing manual labor, minimizing errors, increasing speed, and allowing for higher component density on PCBs.

Q5: What future trends are influencing SMT production lines?

A5: Future trends include increased automation with AI technologies, greater emphasis on sustainability practices, and enhanced flexibility to adapt to rapid changes in product designs.