Content Menu

● Advanced Technology and Precision

>> Vision Systems and Component Recognition

>> Alignment and Positioning

● High-Speed Performance

>> Multi-Head Configuration

>> Optimized Pick and Place Routing

● Flexibility and Adaptability

>> Component Compatibility

>> Quick Changeover Capabilities

● Advanced Feeder Systems

>> Multiple Feeder Slots

>> Intelligent Feeder Management

● User-Friendly Interface and Programming

>> Vision Teach-in Programming

>> Compatibility with Industry-Standard Formats

● Integration and Connectivity

>> SMEMA Interface

>> Industry 4.0 Compatibility

● Quality Control Features

>> Automatic Optical Inspection (AOI)

>> Component Verification

● Energy Efficiency and Environmental Considerations

>> Energy-Saving Features

>> Noise Reduction

● Conclusion

● FAQ

>> 1. What is the typical placement speed of a China SMT PCB pick and place machine?

>> 2. How do China SMT PCB pick and place machines ensure accurate component placement?

>> 3. What types of components can be handled by China SMT PCB pick and place machines?

>> 4. How do China SMT PCB pick and place machines integrate with other equipment in the production line?

>> 5. What maintenance requirements do China SMT PCB pick and place machines typically have?

● Citations:

China has emerged as a global leader in the manufacturing of Surface Mount Technology (SMT) pick and place machines for Printed Circuit Board (PCB) assembly. These machines are essential components in the electronics manufacturing industry, offering high-speed, precision, and efficiency in placing electronic components onto PCBs. In this article, we will explore the key features of China SMT PCB pick and place machines, their impact on the industry, and the latest innovations driving their development.

Advanced Technology and Precision

China SMT PCB pick and place machines are known for their cutting-edge technology and high precision capabilities. These machines utilize advanced vision systems and alignment mechanisms to ensure accurate component placement[3]. The precision placement capabilities of these machines are impressive, with placement tolerances as low as 0.01mm[4]. This level of accuracy is crucial for the assembly of modern electronic devices, which often require extremely tight component spacing and miniaturization.

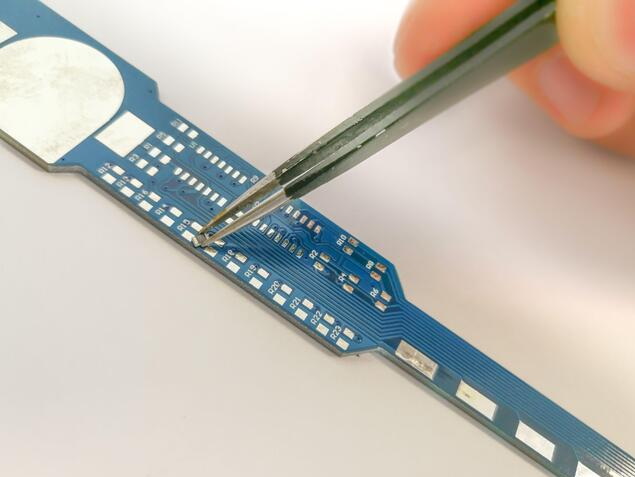

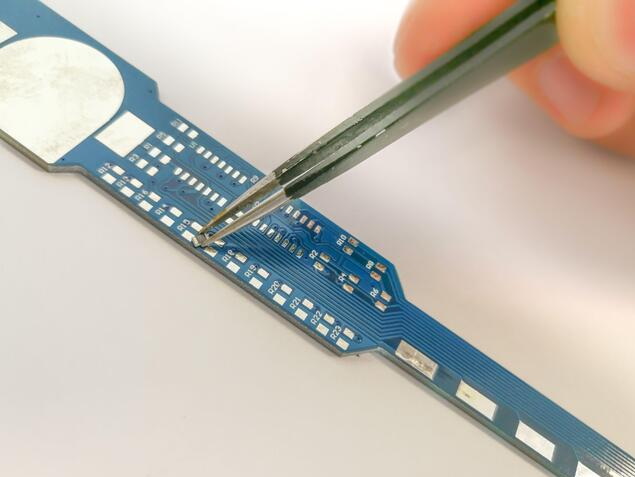

Vision Systems and Component Recognition

One of the standout features of China SMT pick and place machines is their sophisticated vision systems. These systems use cameras and advanced algorithms to identify and locate components in the feeders[3]. The machines can capture images, analyze patterns, and determine the position, orientation, and dimensions of each component with high accuracy. This capability ensures that components are picked up correctly and placed in the exact position on the PCB.

Alignment and Positioning

To achieve precise component placement, China SMT machines employ various alignment techniques. These may include:

1. Fiducial marks recognition

2. Optical sensors for PCB positioning

3. Servo positioning systems for the placement head and PCB carrier platform[1]

These alignment mechanisms work together to ensure that both the PCB and the components are correctly positioned for accurate placement.

High-Speed Performance

Speed is a critical factor in electronics manufacturing, and China SMT pick and place machines excel in this area. Many of these machines are capable of placing components at speeds of up to 100,000 components per hour[4]. Some advanced models can even achieve placement rates of up to 250,000 components per hour[11]. This high-speed performance is essential for meeting the demands of large-scale production and reducing manufacturing time.

Multi-Head Configuration

To achieve such high speeds, many China SMT pick and place machines feature multi-head configurations. For example, some models have up to 68 placement heads, allowing for simultaneous pickup and placement of multiple components[11]. This parallel processing capability significantly boosts the overall throughput of the machine.

Optimized Pick and Place Routing

Chinese manufacturers have invested heavily in optimizing the pick and place routing algorithms used in their machines. These algorithms calculate the most efficient path for component placement, minimizing unnecessary movements and maximizing speed[5]. The result is a smooth and rapid operation that maintains high accuracy even at top speeds.

Flexibility and Adaptability

The electronics industry is characterized by rapid changes in product designs and component types. China SMT pick and place machines are designed with flexibility in mind to meet these evolving needs.

Component Compatibility

These machines can handle a wide range of component types and sizes, from tiny 0201 components to larger ICs and connectors[9]. Many machines support components as small as 0.4 x 0.2mm and as large as 50 x 50mm or even bigger[5]. This versatility allows manufacturers to use a single machine for various product lines and component mixes.

Quick Changeover Capabilities

China SMT pick and place machines often feature quick changeover capabilities, allowing for rapid transitions between different product runs. This is particularly valuable for manufacturers dealing with high-mix, low-volume production scenarios. The machines may include features such as:

1. Automatic nozzle changing systems

2. Easy-to-swap component feeders

3. Programmable placement patterns

These features reduce downtime between production runs and increase overall efficiency.

Advanced Feeder Systems

The component feeding system is a crucial part of any pick and place machine. China SMT machines typically offer a variety of feeder options to accommodate different component packaging types.

Multiple Feeder Slots

Many China SMT pick and place machines come with a large number of feeder slots. For instance, some desktop models feature up to 46 feeder slots[1]. This allows for a wide variety of components to be loaded simultaneously, reducing the need for frequent feeder changes.

Intelligent Feeder Management

Advanced China SMT machines often incorporate intelligent feeder management systems. These systems can:

1. Automatically detect and recognize different feeder types

2. Monitor component levels and alert operators when refills are needed

3. Optimize feeder arrangements for improved efficiency

User-Friendly Interface and Programming

Despite their complex operations, China SMT pick and place machines are designed with user-friendliness in mind. Many machines feature intuitive user interfaces that make programming and operation accessible to operators of all skill levels[4].

Vision Teach-in Programming

Some China SMT machines offer vision teach-in programming capabilities[5]. This feature allows operators to easily program new component placements by simply showing the machine the desired locations on the PCB. The machine's vision system then learns and replicates these placements, significantly reducing programming time.

Compatibility with Industry-Standard Formats

China SMT pick and place machines are typically compatible with industry-standard file formats, such as Gerber files and bill of materials (BOM)[7]. This compatibility ensures seamless integration into existing PCB assembly processes and allows for easy transfer of design data from CAD systems to the pick and place machine.

Integration and Connectivity

Modern China SMT pick and place machines are designed to be part of a larger, integrated SMT assembly line. They can be easily connected to other machines in the production line, such as solder paste printers, reflow ovens, and automated optical inspection (AOI) systems[6].

SMEMA Interface

Many China SMT machines come equipped with a SMEMA (Surface Mount Equipment Manufacturers Association) interface[5]. This standardized interface allows for seamless communication and coordination between different machines in the SMT assembly line, ensuring smooth material flow and synchronization of operations.

Industry 4.0 Compatibility

As the manufacturing industry moves towards greater digitalization and connectivity, many China SMT pick and place machines are being designed with Industry 4.0 principles in mind. These machines may offer features such as:

1. Real-time data collection and analysis

2. Remote monitoring and control capabilities

3. Integration with manufacturing execution systems (MES)

These features allow for better production planning, predictive maintenance, and overall process optimization.

Quality Control Features

Quality control is a critical aspect of PCB assembly, and China SMT pick and place machines incorporate various features to ensure high-quality output.

Automatic Optical Inspection (AOI)

Many China SMT machines include built-in AOI systems that can detect and correct placement errors in real-time[4]. These systems use high-resolution cameras and advanced image processing algorithms to verify the correct placement of components, ensuring that defects are caught and corrected before the PCB moves to the next stage of production.

Component Verification

Advanced China SMT pick and place machines often include component verification features. These may include:

1. Automatic checking of component polarity

2. Verification of component values (for resistors, capacitors, etc.)

3. Detection of missing or incorrect components

These features help to minimize assembly errors and improve overall product quality.

Energy Efficiency and Environmental Considerations

As environmental concerns become increasingly important in manufacturing, China SMT pick and place machine manufacturers are focusing on improving the energy efficiency of their machines.

Energy-Saving Features

Many modern China SMT machines incorporate energy-saving features such as:

1. Low-power standby modes

2. Efficient motors and drive systems

3. Optimized vacuum systems to reduce air consumption

These features not only reduce energy costs but also contribute to a more sustainable manufacturing process.

Noise Reduction

Efforts have also been made to reduce the noise levels of China SMT pick and place machines. This is achieved through the use of advanced motor control techniques, improved mechanical designs, and sound-dampening materials. Lower noise levels contribute to a better working environment for operators and reduce overall factory noise pollution.

Conclusion

China SMT PCB pick and place machines have become a cornerstone of modern electronics manufacturing, offering a powerful combination of speed, precision, and flexibility. The key features of these machines, including advanced vision systems, high-speed performance, flexible component handling, and user-friendly interfaces, make them indispensable tools for PCB assembly.

As the electronics industry continues to evolve, with trends towards miniaturization, increased complexity, and faster production cycles, China SMT pick and place machines are likely to play an even more crucial role. The ongoing innovations in areas such as artificial intelligence, machine learning, and Industry 4.0 integration promise to further enhance the capabilities of these machines, driving continued improvements in electronics manufacturing efficiency and quality.

The success of China's SMT pick and place machine industry is a testament to the country's growing technological prowess and its ability to meet the demanding needs of the global electronics market. As these machines continue to evolve and improve, they will undoubtedly contribute to shaping the future of electronics manufacturing worldwide.

FAQ

1. What is the typical placement speed of a China SMT PCB pick and place machine?

The placement speed of China SMT PCB pick and place machines can vary widely depending on the model and configuration. However, many high-end machines are capable of placing components at speeds of up to 100,000 components per hour. Some advanced models can even achieve placement rates of up to 250,000 components per hour. It's important to note that actual production speeds may be lower depending on factors such as component mix, PCB complexity, and required placement accuracy.

2. How do China SMT PCB pick and place machines ensure accurate component placement?

China SMT PCB pick and place machines use a combination of advanced technologies to ensure accurate component placement:

1. High-precision vision systems for component recognition and alignment

2. Servo positioning systems for precise movement of the placement head and PCB carrier

3. Fiducial mark recognition for PCB alignment

4. Advanced algorithms for optimizing pick and place paths

5. Real-time placement verification using built-in AOI systems

These features work together to achieve placement accuracies as high as ±0.05mm or even better in some cases.

3. What types of components can be handled by China SMT PCB pick and place machines?

China SMT PCB pick and place machines are designed to handle a wide range of surface mount components. This typically includes:

1. Passive components like resistors and capacitors (down to 0201 or even 01005 size)

2. Integrated circuits (ICs) in various package types (QFP, BGA, etc.)

3. LEDs and other optoelectronic components

4. Connectors and sockets

5. Larger components like transformers or heat sinks (depending on the machine's capabilities)

Many machines can handle components ranging from 0.4 x 0.2mm up to 50 x 50mm or larger, providing flexibility for various PCB designs and component mixes.

4. How do China SMT PCB pick and place machines integrate with other equipment in the production line?

China SMT PCB pick and place machines are designed to integrate seamlessly with other equipment in the SMT production line. This integration is typically achieved through:

1. SMEMA interfaces for communication with upstream and downstream equipment

2. Compatibility with industry-standard file formats (Gerber, BOM, etc.) for easy data transfer

3. Support for Industry 4.0 protocols for connectivity with manufacturing execution systems (MES)

4. Customizable conveyor systems for smooth PCB transfer between machines

5. Software interfaces for coordinating operations with solder paste printers, reflow ovens, and inspection systems

This integration allows for the creation of highly efficient, automated PCB assembly lines.

5. What maintenance requirements do China SMT PCB pick and place machines typically have?

While maintenance requirements can vary depending on the specific machine and usage conditions, typical maintenance tasks for China SMT PCB pick and place machines include:

1. Regular cleaning of nozzles, feeders, and vision system components

2. Lubrication of moving parts as per the manufacturer's schedule

3. Calibration of vision systems and placement heads

4. Replacement of wear items such as nozzles and belts

5. Software updates to ensure optimal performance and compatibility

Many modern machines include self-diagnostic features and predictive maintenance capabilities to help reduce downtime and ensure consistent performance. It's important to follow the manufacturer's recommended maintenance schedule to keep the machine operating at peak efficiency.

Citations:

[1] https://www.tronstol.com/products/pick-and-place-machine/

[2] https://www.raypcb.com/smt-machine/

[3] https://www.itechsmt.com/blogs/news/how-pick-and-place-machine-works-1

[4] https://www.hct-smt.com/blog/exploring-the-latest-innovations-in-china-smt-surface-mounting-machines

[5] https://www.hct-smt.com/products/general-smt-pick-and-place-machine/hct-800l-multifunctional-smt-pick-and-place-machine

[6] https://www.pcbonline.com/PCB-Assembly/smt-and-tht/

[7] https://www.itechsmt.com/blogs/news/whats-the-pcb-pick-and-place-machine

[8] https://www.hct-smt.com/blog/enhancing-efficiency--exploring-china-pcb-smt-production-machine-lines

[9] https://www.charmhigh-tech.com/quality-44332853-charmhigh-automatic-smt-chip-mounter-pcb-assembly-smd-pick-and-place-machine

[10] https://www.itechsmt.com/products/fully-automatic-smt-pick-and-place-machine-pcb-assembly-line

[11] https://www.etonsmtmachine.com/pcb-mounting-machine/fastest-pick-and-place-machine-with-250000cph.html

[12] https://www.nextpcb.com/blog/top-10-smt-machines-worldwide