Content Menu

● Understanding SMT Nozzles

>> Types of SMT Nozzles

● OEM SMT Nozzles

>> Advantages of OEM Nozzles

>> Disadvantages of OEM Nozzles

● Aftermarket SMT Nozzles

>> Advantages of Aftermarket Nozzles

>> Disadvantages of Aftermarket Nozzles

● Key Differences Between OEM and Aftermarket SMT Nozzles

● Considerations for Choosing Between OEM and Aftermarket Nozzles

● Conclusion

● Frequently Asked Questions

>> 1. What are SMT nozzles used for?

>> 2. Are aftermarket nozzles compatible with all SMT machines?

>> 3. How can I ensure the quality of aftermarket nozzles?

>> 4. What is the main advantage of using OEM nozzles?

>> 5. Can I use aftermarket nozzles for high-precision applications?

Surface Mount Technology (SMT) nozzles are critical components in the electronics manufacturing process, particularly in the assembly of printed circuit boards (PCBs). These nozzles are responsible for picking and placing electronic components with precision. When it comes to sourcing SMT nozzles, manufacturers often face a choice between Original Equipment Manufacturer (OEM) nozzles and aftermarket nozzles. Understanding the key differences between these two options is essential for making informed purchasing decisions. This article will explore the distinctions between OEM and aftermarket SMT nozzles, their advantages and disadvantages, and considerations for manufacturers.

Understanding SMT Nozzles

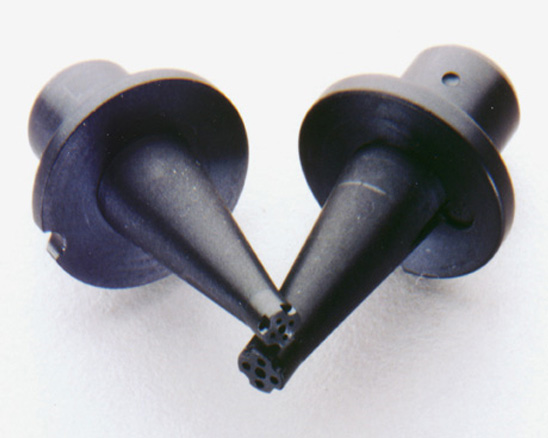

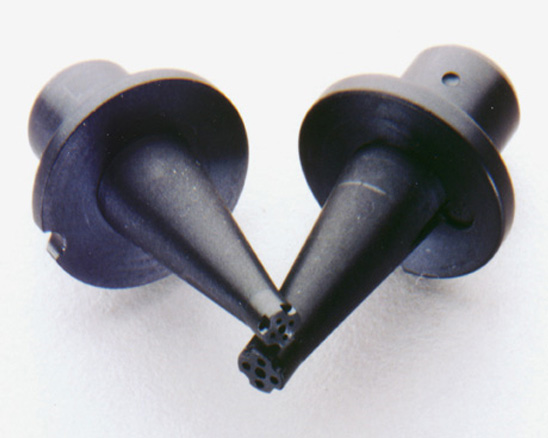

Before diving into the differences between OEM and aftermarket nozzles, it is important to understand what SMT nozzles are and their role in the manufacturing process. SMT nozzles are designed to pick up and place components onto PCBs during the assembly process. They come in various shapes and sizes to accommodate different types of components, such as resistors, capacitors, and integrated circuits. The design of these nozzles is crucial, as it directly impacts the efficiency and accuracy of the assembly process. A well-designed nozzle can significantly reduce the risk of component damage and improve overall production speed.

Types of SMT Nozzles

1. Standard Nozzles: These are the most common types used for general component placement. They are versatile and can handle a wide range of component sizes and shapes, making them suitable for various applications in electronics manufacturing.

2. Custom Nozzles: Designed for specific components or applications, these nozzles are tailored to meet unique requirements. Custom nozzles can enhance the efficiency of the assembly process by ensuring a perfect fit for specialized components, which can be particularly beneficial in industries that require high precision.

3. High-Precision Nozzles: Used for placing small or delicate components, these nozzles offer enhanced accuracy. High-precision nozzles are essential in applications where even the slightest misalignment can lead to significant issues, such as in medical devices or aerospace components.

OEM SMT Nozzles

OEM nozzles are produced by the original manufacturer of the SMT equipment. These nozzles are designed to meet the exact specifications and quality standards set by the equipment manufacturer. This ensures that they work seamlessly with the machines they are intended for, providing a reliable solution for manufacturers.

Advantages of OEM Nozzles

- Quality Assurance: OEM nozzles are manufactured to the highest standards, ensuring reliability and performance. The rigorous quality control processes employed by OEMs mean that these nozzles are less likely to fail during operation, which can save manufacturers time and money in the long run.

- Compatibility: They are guaranteed to fit and function perfectly with the corresponding SMT machines. This compatibility reduces the risk of operational issues that can arise from using non-standard parts, such as misalignment or improper placement of components.

- Warranty and Support: Purchasing OEM nozzles often comes with manufacturer support and warranty, providing peace of mind. This support can be invaluable, especially in the event of equipment failure or performance issues, as manufacturers can rely on the OEM for assistance and replacement parts.

Disadvantages of OEM Nozzles

- Cost: OEM nozzles tend to be more expensive than aftermarket options, which can impact overall production costs. For manufacturers operating on tight budgets, the higher initial investment in OEM nozzles may be a significant drawback.

- Limited Availability: Depending on the manufacturer, OEM nozzles may have limited availability, especially for older models. This can lead to delays in production if a specific nozzle is needed but not readily available from the OEM.

Aftermarket SMT Nozzles

Aftermarket nozzles are produced by third-party manufacturers. These nozzles are designed to be compatible with various SMT machines but are not made by the original equipment manufacturer. The aftermarket sector has grown significantly, providing manufacturers with a range of options that can meet their needs.

Advantages of Aftermarket Nozzles

- Cost-Effectiveness: Aftermarket nozzles are generally less expensive than OEM nozzles, making them an attractive option for cost-conscious manufacturers. This cost savings can be particularly beneficial for companies looking to reduce their overall production expenses without sacrificing quality.

- Variety: There is often a wider range of aftermarket nozzles available, including custom options that may not be offered by OEMs. This variety allows manufacturers to find nozzles that are specifically designed for their unique applications, enhancing the efficiency of their production processes.

- Availability: Aftermarket nozzles can be easier to source, especially for older or discontinued equipment. This accessibility can help manufacturers avoid downtime caused by waiting for OEM parts to become available.

Disadvantages of Aftermarket Nozzles

- Quality Variability: The quality of aftermarket nozzles can vary significantly between manufacturers, which may lead to performance issues. Manufacturers must carefully evaluate the reputation and reliability of aftermarket suppliers to ensure they are getting a quality product.

- Compatibility Issues: While many aftermarket nozzles are designed to fit OEM machines, there can be compatibility issues that affect performance. These issues can lead to increased maintenance costs and potential production delays if the nozzles do not perform as expected.

- Lack of Support: Aftermarket nozzles may not come with the same level of support or warranty as OEM products. This lack of support can be a concern for manufacturers who rely on consistent performance and quick resolution of any issues that arise.

Key Differences Between OEM and Aftermarket SMT Nozzles

| Feature | OEM Nozzles | Aftermarket Nozzles |

| Manufacturing Source | Produced by the original equipment manufacturer | Produced by third-party manufacturers |

| Quality | High and consistent quality | Variable quality depending on the manufacturer |

| Cost | Generally higher | Typically lower |

| Compatibility | Guaranteed compatibility | May have compatibility issues |

| Support | Manufacturer support and warranty | Limited or no support |

| Availability | May be limited for older models | Often more readily available |

Considerations for Choosing Between OEM and Aftermarket Nozzles

When deciding between OEM and aftermarket SMT nozzles, manufacturers should consider several factors:

1. Budget: If cost is a primary concern, aftermarket nozzles may be the better option. However, it is essential to weigh the potential risks associated with quality and compatibility. A lower initial cost may lead to higher long-term expenses if the nozzles do not perform as expected.

2. Production Volume: For high-volume production, the reliability of OEM nozzles may justify the higher cost. In contrast, for lower volume or prototype runs, aftermarket nozzles could be more economical. Manufacturers should assess their production needs and choose the option that aligns with their operational goals.

3. Specific Requirements: If specific nozzle designs are needed for unique components, aftermarket manufacturers may offer more customization options. This flexibility can be a significant advantage for manufacturers working with specialized components or in niche markets.

4. Long-Term Strategy: Consider the long-term implications of using aftermarket nozzles, including potential impacts on machine performance and maintenance. Manufacturers should evaluate whether the cost savings from aftermarket nozzles outweigh the potential risks associated with quality and compatibility.

5. Supplier Relationships: Building relationships with reliable aftermarket suppliers can lead to better quality and service over time. Establishing a strong partnership can help manufacturers ensure they receive consistent quality and support for their nozzle needs.

Conclusion

In summary, the choice between OEM and aftermarket SMT nozzles involves a careful consideration of quality, cost, compatibility, and support. OEM nozzles offer high quality and guaranteed compatibility, making them ideal for critical applications. On the other hand, aftermarket nozzles provide a cost-effective alternative with a wider variety of options, though they may come with risks related to quality and compatibility. Ultimately, manufacturers must assess their specific needs and make informed decisions to optimize their SMT processes.

Frequently Asked Questions

1. What are SMT nozzles used for?

SMT nozzles are used in the assembly of printed circuit boards to pick up and place electronic components accurately. Their design and functionality are crucial for ensuring the efficiency and reliability of the manufacturing process.

2. Are aftermarket nozzles compatible with all SMT machines?

While many aftermarket nozzles are designed to be compatible with various machines, it is essential to verify compatibility with specific models. Manufacturers should consult with suppliers to ensure that the nozzles will work effectively with their equipment.

3. How can I ensure the quality of aftermarket nozzles?

Researching reputable aftermarket manufacturers and reading customer reviews can help ensure quality. Manufacturers should also consider requesting samples or conducting tests to evaluate the performance of aftermarket nozzles before making a bulk purchase.

4. What is the main advantage of using OEM nozzles?

The main advantage of OEM nozzles is their guaranteed quality and compatibility with the corresponding SMT equipment. This assurance can lead to improved production efficiency and reduced downtime due to equipment failures.

5. Can I use aftermarket nozzles for high-precision applications?

Yes, but it is crucial to select high-quality aftermarket nozzles specifically designed for precision applications to avoid performance issues. Manufacturers should carefully evaluate the specifications and performance of aftermarket nozzles to ensure they meet their requirements.