Content Menu

● Introduction to SMT Pads

>> Types of SMT Pads

● Key Design Rules for SMT Pads

>> Symmetry and Pad Size

>> Solder Paste and Mask Design

>> Clearance and Spacing

>> Component Placement and Orientation

>> Thermal Management

● Best Practices for SMT Pad Design

>> Use of Grid Systems

>> Standardization

>> Quality Control

>> Material Selection

● Advanced Techniques for High-Density PCBs

>> Precision Placement Techniques

>> Solder Paste Deposition

>> Thermal Management Innovations

>> Automated Inspection Systems

● Challenges and Considerations

>> Manufacturing Constraints

>> Design for Manufacturability (DFM)

>> Environmental Factors

● Conclusion

● FAQ

>> 1. What is the purpose of symmetry in SMT pad design?

>> 2. How does solder paste coverage affect SMT assembly?

>> 3. What are the benefits of using NSMD pads over SMD pads?

>> 4. Why is thermal management important in SMT design?

>> 5. How does component placement affect signal integrity in SMT PCBs?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the production of smaller, more complex, and cost-effective electronic devices. At the heart of SMT is the design of SMT pads on Printed Circuit Boards (PCBs), which are crucial for ensuring reliable connections between components and the board. In this article, we will delve into the key design rules for SMT pads on PCBs, exploring the principles, best practices, and considerations necessary for optimal PCB design.

Introduction to SMT Pads

SMT pads are the exposed regions of metal on a PCB where surface mount components are soldered. These pads can be rectangular, circular, or square, depending on the component type and package. The design of SMT pads is influenced by factors such as component size, substrate material, assembly equipment capabilities, and quality standards.

Types of SMT Pads

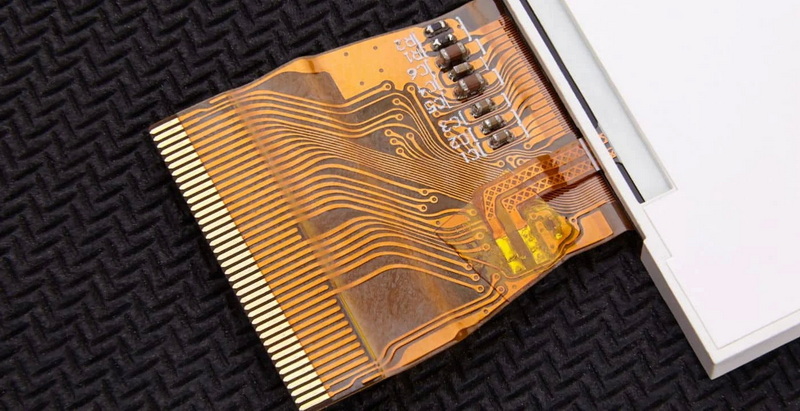

There are primarily two types of pad designs used in SMT: Solder Mask Defined (SMD) and Non-Solder Mask Defined (NSMD) pads.

- SMD Pads: These pads have solder mask apertures that are smaller than the metal pads. The overlapping mask helps prevent pads from lifting off due to mechanical or thermal stress and aids in component positioning during soldering. However, SMD pads reduce the contact area between the pad and the copper surface, limiting the space between adjacent pads. Some manufacturers prefer SMD pads for their enhanced adhesion strength to the PCB substrate, which can be beneficial in applications where flexing and bending occur[1].

- NSMD Pads: In NSMD pads, the solder mask openings are larger than the metal pads, providing a larger surface area for solder joints and greater clearance between pads. This design is beneficial for high-density and fine-pitch components but can be prone to delamination under stress. NSMD pads are generally recommended for their improved solder joint reliability and reduced stress near the pad edges[1][3].

Key Design Rules for SMT Pads

To ensure the manufacturability and reliability of SMT assemblies, several design rules must be followed:

Symmetry and Pad Size

- Symmetry: Ensure that component pads are symmetrical to prevent tombstoning, a defect where components are partially or completely lifted from the PCB pad during soldering.

- Pad Size and Shape: Opposite pads of the same component should be of the same size and shape to ensure uniform soldering and prevent defects.

Solder Paste and Mask Design

- Solder Paste Amount: Maintain an adequate amount of solder paste between footprint pads to prevent solder bridging. IPC-7351B recommends a 1:1 ratio between the copper pad and the paste mask.

- Solder Mask Design: For exposed pads, segment the copper area with solder mask webbing to facilitate solder paste flux outgassing during reflow, reducing voids in solder joints[3].

Clearance and Spacing

- Minimum Clearance: Ensure sufficient clearance between footprint pads and the board edge to support depanelization. Typically, 2-3 mils of clearance is recommended.

- Pad-to-Pad Spacing: Adequate spacing between pads is crucial to prevent solder bridges. For homogeneous SMD components, a spacing of ≥0.3 mm is suggested.

Component Placement and Orientation

- Component Placement: Strategically position components to minimize signal path lengths, reducing potential signal loss and interference.

- Zero-Component Orientation: Define a zero-component orientation to ensure correct placement during assembly, following IPC standards.

Thermal Management

- Thermal Vias: Incorporate thermal vias to effectively dissipate heat from components, preventing overheating and damage.

Best Practices for SMT Pad Design

Adhering to best practices in SMT pad design is essential for optimizing PCB performance and manufacturability:

Use of Grid Systems

- Implement a grid system for component placement to streamline the assembly process and reduce errors.

Standardization

- Standardize component packages and sizes to minimize machine recalibrations and enhance assembly efficiency.

Quality Control

- Implement stringent quality control protocols, including regular equipment calibration and adherence to industry standards like IPC-A-610.

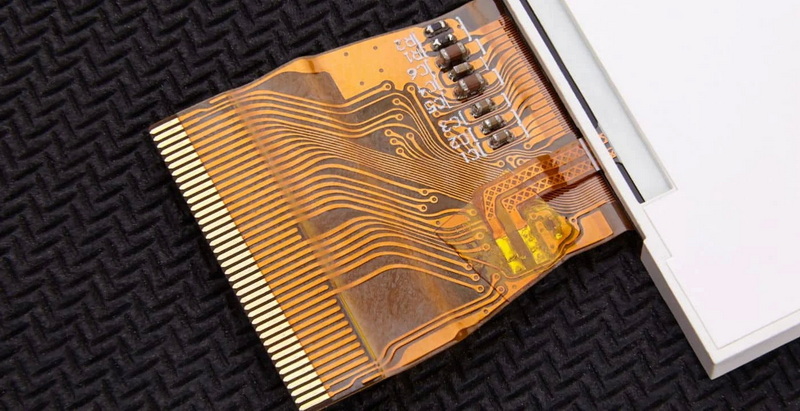

Material Selection

- Choose substrate materials that support thermal management and performance requirements. Materials like FR-4 are commonly used, but for high-performance applications, alternatives such as polyimide might be preferred due to their superior thermal properties[2].

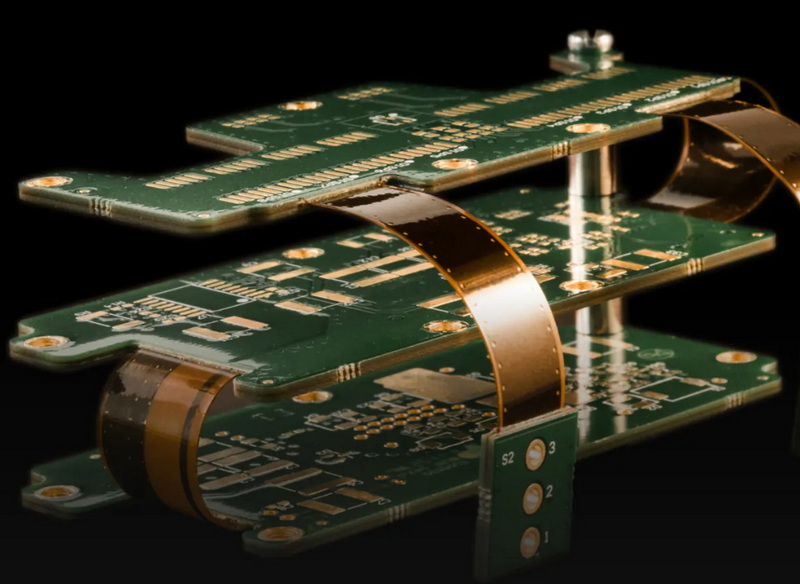

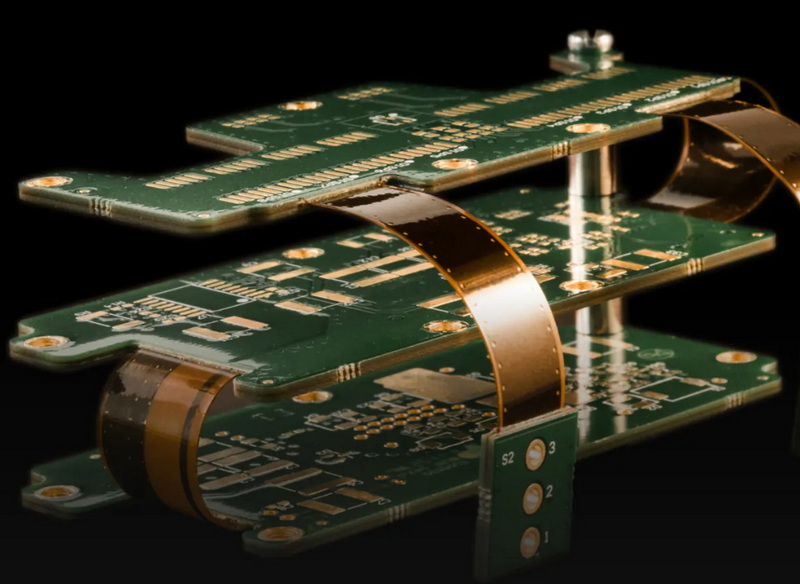

Advanced Techniques for High-Density PCBs

In modern PCB assembly, high-density designs and fine-pitch components require advanced techniques to ensure reliability and efficiency:

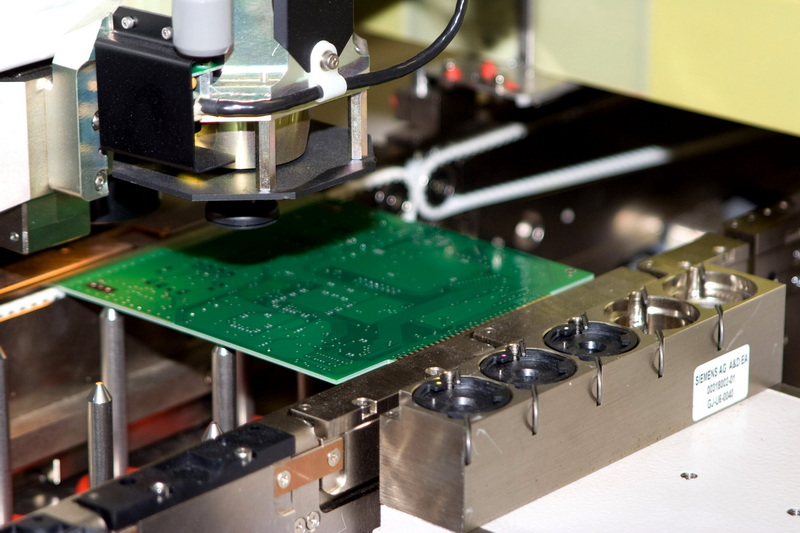

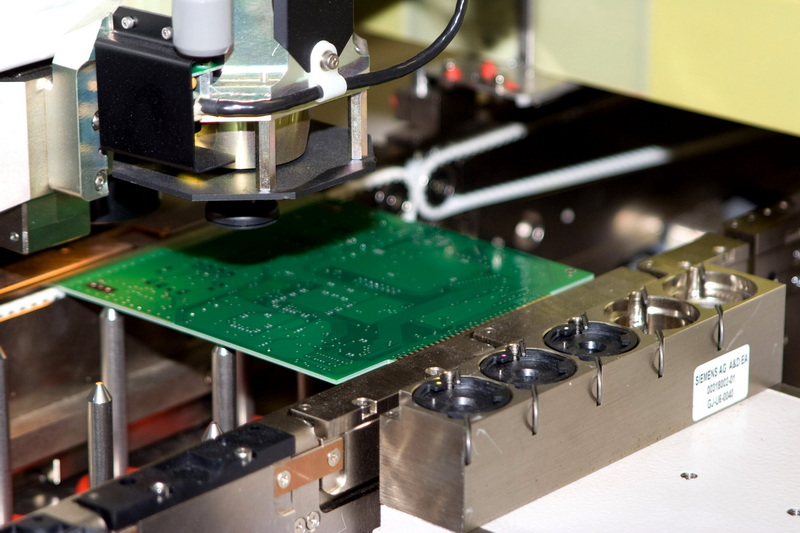

Precision Placement Techniques

- Utilize vision-guided robotic systems for accurate component alignment, minimizing defects in PCBA workflows[5].

Solder Paste Deposition

- Optimize solder paste deposition using fine particle sizes to reduce bridging risks in tight layouts[5].

Thermal Management Innovations

- Employ high-Tg materials or metal-core boards to enhance heat dissipation without sacrificing routing density[5].

Automated Inspection Systems

- Leverage automated optical inspection (AOI) and X-ray inspection systems to verify solder joint quality beneath BGA components[5].

Challenges and Considerations

Despite the advantages of SMT, several challenges and considerations must be addressed:

Manufacturing Constraints

- Assembly Equipment Limitations: Design with assembly equipment capabilities in mind to ensure manufacturability.

- Material Selection: Choose substrate materials that support thermal management and performance requirements.

Design for Manufacturability (DFM)

- DFM Principles: Apply DFM principles to select components and materials that align with standard assembly processes.

Environmental Factors

- Thermal Stress: Consider thermal stress on components and PCBs, especially in high-temperature environments.

Conclusion

Designing SMT pads on PCBs requires careful consideration of symmetry, pad size, solder paste application, clearance, component placement, and thermal management. By following these key design rules and best practices, engineers can optimize PCBs for SMT assembly, ensuring reliable, efficient, and cost-effective production of electronic devices.

FAQ

1. What is the purpose of symmetry in SMT pad design?

Symmetry in SMT pad design is crucial to prevent tombstoning, a defect where components are partially or completely lifted from the PCB pad during soldering. Symmetrical pads ensure uniform soldering and reduce the risk of such defects.

2. How does solder paste coverage affect SMT assembly?

Adequate solder paste coverage is essential for forming reliable solder joints. Typically, a coverage of 60% to 80% is recommended to ensure proper soldering without excessive bridging or voids.

3. What are the benefits of using NSMD pads over SMD pads?

NSMD pads offer a larger surface area for solder joints and greater clearance between pads, making them suitable for high-density and fine-pitch components. However, they can be prone to delamination under thermal and mechanical stress.

4. Why is thermal management important in SMT design?

Thermal management is critical to prevent overheating and damage to components. Incorporating thermal vias and heat sinks helps dissipate heat effectively, ensuring the reliability and performance of electronic devices.

5. How does component placement affect signal integrity in SMT PCBs?

Strategic component placement minimizes signal path lengths, reducing potential signal loss and interference. This is particularly important in high-speed applications where even slight delays can impact performance.

Citations:

[1] https://www.ti.com/lit/an/sprabb3/sprabb3.pdf

[2] https://vohrum.com/from-concept-to-completion-best-practices-in-smt-design-assembly-and-testing-for-high-performance-pcbs/

[3] https://www.analog.com/en/resources/design-notes/smt-assembly-and-pcb-design-guidelines-for-leaded-packages.html

[4] https://www.protoexpress.com/blog/6-common-solder-mask-errors-every-pcb-designer-should-know/

[5] https://www.andwinpcb.com/advanced-smt-techniques-for-streamlined-pcba-bga-assembly/

[6] https://www.linkedin.com/advice/3/how-do-you-ensure-good-smt-pad-design

[7] https://www.pcb-hero.com/blogs/kittys-column/smt-process-design-key-points

[8] https://resources.altium.com/p/best-methods-calculations-pad-size-pcb-design

[9] https://www.smthelp.com/smt-manufacturability-design-guidelines

[10] https://resources.altium.com/p/pcb-layout-guidelines

[11] https://learn.sparkfun.com/tutorials/designing-pcbs-advanced-smd/all

[12] https://www.vse.com/blog/2019/11/19/pcb-pad-design-guidelines-that-follow-dfm-best-practices/

[13] https://www.protoexpress.com/kb/dfm-rules/

[14] https://www.andwinpcb.com/advanced-smt-techniques-revolutionizing-pcb-assembly-efficiency/

[15] https://community.sparkfun.com/t/good-practice-for-smd-routing/23955

[16] https://www.reddit.com/r/embedded/comments/1d97rv1/what_are_your_commandments_of_pcb_design/

[17] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[18] https://community.cadence.com/cadence_technology_forums/pcb-design/f/pcb-design/22775/smt-pad-on-internal-layers

[19] https://www.myemssolutions.com/6-considerations-for-smt-pcb-design/

[20] https://www.protoexpress.com/blog/what-is-pad-pcb-design-development/