Content Menu

● Understanding Double-Sided PCB SMT Assembly

● The Complexity of Double-Sided Assembly

>> Component Placement Considerations

>> Thermal Management Challenges

● The Manufacturing Process Challenges

>> Solder Paste Application

>> Component Placement Precision

>> Reflow Soldering Complexities

● Strategies for Successful Double-Sided PCB SMT Assembly

>> Design for Manufacturability (DFM)

>> Advanced Manufacturing Techniques

>> Quality Control and Inspection

● Advancements in Double-Sided PCB SMT Assembly

>> Improved SMT Equipment

>> Enhanced PCB Materials

● The Future of Double-Sided PCB SMT Assembly

● Conclusion

● FAQ

>> 1. What is the main advantage of double-sided PCB SMT assembly?

>> 2. How does the reflow process differ for double-sided PCB SMT assembly?

>> 3. What are some common defects in double-sided PCB SMT assembly?

>> 4. How does thermal management differ in double-sided PCB SMT assembly?

>> 5. What inspection methods are used for double-sided PCB SMT assemblies?

● Citations:

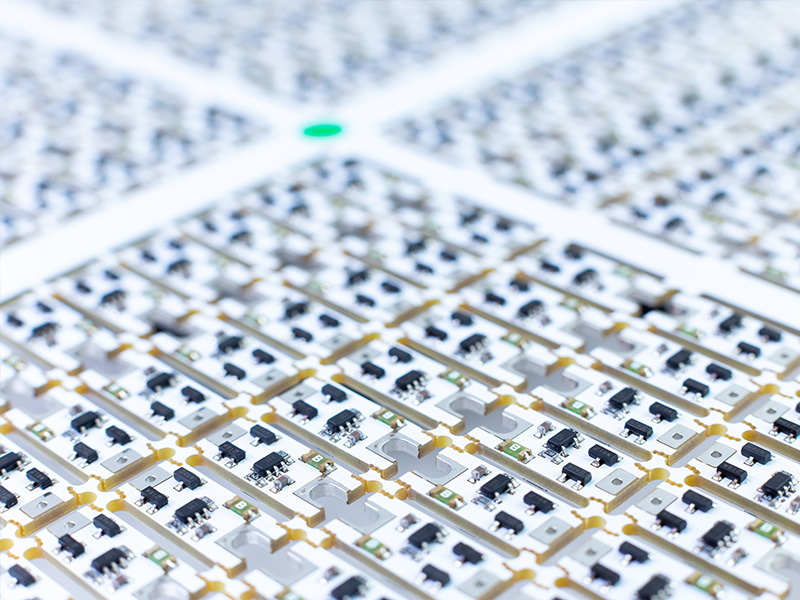

Double-sided PCB SMT assembly is a crucial process in the electronics manufacturing industry, allowing for more compact and efficient designs. However, this technique comes with its own set of challenges that manufacturers must overcome to ensure high-quality, reliable products. In this article, we will explore the key challenges faced in double-sided PCB SMT assembly and discuss strategies to address them.

Understanding Double-Sided PCB SMT Assembly

Before delving into the challenges, it's essential to understand what double-sided PCB SMT assembly entails. Surface Mount Technology (SMT) is a method of producing electronic circuits where components are mounted directly onto the surface of printed circuit boards (PCBs)[1]. Double-sided PCB SMT assembly involves placing components on both sides of the board, maximizing space utilization and allowing for more complex circuit designs.

The Complexity of Double-Sided Assembly

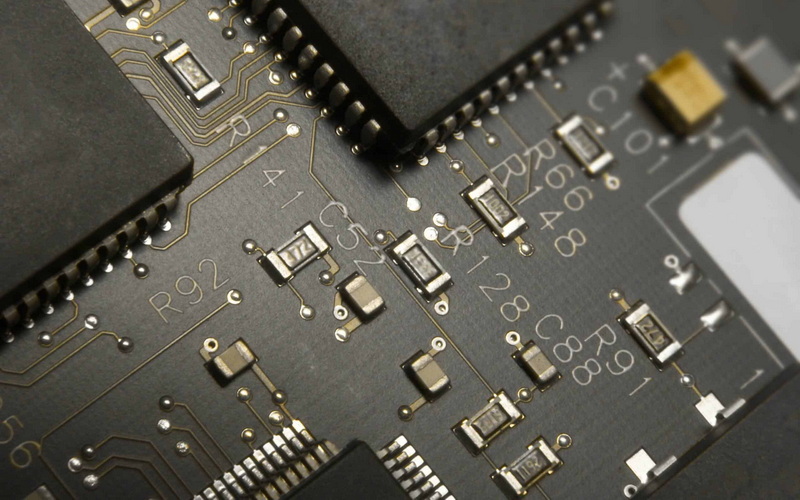

One of the primary challenges in double-sided PCB SMT assembly is the increased complexity compared to single-sided boards. Designers and manufacturers must carefully consider component placement, thermal management, and signal integrity when working with both sides of the PCB[4].

Component Placement Considerations

When assembling components on both sides of a PCB, careful planning is required to ensure that components on one side do not interfere with those on the other. This includes:

1. Avoiding overlapping components

2. Ensuring adequate clearance for heat dissipation

3. Preventing mechanical stress on components during assembly and use

Thermal Management Challenges

Heat dissipation becomes more complex in double-sided assemblies. Components on both sides of the board generate heat, which can lead to thermal stress and potential failures if not properly managed[4]. Engineers must consider:

- Heat distribution across both sides of the board

- Placement of heat-generating components

- Implementation of thermal vias and other cooling solutions

The Manufacturing Process Challenges

The manufacturing process for double-sided PCB SMT assembly presents several unique challenges that must be addressed to ensure high-quality results.

Solder Paste Application

Applying solder paste accurately to both sides of the PCB is crucial for successful assembly. Challenges include:

- Ensuring consistent solder paste volume on both sides

- Preventing smearing or bridging of solder paste

- Maintaining alignment of solder paste with component pads

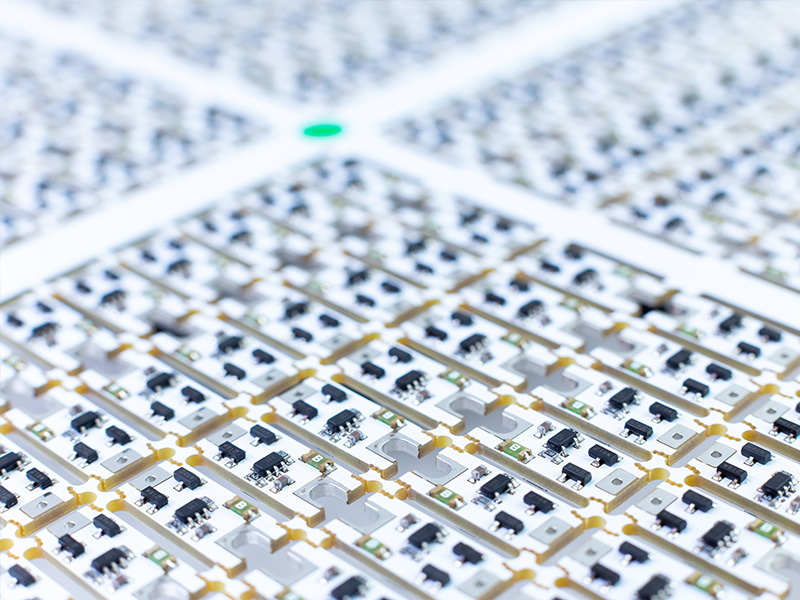

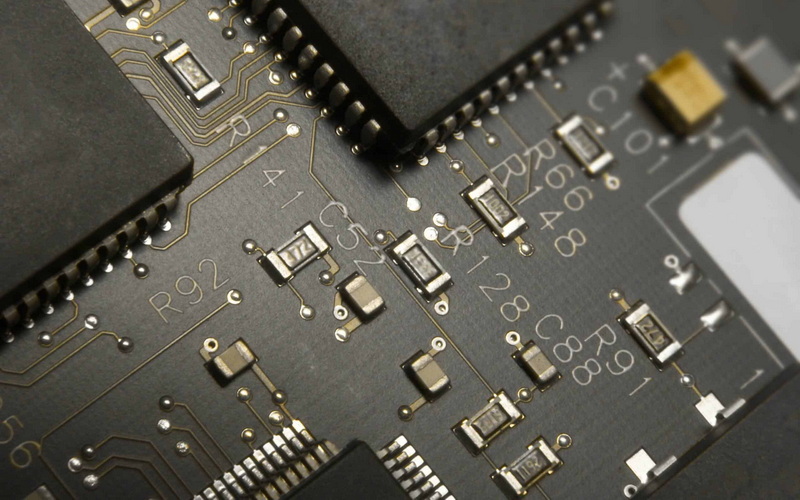

Component Placement Precision

Accurate component placement is essential for double-sided assemblies. Manufacturers must consider:

- Maintaining placement accuracy on both sides of the board

- Compensating for board warpage or thickness variations

- Ensuring proper alignment of components with solder paste deposits

Reflow Soldering Complexities

The reflow soldering process becomes more complex with double-sided assemblies. Key challenges include:

- Preventing components from falling off during the second reflow pass

- Managing different thermal profiles for components on each side

- Avoiding remelting of solder joints on the first side during the second pass

Strategies for Successful Double-Sided PCB SMT Assembly

To overcome these challenges, manufacturers employ various strategies and techniques.

Design for Manufacturability (DFM)

Implementing DFM principles is crucial for successful double-sided PCB SMT assembly. This includes:

- Optimizing component placement for both sides of the board

- Considering thermal management in the design phase

- Ensuring adequate clearance for assembly equipment

Advanced Manufacturing Techniques

Manufacturers use specialized techniques to address the unique challenges of double-sided assembly:

1. Selective Soldering: This technique allows for precise soldering of through-hole components on boards with SMT components on both sides[2].

2. Adhesive Application: Using surface mount adhesives to hold components in place during the second reflow pass[7].

3. Customized Reflow Profiles: Developing specific thermal profiles for each side of the board to ensure proper soldering without damaging components.

Quality Control and Inspection

Rigorous quality control measures are essential for double-sided PCB SMT assembly:

- Automated Optical Inspection (AOI) for both sides of the board

- X-ray inspection for hidden solder joints

- In-circuit testing to verify electrical connections

Advancements in Double-Sided PCB SMT Assembly

As technology progresses, new solutions are emerging to address the challenges of double-sided PCB SMT assembly.

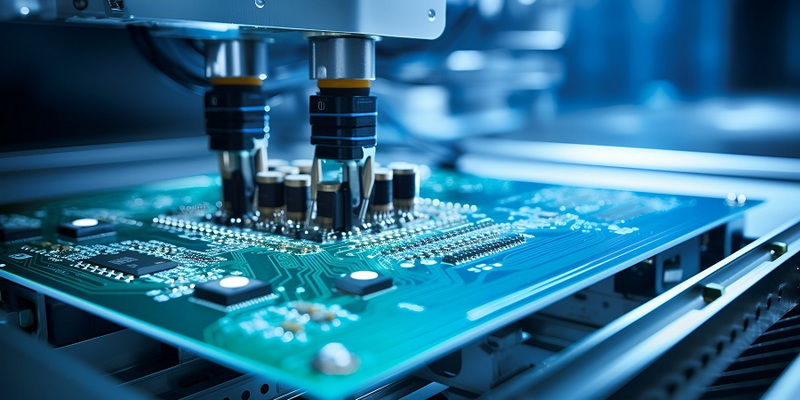

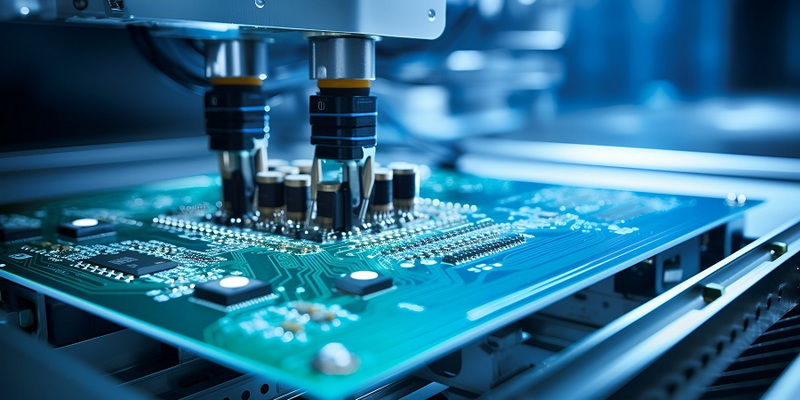

Improved SMT Equipment

Modern SMT equipment is designed to handle the complexities of double-sided assembly:

- Advanced pick-and-place machines with higher accuracy and speed

- Reflow ovens with precise temperature control and profiling capabilities

- Automated inspection systems capable of examining both sides of the board

Enhanced PCB Materials

Developments in PCB materials are helping to mitigate some of the challenges:

- High-temperature PCB substrates that can withstand multiple reflow cycles

- Materials with improved thermal conductivity for better heat management

- Dimensionally stable materials to reduce warpage during assembly

The Future of Double-Sided PCB SMT Assembly

As electronic devices continue to shrink in size while increasing in functionality, the demand for efficient double-sided PCB SMT assembly will only grow. Future developments may include:

- AI-driven design optimization for double-sided boards

- Advanced thermal management solutions integrated into PCB designs

- Improved automation in the assembly process to reduce human error

Conclusion

Double-sided PCB SMT assembly presents numerous challenges, from design considerations to manufacturing complexities. However, with careful planning, advanced manufacturing techniques, and rigorous quality control, these challenges can be overcome. As technology continues to evolve, we can expect to see further improvements in the efficiency and reliability of double-sided PCB SMT assembly processes.

FAQ

1. What is the main advantage of double-sided PCB SMT assembly?

The main advantage of double-sided PCB SMT assembly is the ability to create more compact and complex electronic designs by utilizing both sides of the PCB for component placement. This allows for higher component density and potentially smaller overall product sizes.

2. How does the reflow process differ for double-sided PCB SMT assembly?

In double-sided PCB SMT assembly, the reflow process typically involves two passes through the reflow oven. The first side is assembled and reflowed, then the board is flipped, and the process is repeated for the second side. Special considerations must be made to prevent components on the first side from falling off during the second reflow.

3. What are some common defects in double-sided PCB SMT assembly?

Common defects in double-sided PCB SMT assembly include solder bridging, component misalignment, tombstoning (where components stand on one end), and insufficient solder joints. These defects can occur on both sides of the board and may be more challenging to detect and correct.

4. How does thermal management differ in double-sided PCB SMT assembly?

Thermal management in double-sided PCB SMT assembly is more complex due to heat-generating components on both sides of the board. Engineers must consider heat distribution across the entire assembly, implement thermal vias for heat transfer between layers, and carefully place high-power components to avoid thermal hotspots.

5. What inspection methods are used for double-sided PCB SMT assemblies?

Inspection methods for double-sided PCB SMT assemblies include Automated Optical Inspection (AOI) for both sides of the board, X-ray inspection for hidden solder joints and BGA components, and In-Circuit Testing (ICT) to verify electrical connections. Some manufacturers also use 3D solder paste inspection systems to ensure proper solder paste application on both sides.

Citations:

[1] https://electronics.stackexchange.com/questions/357365/pcb-design-through-hole-components-on-both-sides

[2] https://www.youtube.com/watch?v=6SIN15XG77M

[3] https://www.macrofab.com/blog/smt-assembly-vs-through-hole/

[4] https://www.pcbjhy.com/blog/pros-and-cons-of-double-sided-pcb/

[5] https://www.pcbelec.com/pcb-fabrication-process/double-sided-pcb-manufacturing-process

[6] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[7] https://rushpcb.com/stop-the-drop-fixturing-a-heavy-smt-component-saves-time-money/

[8] https://resources.pcb.cadence.com/blog/2022-double-sided-pcb-assembly-and-manufacturing-processes

[9] https://baike.baidu.com/item/%E7%94%B5%E5%AD%90%E7%BB%84%E8%A3%85%E6%8A%80%E6%9C%AF%E4%B8%93%E4%B8%9A%E8%8B%B1%E8%AF%AD/12086345

[10] https://www.pcbgogo.com/Article/How_does_double_sided_SMT_assembly_work_.html

[11] https://www.zaxis.net/video-manufacturing-double-sided-pcbas/