Content Menu

● Increased Component Density

● Enhanced Performance and Reliability

● Reduced Manufacturing Costs

● Greater Design Flexibility

● Improved Thermal Management

● Compatibility with Advanced Manufacturing Techniques

● Environmental Considerations

● Future Trends in Surface Mount Technology

● Conclusion

● Related Questions

>> 1. What Is Surface Mount Technology?

>> 2. How Does Surface Mount Technology Improve Production Efficiency?

>> 3. What Are Common Applications of Surface Mount Technology?

>> 4. What Are Some Challenges Associated with Surface Mount Technology?

>> 5. How Can Manufacturers Ensure Quality Control in SMT Processes?

Surface Mount Technology (SMT) has transformed the landscape of electronics manufacturing over the past few decades. This innovative process allows for the mounting of electronic components directly onto the surface of printed circuit boards (PCBs), leading to a myriad of advantages that have made it the preferred choice in modern electronics production. In this article, we will explore the key benefits of using Surface Mount Technology in electronics, delve into the surface mount technology process, and discuss its impact on manufacturing efficiency, product performance, and design flexibility.

Increased Component Density

One of the most significant advantages of Surface Mount Technology is its ability to accommodate higher component densities on PCBs. Unlike traditional through-hole components, which require larger holes and more space on the board, SMT components are smaller and can be placed closer together. This increased density allows manufacturers to design more compact devices, which is particularly beneficial in applications where space is at a premium, such as smartphones, tablets, and wearables.

The ability to place components closer together also opens up new possibilities for circuit design. Engineers can create more complex circuits without significantly increasing the size of the PCB. This flexibility is crucial in today's fast-paced electronics market, where miniaturization is often a key selling point.

Moreover, higher component density can lead to improved performance characteristics. For instance, shorter signal paths reduce latency and enhance signal integrity, which is critical for high-speed applications like telecommunications and data processing. As a result, devices manufactured using SMT often demonstrate superior performance metrics compared to those utilizing traditional assembly methods.

Enhanced Performance and Reliability

SMT components typically exhibit better performance and reliability compared to their through-hole counterparts. The surface mount technology process involves soldering components directly onto the PCB's surface, which creates a more robust mechanical connection. This method reduces the risk of solder joint failure, especially in high-vibration environments.

Additionally, SMT components have shorter lead lengths, which minimizes inductance and resistance. This characteristic is particularly important in high-frequency applications where signal integrity is critical. As a result, devices manufactured using SMT often demonstrate improved electrical performance and lower susceptibility to interference.

Furthermore, SMT allows for better thermal management due to its design features. Many SMT components are designed with thermal pads or heat sinks that facilitate efficient heat dissipation. This capability is essential for maintaining optimal operating temperatures in high-performance devices such as CPUs and GPUs, where overheating can lead to reduced performance or even failure.

Reduced Manufacturing Costs

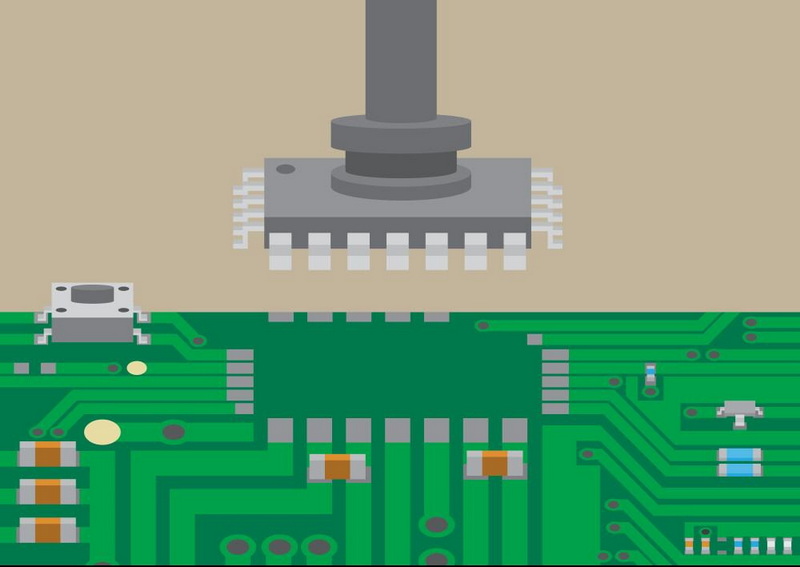

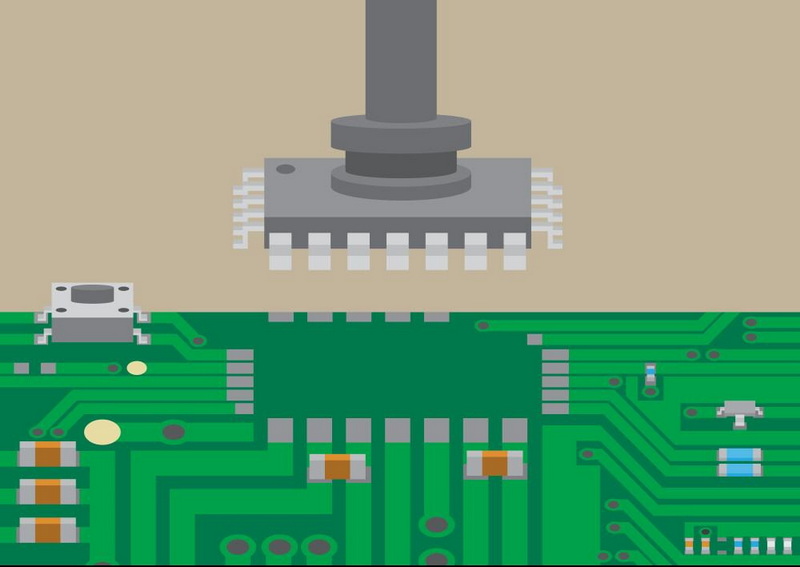

The adoption of Surface Mount Technology can lead to significant cost savings throughout the manufacturing process. SMT allows for automated assembly processes, which can greatly reduce labor costs associated with manual assembly methods used for through-hole components. Automated pick-and-place machines can quickly and accurately position SMT components on PCBs, enhancing production speed and efficiency.

Moreover, because SMT components are smaller and lighter than through-hole components, shipping costs can also be reduced. Manufacturers can transport more products in less space, further contributing to overall cost savings.

In addition to labor and shipping costs, SMT can also reduce material waste during production. The precision involved in automated assembly means fewer errors occur during placement and soldering processes. This efficiency translates into lower scrap rates and less rework required for defective boards.

Greater Design Flexibility

Surface Mount Technology offers unparalleled design flexibility for engineers and designers. The smaller size of SMT components enables more innovative designs that were previously impossible with larger through-hole parts. Designers can experiment with different layouts and configurations without being constrained by component size or hole placement.

This flexibility extends to prototyping as well. Engineers can quickly iterate on designs using SMT, allowing for faster development cycles and quicker time-to-market for new products. The ability to easily modify designs also facilitates rapid testing and validation of new concepts.

Additionally, SMT supports advanced circuit board designs such as multilayer PCBs that maximize space utilization while maintaining functionality. This capability is particularly beneficial for complex electronic systems found in aerospace or medical applications where reliability is paramount.

Improved Thermal Management

Thermal management is a critical consideration in electronics design, especially as devices become more powerful and compact. Surface Mount Technology enhances thermal management through improved heat dissipation capabilities. Many SMT components are designed with thermal pads or vias that facilitate better heat transfer away from sensitive areas of the PCB.

Additionally, because SMT allows for denser component placement, manufacturers can strategically position heat-sensitive components away from heat-generating ones. This thoughtful arrangement helps maintain optimal operating temperatures and prolongs the lifespan of electronic devices.

Furthermore, advanced thermal simulation tools used during the design phase enable engineers to predict thermal behavior under various operating conditions accurately. By analyzing how heat dissipates across a PCB populated with SMT components, designers can make informed decisions about component placement and cooling strategies.

Compatibility with Advanced Manufacturing Techniques

Surface Mount Technology is highly compatible with advanced manufacturing techniques such as automated optical inspection (AOI) and solder paste inspection (SPI). These technologies enhance quality control throughout the surface mount technology process by ensuring that each component is correctly placed and soldered before moving on to subsequent production stages.

The integration of these advanced inspection techniques not only improves product quality but also reduces the likelihood of defects reaching consumers. By catching potential issues early in the manufacturing process, companies can save time and resources while maintaining high standards for their products.

Moreover, incorporating machine learning algorithms into inspection processes allows manufacturers to continuously improve quality control measures by analyzing data from previous production runs. This proactive approach helps identify trends or recurring issues that may affect product quality over time.

Environmental Considerations

As sustainability becomes increasingly important in electronics manufacturing, Surface Mount Technology offers several environmental benefits compared to traditional methods. The reduction in material waste associated with SMT processes contributes to a smaller environmental footprint.

Furthermore, many SMT components are designed to be compatible with lead-free soldering processes, aligning with global initiatives to eliminate hazardous materials from electronic products. This shift towards greener manufacturing practices not only benefits the environment but also appeals to consumers who prioritize eco-friendly products.

Additionally, the compact nature of SMT allows manufacturers to reduce energy consumption during production due to smaller equipment footprints and lower material usage overall. As companies strive toward sustainability goals set by international standards such as ISO 14001, adopting SMT becomes an integral part of their environmental strategy.

Future Trends in Surface Mount Technology

As technology continues to evolve rapidly, so does Surface Mount Technology itself. Emerging trends indicate that we will see further advancements aimed at enhancing efficiency and performance even more:

- Miniaturization: As consumer demand grows for smaller devices with greater functionality—like smartwatches or IoT sensors—manufacturers will continue pushing boundaries regarding component sizes while maintaining reliability.

- Flexible Electronics: The rise of flexible circuits presents new opportunities for integrating SMT into unconventional form factors—enabling wearables or bendable displays that conform comfortably against users' bodies.

- 3D Printing: Innovations like additive manufacturing may soon allow engineers greater freedom when designing complex geometries within PCBs—potentially reshaping how we think about traditional assembly processes altogether.

- Smart Manufacturing: Incorporating IoT technologies into factories could lead manufacturers toward smarter operations—utilizing real-time data analytics alongside automation tools will optimize production workflows while minimizing waste further downline.

- Sustainability Initiatives: With increasing regulatory pressure regarding environmental impacts across industries globally—companies embracing sustainable practices will likely gain competitive advantages over those who don't adapt quickly enough.

Conclusion

In conclusion, Surface Mount Technology has revolutionized the electronics manufacturing industry by offering numerous benefits that enhance performance, reduce costs, and provide greater design flexibility. Its ability to accommodate higher component densities while improving reliability makes it an essential choice for modern electronic devices. As technology continues to advance and consumer demands evolve, SMT will undoubtedly play a pivotal role in shaping the future of electronics manufacturing.

By leveraging the advantages of Surface Mount Technology, manufacturers can create innovative products that meet market needs while maintaining high standards for quality and sustainability.

Related Questions

1. What Is Surface Mount Technology?

Surface Mount Technology (SMT) is a method used in electronic assembly where components are mounted directly onto the surface of PCBs rather than being inserted into holes drilled into them.

2. How Does Surface Mount Technology Improve Production Efficiency?

SMT enhances production efficiency by allowing automated assembly processes that reduce labor costs and increase speed compared to manual assembly methods used for through-hole components.

3. What Are Common Applications of Surface Mount Technology?

Common applications include consumer electronics like smartphones and tablets, automotive systems, medical devices, and various industrial equipment that require compact designs.

4. What Are Some Challenges Associated with Surface Mount Technology?

Challenges include handling small components during assembly, ensuring proper soldering techniques are employed, and managing thermal issues due to high-density layouts.

5. How Can Manufacturers Ensure Quality Control in SMT Processes?

Manufacturers can implement automated inspection techniques such as AOI and SPI during production to ensure that all components are correctly placed and soldered before final assembly.