Content Menu

● Introduction to SMT PCB

● Miniaturization and Space Efficiency

>> Reduced Size and Weight

>> Higher Component Density

● Enhanced Performance

>> Improved High-Frequency Performance

>> Better Electrical Characteristics

● Manufacturing Efficiency

>> Automated Assembly

>> Simplified Production Process

>> Faster Turnaround Times

● Cost-Effectiveness

>> Reduced Material Costs

>> Lower Labor Costs

>> Economies of Scale

● Improved Reliability

>> Enhanced Mechanical Stability

>> Reduced Thermal Stress

>> Fewer Solder Joints

● Design Flexibility

>> Double-Sided Assembly

>> Mixed Technology Designs

>> Fine-Pitch Components

● Environmental Benefits

>> Reduced Material Usage

>> Lower Energy Consumption

>> Easier Recycling

● Challenges and Considerations

>> Initial Investment

>> Repair and Rework

>> Thermal Management

● The Future of SMT PCB in Electronics

>> Continued Miniaturization

>> Integration with Advanced Technologies

>> Sustainability Focus

● Conclusion

● FAQ

>> 1. What is SMT PCB?

>> 2. How does SMT PCB differ from traditional through-hole technology?

>> 3. What are the main advantages of SMT PCB in China's electronics manufacturing?

>> 4. Are there any disadvantages to using SMT PCB?

>> 5. How is the SMT PCB industry evolving in China?

● Citations:

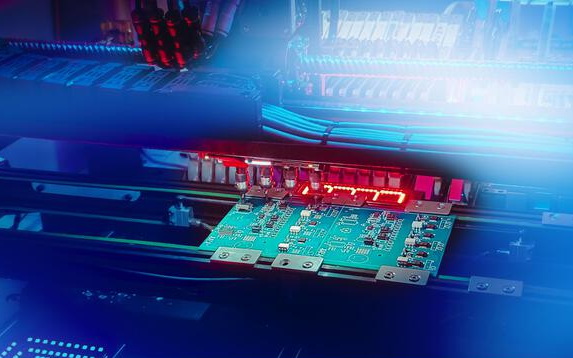

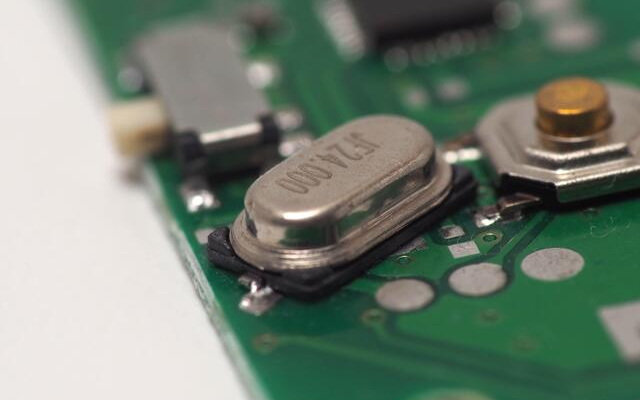

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, offering numerous advantages over traditional through-hole technology. This article explores the key benefits of SMT PCB for electronics, focusing on its impact on manufacturing efficiency, product quality, and overall performance.

Introduction to SMT PCB

Surface Mount Technology (SMT) is a method of producing electronic circuits where components are mounted directly onto the surface of printed circuit boards (PCBs). This technique has become increasingly popular in China and around the world due to its numerous advantages over traditional through-hole technology[1][2].

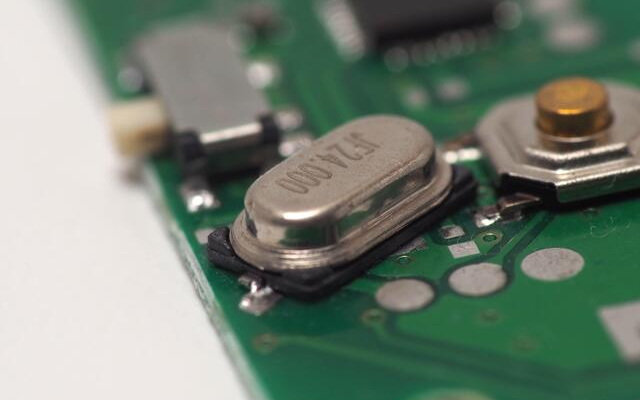

Miniaturization and Space Efficiency

One of the most significant benefits of SMT PCB is the ability to create smaller, more compact electronic devices. SMT components are typically much smaller than their through-hole counterparts, allowing for higher component density on PCBs[5].

Reduced Size and Weight

SMT components can be up to 90% smaller and 60-80% lighter than traditional through-hole components[5]. This reduction in size and weight has enabled the development of increasingly compact and portable electronic devices, from smartphones to wearable technology.

Higher Component Density

The smaller footprint of SMT components allows for more components to be placed on a single PCB. This increased density enables the creation of more complex circuits within a smaller area, leading to more powerful and feature-rich electronic devices[3].

Enhanced Performance

SMT PCB technology not only allows for smaller devices but also contributes to improved performance in various ways.

Improved High-Frequency Performance

The shorter lead lengths and reduced parasitic effects in SMT components result in better high-frequency performance. This is particularly important for modern electronic devices that operate at high speeds and frequencies[5].

Better Electrical Characteristics

SMT components typically have lower lead inductance and resistance compared to through-hole components. This leads to improved signal integrity and reduced electromagnetic interference (EMI), resulting in better overall electrical performance[3].

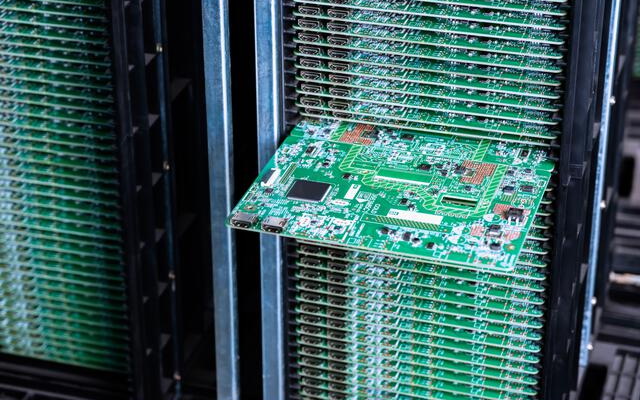

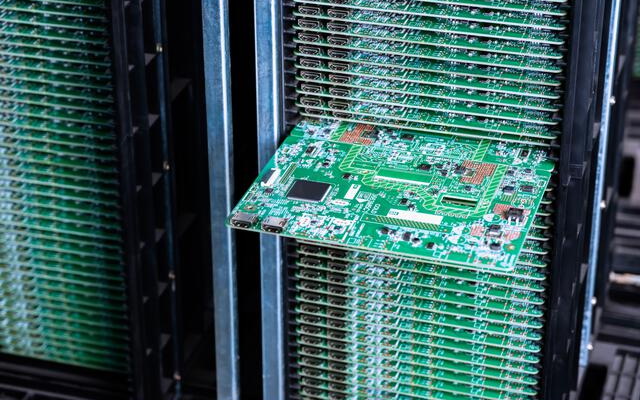

Manufacturing Efficiency

SMT PCB assembly offers significant advantages in terms of manufacturing efficiency, making it the preferred choice for large-scale production in China and globally.

Automated Assembly

SMT is highly compatible with automated assembly processes. Advanced pick-and-place machines can place tens of thousands of components per hour, significantly reducing production time and labor costs[2][5].

Simplified Production Process

The SMT assembly process is more streamlined compared to through-hole technology. It eliminates the need for drilling holes in the PCB and reduces the number of steps required for component placement and soldering[3].

Faster Turnaround Times

The combination of automated assembly and simplified production processes allows for faster turnaround times. This is particularly beneficial during peak production periods, such as the year-end rush in China's electronics manufacturing industry[4].

Cost-Effectiveness

While the initial investment in SMT equipment can be substantial, the technology offers long-term cost benefits for electronics manufacturers.

Reduced Material Costs

SMT components are generally less expensive than their through-hole counterparts due to their smaller size and reduced material usage. This leads to lower overall material costs for PCB assembly[3].

Lower Labor Costs

The high level of automation in SMT assembly significantly reduces labor requirements compared to manual through-hole assembly. This is particularly advantageous in regions where labor costs are rising[2].

Economies of Scale

SMT is particularly well-suited for high-volume production. As production scales up, the cost per unit decreases, making it an economical choice for large-scale manufacturing operations in China and elsewhere[4].

Improved Reliability

SMT PCBs often demonstrate superior reliability compared to through-hole assemblies, contributing to the overall quality and longevity of electronic devices.

Enhanced Mechanical Stability

SMT components are directly soldered to the surface of the PCB, providing a strong mechanical connection. This increased stability makes SMT PCBs more resistant to shock and vibration[3].

Reduced Thermal Stress

The smaller size of SMT components and their direct contact with the PCB surface allow for better heat dissipation. This reduces thermal stress on the components and solder joints, potentially extending the lifespan of the device[5].

Fewer Solder Joints

SMT assemblies typically require fewer solder joints compared to through-hole assemblies. Fewer joints mean fewer potential points of failure, contributing to improved overall reliability[1].

Design Flexibility

SMT PCB technology offers greater design flexibility, allowing engineers to create more complex and innovative electronic devices.

Double-Sided Assembly

SMT components can be placed on both sides of a PCB, effectively doubling the available space for components. This enables the creation of more complex circuits within a given board area[5].

Mixed Technology Designs

SMT is compatible with through-hole technology, allowing designers to create mixed-technology boards. This flexibility enables the use of SMT for most components while still accommodating through-hole components when necessary[1].

Fine-Pitch Components

SMT allows for the use of fine-pitch and ultra-fine-pitch components, which have very closely spaced leads. This enables the integration of highly complex integrated circuits and other advanced components[2].

Environmental Benefits

SMT PCB technology also offers several environmental advantages compared to traditional through-hole assembly.

Reduced Material Usage

The smaller size of SMT components and PCBs results in less material usage overall. This not only reduces costs but also minimizes the environmental impact of electronics manufacturing[3].

Lower Energy Consumption

SMT assembly processes, particularly reflow soldering, often consume less energy compared to wave soldering used in through-hole assembly. This leads to reduced energy consumption in the manufacturing process[5].

Easier Recycling

The compact nature of SMT PCBs and the use of lead-free solders in many applications make these assemblies easier to recycle at the end of their lifecycle[2].

Challenges and Considerations

While SMT PCB technology offers numerous benefits, it's important to consider some of the challenges associated with its implementation.

Initial Investment

Setting up an SMT production line requires a significant initial investment in equipment such as pick-and-place machines, reflow ovens, and inspection systems[4].

Repair and Rework

Repairing and reworking SMT PCBs can be more challenging compared to through-hole assemblies due to the smaller component sizes and closer spacing[3].

Thermal Management

The high component density in SMT designs can lead to increased heat generation, requiring careful thermal management strategies[5].

The Future of SMT PCB in Electronics

As electronic devices continue to evolve, SMT PCB technology is expected to play an increasingly important role in their development and production.

Continued Miniaturization

Ongoing advancements in SMT technology are likely to enable further miniaturization of electronic components and devices[2].

Integration with Advanced Technologies

SMT is expected to integrate seamlessly with other advanced technologies such as 3D printing and flexible electronics, opening up new possibilities for innovative device designs[4].

Sustainability Focus

Future developments in SMT PCB technology are likely to focus on improving sustainability, including the use of more environmentally friendly materials and processes[5].

Conclusion

Surface Mount Technology has transformed the electronics manufacturing landscape, offering numerous benefits that have made it the preferred choice for PCB assembly in China and worldwide. From enabling the creation of smaller, more powerful devices to improving manufacturing efficiency and product reliability, SMT PCB technology has become an indispensable part of modern electronics production.

As the electronics industry continues to evolve, SMT PCB technology is expected to play a crucial role in driving innovation and meeting the growing demand for smaller, faster, and more efficient electronic devices. While challenges exist, the advantages of SMT PCB far outweigh the drawbacks, ensuring its continued dominance in the electronics manufacturing sector for years to come.

FAQ

1. What is SMT PCB?

SMT PCB refers to Printed Circuit Boards assembled using Surface Mount Technology. This technology involves mounting electronic components directly onto the surface of the PCB, as opposed to through-hole technology where component leads are inserted through holes in the board.

2. How does SMT PCB differ from traditional through-hole technology?

SMT PCB differs from through-hole technology in several ways:

- Components are mounted on the surface rather than through holes

- SMT components are generally smaller

- Assembly is more automated

- Higher component density is possible

- Better performance at high frequencies

3. What are the main advantages of SMT PCB in China's electronics manufacturing?

The main advantages of SMT PCB in China's electronics manufacturing include:

- Higher production efficiency

- Reduced labor costs

- Ability to produce smaller and lighter devices

- Improved product performance

- Better suitability for high-volume production

4. Are there any disadvantages to using SMT PCB?

While SMT PCB offers many benefits, there are some potential drawbacks:

- Higher initial equipment costs

- More challenging repair and rework processes

- Potential thermal management issues due to higher component density

- Not suitable for all types of components, especially those subject to high mechanical stress

5. How is the SMT PCB industry evolving in China?

The SMT PCB industry in China is evolving rapidly, with trends including:

- Increasing automation and smart manufacturing practices

- Focus on producing higher quality, more complex PCBs

- Growing emphasis on environmental sustainability

- Integration of SMT with other advanced technologies like AI and IoT

- Continued investment in R&D to further improve SMT processes and capabilities

Citations:

[1] https://levisonenterprises.com/5-advantages-to-using-smt/

[2] https://www.fs-pcba.com/smt-pcba/

[3] https://novaenginc.com/why-surface-mount-technology-is-better-than-conventional-technique/

[4] https://www.x-pcb.com/pcb-manufacturing-in-china-navigating-year-end-rush-with-efficient-pcba-and-smt-services/

[5] https://jlcpcb.com/blog/the-characteristics-of-surface-mount-technology

[6] https://smtnet.com/library/index.cfm?fuseaction=browse_articles&start_at=296

[7] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[8] https://sfxpcb.com/smt-pcba/