Content Menu

● Introduction to SMT Manufacturing

● Enhanced Production Efficiency

>> Faster Assembly Processes

>> Reduced Labor Costs

● Cost-Effectiveness

>> Lower Material Costs

>> Decreased Waste

● Improved Product Quality

>> Enhanced Reliability

>> Better Performance

● Flexibility in Design

>> Miniaturization

>> Versatile Component Options

● Enhanced Thermal Management

>> Improved Heat Dissipation

>> Advanced Cooling Solutions

● Conclusion

● FAQ

>> 1. What is SMT manufacturing?

>> 2. What are the advantages of SMT over traditional methods?

>> 3. How does SMT improve product reliability?

>> 4. Can SMT components be used in high-frequency applications?

>> 5. What role does automation play in SMT manufacturing?

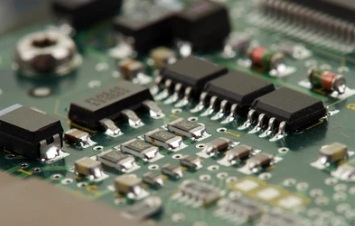

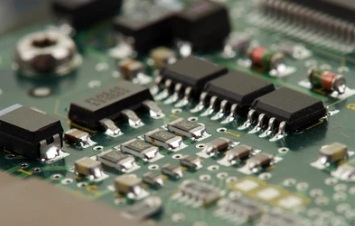

Surface Mount Technology (SMT) manufacturing has revolutionized the electronics industry, offering numerous advantages over traditional manufacturing methods. As the demand for smaller, more efficient electronic devices continues to grow, SMT has emerged as the preferred choice for many manufacturers. This article explores the key benefits of SMT manufacturing, highlighting its impact on efficiency, cost-effectiveness, and product quality.

Introduction to SMT Manufacturing

SMT manufacturing involves the process of mounting electronic components directly onto the surface of printed circuit boards (PCBs). This method contrasts with traditional through-hole technology, where components are inserted into holes drilled in the PCB. The evolution of SMT has been driven by the need for miniaturization, increased functionality, and improved performance in electronic devices.

Enhanced Production Efficiency

One of the most significant benefits of SMT manufacturing is its enhanced production efficiency. SMT allows for a higher density of components on a PCB, which means that more functions can be integrated into a smaller space. This increased density leads to shorter assembly times and reduced manufacturing costs.

Faster Assembly Processes

SMT manufacturing utilizes automated pick-and-place machines that can quickly and accurately position components on the PCB. This automation significantly reduces the time required for assembly compared to manual processes used in traditional methods. As a result, manufacturers can produce larger quantities of products in a shorter timeframe, meeting market demands more effectively.

Reduced Labor Costs

With the automation of the assembly process, labor costs are also reduced. Fewer workers are needed to operate SMT machines, allowing companies to allocate resources more efficiently. This reduction in labor costs contributes to the overall cost-effectiveness of SMT manufacturing.

Cost-Effectiveness

SMT manufacturing is often more cost-effective than traditional methods. The initial investment in SMT equipment may be higher, but the long-term savings in production costs make it a worthwhile investment.

Lower Material Costs

SMT components are generally smaller and lighter than their through-hole counterparts. This reduction in size leads to lower material costs, as manufacturers can use less raw material. Additionally, the ability to place more components on a single PCB reduces the number of boards needed, further lowering costs.

Decreased Waste

The precision of SMT manufacturing minimizes waste during the production process. Automated machines can place components with high accuracy, reducing the likelihood of defects and the need for rework. This efficiency not only saves money but also contributes to a more sustainable manufacturing process.

Improved Product Quality

Another key benefit of SMT manufacturing is the improvement in product quality. The precision and control offered by SMT processes lead to higher-quality electronic devices.

Enhanced Reliability

SMT components are less prone to mechanical stress due to their smaller size and lighter weight. This reduced stress translates to improved reliability and longevity of the final product. Manufacturers can produce devices that withstand harsher conditions and have a longer lifespan, which is crucial in today's competitive market.

Better Performance

The close proximity of components in SMT allows for shorter electrical paths, which can enhance the performance of electronic devices. This is particularly important in high-frequency applications, where signal integrity is critical. SMT manufacturing enables the production of devices that perform better and meet the increasing demands of consumers.

Flexibility in Design

SMT manufacturing offers greater flexibility in design compared to traditional methods. Designers can create more complex and innovative products without being constrained by the limitations of through-hole technology.

Miniaturization

The ability to use smaller components allows for the miniaturization of electronic devices. This trend is particularly evident in consumer electronics, where compact designs are highly sought after. SMT manufacturing enables the creation of smaller, lighter devices that are easier to carry and use.

Versatile Component Options

SMT technology supports a wide range of component types, including passive and active components. This versatility allows manufacturers to experiment with different designs and configurations, leading to innovative products that can stand out in the market.

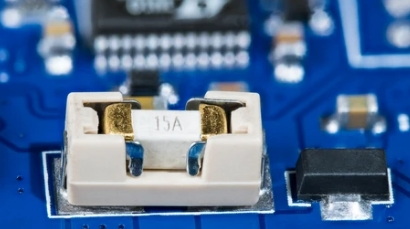

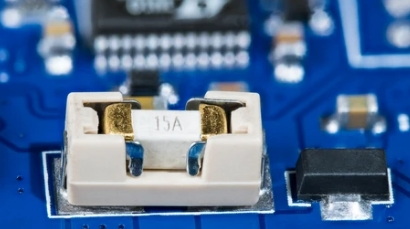

Enhanced Thermal Management

Thermal management is a critical aspect of electronic device design. SMT manufacturing provides better thermal management solutions compared to traditional methods.

Improved Heat Dissipation

The layout of SMT components allows for better heat dissipation. Components can be placed closer together, and the use of thermal vias can help manage heat more effectively. This is particularly important in high-power applications where overheating can lead to device failure.

Advanced Cooling Solutions

SMT manufacturing enables the integration of advanced cooling solutions, such as heat sinks and thermal pads, directly onto the PCB. This integration enhances the overall performance and reliability of electronic devices, making them suitable for demanding applications.

Conclusion

In conclusion, SMT manufacturing offers numerous benefits over traditional methods, including enhanced production efficiency, cost-effectiveness, improved product quality, design flexibility, and better thermal management. As the electronics industry continues to evolve, SMT will play a crucial role in meeting the demands for smaller, more efficient, and higher-performing devices. Manufacturers who adopt SMT technology will not only improve their production processes but also gain a competitive edge in the market.

FAQ

1. What is SMT manufacturing?

Answer: SMT manufacturing, or Surface Mount Technology manufacturing, is a process that involves mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for higher density and more efficient assembly compared to traditional methods.

2. What are the advantages of SMT over traditional methods?

Answer: The advantages of SMT over traditional methods include enhanced production efficiency, cost-effectiveness, improved product quality, design flexibility, and better thermal management.

3. How does SMT improve product reliability?

Answer: SMT improves product reliability by reducing mechanical stress on components due to their smaller size and lighter weight, leading to longer-lasting and more durable electronic devices.

4. Can SMT components be used in high-frequency applications?

Answer: Yes, SMT components are ideal for high-frequency applications because their close proximity on the PCB allows for shorter electrical paths, which enhances signal integrity and overall performance.

5. What role does automation play in SMT manufacturing?

Answer: Automation plays a significant role in SMT manufacturing by utilizing machines for pick-and-place operations, which increases assembly speed, reduces labor costs, and minimizes the risk of human error.