Content Menu

● Understanding SMT Assembly

● The Importance of Inspection in SMT Assembly

● Key Benefits of SMT Assembly Line Inspection

>> Enhanced Quality Assurance

>> Increased Efficiency

>> Cost Reduction

>> Improved Yield Rates

>> Compliance with Industry Standards

● Enhanced Process Control

● Increased Flexibility

● Better Resource Management

● Conclusion

● FAQ

>> 1. What is SMT assembly?

>> 2. What are the common inspection methods used in SMT assembly?

>> 3. How does SMT assembly line inspection improve product quality?

>> 4. What are the cost benefits of SMT assembly line inspection?

>> 5. How does inspection contribute to compliance with industry standards?

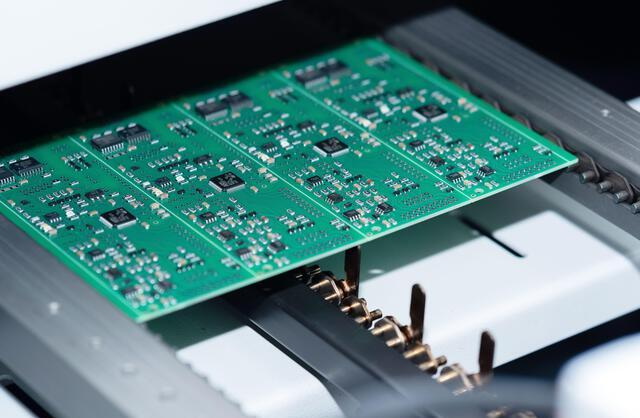

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for the efficient assembly of electronic components onto printed circuit boards (PCBs). As the demand for high-quality electronic devices continues to rise, the importance of effective inspection processes in SMT assembly lines cannot be overstated. This article explores the key benefits of SMT assembly line inspection, highlighting its role in enhancing product quality, reducing costs, and improving overall efficiency.

Understanding SMT Assembly

Before delving into the benefits of SMT assembly line inspection, it is essential to understand what SMT assembly entails. SMT is a method used to mount electronic components directly onto the surface of PCBs. This technique has several advantages over traditional through-hole technology, including:

- Miniaturization: SMT allows for smaller components, enabling the design of compact electronic devices.

- Higher Component Density: More components can be placed on a PCB, improving functionality without increasing size.

- Cost Efficiency: SMT reduces manufacturing costs due to less material usage and faster assembly processes.

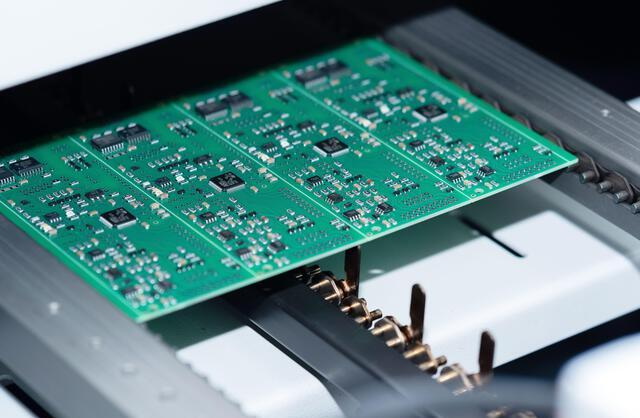

The Importance of Inspection in SMT Assembly

Inspection in SMT assembly is critical for ensuring that the final product meets quality standards. Various inspection methods are employed throughout the assembly process, including:

- Automated Optical Inspection (AOI): This method uses cameras to capture images of the PCB and compare them against predefined standards.

- X-ray Inspection: Used primarily for inspecting solder joints and hidden components, X-ray inspection provides a detailed view of the internal structure of the assembly.

- Functional Testing: This involves testing the assembled PCB to ensure it operates as intended.

Key Benefits of SMT Assembly Line Inspection

Enhanced Quality Assurance

One of the primary benefits of SMT assembly line inspection is the enhancement of quality assurance. By implementing rigorous inspection processes, manufacturers can identify defects early in the production cycle. This proactive approach helps in:

- Reducing Defect Rates: Early detection of defects minimizes the chances of faulty products reaching the market. For instance, AOI systems can detect misaligned components or insufficient solder, allowing for immediate corrective actions.

- Improving Customer Satisfaction: High-quality products lead to increased customer trust and satisfaction, which is crucial for brand reputation. When customers receive reliable products, they are more likely to become repeat buyers and recommend the brand to others.

Increased Efficiency

SMT assembly line inspection contributes significantly to operational efficiency. Automated inspection systems, such as AOI, can quickly analyze PCBs, allowing for:

- Faster Production Cycles: Automated inspections reduce the time spent on manual checks, speeding up the overall production process. This efficiency is particularly important in high-volume manufacturing environments where time-to-market is critical.

- Real-time Feedback: Immediate feedback on defects allows for quick adjustments in the assembly process, preventing further issues. This capability enables manufacturers to maintain a steady workflow and avoid bottlenecks.

Cost Reduction

Implementing effective inspection processes can lead to substantial cost savings. By catching defects early, manufacturers can avoid:

- Rework Costs: Identifying and correcting defects during the assembly process is less expensive than reworking completed products. For example, if a defect is found during AOI, the affected PCB can be corrected before it moves further down the production line, saving time and resources.

- Warranty Claims: High-quality products reduce the likelihood of warranty claims, saving manufacturers money in the long run. A strong reputation for quality can also lead to lower insurance premiums and reduced liability costs.

Improved Yield Rates

Yield rate refers to the percentage of products that pass inspection and meet quality standards. SMT assembly line inspection helps improve yield rates by:

- Identifying Process Inefficiencies: Inspection data can reveal patterns in defects, allowing manufacturers to address underlying issues in the assembly process. For instance, if a specific machine consistently produces defective boards, it can be serviced or replaced.

- Optimizing Component Placement: Accurate inspections ensure that components are placed correctly, reducing the likelihood of errors. This optimization is crucial for maintaining high production standards and minimizing waste.

Compliance with Industry Standards

Many industries have strict quality standards that must be met. SMT assembly line inspection helps manufacturers comply with these standards by:

- Providing Documentation: Inspection processes generate data that can be used to demonstrate compliance with industry regulations. This documentation is essential for audits and certifications, ensuring that manufacturers meet the necessary quality benchmarks.

- Enhancing Traceability: Detailed inspection records allow for better traceability of components and processes, which is essential for quality control. In the event of a product recall, having accurate records can significantly reduce the time and cost associated with identifying affected products.

Enhanced Process Control

Another significant benefit of SMT assembly line inspection is the enhancement of process control. By continuously monitoring the assembly process, manufacturers can:

- Implement Statistical Process Control (SPC): This technique uses statistical methods to monitor and control the manufacturing process. By analyzing data from inspections, manufacturers can identify trends and make informed decisions to improve quality.

- Facilitate Continuous Improvement: Regular inspection data can be used to drive continuous improvement initiatives. By analyzing defects and their root causes, manufacturers can implement changes that lead to better processes and products.

Increased Flexibility

In today's fast-paced electronics market, manufacturers must be able to adapt quickly to changing demands. SMT assembly line inspection provides increased flexibility by:

- Supporting Rapid Prototyping: Inspection processes can be adjusted to accommodate new designs and prototypes, allowing manufacturers to bring new products to market faster.

- Enabling Customization: As customer preferences evolve, manufacturers can quickly modify their inspection processes to ensure that customized products meet quality standards.

Better Resource Management

Effective inspection processes also contribute to better resource management. By identifying defects early, manufacturers can:

- Optimize Material Usage: Reducing waste from defective products allows for more efficient use of materials, which is both cost-effective and environmentally friendly.

- Improve Labor Efficiency: By minimizing the need for rework and repairs, manufacturers can allocate labor resources more effectively, focusing on value-added activities rather than correcting mistakes.

Conclusion

In conclusion, SMT assembly line inspection plays a vital role in the electronics manufacturing industry. By enhancing quality assurance, increasing efficiency, reducing costs, improving yield rates, ensuring compliance with industry standards, enhancing process control, providing increased flexibility, and enabling better resource management, inspection processes contribute significantly to the success of SMT assembly. As technology continues to evolve, the importance of effective inspection methods will only grow, making it essential for manufacturers to invest in advanced inspection technologies.

FAQ

1. What is SMT assembly?

Answer: SMT (Surface Mount Technology) assembly is a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact and efficient designs.

2. What are the common inspection methods used in SMT assembly?

Answer: Common inspection methods include Automated Optical Inspection (AOI), X-ray inspection, and functional testing, each serving different purposes in ensuring product quality.

3. How does SMT assembly line inspection improve product quality?

Answer: By identifying defects early in the production process, SMT assembly line inspection helps reduce defect rates, leading to higher quality products and increased customer satisfaction.

4. What are the cost benefits of SMT assembly line inspection?

Answer: Effective inspection processes can lead to significant cost savings by reducing rework costs, minimizing warranty claims, and optimizing material usage.

5. How does inspection contribute to compliance with industry standards?

Answer: Inspection processes generate documentation and enhance traceability, which are essential for demonstrating compliance with industry regulations and maintaining quality control.