Content Menu

● Introduction to SMT Reels

>> Importance of Standardization

● Industry Standards for SMT Reel Sizes

>> Reel Specifications by Component Type

● Challenges and Considerations

● Advantages of Standardized Reel Sizes

● Carrier Tape Specifications

● Future Developments in SMT Reel Technology

● Impact of Reel Size on Production Efficiency

● Conclusion

● Frequently Asked Questions

>> 1. What are the common reel sizes used in SMT manufacturing?

>> 2. Why is standardization of reel sizes important?

>> 3. How do reel sizes affect production efficiency?

>> 4. What are the challenges associated with improper reel size selection?

>> 5. How will future technologies impact SMT reel management?

● Citations:

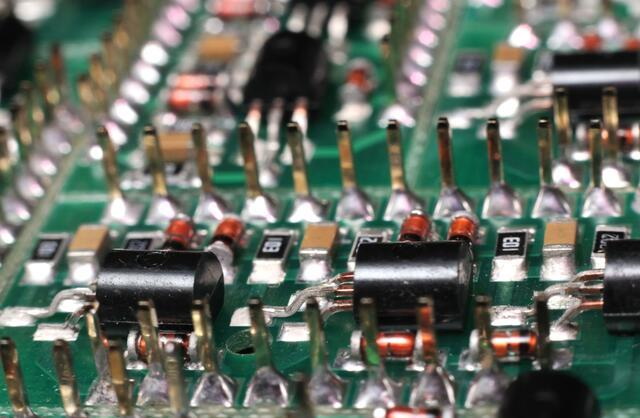

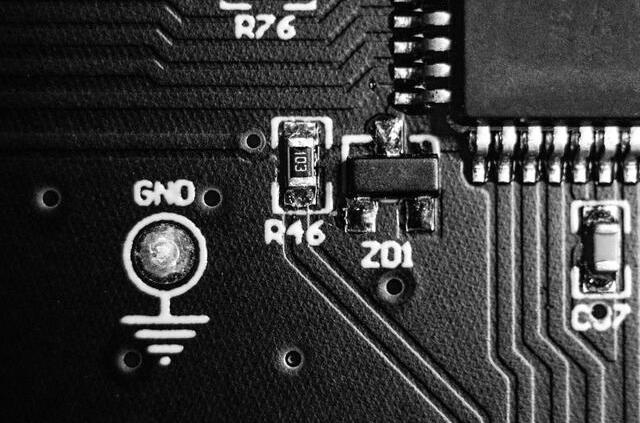

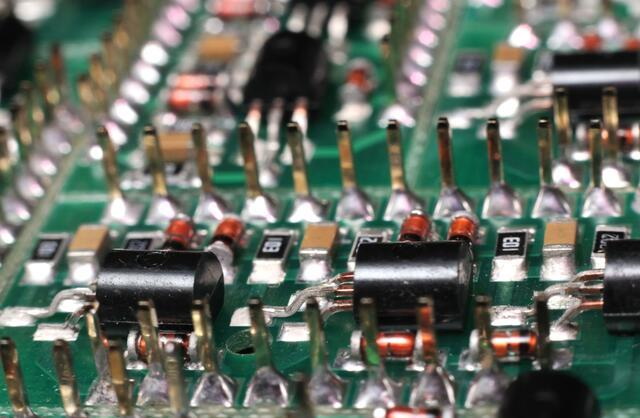

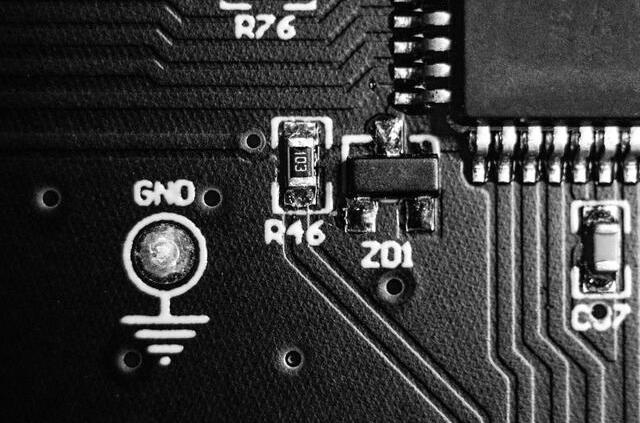

The use of Surface Mount Technology (SMT) reels is a crucial aspect of modern electronic manufacturing, particularly in the assembly of printed circuit boards (PCBs). SMT reels are designed to efficiently store and dispense components such as resistors, capacitors, and integrated circuits, facilitating their placement onto PCBs using automated pick-and-place machines. Understanding the industry standards for SMT reel sizes is essential for optimizing production efficiency, ensuring compatibility with manufacturing equipment, and maintaining component integrity.

Introduction to SMT Reels

SMT reels are typically made from plastic or cardboard and come in various sizes to accommodate different types of components and production volumes. The standardization of reel sizes is important for ensuring that components are properly protected during storage and transportation and that they can be easily integrated into automated assembly processes.

Importance of Standardization

Standardizing SMT reel sizes helps manufacturers in several ways:

- Efficiency in Production: Standard reel sizes allow for easier integration with pick-and-place machines, reducing setup times and increasing production efficiency.

- Component Protection: Properly sized reels ensure that components are securely stored, minimizing the risk of damage during handling and shipping.

- Cost-Effectiveness: Standardization reduces the need for custom reel sizes, which can be more expensive and may require specialized handling equipment.

Industry Standards for SMT Reel Sizes

Industry standards for SMT reel sizes are generally aligned with the requirements of surface mount components and the capabilities of manufacturing equipment. Common reel sizes include:

- Reel Diameter: Typically ranges from 7 inches to 15 inches, with 7-inch reels used for low-volume or small components and larger reels (13 inches and 15 inches) for higher volumes[3][6].

- Reel Width: Common widths include 4mm, 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, and 56mm, depending on component size and weight[2][5].

Reel Specifications by Component Type

Different component types require specific reel sizes and configurations to ensure proper handling and placement:

- Small Components (e.g., 0402, 0603 Resistors/Capacitors): Often packaged on smaller reels (e.g., 7-inch diameter) with narrower widths (e.g., 8mm)[6].

- Larger Components (e.g., QFN, DFN Packages): Typically require larger reels (e.g., 13-inch diameter) with wider widths to accommodate their size and lead count[7].

Challenges and Considerations

While standardizing reel sizes simplifies the manufacturing process, there are challenges and considerations that manufacturers must address:

- Machine Compatibility: Ensuring that reel sizes are compatible with pick-and-place machines is crucial to avoid downtime and re-reeling components[2].

- Component Damage: Improper handling or storage can lead to component damage, emphasizing the need for proper reel size selection and handling practices.

Advantages of Standardized Reel Sizes

Standardized reel sizes offer several advantages in SMT manufacturing:

- Increased Efficiency: Standard reels can be easily loaded onto machines, reducing setup times and improving production throughput.

- Reduced Costs: By minimizing the need for custom reels and specialized handling equipment, manufacturers can lower their operational costs.

- Improved Quality Control: Properly sized reels help maintain component integrity, reducing defects and improving overall product quality.

Carrier Tape Specifications

Carrier tapes are an integral part of SMT reels, providing a protective environment for components during storage and transportation. Key specifications include:

- Tape Width: Must match the component size to ensure proper fit and protection[3].

- Pocket Size and Spacing: Pockets must be sized to accommodate components securely, with spacing adjusted to facilitate efficient component feeding[3].

Future Developments in SMT Reel Technology

As technology advances, there is a growing focus on integrating SMT reel systems with advanced manufacturing technologies:

- Miniaturization: Smaller components require more precise reel sizes and handling techniques to ensure efficient placement.

- Digital Twin Technologies: Using digital models to simulate and optimize reel management and component placement can further enhance production efficiency.

- Automated Storage Systems: Implementing automated storage solutions for reels can improve inventory management and reduce handling times.

Impact of Reel Size on Production Efficiency

The choice of reel size significantly impacts production efficiency, particularly in high-volume manufacturing environments:

- Optimized Machine Setup: Standard reel sizes allow for optimized machine setup, reducing the time spent on adjusting feeders and loading components.

- Reduced Downtime: Ensuring compatibility between reel sizes and machine capabilities minimizes downtime due to re-reeling or component misalignment.

- Enhanced Component Protection: Properly sized reels protect components from damage, reducing waste and improving overall product quality.

Conclusion

Understanding and adhering to industry standards for SMT reel sizes is vital for optimizing electronic manufacturing processes. By selecting the appropriate reel sizes based on component types and production volumes, manufacturers can improve efficiency, reduce costs, and enhance product quality. As technology continues to evolve, the integration of SMT reel systems with advanced manufacturing technologies will play a crucial role in meeting future production demands.

Frequently Asked Questions

1. What are the common reel sizes used in SMT manufacturing?

- Common reel sizes include diameters of 7 inches and 13 inches, with widths ranging from 4mm to 56mm, depending on the component size and type[2][3].

2. Why is standardization of reel sizes important?

- Standardization ensures compatibility with manufacturing equipment, reduces setup times, and helps maintain component integrity during storage and handling.

3. How do reel sizes affect production efficiency?

- Properly sized reels can be easily integrated with pick-and-place machines, reducing setup times and improving production throughput. Incorrect reel sizes can lead to downtime and increased costs.

4. What are the challenges associated with improper reel size selection?

- Improper reel size selection can lead to component damage, machine incompatibility, and increased production costs due to the need for re-reeling or custom handling equipment.

5. How will future technologies impact SMT reel management?

- Future technologies, such as miniaturization and digital twin technologies, will enhance production efficiency by optimizing reel management and component placement processes.

Citations:

[1] https://www.ti.com/lit/ug/snoa403i/snoa403i.pdf

[2] https://forum.digikey.com/t/importance-of-tape-and-reel-specs/4790

[3] https://www.proex1.com/blog/posts/2022/april/a-guide-to-semiconductor-tape-and-reel-solutions/

[4] https://www.protoexpress.com/kb/different-smd-component-package-sizes/

[5] https://www.vishay.com/docs/60034/tapereeldalethinfilm.pdf

[6] https://www.topline.tv/SMDnomen.pdf

[7] https://www.onsemi.com/pub/collateral/brd8011-d.pdf

[8] https://www.digikey.com/htmldatasheets/production/778632/0/0/1/tape-reel-packaging-spec.pdf

[9] https://www.proex1.com/blog/posts/2023/january/the-complete-guide-to-tape-and-reel-packaging-standards/

[10] https://global.neotel.tech/2022/02/24/5-things-you-must-know-about-smt-reel/

[11] https://asselems.com/en/best-practices-in-smt-assembly

[12] https://core-emt.com/imperial-code-vs-metric-code-smd-components-sizes

[13] https://www.vishay.com/docs/80125/smdtapereel.pdf

[14] https://www.surfacemountprocess.com/tape-and-reel-packaging-standards.html

[15] https://www.ultralibrarian.com/2024/01/25/smt-components-size-chart-what-to-know-ulc

[16] https://www.xmsinho.com/plastic-reels-for-industry-smt/

[17] https://www.minicircuits.com/pdfs/tape_reel.pdf

[18] https://quintanarootri.com/pages/wetsuit-2-0-sizing-guide