Content Menu

● Understanding the SMT Stencil Printing Process

● Types of SMT Stencils

>> 1. Framed SMT Stencils

>> 2. Frameless SMT Stencils

>> 3. Step Stencils

>> 4. Electroformed SMT Stencils

● SMT Stencil Materials

>> Stainless Steel

>> Nickel Alloys

>> Other Materials

● Manufacturing Processes of SMT Stencils

● Key Considerations for SMT Stencil Design

● How to Choose the Right SMT Stencil?

● Conclusion

● FAQ

>> 1. What is the main function of an SMT stencil in the SMT printing process?

>> 2. How does a framed SMT stencil differ from a frameless stencil?

>> 3. Why are step stencils used in SMT printing?

>> 4. What materials are commonly used for SMT stencils?

>> 5. How does stencil thickness affect the SMT printing process?

Surface Mount Technology (SMT) stencil printing process is a critical step in the assembly of printed circuit boards (PCBs). The stencil serves as a precise template that allows solder paste to be applied accurately to the PCB pads where components will be mounted. Choosing the right type of stencil is essential for ensuring high-quality solder joints, minimizing defects, and optimizing production efficiency. This article explores the different types of stencils used in the SMT printing process, their materials, manufacturing methods, and how to select the best stencil for your application.

Understanding the SMT Stencil Printing Process

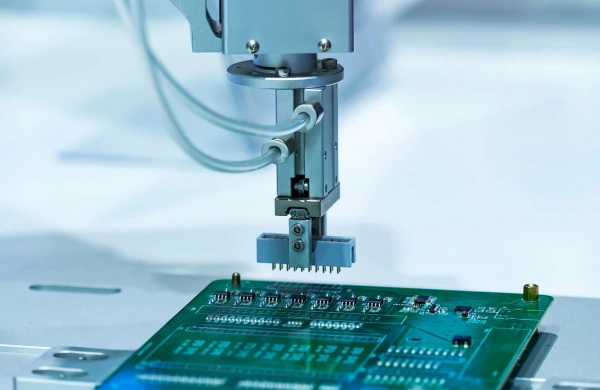

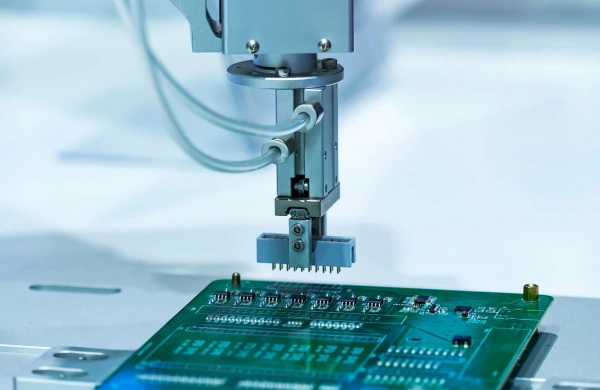

The SMT stencil printing process involves placing a thin metal stencil over the PCB and using a squeegee to spread solder paste across the stencil openings. The solder paste passes through the stencil apertures and deposits onto the PCB pads in the exact shape and volume needed for each component. After printing, the stencil is lifted, leaving solder paste precisely applied to the PCB, ready for component placement and reflow soldering.

This process requires the stencil to be highly accurate, flat, and durable to prevent defects such as insufficient solder, bridging, or misalignment. The stencil design and material directly impact the quality of the solder paste deposition and, consequently, the reliability of the final assembly.

The SMT stencil printing process is often considered the most critical step in surface mount assembly because errors here can propagate through the entire manufacturing flow, causing costly rework or scrap. A well-designed stencil ensures uniform solder paste volume, which is essential for achieving consistent solder joints and minimizing defects such as tombstoning, solder bridging, and insufficient solder.

Types of SMT Stencils

There are several types of SMT stencils, each designed to meet specific production needs, volume requirements, and PCB designs. The main types include:

1. Framed SMT Stencils

Framed SMT stencils are metal stencil sheets permanently fixed and tightly stretched within a rigid metal frame. This frame provides excellent stability and flatness during the printing process, making framed stencils ideal for high-volume and repetitive SMT assembly lines.

Advantages:

- High printing accuracy and repeatability due to the stable frame structure

- Durable and reusable for large production runs, reducing long-term costs

- Easier and faster alignment with PCBs due to the frame's rigidity and standard size

- Reduced risk of stencil deformation during use, maintaining print quality over time

Disadvantages:

- Higher initial cost due to the frame and assembly process

- Requires additional storage space because of the frame size

- Heavier and more expensive to ship compared to frameless stencils

Framed stencils are widely used in automated SMT lines where consistent quality and throughput are critical. They are especially beneficial in environments where thousands of PCBs are printed daily, as their durability and ease of handling improve overall efficiency.

2. Frameless SMT Stencils

Frameless stencils, also known as foil stencils, consist of just the thin metal stencil sheet without a surrounding frame. They are more economical and lightweight compared to framed stencils.

Advantages:

- Lower cost, making them suitable for prototyping and small batch production

- Easy to store and ship due to compact size and light weight

- Flexible and can be customized for specific PCB sizes or shapes

- Can be mounted on reusable frames or tensioning systems as needed

Disadvantages:

- Requires manual mounting on a frame or tensioning system before use, which can add time and variability

- Less stable during printing, which may affect print quality in high-volume or high-speed runs

- More prone to deformation or damage if not handled carefully

Frameless stencils are preferred for hobbyists, prototypes, or low-volume production where cost and flexibility are more important than long-term durability. They allow quick changes and adjustments without the need for a dedicated frame, which is useful during PCB design iterations.

3. Step Stencils

Step stencils have varying thicknesses across the stencil surface, allowing different solder paste volumes to be deposited on different parts of the PCB. This is particularly useful when a PCB contains components with widely varying pad sizes and solder paste requirements.

Advantages:

- Precise control of solder paste volume for mixed component types on the same board

- Improves solder joint quality for fine-pitch and large components simultaneously

- Reduces defects caused by over- or under-deposition of solder paste, such as bridging or insufficient solder

- Enables better thermal and mechanical reliability by optimizing solder volume per pad

Disadvantages:

- More complex and costly to manufacture due to multi-thickness design

- Requires careful design and alignment during printing to ensure correct paste deposition

- May require more frequent inspection and maintenance to maintain print quality

Step stencils are used in advanced SMT applications where solder paste volume control is critical to assembly quality. For example, boards with a mix of tiny 0201 components and large connectors benefit from step stencils to optimize solder paste volume for each pad type.

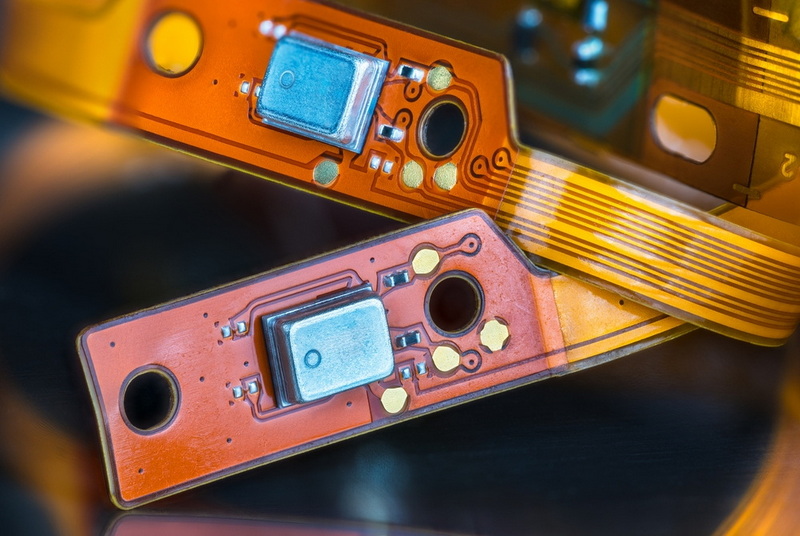

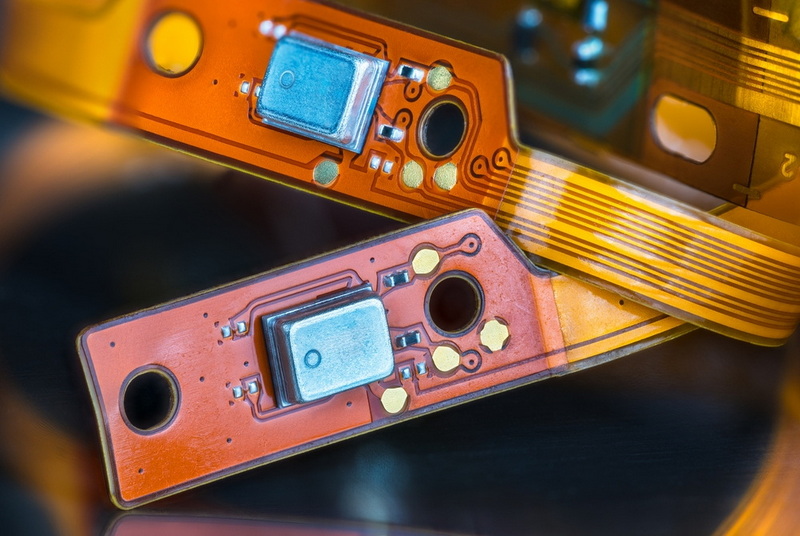

4. Electroformed SMT Stencils

Electroformed stencils are made by electroplating nickel onto a patterned master, resulting in a stencil with very smooth aperture walls and high precision. This manufacturing process produces stencils that excel in paste release and durability.

Advantages:

- Superior paste release due to smooth, vertical aperture walls, minimizing solder paste sticking inside apertures

- Extremely high precision and suitable for ultra-fine pitch components (e.g., 0.3mm pitch and below)

- Longer lifespan compared to laser-cut stainless steel stencils (can last up to 100,000 prints)

- Consistent aperture dimensions, reducing print defects and improving yield

Disadvantages:

- Higher cost and longer manufacturing lead time compared to laser-cut stencils

- Less common for general use, typically reserved for specialized applications requiring ultra-fine pitch or high-volume production

- Nickel material may require special handling and cleaning procedures

Electroformed stencils are ideal for high-precision, high-volume SMT production with very fine-pitch components, such as those found in smartphones, medical devices, and aerospace electronics.

SMT Stencil Materials

The material of the stencil affects its durability, print quality, and compatibility with solder paste and cleaning processes. The most common materials are:

Stainless Steel

- Most widely used material for SMT stencils due to its excellent mechanical properties

- Offers excellent durability, corrosion resistance, and dimensional stability under repeated use and cleaning

- Suitable for most applications and solder pastes, including lead-free and no-clean types

- Cost-effective and provides a good balance of performance and price

- Typically available in thicknesses ranging from 0.05mm to 0.15mm

Nickel Alloys

- Includes electroformed nickel stencils, which provide smoother aperture walls for better paste release

- Higher mechanical strength and wear resistance, resulting in longer stencil life

- Suitable for ultra-fine pitch and high-volume production requiring longer stencil life

- More expensive than stainless steel but justified by improved print quality and durability

Other Materials

- Phosphor bronze and copper are sometimes used but are less common due to lower durability or cost inefficiency

- These materials may be used in specialized applications but generally do not offer the longevity or precision of stainless steel or nickel

Manufacturing Processes of SMT Stencils

The quality of SMT stencils depends significantly on the manufacturing process:

- Laser Cutting: The most common method, using high-precision lasers to cut apertures in stainless steel sheets. Laser-cut stencils offer excellent accuracy, repeatability, and quick turnaround times. Laser cutting allows for complex aperture shapes and fine-pitch designs, making it suitable for most SMT stencil applications.

- Electroforming: Produces nickel stencils by electroplating, resulting in smooth aperture walls and very fine detail for high-precision applications. The electroforming process creates stencils with near-perfect aperture geometry, improving paste release and print consistency.

- Etching: An older method involving chemical etching of stencil apertures. While still used in some cases, etching generally offers less precision and repeatability compared to laser cutting and electroforming, and is less common in modern SMT production.

Laser cutting is preferred for most SMT stencil applications due to its balance of precision, speed, and cost. Electroforming is reserved for specialized applications requiring ultra-fine pitch and superior paste release.

Key Considerations for SMT Stencil Design

Beyond stencil type and material, several design factors influence the success of the SMT stencil printing process:

- Aperture Design: Aperture shape and size affect solder paste volume and release. Common aperture shapes include square, rectangular, circular, and trapezoidal. Rounded corners are often preferred to improve paste release and reduce solder bridging.

- Aperture-to-Pad Ratio: Maintaining an appropriate ratio between aperture size and PCB pad size is critical to avoid insufficient or excessive solder paste deposition.

- Stencil Thickness: Determines the volume of solder paste deposited. Typical thickness ranges from 0.1mm to 0.15mm. Thicker stencils deposit more paste, which is necessary for larger pads or components requiring more solder.

- Surface Finish: A smooth stencil surface reduces solder paste sticking and improves print consistency. Electroformed stencils typically have superior surface finish compared to laser-cut stainless steel.

- Cleaning and Maintenance: Stencils must be cleaned regularly to prevent clogging of apertures and maintain print quality. Material choice affects cleaning method compatibility.

How to Choose the Right SMT Stencil?

When selecting an SMT stencil for your SMT printing process, consider the following factors:

- Production Volume: Framed stencils are best for high-volume production; frameless stencils suit prototyping and small batches.

- Component Types and Pitch: Fine-pitch or mixed component sizes may require step or electroformed stencils for precise paste deposition.

- Cost vs. Durability: Frameless and prototype stencils are cheaper but less durable; framed and electroformed stencils cost more but last longer.

- Stencil Thickness: Determines the volume of solder paste deposited; typical thickness ranges from 0.1mm to 0.15mm, but step stencils offer variable thickness.

- Material Compatibility: Ensure the stencil material is compatible with your solder paste and cleaning processes.

- Alignment and Handling: Framed stencils provide easier alignment and handling in automated lines.

- PCB Design Complexity: Complex boards with mixed pad sizes and fine-pitch components benefit from advanced stencil types like step or electroformed stencils.

By matching these criteria with your PCB design and assembly requirements, you can select the stencil type that optimizes your SMT stencil printing process for quality and efficiency.

Conclusion

The SMT stencil printing process is foundational to the success of surface mount assembly. The choice of stencil type-framed, frameless, step, or electroformed-along with the stencil material and manufacturing method, directly affects solder paste deposition accuracy, print quality, and production efficiency. Framed stencils dominate high-volume production for their stability and durability, while frameless stencils provide cost-effective flexibility for prototyping and small runs. Step stencils offer advanced control for complex boards, and electroformed stencils deliver unmatched precision for ultra-fine pitch components. Understanding these types and their characteristics enables manufacturers to optimize their SMT printing process, reduce defects, and improve overall product reliability.

Selecting the right stencil is not just about cost but also about achieving the best balance between print quality, production volume, and component requirements. As SMT assembly continues to evolve with miniaturization and complexity, stencil technology will remain a key enabler of manufacturing excellence.

FAQ

1. What is the main function of an SMT stencil in the SMT printing process?

An SMT stencil acts as a precise template that allows solder paste to be deposited accurately onto the PCB pads, ensuring reliable solder joints during reflow soldering.

2. How does a framed SMT stencil differ from a frameless stencil?

A framed stencil is permanently fixed within a metal frame providing stability and ease of alignment, ideal for high-volume production. Frameless stencils are just the metal foil without a frame, more economical and flexible for prototyping or small batches.

3. Why are step stencils used in SMT printing?

Step stencils have varying thicknesses to control the volume of solder paste deposited on different parts of the PCB, which is essential when components on the same board have different solder paste requirements.

4. What materials are commonly used for SMT stencils?

Stainless steel is the most common material due to its durability and cost-effectiveness. Electroformed nickel is used for high-precision applications requiring smooth aperture walls and longer stencil life.

5. How does stencil thickness affect the SMT printing process?

Stencil thickness determines the volume of solder paste deposited. Thicker stencils deposit more paste, which is necessary for larger pads, while thinner stencils are used for fine-pitch components to avoid solder bridging.