Content Menu

● Introduction to SMT Stencils

● Types of SMT Stencils Available in China

>> 1. Laser Cut SMT Stencils

>> 2. Chemically Etched SMT Stencils

>> 3. Electroformed SMT Stencils

>> 4. Stainless Steel SMT Stencils with Aluminum Frames

>> 5. Mylar (Plastic) SMT Stencils

● Materials Used in SMT Stencils in China

● SMT Stencil Production Process in China

● Advantages of Choosing SMT Stencils from China

>> Cost-Effectiveness

>> Advanced Technology and Precision

>> Customization and Flexibility

>> Fast Turnaround Times

>> Comprehensive Customer Support

● Applications of SMT Stencils from China

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the most common type of SMT stencil made in China?

>> 2. How does laser cutting improve SMT stencil quality?

>> 3. Are chemically etched stencils still used in China?

>> 4. What materials are typically used for SMT stencils in China?

>> 5. How quickly can SMT stencils be delivered from China?

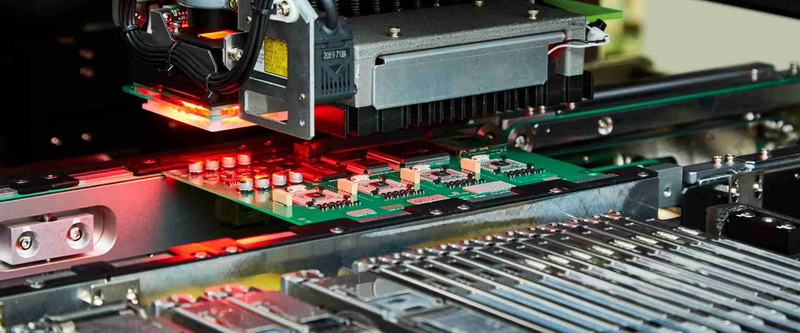

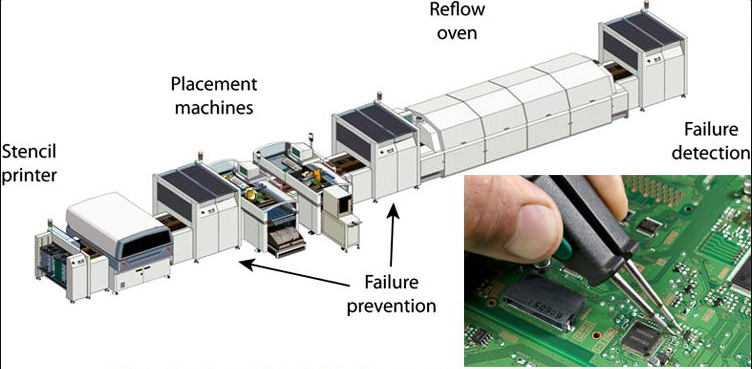

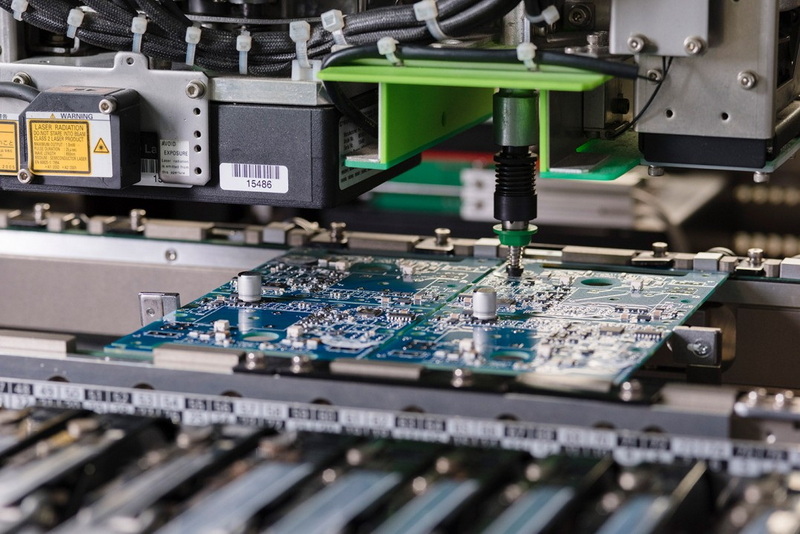

Surface Mount Technology (SMT) stencils are indispensable tools in the electronics manufacturing industry, playing a critical role in the assembly of printed circuit boards (PCBs). As one of the world's largest electronics manufacturing hubs, China produces a wide variety of SMT stencils to cater to the diverse needs of global and domestic electronics manufacturers. This comprehensive article delves into the different types of SMT stencils available in China, their manufacturing processes, materials, applications, and the benefits of sourcing SMT stencils from China.

Introduction to SMT Stencils

An SMT stencil is a thin sheet with precisely cut openings that correspond to the solder pads on a PCB. These openings allow solder paste to be deposited accurately and consistently onto the PCB before components are placed and soldered. The quality and type of SMT stencil directly influence the solder paste deposition, which in turn affects the reliability and performance of the final electronic assembly.

China has emerged as a dominant player in the production of SMT stencils, thanks to its advanced manufacturing technologies, skilled workforce, and cost advantages. The country's SMT stencil manufacturers offer a broad spectrum of stencil types, catering to everything from simple prototypes to complex, high-volume production runs.

Types of SMT Stencils Available in China

The classification of SMT stencils in China is mainly based on the manufacturing process and the materials used. Below are the primary types of SMT stencils produced in China:

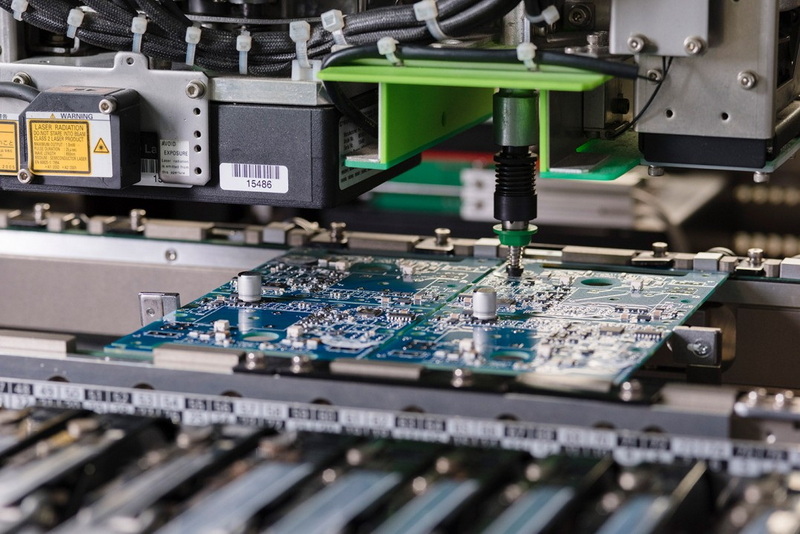

1. Laser Cut SMT Stencils

Laser cut SMT stencils are the most prevalent type available in China and are considered the industry standard for high-quality stencil production.

- Manufacturing Process: A high-precision laser beam cuts apertures into a stainless steel sheet. The laser's accuracy allows for extremely fine apertures with smooth edges.

- Features:

- Precision tolerance as tight as ±0.003mm.

- Conical aperture shapes that facilitate better solder paste release.

- Fast cutting speeds, capable of processing thousands of apertures per hour.

- Ability to handle complex and fine-pitch PCB designs.

- Materials: Typically made from 304HTA stainless steel, which offers excellent durability and corrosion resistance.

- Applications: Ideal for high-density PCB assemblies, including smartphones, computers, and other consumer electronics.

- Advantages: Superior precision, repeatability, and consistent quality make laser cut stencils the preferred choice for most manufacturers.

Chinese companies such as JHYPCB, MKTPCB, and other leading stencil suppliers have optimized laser cutting technology to provide fast turnaround times and competitive pricing, making China a go-to source for laser cut SMT stencils.

2. Chemically Etched SMT Stencils

Chemical etching is one of the older methods of stencil production but is still used in China for specific applications.

- Manufacturing Process: The stencil sheet is coated with a photoresist, exposed to UV light through a photomask, and then developed. The exposed areas are etched away using acid or other chemicals to create apertures.

- Features:

- Suitable for thicker stencil materials.

- Aperture edges may be less smooth and less precise than laser cut stencils.

- Lower cost compared to laser cutting.

- Materials: Stainless steel or nickel alloy sheets.

- Applications: Used mainly for simpler PCB designs or when cost constraints outweigh precision requirements.

- Advantages: Cost-effective for low-complexity stencil needs and prototypes.

While chemical etching is less common for modern, high-density PCB production, it remains a viable option for certain manufacturing scenarios in China.

3. Electroformed SMT Stencils

Electroforming is a specialized process that produces ultra-thin and highly precise SMT stencils.

- Manufacturing Process: Metal is deposited onto a patterned mold through an electrochemical process, building up the stencil layer by layer.

- Features:

- Extremely thin stencil thicknesses, often less than 50 microns.

- Smooth aperture walls with excellent definition.

- High precision suitable for ultra-fine pitch components.

- Materials: Nickel alloy is the preferred material due to its strength and fine detail capabilities.

- Applications: Used in high-end electronics manufacturing where ultra-fine solder paste deposition is critical.

- Advantages: Provides the highest precision and best solder paste release for the most demanding PCB assemblies.

Electroformed stencils are less common but available through specialized Chinese manufacturers focusing on high-end electronics markets.

4. Stainless Steel SMT Stencils with Aluminum Frames

Most SMT stencils in China are stainless steel sheets mounted on aluminum frames to provide rigidity and ease of handling.

- Features:

- Aluminum frames add structural support, preventing warping during the printing process.

- Frames come in various sizes to accommodate different PCB dimensions.

- The combination ensures stencil flatness and consistent printing.

- Applications: Widely used in all types of SMT assembly lines.

- Advantages: Durable and lightweight, these framed stencils are the industry standard for production environments.

Many Chinese manufacturers offer customizable frame sizes and options, allowing clients to specify frame dimensions and stencil thicknesses to suit their production needs.

5. Mylar (Plastic) SMT Stencils

Mylar or plastic stencils are less common but still available in China, mainly for prototyping or educational purposes.

- Manufacturing Process: Apertures are cut into a thin plastic sheet.

- Features:

- Lightweight and inexpensive.

- Lower durability and precision compared to metal stencils.

- Applications: Suitable for low-volume runs, prototypes, or training environments.

- Advantages: Easy to produce and handle, ideal for quick testing but not recommended for mass production.

Materials Used in SMT Stencils in China

The choice of material significantly influences the stencil's performance, durability, and cost. The primary materials used in China's SMT stencil manufacturing include:

- 304HTA Stainless Steel: The industry standard for laser cut stencils, offering excellent corrosion resistance, durability, and precision.

- Nickel Alloy: Used primarily in electroformed stencils, nickel provides superior detail for ultra-fine pitch applications.

- Mylar (Plastic): Used for low-cost, low-precision applications such as prototypes or educational tools.

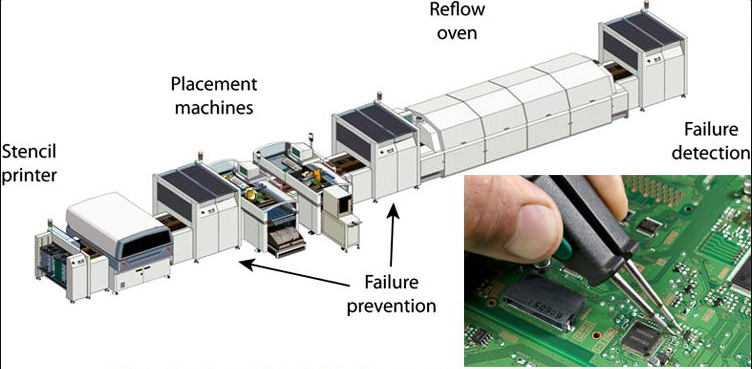

SMT Stencil Production Process in China

The production of SMT stencils in China follows a rigorous process to ensure quality and precision:

1. Stencil Design: Engineers use CAD software to create detailed aperture patterns based on the PCB layout and component placement data.

2. Material Preparation: Selection and preparation of metal sheets or plastic films.

3. Cutting or Etching: Depending on the type, apertures are created using laser cutting, chemical etching, or electroforming.

4. Polishing: Electrolytic or mechanical polishing smooths aperture edges to improve solder paste release.

5. Cleaning: Thorough cleaning removes residues and contaminants that could affect solder paste application.

6. Quality Inspection: Aperture dimensions, stencil flatness, and surface finish are inspected using optical and mechanical measurement tools.

7. Packaging and Delivery: Stencils are carefully packaged to prevent damage during shipping.

Chinese manufacturers have optimized these steps to reduce lead times, often delivering standard laser cut SMT stencils within 12 to 48 hours.

Advantages of Choosing SMT Stencils from China

Cost-Effectiveness

China's large-scale manufacturing infrastructure and competitive labor costs enable stencil producers to offer highly affordable prices without compromising quality.

Advanced Technology and Precision

The adoption of state-of-the-art laser cutting machines and quality control systems ensures that Chinese SMT stencils meet international standards for precision and reliability.

Customization and Flexibility

Chinese manufacturers provide extensive customization options, including stencil thickness, aperture shapes, frame sizes, and surface finishes, catering to a wide range of PCB assembly requirements.

Fast Turnaround Times

Thanks to streamlined production processes and efficient supply chains, many Chinese stencil suppliers can deliver orders rapidly, supporting fast-paced electronics manufacturing environments.

Comprehensive Customer Support

Many suppliers offer engineering consultation, stencil design optimization, and after-sales support, helping customers achieve optimal solder paste printing results.

Applications of SMT Stencils from China

SMT stencils manufactured in China are widely used across various industries, including:

- Consumer electronics (smartphones, tablets, laptops)

- Automotive electronics

- Industrial control systems

- Medical devices

- Telecommunications equipment

- Aerospace and defense electronics

The versatility and quality of Chinese SMT stencils make them suitable for both high-volume production and specialized, high-precision applications.

Conclusion

China's SMT stencil industry offers a comprehensive range of stencil types, each designed to meet specific manufacturing needs. From the highly precise laser cut stencils that dominate the market to cost-effective chemically etched options and ultra-fine electroformed stencils, Chinese manufacturers provide solutions for virtually every PCB assembly challenge. With advanced technology, competitive pricing, rapid delivery, and extensive customization capabilities, sourcing SMT stencils from China is a strategic choice for electronics manufacturers worldwide seeking quality and efficiency.

Frequently Asked Questions (FAQ)

1. What is the most common type of SMT stencil made in China?

The most common type is the laser cut SMT stencil, renowned for its high precision and suitability for complex, fine-pitch PCB designs.

2. How does laser cutting improve SMT stencil quality?

Laser cutting produces smooth, conical apertures with tight tolerances, which enhances solder paste release and printing accuracy.

3. Are chemically etched stencils still used in China?

Yes, chemically etched stencils are used primarily for simpler PCB designs and when lower costs are a priority, though they offer less precision than laser cut stencils.

4. What materials are typically used for SMT stencils in China?

The primary materials are 304HTA stainless steel for laser cut stencils, nickel alloy for electroformed stencils, and Mylar plastic for low-cost prototypes.

5. How quickly can SMT stencils be delivered from China?

Delivery times vary but can be as fast as 12 hours for standard laser cut stencils, with typical lead times ranging from 1 to 2 days depending on order complexity.