Content Menu

● Understanding SMT Feeders

● Types of SMT Component Feeders

● Functionality and Benefits of SMT Feeders

● Integration with SMT Assembly Lines

● Choosing the Right SMT Feeder

● Advancements in SMT Feeder Technology

● Common Applications of SMT Feeders

● Challenges in Using SMT Feeders

● Future Trends in SMT Feeding Technology

● Case Studies Highlighting Feeder Effectiveness

>> 1. Consumer Electronics Manufacturer DEF

>> 2. Automotive Electronics Manufacturer ABC

>> 3. Medical Device Company XYZ

● Conclusion

● FAQs

>> 1. What is an SMT feeder?

>> 2. What are the main types of SMT feeders?

>> 3. How do tape feeders work?

>> 4. Why are tray feeders important?

>> 5. What factors should be considered when choosing an SMT feeder?

● Citations:

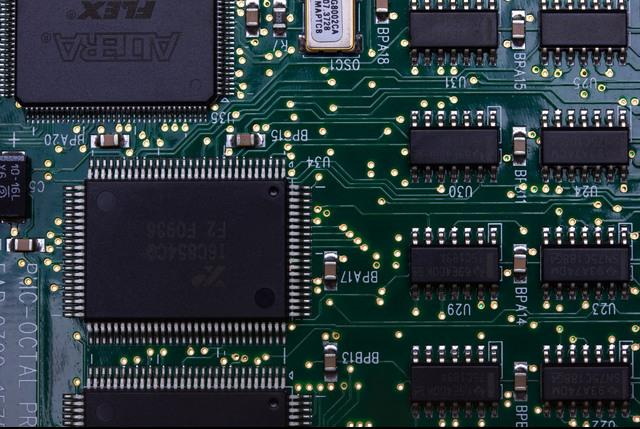

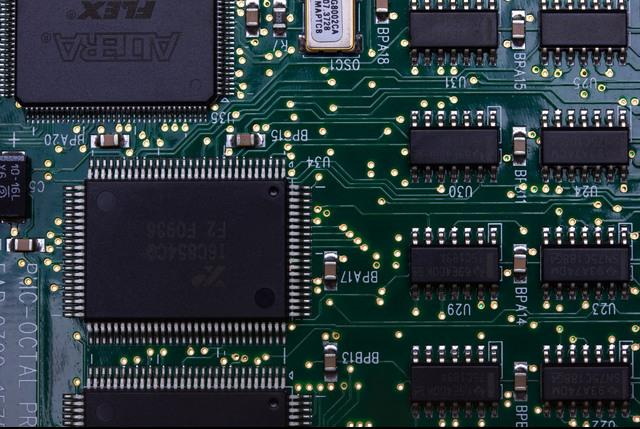

Surface Mount Technology (SMT) has revolutionized the landscape of electronics manufacturing, enabling the efficient assembly of components onto printed circuit boards (PCBs). A crucial element in this process is the SMT feeder, which is responsible for delivering components to pick-and-place machines with precision and speed. This article delves into the various types of SMT component feeders, their functionalities, and their significance in the manufacturing process.

Understanding SMT Feeders

SMT feeders are devices designed to hold and feed electronic components such as resistors, capacitors, and integrated circuits (ICs) to pick-and-place machines. These feeders ensure that components are delivered accurately, optimizing the assembly process. The choice of feeder significantly impacts production efficiency, placement accuracy, and overall manufacturing costs.

Types of SMT Component Feeders

There are several types of SMT feeders available, each tailored to accommodate specific component sizes, shapes, and production requirements. Below are the most common types:

- Tape Feeders: The most widely used type of feeder in SMT assembly. Tape feeders utilize reels of adhesive tape to securely hold components. They unwind the tape to present each component to the pick-and-place machine's nozzle. This type is suitable for small components like surface mount devices (SMDs) and is known for its reliability and ease of integration.

- Tray Feeders: These feeders use trays with compartments to hold larger or irregularly shaped components. Tray feeders can be single-layer or multi-layer structures, allowing manufacturers to handle a variety of component types efficiently. They are particularly useful for delicate or expensive components that require careful handling.

- Stick Feeders: Designed for components packaged in linear sticks, stick feeders utilize gravity or vibration to move components to the pick-up location. They are ideal for small ICs and other non-polar rectangular or cylindrical components.

- Tube Feeders: Tube feeders are used for long and delicate components such as LEDs or resistors. They gently guide components from a refillable tube to the pick-up point, ensuring minimal damage during transit. However, tube feeders may exhibit stability issues that can affect production efficiency.

- Vibratory Bowl Feeders: These feeders use vibration to orient and feed components into a pick-and-place machine. They are effective for larger components or those with irregular shapes that do not fit well into tape or stick feeders.

- Bulk Feeders: Bulk feeders handle chip-style components that are used in large quantities. They dispense components stored in bulk cases using a unique rotary positioning mechanism. While generally cheaper than tape feeders, bulk feeders may face challenges related to component debris during feeding.

- Direct Die Feeders: These specialized feeders are used for flip-chip or chip-on-board applications. They eliminate the need for separate production lines for different types of SMT processes by combining them into one system, enhancing speed and flexibility.

Functionality and Benefits of SMT Feeders

SMT feeders offer several advantages that contribute to improved production efficiency:

- Precision Component Handling: By ensuring accurate positioning of components, SMT feeders minimize placement errors and enhance the quality of PCB assemblies.

- Enhanced Production Efficiency: Automated feeding processes significantly increase throughput, reducing cycle times and improving overall efficiency.

- Flexibility and Adaptability: Different types of SMT feeders cater to diverse production needs, allowing manufacturers to handle various component types seamlessly.

- Cost-effectiveness: By reducing labor costs associated with manual handling and increasing reliability, SMT feeders contribute to long-term cost savings.

Integration with SMT Assembly Lines

SMT feeders are integral components of automated SMT assembly lines, working in tandem with pick-and-place machines, solder paste printers, and reflow ovens to achieve streamlined production processes. Their compatibility with industry-standard machines ensures smooth integration and operation, supporting continuous production without interruptions.

Choosing the Right SMT Feeder

Selecting the appropriate SMT feeder depends on various factors:

- Component Size and Shape: Different feeders accommodate different component sizes and shapes. It is essential to choose a feeder that matches your specific requirements.

- Production Volume: High-volume productions may benefit from tape or bulk feeders, while low-volume productions might be better suited for stick or tray feeders.

- Feeder Compatibility: Ensure that the chosen feeder is compatible with your existing pick-and-place machines to avoid integration issues.

Advancements in SMT Feeder Technology

As technology evolves, so do SMT feeders. Recent advancements have led to improved designs that enhance performance:

- High-Speed Electric Feeders: Modern tape feeders have transitioned from mechanical designs to high-speed electric variants that offer greater precision and faster feeding rates. These advancements reduce downtime caused by mechanical failures and improve overall machine reliability.

- Smart Technology Integration: Some newer feeder models incorporate smart technology that allows real-time monitoring and diagnostics. This capability enables manufacturers to predict maintenance needs before issues arise, significantly reducing unexpected downtime.

- Modular Designs: Many contemporary SMT feeders feature modular designs that allow easy upgrades and repairs. This flexibility ensures that manufacturers can adapt their equipment as production needs change without incurring significant costs.

Common Applications of SMT Feeders

SMT feeders are utilized across various industries due to their versatility:

- Consumer Electronics: In this sector, SMT feeders play a crucial role in assembling devices such as smartphones, tablets, and laptops where compactness is vital.

- Automotive Industry: With the rise of electronic control units (ECUs) in vehicles, SMT feeders facilitate the efficient assembly of automotive electronics, ensuring reliability in critical applications such as safety systems.

- Medical Devices: The medical industry relies on precise component placement for devices like pacemakers and diagnostic equipment. SMT feeders help maintain high standards required for medical device manufacturing.

Challenges in Using SMT Feeders

While SMT feeders provide numerous benefits, they also come with challenges:

- Component Compatibility Issues: Not all components can be effectively fed by every type of feeder. Manufacturers must ensure compatibility between their chosen feeder type and the specific components they use.

- Maintenance Requirements: Regular maintenance is necessary for optimal performance. Dust accumulation or mechanical wear can lead to feeding errors if not addressed promptly.

- Initial Investment Costs: High-quality SMT feeders can represent a significant upfront investment. However, this cost can often be justified by improved efficiency and reduced labor costs over time.

Future Trends in SMT Feeding Technology

The future of SMT feeding technology looks promising with several emerging trends:

- Increased Automation: As automation becomes more prevalent in manufacturing processes, we can expect more advanced feeder systems capable of integrating seamlessly with automated workflows.

- Artificial Intelligence (AI) Integration: AI could revolutionize how feeders operate by enabling adaptive feeding strategies based on real-time data analysis. This technology could optimize component delivery based on varying production conditions.

- Sustainability Initiatives: With growing concerns about environmental impact, manufacturers are likely to focus on creating more sustainable feeder systems that minimize waste and energy consumption during operation.

Case Studies Highlighting Feeder Effectiveness

To illustrate the effectiveness of various types of SMT feeders in real-world applications:

1. Consumer Electronics Manufacturer DEF

- *Background*: Consumer Electronics Company DEF needed cost-effective yet reliable SMT assembly machines.

- *Solution*: DEF partnered with a Chinese manufacturer renowned for its expertise in producing high-quality SMT assembly machines at competitive prices.

- *Results*: The Chinese-made machines provided DEF with a cost-effective solution without compromising performance or quality. The placement heads and feeders delivered consistent results.

- *Testimonial*: "These machines have been instrumental in helping us scale our production."

2. Automotive Electronics Manufacturer ABC

- *Background*: Required high-quality machines to meet stringent automotive standards.

- *Solution*: Selected machines from a reputable supplier known for quality.

- *Results*: Machines exceeded rigorous quality requirements; precision placement heads contributed significantly.

- *Testimonial*: "These machines have helped us maintain our reputation for excellence."

3. Medical Device Company XYZ

- *Background*: Needed precise assembly capabilities for sensitive medical devices.

- *Solution*: Implemented advanced tape and tray feeder systems.

- *Results*: Achieved significant improvements in accuracy; reduced defects dramatically.

- *Testimonial*: "The new systems have transformed our assembly line efficiency."

Conclusion

In summary, SMT component feeders are integral to the efficiency and accuracy of electronic assembly processes. Understanding the different types of feeders available allows manufacturers to select the best options for their specific needs while optimizing production lines and minimizing costs. As technology continues to evolve, advancements in feeder design will further enhance their capabilities—paving the way for even greater efficiencies in electronics manufacturing.

FAQs

1. What is an SMT feeder?

An SMT feeder is an electric device that holds and supplies electronic components for placement on printed circuit boards (PCBs). It delivers these components accurately to pick-and-place machines during assembly processes.

2. What are the main types of SMT feeders?

The main types include tape feeders, tray feeders, stick feeders, tube feeders, vibratory bowl feeders, bulk feeders, and direct die feeders. Each type is designed for specific component sizes and shapes.

3. How do tape feeders work?

Tape feeders utilize reels of adhesive tape that hold SMD components securely. The feeder unwinds the tape to present each component at a fixed pickup position for placement by pick-and-place machines.

4. Why are tray feeders important?

Tray feeders accommodate larger or irregularly shaped components that cannot be effectively handled by tape or stick feeders. They provide secure storage and careful handling for delicate parts during assembly.

5. What factors should be considered when choosing an SMT feeder?

Key factors include component size and shape, production volume requirements, compatibility with existing machinery, and specific handling needs for different types of electronic parts.

Citations:

[1] https://www.hayawin.com/products/smt-feeder.html

[2] https://www.hct-smt.com/blog/inside-look--exploring-china-s-smt-assembly-machine-components

[3] https://www.eevblog.com/forum/manufacture/setting-up-a-real-smt-line-advice/

[4] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

[5] https://www.allaismt.com/2023/05/25/understanding-the-differences-between-smt-radial-and-axial-feeders/

[6] https://smt.yamaha-motor-robotics.de/success-stories/

[7] https://www.zjyingxing.com/info/what-are-the-cleaning-and-maintenance-methods-82799641.html

[8] https://www.hayawin.com/news-smt-machine-types-and-features-of-excellent-smt-machines.html

[9] https://hawkerrichardson.com.au/case_study/smt-line-at-philips-dynalite/

[10] https://www.sunzontech.com/how-to-do-smt-pick-and-place-machine-maintenance-work/