Content Menu

● Understanding SMT Components

>> Active Components

>> Passive Components

● Importance of Size Specifications

● Common SMT Component Sizes

● Types of SMT Packages

● Standardization of Sizes

>> JEDEC Standards

>> EIA Standards

● Trends in SMT Component Sizes

● Challenges with Smaller Sizes

● Future Directions in SMT Component Design

● Conclusion

● FAQs

>> 1. What is an SMT component?

>> 2. How do I choose the right size for an SMT component?

>> 3. What are some common sizes for SMD resistors?

>> 4. Why is standardization important in SMT component sizes?

>> 5. What challenges do smaller SMT component sizes present?

● Citations:

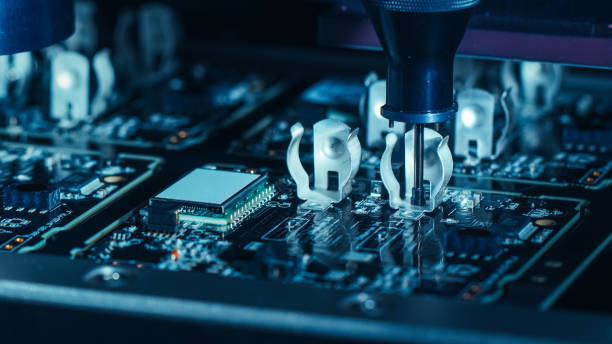

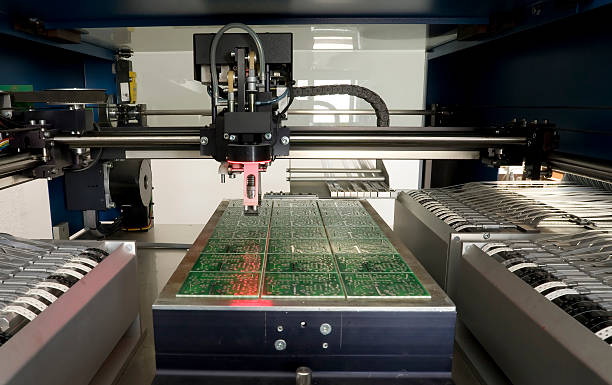

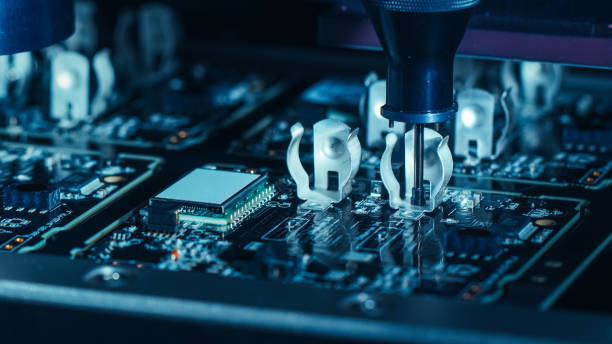

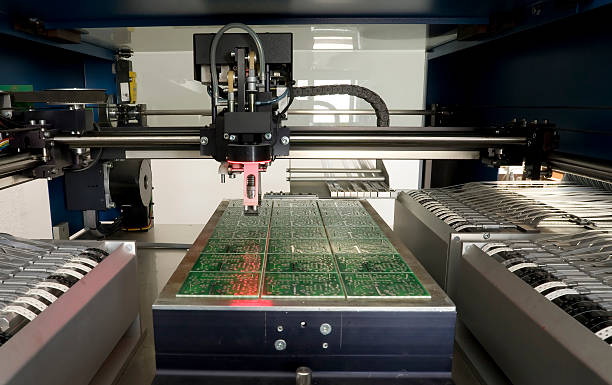

Surface Mount Technology (SMT) has revolutionized the electronics industry by allowing components to be mounted directly onto the surface of printed circuit boards (PCBs). This method not only saves space but also enhances the performance and reliability of electronic devices. As the demand for smaller, more efficient electronics grows, understanding the size specifications of SMT components is crucial for designers and manufacturers. This article will explore the various size specifications for SMT components, including a detailed size chart, and discuss their implications in PCB design.

Understanding SMT Components

SMT components can be categorized into two main types: active and passive components. Active components include transistors, diodes, and integrated circuits (ICs), while passive components encompass resistors, capacitors, and inductors. Each type of component has specific size specifications that are standardized across the industry to ensure compatibility and efficiency in manufacturing.

Active Components

Active components are those that require a power source to operate. They are responsible for controlling the flow of electricity in a circuit. Common examples include:

- Transistors: Used for amplification or switching.

- Diodes: Allow current to flow in one direction only.

- Integrated Circuits (ICs): Miniaturized circuits that can perform various functions depending on their design.

These components come in various package sizes, which can significantly affect their performance and how they are used in circuits.

Passive Components

Passive components do not require an external power source to function; they react to electrical signals. Examples include:

- Resistors: Limit current flow.

- Capacitors: Store electrical energy temporarily.

- Inductors: Store energy in a magnetic field when electrical current flows through them.

The size of passive components is equally important as it influences their electrical characteristics and suitability for specific applications.

Importance of Size Specifications

The size of SMT components is critical for several reasons:

- Space Efficiency: Smaller components allow for more compact designs, which is essential in modern electronics where space is at a premium.

- Performance: The physical dimensions can affect electrical performance, including resistance, capacitance, and inductance.

- Manufacturing Compatibility: Standardized sizes facilitate automated assembly processes, reducing production costs and time.

- Thermal Management: Smaller components may have different thermal properties that can influence heat dissipation in a circuit.

Common SMT Component Sizes

SMT component sizes are typically denoted by their dimensions in either millimeters (mm) or inches (in). Below is a comprehensive size chart that outlines common SMT component sizes along with their respective dimensions:

| SMD Package | Dimensions (mm) | Dimensions (in) |

| 01005 | 0.4 x 0.2 | 0.016 x 0.008 |

| 0201 | 0.6 x 0.3 | 0.024 x 0.012 |

| 0402 | 1.0 x 0.5 | 0.040 x 0.020 |

| 0603 | 1.6 x 0.8 | 0.063 x 0.031 |

| 0805 | 2.0 x 1.25 | 0.079 x 0.049 |

| 1206 | 3.2 x 1.6 | 0.126 x 0.063 |

| 2012 | 5.0 x 3.2 | 0.197 x 0.126 |

| SOT-23 | 3.0 x 1.75 | 0.118 x 0.069 |

| SOIC | Various | Various |

This chart provides a quick reference for designers when selecting components for their PCBs.

Types of SMT Packages

SMT packages come in various forms depending on the type of component:

- Resistors and Capacitors: These typically use rectangular packages such as the 0805, 0603, and 0402 sizes.

- Transistors: Common packages include SOT-23, SOT-223, and SOT-323, which are designed for small-signal applications.

- Integrated Circuits (ICs): ICs can be found in several package types including:

- Small Outline Integrated Circuit (SOIC): A common package for ICs with leads on two sides.

- Quad Flat Package (QFP): Features leads on all four sides, suitable for larger ICs.

- Ball Grid Array (BGA): Allows for high pin counts with a grid of solder balls on the bottom of the package.

Each package type has its own set of specifications that dictate its dimensions and pin configurations.

Standardization of Sizes

The standardization of SMT component sizes is governed by organizations such as JEDEC and EIA, which provide guidelines to ensure uniformity across the industry. These standards help manufacturers produce components that are interchangeable, thus simplifying the design process for engineers.

JEDEC Standards

JEDEC (Joint Electron Device Engineering Council) provides standards that define package dimensions, lead configurations, and other specifications necessary to ensure compatibility among different manufacturers' products.

EIA Standards

The EIA (Electronic Industries Alliance) also contributes to standardization efforts by providing guidelines on component sizes and layouts that enhance manufacturability and reliability in electronic assemblies.

Trends in SMT Component Sizes

As technology advances, there is a clear trend towards smaller component sizes:

- Miniaturization: The push for smaller devices has led to the development of ultra-small sizes like the 01005 package, which is becoming increasingly popular in consumer electronics.

- Higher Density: Manufacturers are increasingly designing PCBs that accommodate more components in a smaller area, leading to higher circuit density without compromising functionality.

- Enhanced Performance: Smaller components often feature improved performance characteristics such as lower parasitic capacitance and inductance, which are critical in high-frequency applications.

Challenges with Smaller Sizes

While smaller SMT component sizes offer numerous benefits, they also present challenges:

- Placement Accuracy: Automated placement machines must be highly accurate to handle tiny components effectively; any misalignment can lead to circuit failures or reduced performance.

- Thermal Management: Smaller packages can lead to increased heat density, requiring careful thermal management strategies such as heat sinks or thermal vias to dissipate heat effectively.

- Handling Difficulty: Tiny components can be difficult to handle during assembly processes due to their size; specialized tools may be required to manipulate them without damage.

Future Directions in SMT Component Design

The future of SMT component design will likely focus on several key areas:

- Integration of Functions: There will be an increasing trend towards integrating multiple functions into single packages (e.g., System-on-Chip designs), reducing board space requirements even further while enhancing functionality.

- Advanced Materials: New materials that improve thermal conductivity or reduce electromagnetic interference may emerge, allowing designers more flexibility with component placement and layout.

- Smart Components: The rise of IoT (Internet of Things) devices will drive demand for smart components that can communicate with each other while maintaining compact sizes.

Conclusion

Understanding the different size specifications of SMT components is essential for anyone involved in PCB design or manufacturing. The standardization of these sizes facilitates compatibility and efficiency in production while enabling designers to create compact and high-performance electronic devices. As technology continues to evolve, staying informed about these specifications will be crucial for future innovations in electronics.

FAQs

1. What is an SMT component?

An SMT component is an electronic part designed to be mounted directly onto the surface of a PCB using Surface Mount Technology (SMT), which allows for faster assembly and reduced space requirements compared to traditional through-hole mounting methods.

2. How do I choose the right size for an SMT component?

When selecting an SMT component size, consider factors such as available board space, thermal management needs, electrical performance requirements, and compatibility with other components on the PCB.

3. What are some common sizes for SMD resistors?

Common SMD resistor sizes include 0402, 0603, 0805, and 1206, with dimensions ranging from 1×0.5 mm1×0.5 mm to 3.2×1.6 mm3.2×1.6 mm.

4. Why is standardization important in SMT component sizes?

Standardization ensures compatibility among different manufacturers' products, simplifies design processes, reduces costs associated with production changes, and enhances overall product reliability.

5. What challenges do smaller SMT component sizes present?

Smaller sizes can complicate handling during assembly due to their diminutive nature, require precise placement accuracy from machinery, and pose challenges related to thermal management due to higher heat density.

Citations:

[1] https://www.ultralibrarian.com/2024/01/25/smt-components-size-chart-what-to-know-ulc

[2] https://eepower.com/resistor-guide/resistor-standards-and-codes/resistor-sizes-and-packages/

[3] https://www.protoexpress.com/kb/different-smd-component-package-sizes/

[4] https://topdiode.com/news/SMT__SMD_Component_Packages.html

[5] https://www.electronics-notes.com/articles/electronic_components/surface-mount-technology-smd-smt/packages.php

[6] https://www.wevolver.com/article/smd-components

[7] https://www.pcbonline.com/blog/smd-sizes.html

[8] https://www.zaxis.net/smd-package-types-sizes/

[9] https://core-emt.com/imperial-code-vs-metric-code-smd-components-sizes

[10] https://www.topline.tv/sizechart.html