Content Menu

● Introduction to SMT Components

● Common Shapes of SMT Components

>> 1. Chip Components

>> 2. MELF (Metal Electrode Leadless Face) Components

>> 3. SOIC (Small Outline Integrated Circuit)

>> 4. QFN (Quad Flat No-leads) Packages

>> 5. BGA (Ball Grid Array) Packages

● Other Notable SMT Component Shapes

>> 6. DFN (Dual Flat No-leads) Packages

>> 7. CSP (Chip Scale Package)

>> 8. TSSOP (Thin Shrink Small Outline Package)

● Design Considerations for SMT Components

● Conclusion

● FAQ

>> 1. What are the advantages of using SMT components?

>> 2. How do SMT components differ from through-hole components?

>> 3. What are some common applications of SMT components?

>> 4. How are SMT components identified?

>> 5. What challenges are associated with using SMT components?

● Citations:

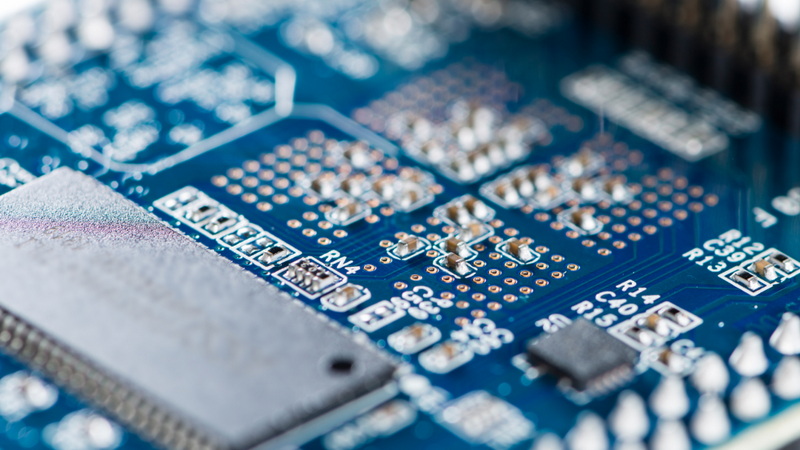

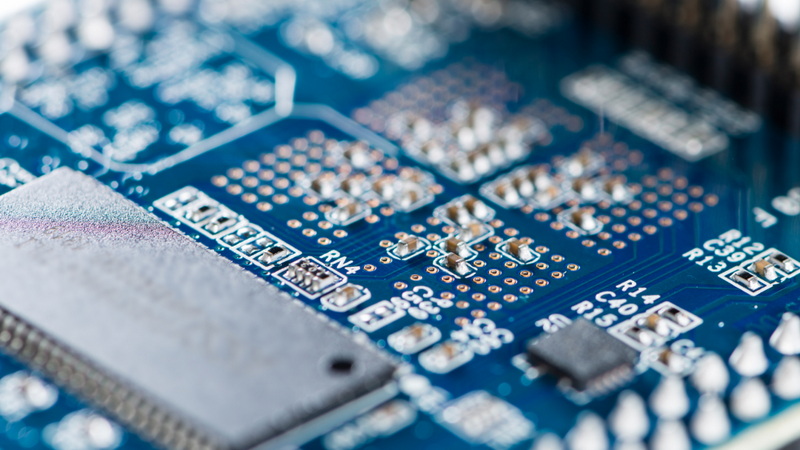

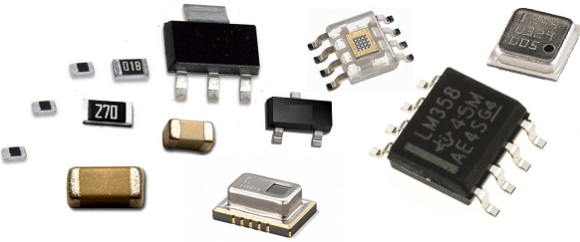

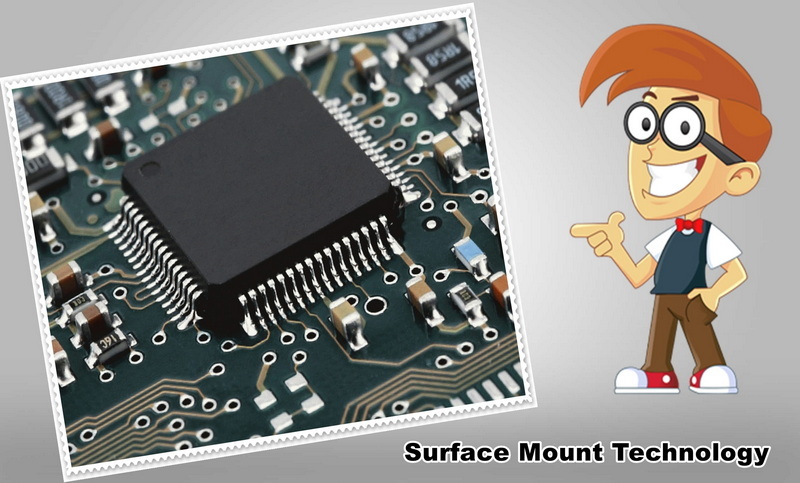

Surface Mount Technology (SMT) has transformed the landscape of electronic manufacturing by enabling components to be directly mounted onto the surface of printed circuit boards (PCBs). This innovative approach contrasts sharply with traditional through-hole technology, which required components to be inserted into drilled holes. SMT components, also referred to as Surface Mount Devices (SMDs), come in a variety of shapes and sizes tailored for specific applications in electronic design and manufacturing.

Introduction to SMT Components

SMT components are vital to contemporary electronics, providing significant advantages such as reduced size, weight, and cost, alongside enhanced performance and reliability. These components are utilized across a wide array of applications, from consumer electronics like smartphones and laptops to critical industrial equipment.

The increase in demand for compact and efficient electronic devices has spurred the development of diverse SMT component shapes. Understanding these shapes is essential for engineers and designers seeking to optimize their projects for performance and manufacturability.

Common Shapes of SMT Components

1. Chip Components

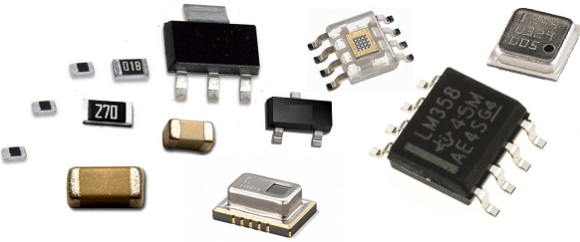

Chip components are among the most prevalent types of SMT components. They are typically rectangular and come in various standardized sizes, such as 0402, 0603, and 0805. These components include:

- Resistors: Used to limit current flow.

- Capacitors: Store electrical energy temporarily.

- Inductors: Store energy in a magnetic field when electrical current flows through them.

The compact nature of chip components makes them ideal for high-density PCB layouts, allowing for more efficient use of space. Chip resistors, for instance, are available in different tolerances and power ratings, making them versatile for various applications. Capacitors can be ceramic, tantalum, or aluminum-based, each serving different purposes based on capacitance values and voltage ratings.

2. MELF (Metal Electrode Leadless Face) Components

MELF components are cylindrical in shape and often used for precision resistors and diodes. Their unique design allows for excellent thermal and electrical performance, making them suitable for applications that require high reliability. The leadless nature of MELF components enhances their mounting stability on PCBs.

MELF resistors are particularly favored in high-frequency applications due to their low inductance characteristics. They offer superior performance compared to traditional chip resistors in certain scenarios where signal integrity is crucial.

3. SOIC (Small Outline Integrated Circuit)

SOIC packages are rectangular with leads extending from two sides. They are commonly used for integrated circuits due to their compact size and efficient layout capabilities. SOIC packages allow multiple electronic functions to be housed within a single component, thereby saving space on the PCB.

SOICs can accommodate a range of functions including amplifiers, voltage regulators, and microcontrollers. Their design facilitates easy soldering during the assembly process while maintaining a low profile on the PCB.

4. QFN (Quad Flat No-leads) Packages

QFN packages have a square or rectangular shape with no leads protruding from the package itself. Instead, they feature pads on the underside that are soldered directly to the PCB. This design minimizes the overall package size while enhancing thermal performance, making QFN an excellent choice for high-performance applications.

QFN packages are often used in RF applications due to their low parasitic inductance and capacitance. The compact design allows designers to place multiple components closer together on the PCB without compromising performance.

5. BGA (Ball Grid Array) Packages

BGA packages consist of a square or rectangular body with an array of solder balls located on the underside. This configuration is particularly beneficial for high-density integrated circuits like microprocessors and memory chips. BGAs provide superior electrical performance and thermal management due to their large contact area with the PCB.

The solder balls allow for a larger number of connections compared to traditional leaded packages, enabling more complex designs within a smaller footprint. Additionally, BGAs facilitate better heat dissipation compared to other package types due to their flat surface area.

Other Notable SMT Component Shapes

In addition to the common shapes mentioned above, several other SMT component types play crucial roles in electronic design:

- SOT (Small Outline Transistor): These packages are used primarily for transistors and come in various sizes like SOT-23, SOT-323, and SOT-523. SOT packages allow for easy integration into circuits requiring amplification or switching functions.

- QFP (Quad Flat Package): A flat package with leads on all four sides, commonly used for integrated circuits requiring multiple connections. QFPs can house complex logic functions within a compact area.

- PLCC (Plastic Leaded Chip Carrier): A square package that allows for surface mounting on PCBs while providing access to multiple pins around its perimeter. PLCCs are often used in programmable logic devices due to their versatility.

6. DFN (Dual Flat No-leads) Packages

DFN packages resemble QFN packages but typically have slightly different dimensions or pad layouts. Like QFNs, they do not have leads extending from the package but instead rely on solder pads on the bottom surface for mounting. DFNs are particularly useful in applications where space is at a premium while still requiring good thermal performance.

7. CSP (Chip Scale Package)

CSPs are one of the smallest packaging options available today, designed so that the package size is almost identical to that of the die itself. This type of packaging is advantageous in mobile devices where space constraints are critical. CSPs provide excellent electrical performance due to their minimal distance between the die and PCB.

8. TSSOP (Thin Shrink Small Outline Package)

TSSOP packages are similar to SOIC but are thinner and have narrower lead spacing. They are used when board space is limited but still require multiple connections within an integrated circuit format.

Design Considerations for SMT Components

When designing PCBs that utilize SMT components, several factors must be considered:

- Footprint: Each component type has a specific footprint that must be adhered to during PCB layout design. Accurate footprints ensure proper soldering and functionality.

- Thermal Management: High-power components generate heat that must be dissipated effectively. Designers should consider thermal vias or heat sinks when placing these components.

- Signal Integrity: High-speed signals may require careful routing techniques such as controlled impedance traces or differential pairs to minimize interference.

- Manufacturability: The arrangement of SMT components affects how easily a PCB can be assembled using automated processes like pick-and-place machines.

Conclusion

The variety of shapes and sizes of SMT components enables flexibility in electronic design, allowing engineers to optimize their circuits based on performance requirements, available space, and cost considerations. As technology continues to advance, there will be an increasing demand for smaller, more efficient components that can deliver enhanced functionality without sacrificing reliability or manufacturability.

Understanding the different shapes of SMT components is essential for anyone involved in electronics design or manufacturing. It not only helps in selecting appropriate components but also aids in designing PCBs that maximize efficiency while minimizing costs.

By recognizing the characteristics and applications of various SMT component shapes—ranging from chip resistors to advanced BGA packages—designers can create innovative solutions tailored to meet modern electronic demands effectively.

FAQ

1. What are the advantages of using SMT components?

SMT components offer several advantages including reduced size and weight, lower production costs due to automated assembly processes, improved performance and reliability, as well as higher component density on PCBs which is crucial for modern electronic devices.

2. How do SMT components differ from through-hole components?

SMT components are mounted directly onto the surface of PCBs without leads that go through holes, unlike through-hole components which require insertion into drilled holes. This difference allows SMT components to be smaller and more suitable for automated assembly processes.

3. What are some common applications of SMT components?

SMT components find applications across various sectors including consumer electronics (like smartphones), telecommunications equipment, automotive systems, industrial machinery, and medical devices due to their versatility and efficiency.

4. How are SMT components identified?

SMT components are identified by their package type and size which are often marked on the component itself or specified in manufacturer datasheets. Common package types include chip resistors/capacitors, MELF resistors, SOICs, QFNs, and BGAs.

5. What challenges are associated with using SMT components?

Challenges with SMT components include precise placement during assembly processes and potential issues related to thermal management due to high density layouts. However, advancements in manufacturing technology have significantly mitigated these challenges over time.

Citations:

[1] https://www.ultralibrarian.com/2024/01/25/smt-components-size-chart-what-to-know-ulc

[2] https://www.intel.sg/content/dam/www/public/us/en/documents/packaging-databooks/packaging-chapter-07-databook.pdf

[3] https://flexipcb.com/assembly/surface-mount-components/

[4] https://www.pcbonline.com/blog/pcb-smt-components.html

[5] https://en.wikipedia.org/wiki/Surface-mount_technology

[6] https://www.zaxis.net/smd-package-types-sizes/

[7] https://vectorbluehub.com/smd-components-a-look-at-different-types-and-how-to-identify-them