Content Menu

● Understanding SMT Reels

● Paper SMT Reels

>> Characteristics

>> Advantages

>> Limitations

● Plastic SMT Reels

>> Characteristics

>> Advantages

>> Limitations

● Factors to Consider When Choosing Between Paper and Plastic SMT Reels

>> Component Size and Type

>> Environmental Conditions

>> ESD Protection Requirements

>> Cost Considerations

>> Environmental Impact

● Industry Trends and Future Outlook

● Impact on SMT Assembly Process

>> Feeding and Placement Accuracy

>> Production Speed

>> Component Protection During Assembly

>> Storage and Handling

● Economic Considerations

>> Initial Cost

>> Long-term Cost

>> Shipping and Storage Costs

>> Waste Management Costs

● Environmental Impact and Sustainability

>> Biodegradability

>> Recyclability

>> Resource Consumption

>> Carbon Footprint

● Technological Advancements in SMT Reel Design

>> Improved Paper Reels

>> Enhanced Plastic Formulations

>> Composite Materials

>> Smart Packaging Solutions

● Conclusion

● FAQ

>> 1. What are the main differences between paper and plastic SMT reels?

>> 2. How do paper and plastic SMT reels affect the assembly process?

>> 3. Are paper SMT reels more environmentally friendly than plastic ones?

>> 4. Which type of SMT reel is better for ESD-sensitive components?

>> 5. How do I choose between paper and plastic SMT reels for my manufacturing process?

● Citations:

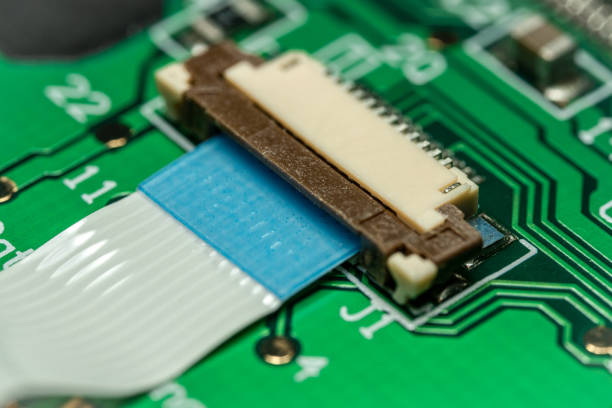

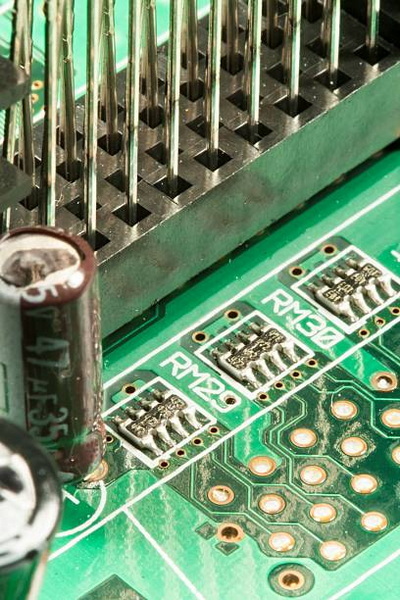

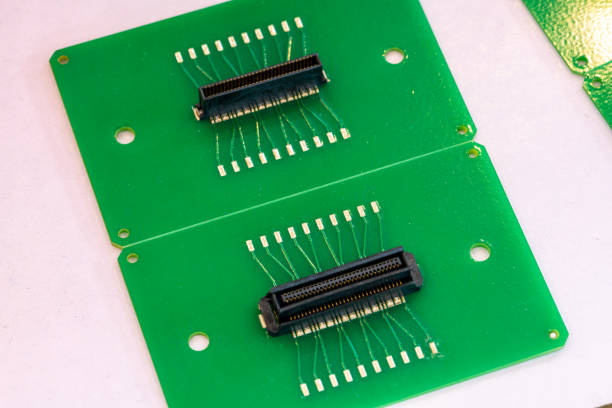

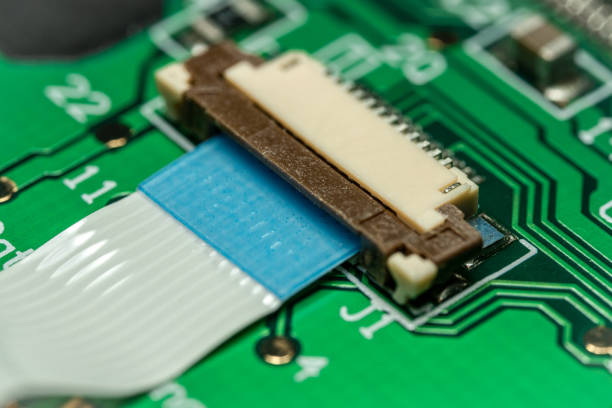

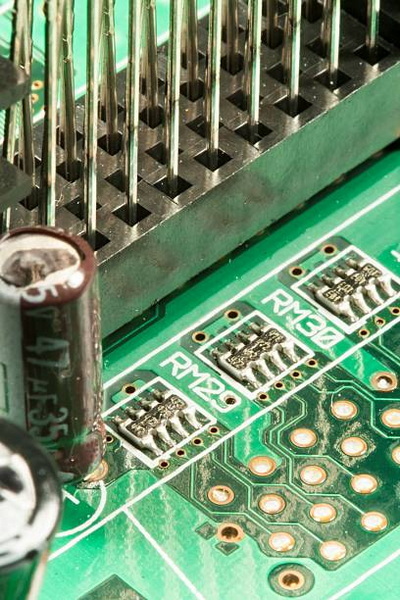

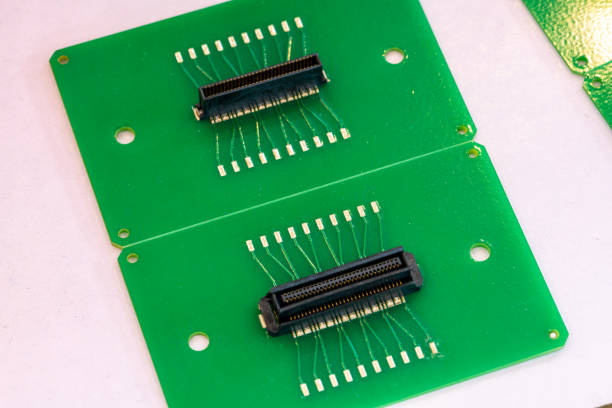

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for more compact and efficient circuit board designs. A crucial component of this process is the SMT reel, which stores and dispenses electronic components during assembly. Two primary materials are used for these reels: paper and plastic. Each has its own set of characteristics, advantages, and limitations. This article will explore the differences between paper and plastic SMT reels, their applications, and the factors to consider when choosing between them.

Understanding SMT Reels

Before delving into the differences, it's essential to understand what SMT reels are and their role in the manufacturing process. SMT reels are spools used to hold and dispense surface mount components such as resistors, capacitors, and integrated circuits[3]. These reels are designed to work with pick-and-place machines, which automatically place components onto printed circuit boards (PCBs) during assembly.

Paper SMT Reels

Characteristics

Paper SMT reels are typically made from cardboard and are widely used in the industry. They are often the first choice for packaging smaller passive components like resistors and capacitors[1][12].

Advantages

1. Cost-effective: Paper reels are generally less expensive to produce than their plastic counterparts.

2. Environmentally friendly: Being made from cardboard, paper reels are biodegradable and more easily recyclable[12].

3. Suitable for small components: Paper carriers work well for passive components up to approximately 0.9 mm in thickness[5].

4. Lightweight: Paper reels are lighter than plastic ones, which can reduce shipping costs.

Limitations

1. Limited protection: Paper reels offer less protection against physical damage and environmental factors like moisture.

2. ESD sensitivity: Paper carrier tapes are only capable of protecting sensitive devices from electrostatic discharge (ESD) when used in a moist environment[5].

3. Thickness limitations: Beyond 0.9 mm thickness, paper carrier tapes may be too thick, resulting in handling difficulties and errors when feeding into SMT assembly equipment[5].

Plastic SMT Reels

Characteristics

Plastic SMT reels are constructed from various polymers, with polystyrene and polycarbonate being the most common materials[5]. They are often used for larger components or those requiring more protection.

Advantages

1. Enhanced protection: Plastic reels offer better protection against physical damage and environmental factors.

2. ESD protection: Plastic carrier tapes are available in dissipative and conductive versions to protect ESD-sensitive parts[5].

3. Deeper pockets: Plastic reels can accommodate thicker components due to their ability to have deeper, more rigid pockets[5].

4. Durability: Plastic reels are more resistant to wear and tear, making them suitable for multiple uses.

Limitations

1. Higher cost: Plastic reels are generally more expensive to produce than paper reels.

2. Environmental concerns: Most plastic reels are not biodegradable, raising environmental issues[12].

3. Camber effect: Some plastic reels, particularly those made of polystyrene, can exhibit a phenomenon called camber, where the carrier tape curves in the X/Y plane[5].

Factors to Consider When Choosing Between Paper and Plastic SMT Reels

Component Size and Type

The size and type of components being packaged play a crucial role in determining the appropriate reel material. Paper reels are typically suitable for small passive components like resistors and capacitors, while plastic reels are better for larger or more sensitive components[9].

Environmental Conditions

Consider the environmental conditions the reels will be exposed to during storage and transportation. Plastic reels offer better protection against moisture and other environmental factors, making them a better choice for components that are sensitive to these conditions.

ESD Protection Requirements

For components that are sensitive to electrostatic discharge, plastic reels with dissipative or conductive properties may be necessary[5]. Paper reels can only provide ESD protection in moist environments, which may not be suitable for all applications.

Cost Considerations

Paper reels are generally less expensive than plastic reels. For high-volume production of small, passive components, paper reels may offer a more cost-effective solution. However, for more sensitive or expensive components, the added protection of plastic reels may justify the higher cost.

Environmental Impact

With increasing focus on sustainability in manufacturing, the environmental impact of packaging materials is becoming more important. Paper reels have an advantage in this area, being biodegradable and more easily recyclable[12]. However, advancements in recyclable plastics may narrow this gap in the future.

Industry Trends and Future Outlook

The electronics manufacturing industry is constantly evolving, and so are the materials and technologies used in SMT reels. Some emerging trends include:

1. Recyclable plastics: Development of more environmentally friendly plastic materials for SMT reels.

2. Hybrid materials: Exploration of composite materials that combine the benefits of both paper and plastic.

3. Smart reels: Integration of RFID or other tracking technologies into SMT reels for improved inventory management and traceability.

4. Automated reel handling systems: Advancements in automated systems that can handle both paper and plastic reels efficiently.

Impact on SMT Assembly Process

The choice between paper and plastic SMT reels can have significant implications for the assembly process:

Feeding and Placement Accuracy

Plastic reels, especially those made from engineered plastics, generally offer better feeding accuracy due to their dimensional stability. This can lead to improved placement accuracy in the pick-and-place process, which is crucial for fine-pitch components[5].

Production Speed

The material of the SMT reel can affect production speed. Plastic reels, being more robust, can often withstand higher feeding speeds without risking damage to the components or the tape itself. However, for many standard components, paper reels are still capable of meeting production speed requirements.

Component Protection During Assembly

Plastic reels with deeper pockets provide better protection for components during the assembly process, reducing the risk of damage from vibration or movement. This is particularly important for larger or more delicate components[5].

Storage and Handling

Plastic reels are generally more durable and can withstand repeated handling better than paper reels. This makes them a good choice for components that may need to be stored for extended periods or used across multiple production runs.

Economic Considerations

When evaluating the economic impact of choosing between paper and plastic SMT reels, several factors come into play:

Initial Cost

Paper reels are typically less expensive to purchase than plastic reels. For high-volume production of standard components, this can result in significant cost savings[9].

Long-term Cost

While plastic reels have a higher initial cost, their durability may make them more cost-effective in the long run, especially for components that are used frequently or in multiple production runs.

Shipping and Storage Costs

Paper reels are lighter than plastic reels, which can reduce shipping costs. However, plastic reels may offer better protection during shipping, potentially reducing the risk of damage and associated costs[12].

Waste Management Costs

The disposal or recycling of SMT reels should also be considered. Paper reels may have lower waste management costs due to their biodegradability and easier recycling process[12].

Environmental Impact and Sustainability

As the electronics industry faces increasing pressure to improve its environmental footprint, the choice of SMT reel material becomes an important consideration:

Biodegradability

Paper reels have a clear advantage in terms of biodegradability. They can decompose naturally, reducing long-term environmental impact[12].

Recyclability

Both paper and plastic reels can be recycled, but paper reels are generally easier and less energy-intensive to recycle. However, advancements in plastic recycling technologies are narrowing this gap.

Resource Consumption

Paper reels consume trees as a resource, which raises concerns about deforestation. On the other hand, plastic reels are typically made from petroleum-based materials, which are non-renewable resources[12].

Carbon Footprint

The production, transportation, and disposal of SMT reels all contribute to their overall carbon footprint. A comprehensive life cycle assessment would be needed to determine which material has a lower overall environmental impact.

Technological Advancements in SMT Reel Design

The field of SMT reel design is not static, and ongoing technological advancements are addressing some of the limitations of both paper and plastic reels:

Improved Paper Reels

Manufacturers are developing stronger, more moisture-resistant paper materials for SMT reels, expanding their potential applications.

Enhanced Plastic Formulations

New plastic formulations are being developed to address issues like camber in polystyrene reels and to improve the overall performance of plastic reels[5].

Composite Materials

Some manufacturers are exploring composite materials that combine the benefits of both paper and plastic, aiming to create reels that are both environmentally friendly and highly protective.

Smart Packaging Solutions

Integration of technologies like RFID tags into SMT reels is enabling better inventory management and traceability throughout the supply chain.

Conclusion

The choice between paper and plastic SMT reels is not a one-size-fits-all decision. It depends on various factors including the type and size of components, environmental conditions, ESD requirements, cost considerations, and environmental impact. Paper reels offer cost-effectiveness and environmental benefits, making them suitable for small, passive components in high-volume production. Plastic reels provide better protection and durability, making them ideal for larger, more sensitive components or those requiring ESD protection.

As the electronics manufacturing industry continues to evolve, we can expect to see further innovations in SMT reel technology. These advancements will likely aim to combine the best features of both paper and plastic reels while addressing environmental concerns. Manufacturers must carefully consider their specific needs and the overall impact of their choice when selecting between paper and plastic SMT reels.

Ultimately, the decision should be based on a holistic evaluation of all relevant factors, including technical requirements, economic considerations, and environmental impact. By making an informed choice, manufacturers can optimize their SMT assembly process, reduce costs, and contribute to more sustainable manufacturing practices.

FAQ

1. What are the main differences between paper and plastic SMT reels?

Paper SMT reels are typically made from cardboard and are more cost-effective and environmentally friendly. They are suitable for small passive components up to 0.9 mm in thickness. Plastic SMT reels, made from polymers like polystyrene or polycarbonate, offer better protection against physical damage and environmental factors. They can accommodate larger components and provide better ESD protection[1][5].

2. How do paper and plastic SMT reels affect the assembly process?

Plastic SMT reels generally offer better feeding accuracy due to their dimensional stability, which can lead to improved placement accuracy in the pick-and-place process. They can also withstand higher feeding speeds. Paper reels, while capable of meeting standard production speeds, may be more susceptible to damage during high-speed assembly[5].

3. Are paper SMT reels more environmentally friendly than plastic ones?

Yes, paper SMT reels are generally considered more environmentally friendly. They are biodegradable and more easily recyclable compared to plastic reels. However, they do consume trees as a resource. Plastic reels, while not biodegradable, are durable and can be reused multiple times, which may offset some of their environmental impact[12].

4. Which type of SMT reel is better for ESD-sensitive components?

Plastic SMT reels are generally better for ESD-sensitive components. They are available in dissipative and conductive versions specifically designed to protect against electrostatic discharge. Paper reels can only provide ESD protection in moist environments, which may not be suitable for all applications or components[5].

5. How do I choose between paper and plastic SMT reels for my manufacturing process?

The choice depends on several factors:

1. Component size and type: Paper for small passives, plastic for larger or sensitive components.

2. Environmental conditions: Consider exposure to moisture and other factors.

3. ESD requirements: Plastic is generally better for ESD-sensitive components.

4. Cost considerations: Paper is typically less expensive for high-volume production.

5. Environmental impact: Paper is more biodegradable, but plastic may be reusable.

Evaluate these factors based on your specific manufacturing needs and priorities[9].

Citations:

[1] https://www.chemi-con.co.jp/en/faq/detail.php?id=SMDpackage

[2] https://auroraboardworks.com/manufacturing/smt-assembly/

[3] https://global.neotel.tech/2022/02/24/5-things-you-must-know-about-smt-reel/

[4] https://jphe.amegroups.org/article/view/4265/10863

[5] https://multimedia.3m.com/mws/media/611487O/choosing-carrier-and-cover-tape.pdf

[6] https://www.hayawin.com/resources/what-is-the-difference-between-smt-and-smd.html

[7] https://global.neotel.tech/2023/01/05/what-is-smt-reel-storage-solution/

[8] https://www.163.com/dy/article/EDIGQUV605370K28.html

[9] https://www.proex1.com/blog/posts/2022/june/tape-and-reel-faqs/

[10] https://www.macrofab.com/blog/smt-assembly-vs-through-hole/

[11] https://www.sohu.com/a/793967857_120288885

[12] https://www.topline.tv/SMDnomen.pdf

[13] https://www.epectec.com/articles/differences-between-through-hole-and-surface-mount-pcb-designs.html