Content Menu

● Introduction to SMT PCB Coating Machines

>> Benefits of Automated SMT PCB Coating Machines

● Cost Factors Associated with SMT PCB Coating Machines

>> Initial Investment Costs

>> Operational Costs

>> Labor Costs

● Managing Costs Effectively

● Enhancing Product Reliability

>> Industry Applications

● Future Trends in SMT PCB Coating

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using automated SMT PCB coating machines?

>> 2. How do I choose the right SMT PCB coating machine for my production needs?

>> 3. What are the key operational costs associated with SMT PCB coating machines?

>> 4. How can I reduce labor costs when using an SMT PCB coating machine?

>> 5. What are the long-term benefits of investing in an SMT PCB coating machine?

In the realm of modern electronics manufacturing, Surface Mount Technology (SMT) plays a pivotal role in assembling printed circuit boards (PCBs). One crucial step in enhancing the durability and reliability of these PCBs is applying a conformal coating, which protects the components from environmental stressors such as moisture, dust, and chemicals. Investing in an SMT PCB coating machine is a significant decision that involves several cost implications. This article delves into the various factors affecting the cost of such an investment and provides insights into how these costs can be managed effectively.

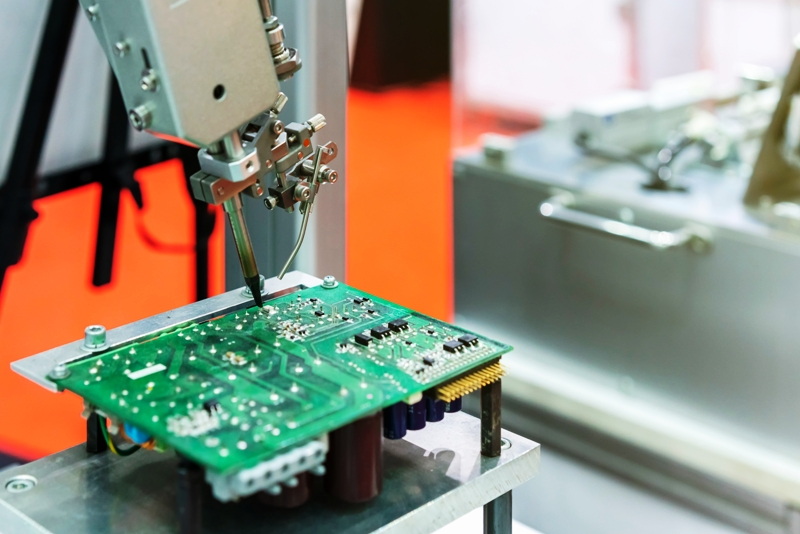

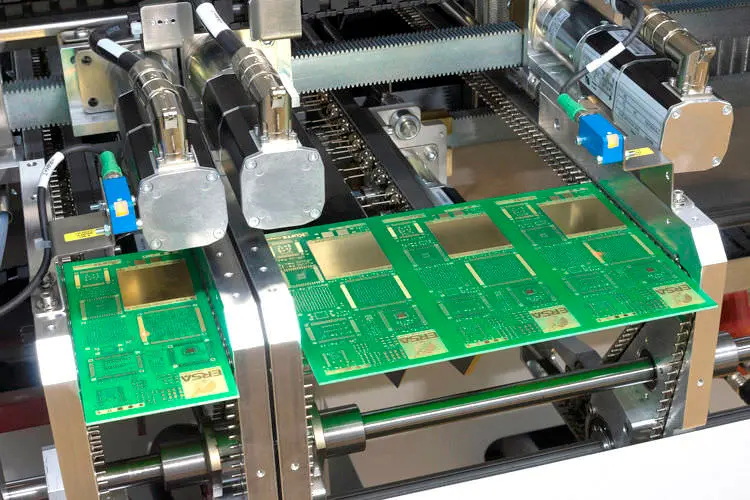

Introduction to SMT PCB Coating Machines

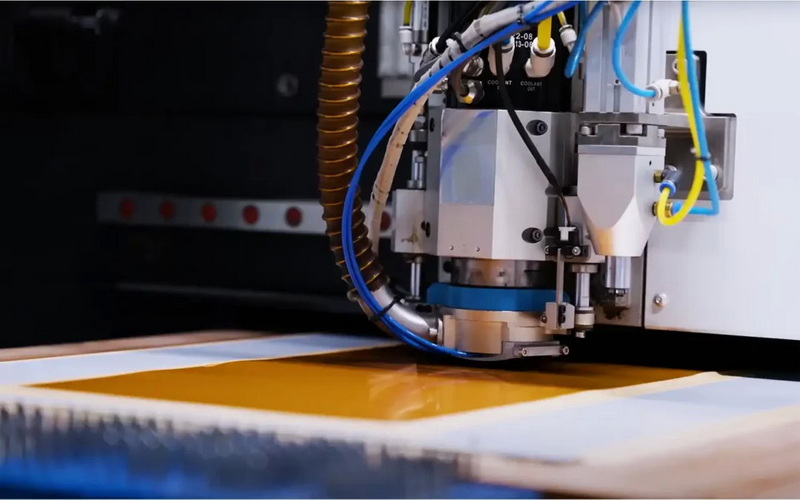

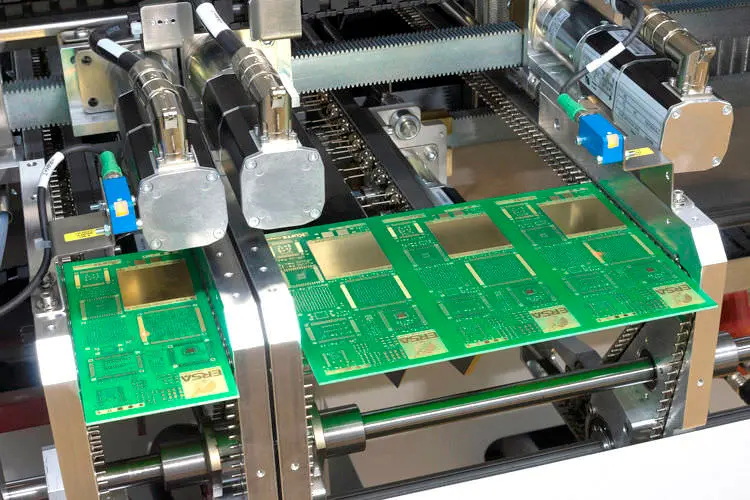

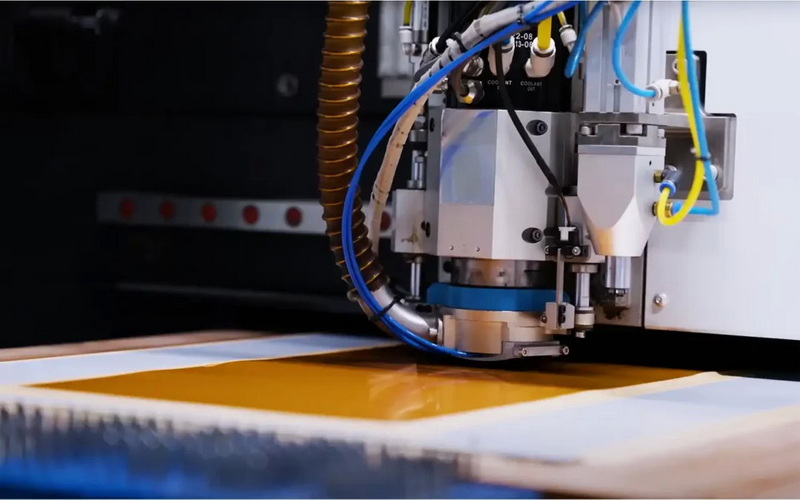

SMT PCB coating machines are designed to apply conformal coatings to PCBs, ensuring they remain functional under harsh conditions. These machines can be automated, allowing for precise and efficient coating processes. The use of automated systems not only enhances production speed but also reduces labor costs and improves quality consistency.

Benefits of Automated SMT PCB Coating Machines

1. Precision and Efficiency: Automated machines can apply coatings with high precision, minimizing waste and ensuring uniform coverage.

2. Increased Throughput: By automating the coating process, manufacturers can significantly increase production volumes without proportional increases in labor costs.

3. Reduced Labor Costs: Automated systems reduce the need for manual labor, which is particularly beneficial in high-volume production environments.

4. Improved Quality Control: Automated machines can maintain consistent quality standards, reducing the likelihood of human error.

Cost Factors Associated with SMT PCB Coating Machines

Investing in an SMT PCB coating machine involves several cost factors:

Initial Investment Costs

- Equipment Purchase: The cost of purchasing an SMT PCB coating machine can vary widely, depending on the level of automation, precision, and brand. Basic models may start at tens of thousands of dollars, while advanced systems can cost millions.

- Facility Setup: The production facility must be equipped with appropriate ventilation, power supply, and cleanliness standards, adding to the initial investment.

- Installation and Calibration: Additional costs may be incurred for the installation and calibration of the machinery to ensure it operates optimally.

Operational Costs

- Raw Materials: The cost of conformal coating materials, which can vary based on quality and brand, is an ongoing expense. These materials include acrylic, epoxy, silicone, and polyurethane-based coatings, each with different properties and applications.

- Energy Consumption: Running automated machinery requires significant energy, contributing to operational costs. Energy-efficient models can help mitigate these expenses.

- Maintenance and Upgrades: Regular maintenance and occasional upgrades are necessary to ensure the machinery remains efficient and reliable. This includes replacing worn parts, updating software, and ensuring compliance with evolving industry standards.

Labor Costs

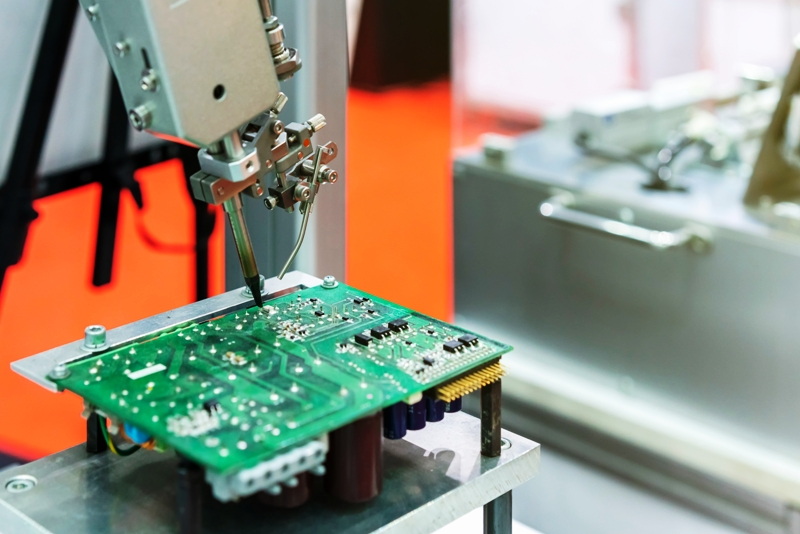

- Skilled Personnel: While automation reduces labor needs, skilled technicians are still required for machine operation and maintenance. These personnel must be trained to handle complex machinery and troubleshoot issues efficiently.

- Training Costs: Employees may need training to operate new machinery effectively, which can involve both initial training and ongoing education to keep up with technological advancements.

Managing Costs Effectively

To manage costs effectively, manufacturers should consider the following strategies:

1. Optimize Production Volume: Ensure that the production volume justifies the investment in automated machinery. High-volume production can help spread fixed costs over more units, reducing the cost per unit.

2. Select Appropriate Equipment: Choose machinery that aligns with production needs and budget constraints. This involves evaluating the level of automation required, the types of coatings to be applied, and the desired throughput.

3. Implement Efficient Maintenance Schedules: Regular maintenance can prevent costly downtime and extend equipment lifespan. Predictive maintenance techniques, such as monitoring equipment performance and scheduling maintenance based on usage, can be particularly effective.

4. Source Raw Materials Strategically: Negotiate with suppliers to secure favorable pricing for conformal coating materials. Building long-term relationships with suppliers can lead to better pricing and more reliable supply chains.

5. Consider Energy Efficiency: Choose machinery with energy-efficient designs to reduce operational costs over time. This can involve selecting models with advanced power management systems or those that use less energy-intensive processes.

Enhancing Product Reliability

One of the primary benefits of using SMT PCB coating machines is the enhancement of product reliability. By applying a conformal coating, manufacturers can protect PCBs from environmental factors that could otherwise lead to premature failure. This is particularly important in industries where electronic devices are exposed to harsh conditions, such as aerospace, automotive, and industrial automation.

Industry Applications

- Aerospace: In aerospace, conformal coatings are crucial for ensuring the reliability of electronic components under extreme temperatures and humidity conditions.

- Automotive: The automotive industry relies on conformal coatings to protect PCBs from moisture, dust, and chemicals in vehicles.

- Industrial Automation: In industrial settings, coatings help protect electronics from dust, moisture, and chemicals, ensuring continuous operation.

Future Trends in SMT PCB Coating

As technology advances, SMT PCB coating machines are likely to incorporate more sophisticated automation and precision technologies. Trends include:

- Advanced Robotics: Integration of robotics for more precise and flexible coating applications.

- AI-Powered Quality Control: Use of artificial intelligence to monitor and adjust coating processes in real-time for optimal quality.

- Sustainable Materials: Development of more environmentally friendly conformal coating materials that maintain performance while reducing environmental impact.

Conclusion

Investing in an SMT PCB coating machine is a strategic decision that can enhance the reliability and durability of PCBs. While the initial investment and operational costs are significant, these can be managed effectively by optimizing production processes, selecting appropriate equipment, and implementing efficient maintenance schedules. As the demand for high-quality electronic components continues to grow, the benefits of automated SMT PCB coating machines will become increasingly evident.

Frequently Asked Questions

1. What are the primary benefits of using automated SMT PCB coating machines?

Answer: Automated SMT PCB coating machines offer benefits such as increased precision, higher throughput, reduced labor costs, and improved quality control. These machines are particularly advantageous in high-volume production environments where consistency and efficiency are crucial.

2. How do I choose the right SMT PCB coating machine for my production needs?

Answer: When selecting an SMT PCB coating machine, consider factors such as production volume, desired level of automation, and budget constraints. It's also important to evaluate the machine's precision, speed, and compatibility with various conformal coating materials.

3. What are the key operational costs associated with SMT PCB coating machines?

Answer: Key operational costs include the cost of conformal coating materials, energy consumption, and maintenance expenses. Regular maintenance is essential to prevent equipment downtime and extend its lifespan.

4. How can I reduce labor costs when using an SMT PCB coating machine?

Answer: Labor costs can be reduced by maximizing automation in the coating process. While skilled technicians are still needed for machine operation and maintenance, automation significantly decreases the need for manual labor.

5. What are the long-term benefits of investing in an SMT PCB coating machine?

Answer: Long-term benefits include enhanced product reliability, increased production efficiency, and the ability to meet high-volume demands without significant increases in labor costs. Additionally, automated machines can help reduce rework and warranty claims by maintaining consistent quality standards.