Content Menu

● Understanding PCB SMT Stencils

● Common Materials Used for PCB SMT Stencils

>> 1. Stainless Steel

>>> Advantages of Stainless Steel Stencils:

>>> Limitations of Stainless Steel Stencils:

>> 2. Nickel Alloys

>>> Advantages of Nickel Alloy Stencils:

>>> Limitations of Nickel Alloy Stencils:

>> 3. Polyimide (Plastic)

>>> Advantages of Polyimide Stencils:

>>> Limitations of Polyimide Stencils:

● Factors Influencing Material Selection for PCB SMT Stencils

>> 1. Production Volume

>> 2. Component Types and Pitch

>> 3. Solder Paste Characteristics

>> 4. Environmental Factors

>> 5. Cost Considerations

>> 6. Printing Process Requirements

● Manufacturing Processes for PCB SMT Stencils

>> 1. Laser Cutting

>> 2. Chemical Etching

● Importance of Stencil Design in PCB Assembly

>> Aperture Size and Shape

>> Stencil Thickness

>> Step Stencils

● Maintenance and Care of PCB SMT Stencils

>> Regular Cleaning

>> Proper Storage

>> Inspection

>> Polishing

● Future Trends in PCB SMT Stencil Materials and Technology

>> Nano-Coated Stencils

>> Advanced Alloys

>> 3D-Printed Stencils

>> Smart Stencils

● Conclusion

● FAQ

>> 1. What is the most commonly used material for PCB SMT stencils?

>> 2. How does the choice of stencil material affect solder paste printing quality?

>> 3. What are the advantages of using nickel alloy stencils over stainless steel?

>> 4. How do plastic (polyimide) stencils compare to metal stencils for PCB assembly?

>> 5. What factors should be considered when selecting a material for PCB SMT stencils?

● Citations:

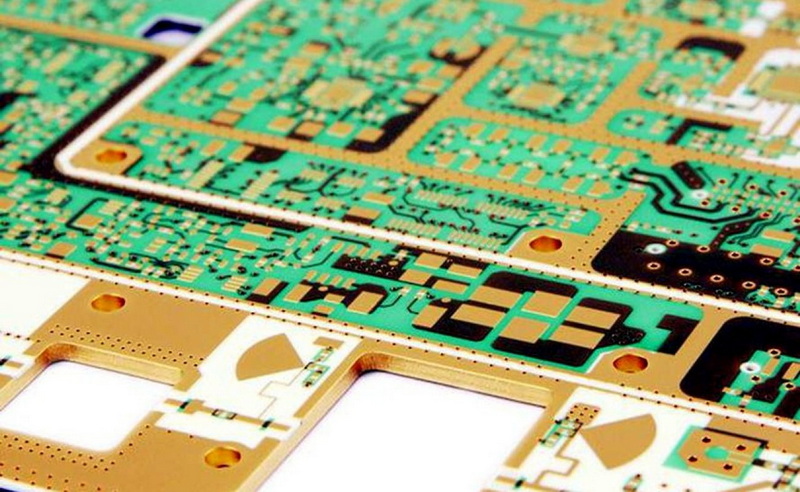

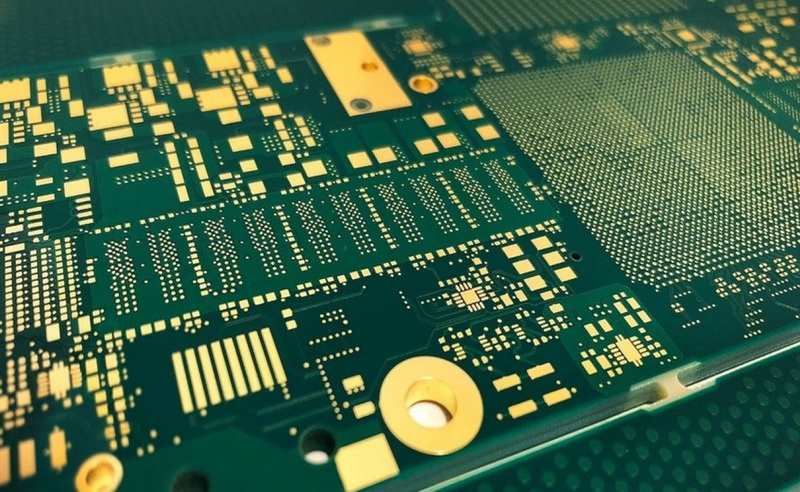

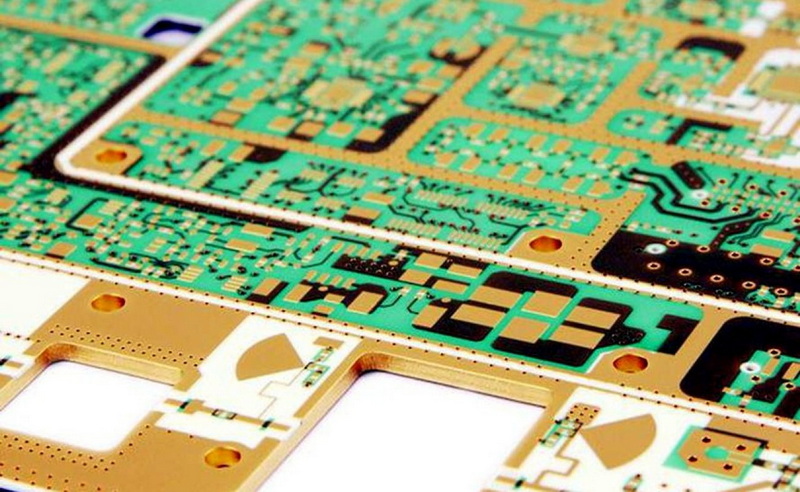

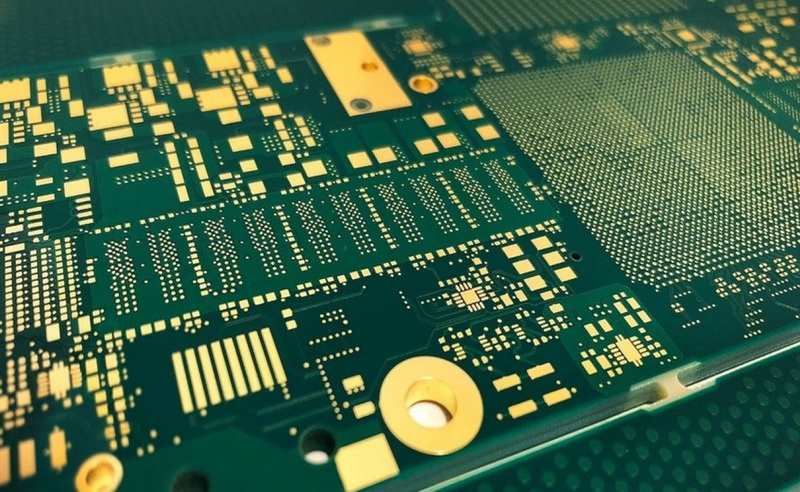

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, more efficient, and cost-effective printed circuit boards (PCBs). At the heart of this process lies the SMT stencil, a crucial tool that ensures precise and consistent application of solder paste onto PCB pads[7]. The choice of material for PCB SMT stencils plays a vital role in determining the quality, durability, and overall performance of the stencil during the assembly process.

Understanding PCB SMT Stencils

Before delving into the common materials used for PCB SMT stencils, it's essential to understand what these stencils are and their importance in the PCB assembly process.

PCB SMT stencils are thin sheets of material with precisely cut openings or apertures that correspond to the solder pad locations on a PCB. These stencils are used to apply solder paste accurately onto the PCB, which is crucial for creating reliable solder joints between components and the board[7].

The primary function of an SMT stencil is to control the amount and placement of solder paste on the PCB. This precision is critical because it directly affects the quality of the final product, including the strength of solder joints and the overall reliability of the electronic device.

Common Materials Used for PCB SMT Stencils

Several materials are commonly used in the manufacturing of PCB SMT stencils, each with its own set of characteristics, advantages, and limitations. Let's explore these materials in detail:

1. Stainless Steel

Stainless steel is by far the most commonly used material for PCB SMT stencils[1][4]. Its popularity stems from a combination of favorable properties that make it ideal for the stencil manufacturing process and subsequent use in PCB assembly.

Advantages of Stainless Steel Stencils:

- Durability: Stainless steel offers excellent strength and resistance to wear, making it suitable for high-volume production runs[4].

- Corrosion Resistance: The material's inherent resistance to corrosion ensures that the stencil maintains its integrity even when exposed to various chemicals used in the PCB assembly process.

- Dimensional Stability: Stainless steel maintains its shape and size across repeated solder paste printing cycles, ensuring consistent performance[6].

- Cost-Effectiveness: Compared to some other materials, stainless steel offers a good balance between performance and cost, making it an economical choice for many applications[6].

- Precision: Laser cutting techniques can create highly accurate apertures in stainless steel, essential for fine-pitch components and complex PCB designs[5].

Limitations of Stainless Steel Stencils:

- Weight: Stainless steel is relatively heavy, which can make handling and transportation more challenging, especially for larger stencils[4].

- Minor Abrasions: Over time, stainless steel stencils may develop minor abrasions, which could affect print quality in high-precision applications[6].

2. Nickel Alloys

Nickel alloys, such as Inconel or Monel, are another popular choice for PCB SMT stencils, especially in applications requiring superior mechanical properties or resistance to harsh environments[7].

Advantages of Nickel Alloy Stencils:

- Superior Mechanical Strength: Nickel alloys offer excellent mechanical strength, making them suitable for demanding applications[7].

- High-Temperature Resistance: These alloys perform well in high-temperature environments, which can be beneficial in certain manufacturing processes[7].

- Smooth Surface: Nickel stencils typically have a smoother surface than stainless steel, which can aid in better paste release and print quality[6].

- Reduced Abrasion: Nickel alloys tend to exhibit less abrasion over time compared to stainless steel, potentially extending the stencil's lifespan[6].

Limitations of Nickel Alloy Stencils:

- Cost: Nickel alloy stencils are generally more expensive than their stainless steel counterparts[6].

- Chemical Sensitivity: Some nickel alloys may exhibit more swelling when exposed to certain solder paste chemicals, which could affect aperture dimensions over time[6].

3. Polyimide (Plastic)

While less common for high-volume production, polyimide or plastic stencils have their place in PCB assembly, particularly for prototyping or low-volume runs.

Advantages of Polyimide Stencils:

- Cost-Effective: Plastic stencils are generally the least expensive option, making them attractive for small-scale production or prototyping[6].

- Lightweight: The low density of plastic materials makes these stencils easy to handle and transport.

- Flexibility: Plastic stencils can be more flexible than metal ones, which can be advantageous in certain applications.

Limitations of Polyimide Stencils:

- Limited Durability: Plastic stencils have lower strength and durability compared to metal alternatives, making them unsuitable for high-volume production[6].

- Chemical Absorption: Plastics can absorb solvents from solder pastes, leading to swelling and potential changes in aperture dimensions over time[6].

- Temperature Sensitivity: Plastic stencils may not perform well in high-temperature environments, limiting their use in certain manufacturing processes.

Factors Influencing Material Selection for PCB SMT Stencils

Choosing the right material for a PCB SMT stencil involves considering several factors:

1. Production Volume

The expected production volume significantly influences the choice of stencil material. For high-volume production runs, durable materials like stainless steel or nickel alloys are preferred. For low-volume production or prototyping, more cost-effective options like frameless stencils or even plastic stencils might be suitable[4].

2. Component Types and Pitch

The types of components being used and their pitch (the distance between leads) play a crucial role in material selection. For fine-pitch components or complex PCB layouts, materials that allow for precise aperture cutting and maintain dimensional stability are essential[7].

3. Solder Paste Characteristics

Different solder pastes may interact differently with stencil materials. Some pastes may cause swelling in certain materials, affecting print quality over time. The compatibility between the solder paste and stencil material should be considered[6].

4. Environmental Factors

If the manufacturing environment involves exposure to high temperatures or corrosive chemicals, materials with appropriate resistance properties should be chosen[7].

5. Cost Considerations

While not the only factor, the cost of the stencil material relative to the overall production budget and expected lifespan of the stencil should be taken into account[4].

6. Printing Process Requirements

The specific requirements of the printing process, such as print speed, release characteristics, and cleaning frequency, can influence the choice of stencil material[5].

Manufacturing Processes for PCB SMT Stencils

The manufacturing process used to create the stencil can be as important as the material itself in determining the stencil's performance. The two primary methods for manufacturing PCB SMT stencils are:

1. Laser Cutting

Laser cutting is the most common and precise method for manufacturing SMT stencils[5]. This process involves using high-energy laser beams to create precise aperture walls with sharp edges. The advantages of laser cutting include:

- High Accuracy: Laser cutting provides excellent precision in defining solder paste deposition areas, crucial for reliable electrical connections[5].

- Flexibility: This method can accommodate intricate PCB designs and fine-pitch components[5].

- Consistency: Laser cutting ensures uniform aperture sizes and shapes across the entire stencil.

2. Chemical Etching

While less common than laser cutting, chemical etching is still used in some stencil manufacturing processes. This method involves selectively removing material using chemical solutions[5]. The advantages of chemical etching include:

- Complex Designs: Chemical etching can create intricate aperture designs with precise tolerances[5].

- Cost-Effectiveness: For certain applications, chemical etching may be more cost-effective than laser cutting.

However, chemical etching has some drawbacks, including potential environmental concerns and less precision compared to laser cutting for very fine features.

Importance of Stencil Design in PCB Assembly

While the material of the stencil is crucial, the design of the stencil itself plays an equally important role in ensuring high-quality PCB assembly. Key aspects of stencil design include:

Aperture Size and Shape

The size and shape of the apertures in the stencil directly affect the amount and distribution of solder paste deposited on the PCB. Proper design ensures that each component receives the correct amount of solder paste for reliable connections.

Stencil Thickness

The thickness of the stencil affects the volume of solder paste deposited. Thicker stencils deposit more paste, which may be necessary for larger components, while thinner stencils are often used for fine-pitch components.

Step Stencils

In some cases, a single PCB may require different solder paste volumes for various components. Step stencils, which have multiple thickness levels within a single stencil, can accommodate these varying requirements[7].

Maintenance and Care of PCB SMT Stencils

Proper maintenance of SMT stencils is essential for ensuring consistent performance and longevity. Some key maintenance practices include:

Regular Cleaning

Stencils should be cleaned regularly to remove any residual solder paste or contaminants. This can be done using specialized cleaning solutions and equipment designed for stencil maintenance.

Proper Storage

When not in use, stencils should be stored in a clean, dry environment to prevent damage or contamination.

Inspection

Regular inspection of the stencil for signs of wear, damage, or clogged apertures is crucial. Any issues should be addressed promptly to maintain print quality.

Polishing

For some stencil materials, periodic polishing can help maintain a smooth surface, improving paste release and print quality[4].

Future Trends in PCB SMT Stencil Materials and Technology

As the electronics industry continues to evolve, so too does the technology behind PCB SMT stencils. Some emerging trends include:

Nano-Coated Stencils

Nano-coatings applied to stencil surfaces can improve paste release and reduce the need for frequent cleaning, potentially increasing productivity in high-volume production environments.

Advanced Alloys

Research into new metal alloys continues, aiming to develop materials with improved durability, thermal properties, and chemical resistance.

3D-Printed Stencils

While still in its early stages, 3D printing technology is being explored for stencil production, potentially offering new design possibilities and faster prototyping.

Smart Stencils

Integration of sensors and monitoring technologies into stencils could provide real-time data on print quality and stencil performance, enabling proactive maintenance and process optimization.

Conclusion

The choice of material for PCB SMT stencils is a critical decision that impacts the quality, efficiency, and reliability of the PCB assembly process. While stainless steel remains the most widely used material due to its excellent balance of properties and cost-effectiveness, other materials like nickel alloys and polyimide have their place in specific applications.

The selection of stencil material should be based on a careful consideration of factors including production volume, component types, environmental conditions, and cost constraints. Additionally, the manufacturing process, stencil design, and proper maintenance all play crucial roles in ensuring optimal stencil performance.

As the electronics industry continues to push the boundaries of miniaturization and complexity, the technology behind PCB SMT stencils will undoubtedly continue to evolve. Staying informed about new materials, manufacturing techniques, and maintenance practices will be essential for electronics manufacturers looking to maintain a competitive edge in this rapidly advancing field.

FAQ

1. What is the most commonly used material for PCB SMT stencils?

Stainless steel is the most commonly used material for PCB SMT stencils. It offers an excellent balance of durability, corrosion resistance, and cost-effectiveness, making it suitable for a wide range of applications in PCB assembly[1][4].

2. How does the choice of stencil material affect solder paste printing quality?

The choice of stencil material can significantly impact solder paste printing quality. Different materials have varying surface properties, which affect paste release and print definition. For example, nickel alloys often provide smoother surfaces than stainless steel, potentially improving paste release and print quality, especially for fine-pitch components[6].

3. What are the advantages of using nickel alloy stencils over stainless steel?

Nickel alloy stencils offer several advantages over stainless steel, including superior mechanical strength, high-temperature resistance, and smoother surfaces. These properties make nickel alloys particularly suitable for demanding applications or environments where high precision and durability are crucial[7].

4. How do plastic (polyimide) stencils compare to metal stencils for PCB assembly?

Plastic or polyimide stencils are generally less durable and have lower temperature resistance compared to metal stencils. However, they are more cost-effective and lightweight, making them suitable for prototyping or low-volume production runs. Plastic stencils are not typically used for high-volume production due to their limited lifespan and potential for chemical absorption from solder pastes[6].

5. What factors should be considered when selecting a material for PCB SMT stencils?

When selecting a material for PCB SMT stencils, several factors should be considered, including production volume, component types and pitch, solder paste characteristics, environmental factors (such as temperature and chemical exposure), cost considerations, and specific printing process requirements. The choice of material should balance these factors to ensure optimal performance and cost-effectiveness for the particular application[4][7].

Citations:

[1] https://jlcpcb.com/blog/how-to-choose-a-smt-stencil

[2] https://www.wevolver.com/article/pcb-stencil

[3] https://www.multi-circuit-boards.eu/en/pcb-design-aid/smd-stencils.html

[4] https://jlcpcb.com/blog/why-pcb-stencils-are-key-to-high-quality-smt-assembly

[5] https://jlcpcb.com/blog/guide-to-smt-stencils-in-pcb-assembly

[6] https://www.elepcb.com/blog/pcb-stencil-smt-assembly/

[7] https://pcbpit.com/smt-stencil-a-comprehensive-guide/

[8] https://www.pcbelec.com/how-to-use-pcb-stencil.html

[9] http://www.qualiecocircuits.com.au/stencil-technology-other-aspects.html

[10] https://www.aipcba.com/pcb/smt-stencil-fabrication.html