Content Menu

● Understanding the SMT PCB Production Line

● Common Challenges in SMT PCB Production Lines

>> 1. Component Placement Accuracy

>> 2. Solder Paste Application Consistency

>> 3. Soldering Defects

>> 4. Handling Fine-Pitch and Miniaturized Components

>> 5. Rework and Repair Difficulties

>> 6. Process Control and Quality Assurance

>> 7. Environmental and Cost Considerations

● Conclusion

● FAQ

>> 1. What is the main cause of solder bridging in SMT PCB production lines?

>> 2. How can component placement accuracy be improved in SMT lines?

>> 3. Why is rework more difficult in SMT PCB assemblies compared to through-hole assemblies?

>> 4. What role does solder paste inspection (SPI) play in SMT production?

>> 5. How does environmental control affect SMT PCB production quality?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the assembly of smaller, faster, and more complex printed circuit boards (PCBs). The SMT PCB production line is a critical process where electronic components are mounted directly onto the surface of PCBs using automated machines. Despite its advantages, the SMT PCB production line faces several common challenges that can impact product quality, production efficiency, and cost-effectiveness.

This article explores these challenges in detail, providing insights into their causes, effects, and practical solutions to optimize SMT PCB production lines.

Understanding the SMT PCB Production Line

An SMT PCB production line typically involves several key stages:

- Material preparation and inspection

- Solder paste printing using stencils

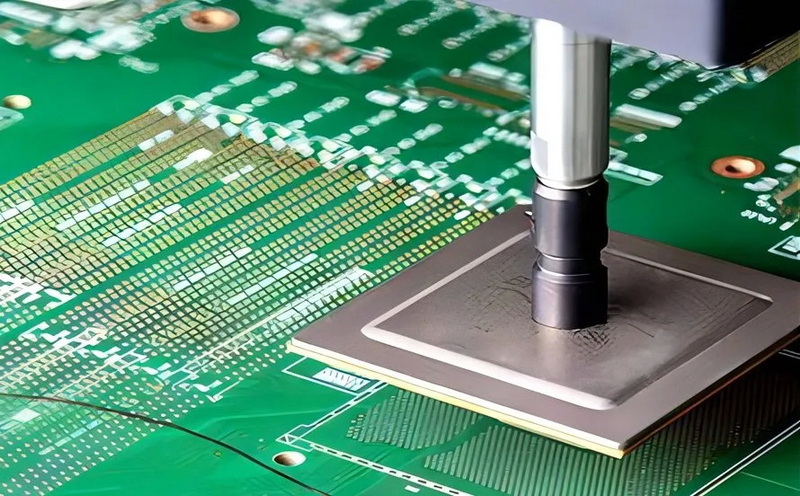

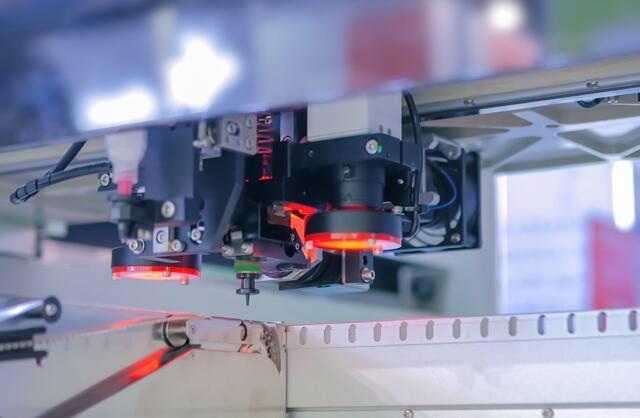

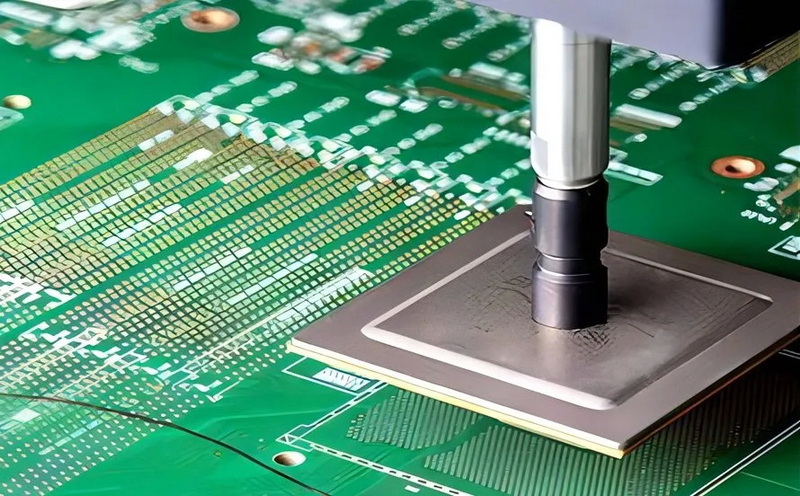

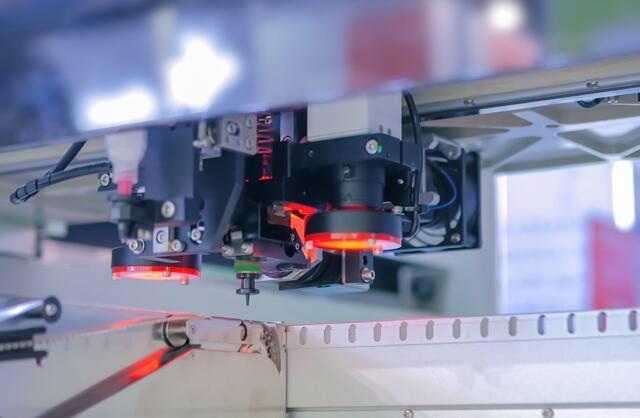

- Component placement by pick-and-place machines

- Reflow soldering to form electrical and mechanical connections

- Cleaning and inspection (including Automated Optical Inspection - AOI)

- Testing and final assembly

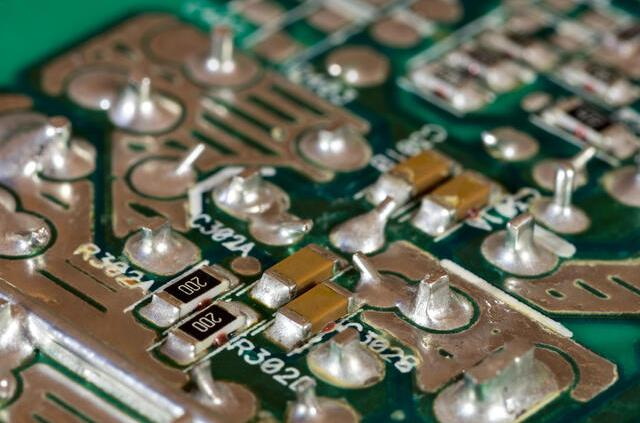

Each stage requires precision and control to ensure the final PCB meets quality and reliability standards. The complexity of modern PCBs, with smaller components and finer pitches, increases the difficulty of maintaining consistent quality throughout the SMT PCB production line.

The SMT PCB production line is highly automated, relying on sophisticated machinery such as stencil printers, pick-and-place machines, reflow ovens, and inspection systems. However, the integration of these processes also means that a failure or inefficiency in one stage can cascade and affect the entire production output. Therefore, understanding and addressing the common challenges in each phase is critical for manufacturers aiming to produce high-quality PCBs.

Common Challenges in SMT PCB Production Lines

1. Component Placement Accuracy

Challenge:

Accurate placement of components on the PCB is fundamental. Misalignment can cause short circuits, open circuits, or degraded device performance. The challenge increases with the miniaturization of components and the use of fine-pitch devices.

Causes:

- Calibration errors in pick-and-place machines

- Operator errors or insufficient training

- Mechanical wear and tear of equipment

- Variations in PCB warpage or flatness affecting placement precision

Effects:

Misplaced components can lead to electrical failures, increased rework rates, and reduced yield. For example, a misaligned QFN (Quad Flat No-Lead) package may cause poor solder joints that result in intermittent connections.

Solutions:

- Use high-precision placement machines with regular calibration and maintenance schedules.

- Implement operator training programs emphasizing placement accuracy and machine handling.

- Employ advanced vision systems with fiducial recognition to improve alignment accuracy.

- Monitor PCB warpage and use fixtures or carriers to maintain flatness during placement.

2. Solder Paste Application Consistency

Challenge:

Inconsistent or insufficient solder paste application leads to weak solder joints, tombstoning (where one side of a component lifts off the pad), solder bridging, and open circuits.

Causes:

- Poor stencil quality or misalignment

- Clogged stencil apertures due to dried solder paste residues

- Incorrect solder paste metal-to-flux ratio affecting viscosity and wetting

- Environmental factors like humidity and temperature affecting solder paste behavior

- Variability in squeegee pressure and speed during printing

Effects:

Poor solder paste deposition results in defective solder joints, which can cause functional failures and reliability issues in the field. Tombstoning can cause components to lift and lose contact on one side, while bridging causes short circuits.

Solutions:

- Utilize high-quality, well-maintained stencils with precise alignment systems.

- Regularly clean stencil apertures to avoid clogging and ensure uniform paste release.

- Use solder paste with appropriate metal content (typically 85-90% metal for fine-pitch applications) and store it under controlled temperature and humidity.

- Implement automated solder paste inspection (SPI) systems to detect defects early and provide feedback for process adjustments.

- Optimize printing parameters such as squeegee pressure, speed, and angle to achieve consistent paste deposits.

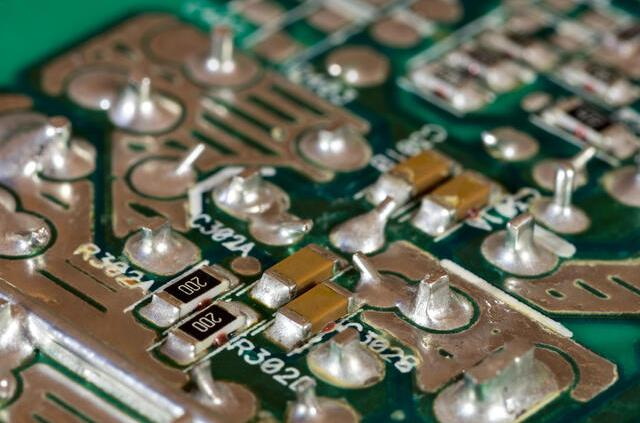

3. Soldering Defects

Challenge:

Defects such as solder bridging, insufficient solder joints, cold joints, and solder balls can compromise electrical connectivity and mechanical strength.

Causes:

- Excessive or insufficient solder paste volume

- Improper reflow oven temperature profiles, including incorrect ramp rates or peak temperatures

- Component placement pressure causing solder paste displacement

- Poor solder paste quality or improper storage leading to degradation

- Contamination on PCB pads or component leads

Effects:

Soldering defects can cause immediate functional failures or latent reliability problems, such as intermittent connections or early-life failures under thermal or mechanical stress.

Solutions:

- Optimize solder paste volume by adjusting stencil thickness and aperture size to match component requirements.

- Develop and maintain proper reflow profiles with controlled preheat, soak, reflow, and cooling zones tailored to the solder paste and component specifications.

- Monitor and control component placement force to prevent paste displacement.

- Use high-quality solder paste and adhere to recommended storage conditions to maintain paste integrity.

- Ensure PCB pads and component leads are clean and free from oxidation or contamination before assembly.

4. Handling Fine-Pitch and Miniaturized Components

Challenge:

The increasing use of fine-pitch components (less than 0.5 mm lead spacing) and very small devices demands higher precision and process control.

Causes:

- Limitations in machine vision systems for accurate placement and inspection at very small scales

- Increased risk of solder bridging and tombstoning due to tight spacing and small solder volumes

- Difficulties in rework and repair due to small size and leadless packages such as QFNs and BGAs (Ball Grid Arrays)

Effects:

Handling fine-pitch components incorrectly can lead to higher defect rates, increased rework, and lower yields, impacting overall production efficiency and cost.

Solutions:

- Invest in advanced pick-and-place machines with enhanced vision and alignment capabilities, including 3D inspection and laser alignment.

- Employ nano-coated stencils to improve solder paste release and consistency, reducing bridging and tombstoning risks.

- Use specialized rework stations designed for fine-pitch components with precise temperature control and magnification.

- Implement stringent process controls and inspection at every stage, including SPI and AOI systems capable of detecting fine-pitch defects.

5. Rework and Repair Difficulties

Challenge:

Due to the compactness and complexity of SMT assemblies, reworking defective boards is challenging and time-consuming.

Causes:

- Leadless and ultra-small components are difficult to remove and replace without damaging PCB pads or adjacent components.

- Risk of thermal damage to sensitive components during rework.

- Limited accessibility on densely populated boards complicates manual repair operations.

Effects:

Rework can introduce new defects, damage PCBs, or reduce long-term reliability if not performed correctly. It also increases production costs and delays delivery schedules.

Solutions:

- Minimize defects through process optimization and inline inspection to reduce rework frequency.

- Use precision rework tools with temperature control, vacuum pick-up, and magnification to safely remove and replace components.

- Train technicians in specialized SMT rework techniques and best practices.

- Design PCBs with reworkability in mind, providing adequate spacing and thermal reliefs where possible.

6. Process Control and Quality Assurance

Challenge:

Maintaining consistent quality in the SMT PCB production line requires tight process control and real-time monitoring.

Causes:

- Variability in materials, equipment, and operator performance.

- Lack of integrated data management and feedback systems.

- Environmental fluctuations affecting solder paste and component behavior.

Effects:

Inconsistent processes lead to unpredictable yields, increased scrap rates, and customer dissatisfaction.

Solutions:

- Implement centralized online management and control systems for real-time process monitoring and data collection.

- Use automated inspection tools such as AOI and X-ray inspection to detect defects early in the production line.

- Conduct regular process audits, root cause analysis, and continuous improvement initiatives such as Six Sigma or Lean Manufacturing.

- Control environmental conditions such as temperature and humidity in production areas to stabilize material behavior.

7. Environmental and Cost Considerations

Challenge:

SMT production lines consume materials like solder paste, flux, and cleaning agents that can impact the environment and increase operational costs.

Causes:

- Use of hazardous chemicals and materials.

- Waste generation from stencil cleaning and solder paste residues.

- High labor and equipment maintenance costs.

Effects:

Environmental regulations may impose restrictions and penalties, while inefficient processes increase production costs and reduce competitiveness.

Solutions:

- Adopt environmentally friendly materials and processes, such as lead-free solder pastes and water-based cleaning agents.

- Optimize material usage and recycling where possible to reduce waste.

- Invest in automation to reduce labor costs and improve efficiency.

- Implement energy-efficient equipment and practices to reduce the carbon footprint of production.

Conclusion

The SMT PCB production line is a sophisticated and essential part of modern electronics manufacturing. While it offers significant advantages in terms of miniaturization, speed, and functionality, it also presents numerous challenges. These include ensuring component placement accuracy, consistent solder paste application, managing soldering defects, handling fine-pitch components, difficulty in rework, maintaining process control, and addressing environmental and cost concerns.

Addressing these challenges requires a combination of advanced equipment, skilled personnel, stringent process controls, and continuous improvement strategies. By doing so, manufacturers can enhance product quality, reduce defects, increase production efficiency, and remain competitive in the rapidly evolving electronics industry.

FAQ

1. What is the main cause of solder bridging in SMT PCB production lines?

Solder bridging is primarily caused by excessive solder paste deposition, misalignment of the stencil apertures to PCB pads, improper solder paste metal-to-flux ratio, and incorrect reflow oven temperature profiles.

2. How can component placement accuracy be improved in SMT lines?

Improvement can be achieved by using high-precision pick-and-place machines, regular calibration, operator training, and routine equipment maintenance.

3. Why is rework more difficult in SMT PCB assemblies compared to through-hole assemblies?

SMT components are smaller, often leadless, and densely packed, making removal and replacement challenging without damaging adjacent parts or the PCB itself.

4. What role does solder paste inspection (SPI) play in SMT production?

SPI systems detect solder paste defects early, such as insufficient or excessive paste, enabling corrective actions before component placement and reflow, thus reducing defects.

5. How does environmental control affect SMT PCB production quality?

Environmental factors like humidity and temperature affect solder paste behavior and component handling. Controlled environments help maintain consistent solder paste viscosity and prevent defects such as tombstoning and bridging.