Content Menu

● Understanding SMT Breakout PCBs

>> Key Features of SMT Breakout PCBs

● Common Applications of SMT Breakout PCBs

>> 1. Prototyping and Development

>> 2. Education and Learning

>> 3. Sensor Integration

>> 4. Microcontroller and Processor Testing

>> 5. RF and Wireless Module Integration

>> 6. High-Speed Circuit Design

>> 7. Power Management Circuits

>> 8. Display and Interface Prototyping

>> 9. Audio Circuit Development

>> 10. Automotive Electronics Prototyping

● Advantages of Using SMT Breakout PCBs

● Designing with SMT Breakout PCBs

● Future Trends in SMT Breakout PCBs

● Challenges and Considerations

● Conclusion

● FAQ

>> 1. What is the main purpose of an SMT breakout PCB?

>> 2. Can SMT breakout PCBs be used in final products?

>> 3. How do SMT breakout PCBs affect signal integrity in high-frequency applications?

>> 4. Are there any limitations to using SMT breakout PCBs?

>> 5. How do I choose the right SMT breakout PCB for my project?

● Citations:

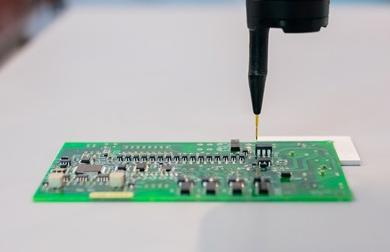

Surface Mount Technology (SMT) breakout PCBs have become an essential tool in the world of electronics design and prototyping. These small but mighty boards serve as a bridge between the miniature world of SMT components and the more accessible realm of through-hole prototyping. In this comprehensive exploration, we'll delve into the various applications of SMT breakout PCBs, their benefits, and how they're revolutionizing the way engineers and hobbyists approach electronic projects.

Understanding SMT Breakout PCBs

Before we dive into the applications, it's crucial to understand what SMT breakout PCBs are and why they're so valuable. SMT breakout PCBs are small printed circuit boards designed to "break out" the pins of surface-mount components into a more manageable format, typically with standard 0.1" (2.54mm) spaced through-hole pins[1]. This conversion allows SMT components to be easily integrated into breadboard prototypes or through-hole PCB designs.

Key Features of SMT Breakout PCBs

1. Pin Conversion: They transform dense SMT pinouts into widely spaced through-hole pins.

2. Compatibility: Enable the use of SMT components in breadboard prototyping.

3. Flexibility: Allow for easy swapping and testing of different SMT components.

4. Accessibility: Make advanced SMT parts accessible to hobbyists and students.

Common Applications of SMT Breakout PCBs

Now, let's explore the diverse range of applications where SMT breakout PCBs prove invaluable.

1. Prototyping and Development

One of the primary applications of SMT breakout PCBs is in the realm of prototyping and development. Engineers and designers use these boards to quickly test and integrate SMT components into their circuit designs without the need for specialized SMT soldering equipment[1].

Benefits in Prototyping:

- Rapid iteration of designs

- Easy component swapping for testing different parts

- Reduced risk of damaging expensive SMT components

2. Education and Learning

SMT breakout PCBs play a crucial role in educational settings, allowing students to work with modern SMT components while using familiar through-hole prototyping techniques[6].

Educational Advantages:

- Hands-on experience with current technology

- Simplified introduction to SMT concepts

- Bridging the gap between theory and practical application

3. Sensor Integration

Many modern sensors come in SMT packages. Breakout PCBs make it easy to incorporate these sensors into larger projects or experimental setups[5].

Examples of Sensor Applications:

- Environmental monitoring (temperature, humidity, pressure)

- Motion detection and accelerometers

- Light and color sensors

4. Microcontroller and Processor Testing

SMT breakout PCBs are particularly useful for testing and prototyping with microcontrollers and processors that are only available in SMT packages[1].

Advantages for Microcontroller Projects:

- Easy access to all pins for debugging

- Simplified power and programming connections

- Ability to create custom development boards

5. RF and Wireless Module Integration

Many RF and wireless modules come in SMT formats. Breakout PCBs allow for easy integration and testing of these components in wireless projects[3].

RF Applications:

- Bluetooth and WiFi module testing

- IoT device prototyping

- Amateur radio projects

6. High-Speed Circuit Design

For high-speed circuits, SMT components often offer better performance. Breakout PCBs allow designers to incorporate these high-performance parts into their prototypes[3].

High-Speed Design Benefits:

- Reduced parasitic capacitance and inductance

- Improved signal integrity

- Easier testing of high-frequency components

7. Power Management Circuits

Many power management ICs are only available in SMT packages. Breakout PCBs make it possible to prototype and test power supply designs using these advanced components[5].

Power Management Applications:

- Voltage regulator testing

- Battery management system prototyping

- Power converter design

8. Display and Interface Prototyping

SMT breakout PCBs are useful for integrating small displays and interface components that often come in SMT packages[6].

Display and Interface Uses:

- OLED and LCD module testing

- Touch sensor integration

- LED driver circuit prototyping

9. Audio Circuit Development

Many modern audio ICs are SMT-only. Breakout PCBs allow audio enthusiasts and professionals to experiment with these components[5].

Audio Applications:

- Amplifier circuit testing

- Digital-to-analog converter (DAC) integration

- Audio effects pedal prototyping

10. Automotive Electronics Prototyping

The automotive industry heavily uses SMT components. Breakout PCBs facilitate the prototyping and testing of automotive electronic systems[3].

Automotive Prototyping Examples:

- CAN bus interface testing

- Sensor integration for vehicle diagnostics

- LED lighting control systems

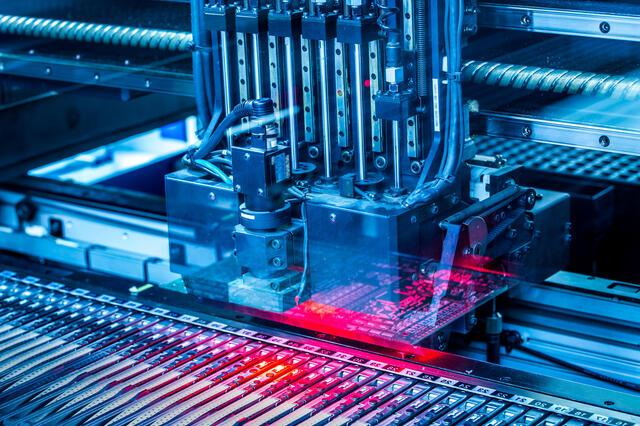

Advantages of Using SMT Breakout PCBs

The widespread use of SMT breakout PCBs in various applications is due to several key advantages:

1. Accessibility: They make advanced SMT components accessible to a wider range of users, from hobbyists to professional engineers[1].

2. Cost-Effectiveness: Breakout PCBs allow for testing and prototyping without the need for expensive SMT assembly equipment[3].

3. Flexibility: They enable easy swapping of components and quick design iterations[6].

4. Reduced Risk: Using breakout PCBs minimizes the risk of damaging expensive or delicate SMT components during prototyping[1].

5. Educational Value: They serve as an excellent tool for teaching and learning about modern electronic components and circuit design[6].

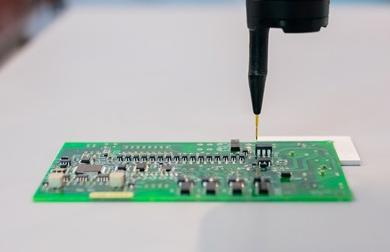

Designing with SMT Breakout PCBs

When incorporating SMT breakout PCBs into your designs, consider the following best practices:

1. Proper Pin Labeling: Ensure that the breakout board clearly labels all pins to avoid confusion and miswiring.

2. Adequate Spacing: Design the board with sufficient spacing between pins to accommodate standard breadboard and perfboard layouts.

3. Multiple Mounting Options: Include both through-hole pins and castellated edges for versatile mounting options.

4. Consideration of Signal Integrity: For high-speed applications, keep trace lengths short and use proper grounding techniques.

5. Thermal Management: For components that generate significant heat, include thermal vias or copper pours for better heat dissipation.

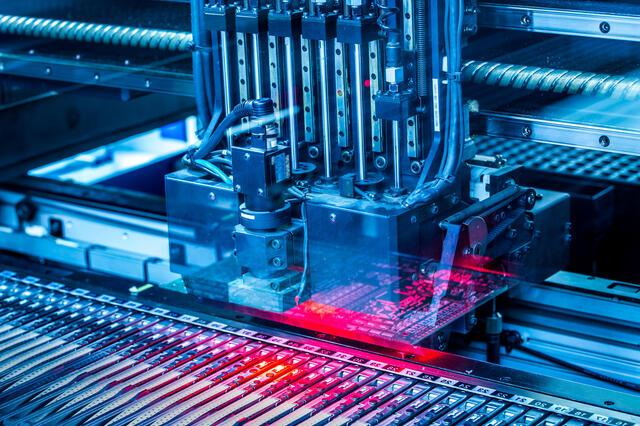

Future Trends in SMT Breakout PCBs

As electronics continue to evolve, we can expect to see some exciting trends in SMT breakout PCB design and application:

1. Increased Miniaturization: Breakout PCBs for even smaller SMT packages, such as 0201 and 01005 components.

2. Multi-Component Breakouts: Boards that break out multiple related SMT components on a single PCB for more complex prototyping.

3. Integrated Test Points: Inclusion of dedicated test points and debug interfaces on breakout PCBs.

4. Modular Breakout Systems: Development of standardized, interconnectable breakout modules for rapid prototyping of complex systems.

5. Advanced Materials: Use of high-performance PCB materials for improved signal integrity in high-frequency applications.

Challenges and Considerations

While SMT breakout PCBs offer numerous advantages, there are some challenges to consider:

1. Signal Integrity: The additional traces and connections can impact high-frequency signal performance.

2. Size Limitations: Breakout PCBs inevitably increase the overall footprint compared to direct SMT integration.

3. Cost in Production: While beneficial for prototyping, using breakout PCBs in final products can increase production costs.

4. Thermal Considerations: Some high-power SMT components may require additional thermal management when used with breakout PCBs.

5. Parasitic Effects: The added length in signal paths can introduce unwanted parasitic capacitance and inductance.

Conclusion

SMT breakout PCBs have revolutionized the way engineers, hobbyists, and students approach electronic prototyping and development. By bridging the gap between advanced SMT components and traditional through-hole prototyping methods, these versatile boards enable rapid innovation, simplified testing, and accessible learning across a wide range of applications. From sensor integration and microcontroller development to high-speed circuit design and audio applications, SMT breakout PCBs continue to play a crucial role in the electronics industry.

As technology advances, we can expect to see even more innovative uses for SMT breakout PCBs, further enhancing their value in both educational and professional settings. Whether you're a seasoned engineer or a curious hobbyist, incorporating SMT breakout PCBs into your projects can open up new possibilities and streamline your development process.

FAQ

1. What is the main purpose of an SMT breakout PCB?

The main purpose of an SMT breakout PCB is to convert the compact, closely-spaced pins of surface-mount components into a more accessible format, typically with standard 0.1" spaced through-hole pins. This allows SMT components to be easily used in breadboard prototypes or through-hole PCB designs.

2. Can SMT breakout PCBs be used in final products?

While SMT breakout PCBs are primarily designed for prototyping and development, they can be used in final products in some cases. However, this is generally not recommended for high-volume production as it can increase costs and overall product size. In final designs, it's usually more efficient to integrate SMT components directly onto the main PCB.

3. How do SMT breakout PCBs affect signal integrity in high-frequency applications?

SMT breakout PCBs can potentially impact signal integrity in high-frequency applications due to the additional trace length and potential for increased parasitic capacitance and inductance. For critical high-frequency designs, it's important to use high-quality breakout PCBs with proper layout considerations, or to transition to direct SMT integration for the final design.

4. Are there any limitations to using SMT breakout PCBs?

Yes, there are some limitations to using SMT breakout PCBs:

- They increase the overall footprint of the component

- They may introduce additional parasitic effects

- They can add cost in production scenarios

- Some very high-frequency or high-power applications may not be suitable for breakout board use

5. How do I choose the right SMT breakout PCB for my project?

When choosing an SMT breakout PCB, consider the following factors:

- Ensure the breakout board matches the exact pinout of your SMT component

- Check that the board provides the necessary connections and features for your application

- Consider the quality of the PCB material, especially for high-frequency applications

- Look for clear pin labeling and adequate spacing for easy prototyping

- Verify that the board's size and mounting options are compatible with your project requirements

Citations:

[1] https://www.raypcb.com/smt-breakout-boards/

[2] https://jlcpcb.com/blog/the-characteristics-of-surface-mount-technology

[3] https://www.vse.com/blog/2020/05/07/surface-mount-technology-advantages-and-disadvantages-for-pcb-assembly/

[4] https://forums.adafruit.com/viewtopic.php?t=183930

[5] https://www.macrofab.com/blog/smt-assembly-vs-through-hole/

[6] https://www.adafruit.com/product/1212

[7] https://www.pcbgogo.com/current-events/Surface_Mount_Technology___All_You_Need_To_Know___PCBGOGO.html

[8] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[9] https://jhdpcb.com/blog/efficient-smt-assembly/

[10] https://www.mpe-electronics.co.uk/2024/10/22/advantages-and-disadvantages-of-surface-mount-technology

[11] https://vectorbluehub.com/smt-assembly