Content Menu

● Understanding SMT Machines

● Importance of Spare Parts in SMT Machines

● Best Spare Parts for SMT Machines

>> Nozzles

>> Feeders

>> Filters

>> Belts and Rollers

>> Sensors

● Additional Essential Spare Parts

>> Cameras

>> Power Supplies

>> Control Boards

● Choosing the Right Spare Parts

● Maintenance Tips for SMT Machines

● Conclusion

● FAQ

>> 1. What are common issues faced with SMT machines?

>> 2. How often should I replace spare parts in my SMT machine?

>> 3. Can I use non-branded spare parts?

>> 4. What maintenance practices should I follow?

>> 5. Where can I purchase high-quality spare parts?

● Citations:

Surface Mount Technology (SMT) has revolutionized the manufacturing of electronic components, allowing for more compact and efficient designs. As the demand for SMT machines increases, so does the need for high-quality spare parts that ensure optimal performance and longevity. In this article, we will explore the best spare parts for SMT machines, their importance, and how they contribute to maintaining a seamless production line.

Understanding SMT Machines

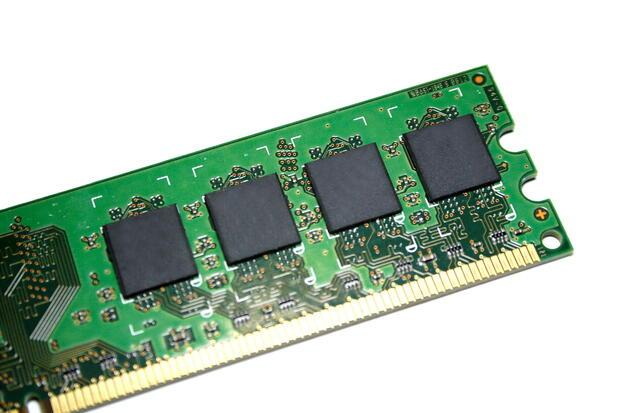

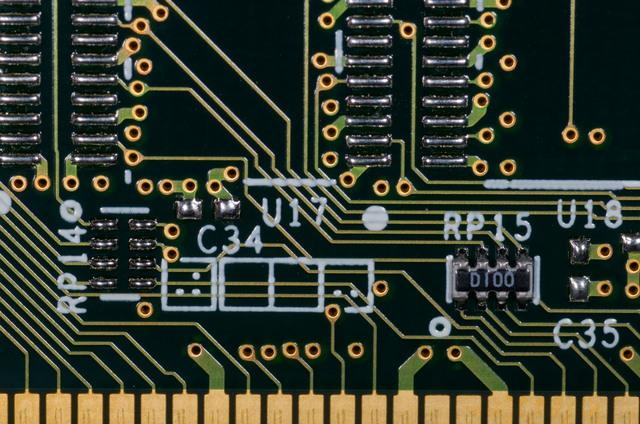

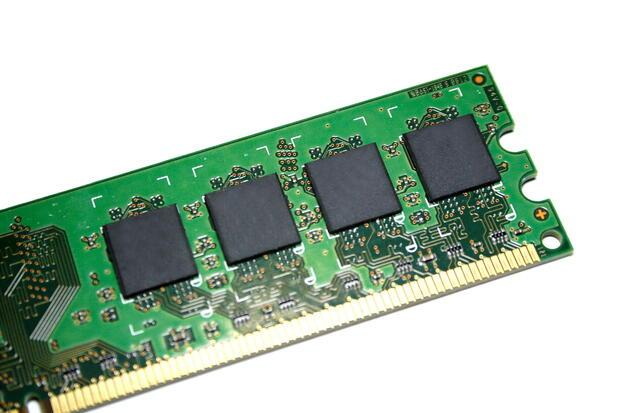

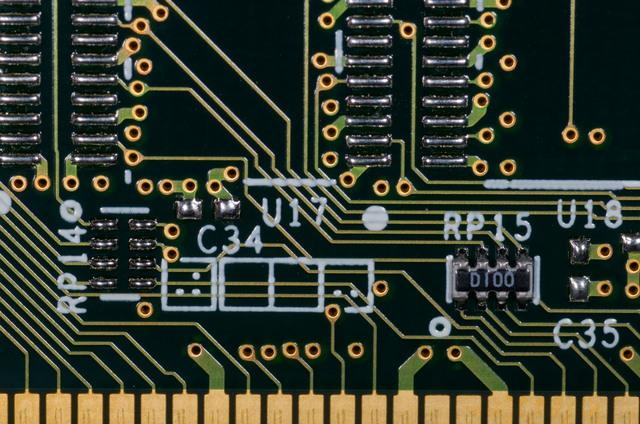

SMT machines are essential in the assembly of electronic components onto printed circuit boards (PCBs). They utilize various components and systems to ensure precise placement and soldering of surface mount devices (SMDs). The primary types of SMT machines include:

- Pick-and-Place Machines: These machines are responsible for picking up electronic components and placing them accurately on PCBs.

- Soldering Machines: Used to solder components onto the boards, ensuring a strong electrical connection.

- Inspection Equipment: Vital for checking the quality of solder joints and component placement.

The efficiency and reliability of these machines are critical to meeting production demands, making it imperative to use high-quality spare parts.

Importance of Spare Parts in SMT Machines

High-quality spare parts are crucial for several reasons:

- Performance: Quality spare parts ensure that machines operate at peak efficiency, reducing downtime.

- Cost-effectiveness: Investing in reliable spare parts can save costs associated with machine repairs and replacements.

- Longevity: Using the right spare parts can extend the lifespan of SMT machines.

In a fast-paced manufacturing environment, any downtime can lead to significant losses. Therefore, maintaining an inventory of essential spare parts is a strategic move that can enhance productivity.

Best Spare Parts for SMT Machines

Here's a detailed look at some of the best spare parts available for SMT machines:

Nozzles

Nozzles play a critical role in pick-and-place operations. They are responsible for picking up components and placing them accurately on PCBs. High-quality nozzles ensure minimal damage to components and precise placement.

- Types of Nozzles:

- Standard Nozzles: Suitable for most SMDs.

- Specialized Nozzles: Designed for specific component shapes or sizes, such as those used for odd-form components or larger packages.

Selecting the right nozzle type is crucial for optimizing machine performance. For instance, using a specialized nozzle can significantly improve handling delicate components without causing damage.

Feeders

Feeders supply components to the pick-and-place machine. They can significantly affect production speed and accuracy.

- Types of Feeders:

- Auto-load Feeders: Reduce manual labor by automatically loading components into the machine.

- Manual Feeders: Require operator intervention but are often more cost-effective.

Choosing the right feeder depends on your production volume and component types. Automated feeders can improve efficiency but may require more initial investment.

Filters

Filters are essential for maintaining clean air supply within SMT machines. They prevent dust and debris from contaminating components and PCBs.

- Types of Filters:

- HEPA Filters: High-efficiency particulate air filters that trap small particles.

- Activated Carbon Filters: Effective in removing odors and volatile organic compounds.

Regularly replacing filters is crucial to maintaining an optimal working environment within SMT machines, thus ensuring high-quality production standards.

Belts and Rollers

These components are crucial for the movement of PCBs through various stages of assembly. Worn-out belts can lead to misalignment and production errors.

- Maintenance Tips:

- Regularly inspect belts for wear.

- Replace belts as needed to maintain smooth operation.

Using high-quality belts can reduce slippage and improve overall machine reliability. It's also important to keep rollers clean to avoid contamination that could affect PCB movement.

Sensors

Sensors monitor various parameters within SMT machines, such as component placement accuracy and machine speed. High-quality sensors provide real-time feedback, allowing for immediate adjustments.

- Types of Sensors:

- Optical Sensors: Used for detecting component presence and alignment.

- Pressure Sensors: Monitor pneumatic systems within feeders.

Investing in advanced sensors can enhance automation capabilities, leading to improved accuracy in component placement and reduced error rates during production.

Additional Essential Spare Parts

In addition to the primary spare parts mentioned above, there are several other components that play vital roles in ensuring optimal performance:

Cameras

Modern SMT machines often incorporate advanced camera systems for inspection purposes. These cameras help verify component placement accuracy and detect defects during assembly.

- Benefits of High-Quality Cameras:

- Enhanced image resolution allows for better defect detection.

- Real-time feedback helps operators make immediate adjustments during production runs.

Power Supplies

Reliable power supplies are essential for maintaining consistent operation across all machine components. Fluctuations in power can lead to machine malfunctions or even damage sensitive electronics.

- Key Considerations:

- Ensure compatibility with your SMT machine's specifications.

- Opt for power supplies with built-in surge protection features.

Control Boards

Control boards manage the operations of various machine functions, including movement control, sensor integration, and data processing. A malfunctioning control board can halt production entirely.

- Maintenance Tips:

- Regularly check connections and firmware updates.

- Replace aging control boards proactively to avoid unexpected failures.

Choosing the Right Spare Parts

When selecting spare parts for SMT machines, consider the following factors:

- Compatibility: Ensure that spare parts are compatible with your specific SMT machine model.

- Quality: Opt for high-quality parts from reputable manufacturers to guarantee performance.

- Cost: Balance cost with quality; cheaper parts may lead to higher long-term expenses due to frequent replacements.

Maintenance Tips for SMT Machines

To maximize the lifespan and efficiency of your SMT machines, adhere to these maintenance tips:

1. Regular Cleaning: Keep machines clean to prevent dust buildup that can affect performance.

2. Scheduled Inspections: Conduct regular inspections to identify worn or damaged parts early.

3. Operator Training: Ensure that operators are well-trained in machine operation and maintenance procedures.

4. Inventory Management: Maintain an inventory of critical spare parts to minimize downtime during repairs or replacements.

5. Documentation: Keep detailed records of maintenance activities and part replacements to track performance over time.

Conclusion

Investing in quality spare parts is essential for maintaining the efficiency and longevity of SMT machines. By understanding which parts are critical—such as nozzles, feeders, filters, belts, rollers, sensors, cameras, power supplies, and control boards—manufacturers can ensure their production lines run smoothly. Regular maintenance combined with careful selection of spare parts will not only enhance productivity but also reduce operational costs in the long run.

FAQ

1. What are common issues faced with SMT machines?

Common issues include misalignment during placement, component damage due to improper handling, and downtime caused by equipment failure.

2. How often should I replace spare parts in my SMT machine?

The replacement frequency depends on usage; however, it is advisable to inspect critical components like nozzles and feeders regularly and replace them based on wear patterns.

3. Can I use non-branded spare parts?

While non-branded parts may be cost-effective, it is essential to ensure they meet quality standards to avoid compromising machine performance.

4. What maintenance practices should I follow?

Regular cleaning, inspections, timely replacement of worn-out parts, and operator training are vital maintenance practices.

5. Where can I purchase high-quality spare parts?

High-quality spare parts can be purchased from authorized distributors or reputable online suppliers specializing in SMT equipment.

Citations:

[1] https://scanditronictech.com/products/smt-machine-spare-parts/

[2] https://www.youtube.com/watch?v=1YXxm8as4nQ

[3] https://global.yamaha-motor.com/business/smt/faq/

[4] http://www.hotessay.net/news_show.php?id=387

[5] https://www.nextpcb.com/blog/top-10-smt-machines-worldwide

[6] https://www.youtube.com/watch?v=OtCb_WFMwQQ

[7] https://smtfuture.com/faq/

[8] https://www.raypcb.com/smt-machine/