Content Menu

● Understanding Nano SMT WiFi PCBs

● Component Selection

● Layout Optimization

>> Careful Component Placement

>> RF Considerations

>> Power Distribution

● Manufacturing Considerations

● Advanced Techniques

>> Embedded Components

>> 3D PCB Design

>> High-Density Interconnect (HDI)

● Simulation and Verification

● Prototyping and Testing

● Conclusion

● FAQ

>> 1. What is the minimum trace width typically used in nano SMT WiFi PCBs?

>> 2. How can I improve the antenna performance in a nano SMT WiFi PCB design?

>> 3. What are the key challenges in power distribution for nano SMT WiFi PCBs?

>> 4. How do I ensure proper grounding in a nano SMT WiFi PCB design?

>> 5. What are the best practices for component placement in nano SMT WiFi PCBs?

● Citations:

Designing nano SMT WiFi PCBs requires a deep understanding of both surface mount technology (SMT) and the intricacies of wireless communication. As the demand for smaller, more efficient devices continues to grow, engineers face the challenge of cramming increasingly complex functionality into ever-shrinking form factors. This article will explore the best practices for designing nano SMT WiFi PCBs, covering everything from component selection to layout optimization and manufacturing considerations.

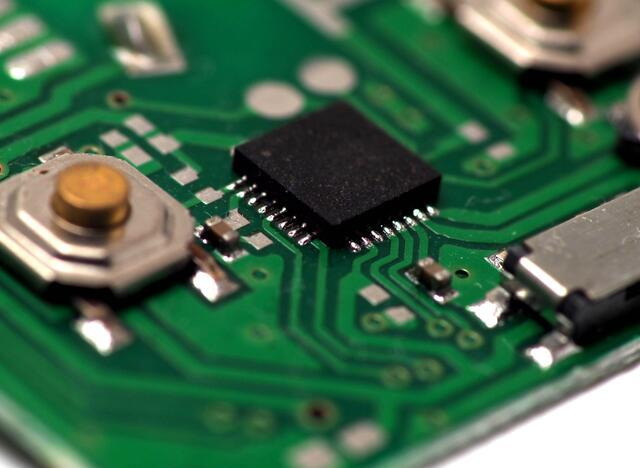

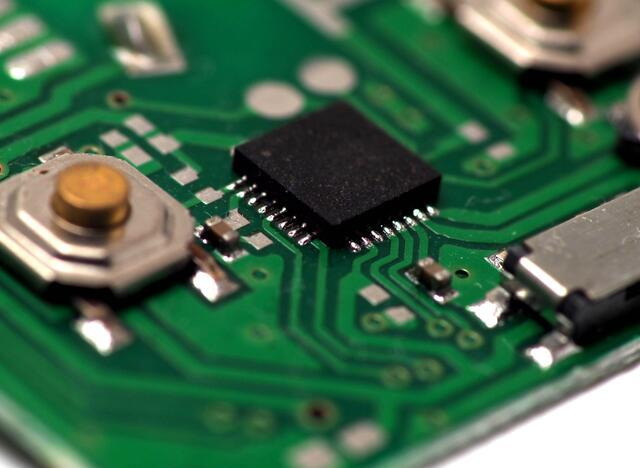

Understanding Nano SMT WiFi PCBs

Before delving into the best practices, it's crucial to understand what sets nano SMT WiFi PCBs apart from other designs. Nano SMT WiFi PCBs are characterized by their extremely small size, typically measuring just a few millimeters in each dimension. These boards utilize surface mount technology exclusively, with components often as small as 01005 (0.4mm x 0.2mm) or even 008004 (0.25mm x 0.125mm). The WiFi functionality adds another layer of complexity, requiring careful consideration of RF design principles.

Component Selection

Choosing the right components is critical when designing nano SMT WiFi PCBs. Here are some key considerations:

1. Size Matters: Opt for the smallest available package sizes that can still meet your performance requirements. For passive components like resistors and capacitors, 01005 or 008004 packages are often suitable.

2. Integrated Solutions: Look for highly integrated WiFi modules or System-on-Chip (SoC) solutions that combine multiple functions into a single package. This can significantly reduce board space requirements.

3. Low-Power Components: Given the compact nature of nano SMT WiFi PCBs, power dissipation is a crucial concern. Choose components with low power consumption to minimize heat generation and extend battery life in portable devices.

4. High-Frequency Considerations: For WiFi functionality, select components rated for operation at the required frequencies (typically 2.4GHz and/or 5GHz). Pay special attention to the quality factor (Q) of passive components used in RF circuits.

Layout Optimization

The layout of a nano SMT WiFi PCB is perhaps the most critical aspect of the design process. Here are some best practices to follow:

Careful Component Placement

1. Group Related Components: Place components with similar functions close together to minimize trace lengths and reduce signal interference.

2. Consider Signal Flow: Arrange components to create a logical signal flow across the board, minimizing crossovers and long traces.

3. Thermal Management: Place heat-generating components away from sensitive RF circuits and consider using thermal vias to dissipate heat more effectively.

RF Considerations

1. Antenna Placement: Position the antenna or antenna connector at the edge of the board, away from other components and ground planes that could interfere with radiation patterns.

2. Impedance Matching: Ensure that all RF traces are properly impedance-matched (typically 50Ω) to minimize signal reflections and maximize power transfer.

3. Keep It Short: Minimize the length of RF traces to reduce signal loss and potential interference.

4. Ground Plane Design: Implement a solid ground plane beneath RF traces and components to provide a low-impedance return path for signals.

Power Distribution

1. Separate Power Planes: Use separate power planes for digital and analog/RF sections of the board to minimize noise coupling.

2. Decoupling Capacitors: Place decoupling capacitors as close as possible to the power pins of ICs to reduce noise and ensure stable power supply.

3. Power Integrity Analysis: Conduct power integrity simulations to ensure that voltage drops across the board are within acceptable limits.

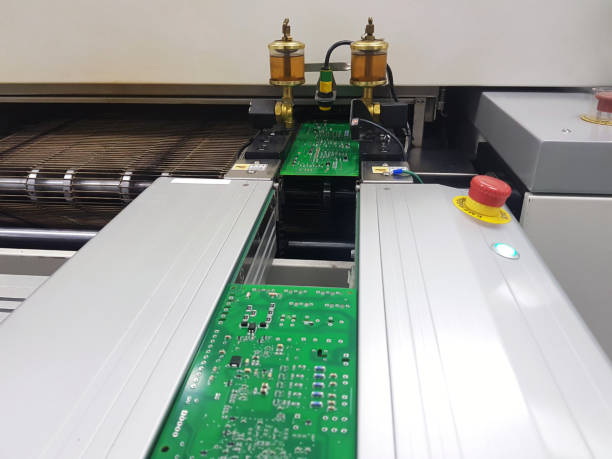

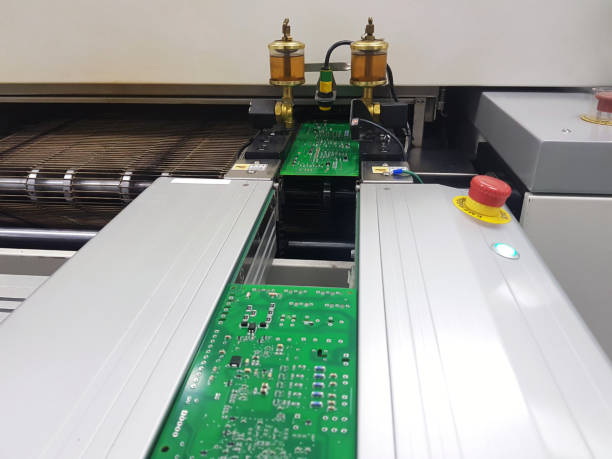

Manufacturing Considerations

Designing for manufacturability is crucial when working with nano SMT WiFi PCBs. Consider the following:

1. DFM Guidelines: Adhere to Design for Manufacturing (DFM) guidelines provided by your PCB manufacturer. These may include minimum trace widths, spacing requirements, and via specifications.

2. Solder Mask Defined Pads: For extremely small components, consider using solder mask defined pads to improve solder joint reliability.

3. Fiducial Marks: Include fiducial marks on the board to aid in automated assembly processes.

4. Test Points: Incorporate test points where possible to facilitate testing and debugging, but be mindful of their impact on RF performance.

Advanced Techniques

To push the boundaries of nano SMT WiFi PCB design, consider these advanced techniques:

Embedded Components

Embedding passive components within the PCB substrate can significantly reduce board size and improve performance by shortening signal paths. This technique is particularly useful for decoupling capacitors and RF matching networks.

3D PCB Design

Utilizing the Z-axis by implementing a 3D PCB design can help maximize space utilization in extremely compact devices. This may involve folding flexible PCB sections or using rigid-flex PCB technology.

High-Density Interconnect (HDI)

HDI techniques such as micro vias and buried vias can increase routing density and improve signal integrity in nano SMT WiFi PCBs. However, these techniques often come with increased manufacturing costs.

Simulation and Verification

Given the complexity of nano SMT WiFi PCB designs, simulation and verification are crucial steps in the design process:

1. Electromagnetic Simulation: Use EM simulation tools to analyze antenna performance, signal integrity, and potential EMI issues.

2. Thermal Analysis: Conduct thermal simulations to identify potential hotspots and ensure adequate heat dissipation.

3. Signal Integrity Analysis: Perform signal integrity simulations, particularly for high-speed digital signals and RF traces.

4. Power Integrity Analysis: Verify that the power distribution network can deliver clean, stable power to all components under various operating conditions.

Prototyping and Testing

Despite the best simulation efforts, prototyping and testing remain essential steps in the development of nano SMT WiFi PCBs:

1. Prototype Iterations: Plan for multiple prototype iterations to refine the design and address any issues discovered during testing.

2. RF Testing: Conduct thorough RF testing, including antenna performance, sensitivity, and output power measurements.

3. Environmental Testing: Subject prototypes to environmental tests such as temperature cycling and humidity exposure to ensure reliability in real-world conditions.

4. EMC Testing: Perform EMC testing to ensure compliance with relevant regulations and standards.

Conclusion

Designing nano SMT WiFi PCBs presents unique challenges that require a combination of expertise in RF design, surface mount technology, and miniaturization techniques. By following the best practices outlined in this article, engineers can create highly compact and efficient WiFi-enabled devices that meet the demands of modern applications.

Key takeaways include:

- Careful component selection, focusing on size, integration, and power efficiency

- Optimized layout design, with particular attention to RF considerations and power distribution

- Adherence to manufacturing guidelines and incorporation of advanced techniques like embedded components and HDI

- Thorough simulation, verification, and testing processes to ensure performance and reliability

As technology continues to evolve, the principles discussed here will serve as a foundation for pushing the boundaries of what's possible in nano SMT WiFi PCB design.

FAQ

1. What is the minimum trace width typically used in nano SMT WiFi PCBs?

The minimum trace width for nano SMT WiFi PCBs can be as small as 0.075mm (3 mils) or even less, depending on the manufacturer's capabilities. However, it's important to balance signal integrity requirements with manufacturability. For RF traces, wider traces may be necessary to achieve the desired impedance.

2. How can I improve the antenna performance in a nano SMT WiFi PCB design?

To improve antenna performance in a nano SMT WiFi PCB:

- Keep the antenna area clear of other components and ground planes

- Use a proper impedance matching network

- Consider using a dedicated antenna module or chip antenna designed for small form factors

- Implement a ground plane cutout beneath the antenna to improve radiation efficiency

3. What are the key challenges in power distribution for nano SMT WiFi PCBs?

Key challenges in power distribution for nano SMT WiFi PCBs include:

- Limited space for power planes and decoupling capacitors

- Potential for voltage drops due to thin traces and small via sizes

- Noise coupling between digital and RF sections of the board

- Heat dissipation in a compact form factor

4. How do I ensure proper grounding in a nano SMT WiFi PCB design?

To ensure proper grounding in a nano SMT WiFi PCB:

- Implement a solid ground plane, preferably on multiple layers

- Use plenty of vias to connect ground planes between layers

- Keep ground return paths as short as possible, especially for RF signals

- Consider using ground stitching vias around the board edges to reduce EMI

5. What are the best practices for component placement in nano SMT WiFi PCBs?

Best practices for component placement in nano SMT WiFi PCBs include:

- Group related components together to minimize trace lengths

- Place heat-generating components away from sensitive RF circuits

- Position the antenna or antenna connector at the board edge

- Ensure adequate spacing between components for manufacturability

- Consider the pick-and-place direction for automated assembly

Citations:

[1] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[2] https://www.pcbonline.com/blog/complex-pcb-assembly.html

[3] https://www.venture-mfg.com/rf-pcb-design-guidelines/

[4] https://www.analog.com/cn/resources/packaging-quality-symbols-footprints/package-resources.html

[5] https://www.nano-di.com/resources/blog/2019-pcb-design-and-network-segmentation-best-practices-for-defense-companies

[6] https://jlcpcb.com/blog/design-process-of-a-surface-mount-pcb

[7] https://www.protoexpress.com/blog/pcb-design-challenges-with-solutions-for-engineers/

[8] https://patents.google.com/patent/CN112040669B/zh