Content Menu

● Understanding SMT in Production

● Key Benefits of SMT in High-Volume Manufacturing

>> Increased Production Speed

>> Cost Efficiency

>> Enhanced Design Flexibility

>> Improved Electrical Performance

>> Miniaturization of Devices

>> Higher Component Density

>> Reduced Manufacturing Time

>> Automation Capabilities

>> Lower Environmental Impact

>> Versatility Across Applications

● Challenges Associated with SMT

● Conclusion

● Related Questions

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does SMT improve electrical performance?

>> 3. What are some challenges associated with implementing SMT?

>> 4. Why is miniaturization important in electronics?

>> 5. In what industries is SMT commonly used?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing landscape, particularly in high-volume production environments. By allowing for the mounting of electronic components directly onto the surface of printed circuit boards (PCBs), SMT offers numerous advantages over traditional through-hole technology (THT). This article will explore the benefits of SMT in high-volume manufacturing, detailing its implications for efficiency, cost-effectiveness, and product performance.

Understanding SMT in Production

SMT Meaning in Production

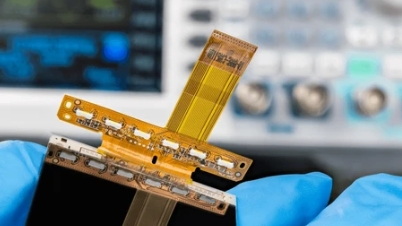

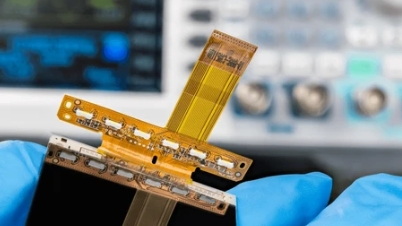

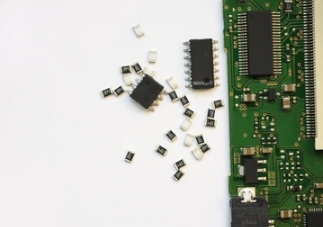

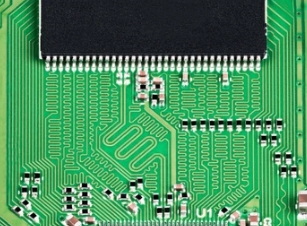

SMT stands for Surface Mount Technology, a method that involves placing electronic components directly onto the surface of PCBs. This contrasts with THT, where components are inserted into drilled holes. SMT has gained prominence due to its ability to support more compact and efficient designs, which is crucial in today's technology-driven world.

The SMT process typically includes several key steps:

- Solder Paste Printing: A stencil is used to apply solder paste to the PCB pads.

- Component Placement: Automated pick-and-place machines position the components on the solder paste.

- Reflow Soldering: The assembled boards pass through a reflow oven where the solder paste melts and solidifies, creating a permanent bond.

This streamlined process not only enhances production speed but also improves the overall quality of the assembled PCBs.

Key Benefits of SMT in High-Volume Manufacturing

Increased Production Speed

One of the primary advantages of SMT is its ability to significantly increase production speed. Automated assembly lines can place thousands of components per hour, far exceeding manual assembly rates. This efficiency is critical in high-volume manufacturing where time-to-market is essential.

Cost Efficiency

While the initial setup costs for SMT equipment can be higher than THT, the long-term savings are substantial. The smaller size of SMT components allows for denser PCB layouts, reducing material costs and enabling more efficient use of space. Additionally, automation reduces labor costs and minimizes human error, leading to fewer defects and lower rework costs.

Enhanced Design Flexibility

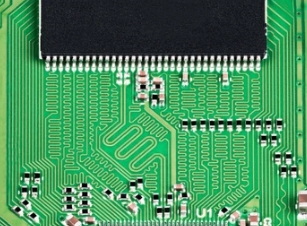

SMT allows for greater design flexibility by enabling components to be mounted on both sides of a PCB. This capability supports more complex circuit designs and higher component densities, which are essential for modern electronic devices that demand high functionality within limited space.

Improved Electrical Performance

The shorter lead lengths associated with SMT components reduce parasitic inductance and capacitance, resulting in improved signal integrity. This enhancement is particularly important for high-frequency applications where signal degradation can significantly impact performance. As a result, devices using SMT can operate more efficiently and reliably.

Miniaturization of Devices

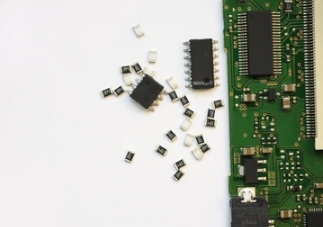

SMT has facilitated the miniaturization of electronic devices by allowing manufacturers to use smaller components without sacrificing performance. This trend is evident in consumer electronics such as smartphones and tablets, where space constraints necessitate compact designs.

Higher Component Density

The ability to place more components on a smaller PCB area leads to higher component density. This characteristic not only improves performance but also supports advanced functionalities such as multi-layered PCBs that can accommodate complex circuits.

Reduced Manufacturing Time

The elimination of drilling holes during assembly saves significant time compared to THT processes. This reduction in manufacturing time contributes to faster turnaround times for product development and production runs.

Automation Capabilities

SMT processes are highly amenable to automation, which enhances consistency and quality across production runs. Automated systems can perform tasks such as solder paste application, component placement, and inspection with high precision and speed.

Lower Environmental Impact

By reducing material waste through more efficient designs and processes, SMT contributes to a lower environmental footprint compared to traditional manufacturing methods. The smaller size of SMT components also means less packaging material is required during shipping.

Versatility Across Applications

SMT is versatile and applicable across various industries including telecommunications, consumer electronics, automotive, and medical devices. Its adaptability allows manufacturers to meet diverse market demands while maintaining high-quality standards.

Challenges Associated with SMT

While SMT offers numerous benefits, it is not without challenges:

- Initial Setup Costs: The cost of acquiring automated equipment can be significant.

- Complexity in Inspection: The small size of SMT components requires advanced inspection techniques to ensure quality control.

- Repair Difficulties: Repairing or replacing faulty SMT components can be more challenging than with THT due to their size and placement on the board.

Despite these challenges, the advantages of using SMT in high-volume manufacturing far outweigh the drawbacks for most applications.

Conclusion

In conclusion, Surface Mount Technology (SMT) has become indispensable in high-volume manufacturing due to its numerous benefits including increased production speed, cost efficiency, enhanced design flexibility, improved electrical performance, miniaturization capabilities, higher component density, reduced manufacturing time, automation potential, lower environmental impact, and versatility across various applications. As technology continues to evolve and consumer demands grow more complex, SMT will likely remain at the forefront of electronic manufacturing processes.

Related Questions

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) refers to a method used for mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for automated assembly processes that enhance efficiency and reduce costs.

2. How does SMT improve electrical performance?

SMT improves electrical performance by minimizing lead lengths which reduces parasitic inductance and capacitance, thus enhancing signal integrity especially in high-frequency applications.

3. What are some challenges associated with implementing SMT?

Challenges include higher initial setup costs for automated equipment, complexity in inspection due to small component sizes, and difficulties in repairing or replacing faulty components on PCBs.

4. Why is miniaturization important in electronics?

Miniaturization allows for more compact devices that fit within today's increasingly space-constrained environments while maintaining or improving functionality and performance.

5. In what industries is SMT commonly used?

SMT is widely used across various industries including telecommunications, consumer electronics (like smartphones), automotive applications, medical devices, and industrial equipment due to its versatility and efficiency.