Content Menu

● Understanding Laser Cut SMT Stencils

>> The Laser Cutting Process

● Key Benefits of Laser Cut SMT Stencils

>> 1. Superior Precision and Accuracy

>> 2. Excellent Edge Definition and Wall Quality

>> 3. Flexibility in Design and Materials

>> 4. Rapid Turnaround Time

>> 5. Environmentally Friendly Production

● Comparing Laser Cut Stencils to Other Methods

>> Laser Cut vs. Chemical Etching

>> Laser Cut vs. Electroforming

● Applications of Laser Cut SMT Stencils

>> 1. High-Density PCB Assembly

>> 2. Medical and Military Electronics

>> 3. Prototyping and Low-Volume Production

>> 4. Consumer Electronics

● Best Practices for Using Laser Cut SMT Stencils

>> 1. Proper Stencil Design

>> 2. Stencil Handling and Maintenance

>> 3. Regular Inspection and Replacement

>> 4. Optimize Printing Parameters

>> 5. Choose the Right Stencil Material

● Future Trends in Laser Cut SMT Stencils

● Conclusion

● Frequently Asked Questions

>> 1. What is the typical lifespan of a laser cut SMT stencil?

>> 2. Can laser cut stencils be used for both leaded and lead-free solder paste?

>> 3. How do laser cut stencils compare to nano-coated stencils?

>> 4. Are there any limitations to the size of PCBs that can be accommodated by laser cut stencils?

>> 5. How does the cost of laser cut stencils compare to other stencil manufacturing methods?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for smaller, more compact devices with increased functionality. At the heart of this technology lies the SMT stencil, a crucial component in the PCB assembly process. Among the various methods of stencil production, laser cutting has emerged as a superior technique, offering numerous advantages over traditional methods. This article explores the benefits of using laser cut SMT stencils and why they have become the preferred choice for many manufacturers.

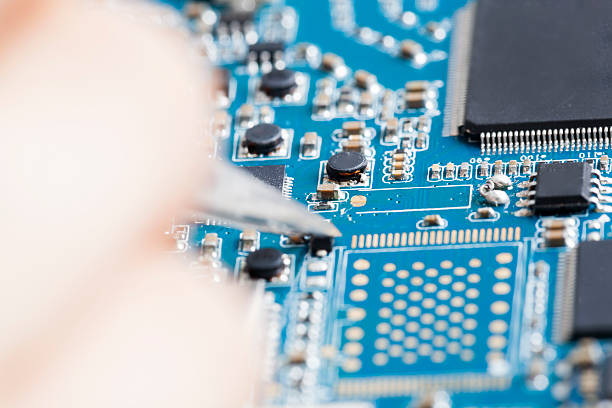

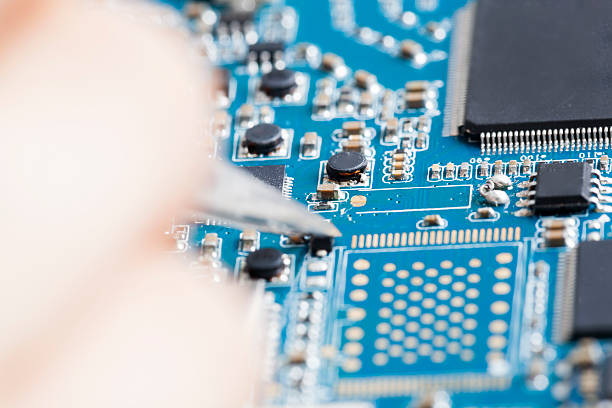

Understanding Laser Cut SMT Stencils

Laser cut SMT stencils are manufactured using high-powered lasers to precisely cut apertures into stainless steel or other suitable materials. This advanced technology allows for the creation of stencils with exceptional accuracy and consistency, crucial for the increasingly complex and miniaturized world of electronic components.

The Laser Cutting Process

The process of creating a laser cut SMT stencil involves several steps:

1. Material selection: Typically, high-nickel content stainless steel is chosen for its superior strength and smaller surface grain structure[1].

2. Design preparation: The stencil design is converted into a format compatible with the laser cutting machine.

3. Laser cutting: A high-powered laser beam cuts the apertures into the stencil material with extreme precision[4].

4. Post-processing: Depending on requirements, the stencil may undergo additional treatments such as electropolishing or nickel plating.

Key Benefits of Laser Cut SMT Stencils

1. Superior Precision and Accuracy

Laser cutting technology offers unparalleled precision in creating stencil apertures. Modern laser systems can achieve tolerances as tight as 5μm, ensuring exceptional accuracy in pad positioning[1]. This level of precision is crucial for:

- Ultra-fine pitch patterns: Laser cut stencils can easily handle patterns less than 250μm, accommodating the most challenging very fine pitch devices[1].

- Consistent aperture size and shape: The laser cutting process ensures that each aperture is cut to exact specifications, maintaining uniformity across the entire stencil[10].

2. Excellent Edge Definition and Wall Quality

The laser cutting process results in stencils with superior edge definition and wall quality:

- Smooth internal pad walls: Geometric changes in wall structure are less than 3μm, promoting superior paste release characteristics[1].

- Sharp edge definition: This feature ensures clean solder paste release, critical for achieving high-quality solder joints[10].

3. Flexibility in Design and Materials

Laser cutting technology offers great flexibility in both design and material choices:

- Diverse aperture shapes: Almost any cutting contour is possible with minimal radii, and circular openings show perfect roundness[6].

- Material versatility: Laser systems can cut sheets ranging from 20μm up to 1mm in thickness, accommodating various stencil requirements[6].

4. Rapid Turnaround Time

Compared to traditional chemical etching methods, laser cutting offers significantly faster production times:

- Efficient process: Laser cutting is a fast and efficient process, allowing for quicker stencil production[2].

- High-speed cutting: Advanced laser systems can cut up to 20,000 apertures per hour, enabling rapid prototyping and production[8].

5. Environmentally Friendly Production

Laser cutting is a more environmentally friendly process compared to chemical etching:

- No harsh chemicals: The process doesn't require the use of etching chemicals, reducing environmental impact.

- Minimal waste: Laser cutting is a precise process that minimizes material waste.

Comparing Laser Cut Stencils to Other Methods

To fully appreciate the benefits of laser cut SMT stencils, it's helpful to compare them with other stencil manufacturing methods.

Laser Cut vs. Chemical Etching

Chemical etching is a traditional method of stencil production that involves using chemicals to remove material from a metal sheet. While it has its advantages, laser cutting generally outperforms chemical etching in several areas:

| Feature | Laser Cut | Chemical Etching |

| Precision | +/- 5 microns | +/- 50 microns |

| Edge Definition | Sharp, clean edges | Potential for undercutting |

| Aperture Consistency | Highly consistent | More variable |

| Production Speed | Fast | Slower |

| Environmental Impact | Low | Higher due to chemical use |

Laser Cut vs. Electroforming

Electroforming is another method used for stencil production, particularly for fine-pitch applications. While electroformed stencils can offer excellent quality, laser cut stencils have some distinct advantages:

- Faster production time

- Greater flexibility in design changes

- More cost-effective for larger stencils or higher volume production

Applications of Laser Cut SMT Stencils

Laser cut SMT stencils are widely used across various industries and applications due to their superior quality and versatility.

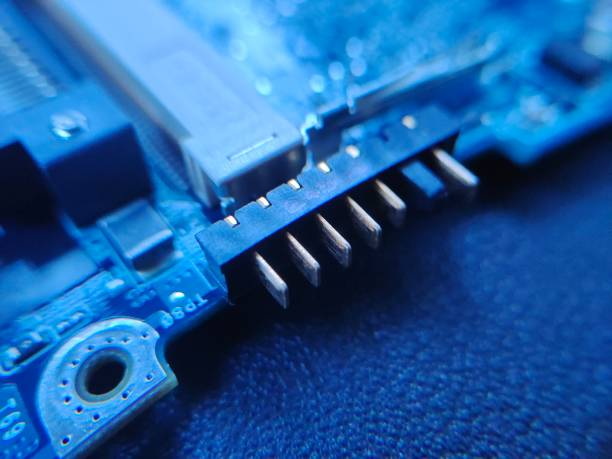

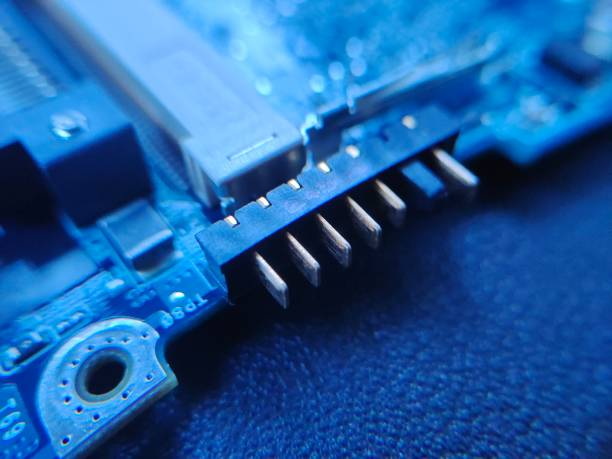

1. High-Density PCB Assembly

As electronic devices continue to shrink in size while increasing in functionality, PCB designs are becoming increasingly complex and dense. Laser cut stencils excel in these applications:

- Fine-pitch components: Ideal for BGAs and other components with pitches below 0.8mm[10].

- 0402 and smaller components: Laser cut stencils provide the precision needed for these tiny components[10].

2. Medical and Military Electronics

In industries where reliability and precision are paramount, laser cut stencils are the preferred choice:

- High-reliability applications: The consistency and accuracy of laser cut stencils contribute to more reliable solder joints.

- Compliance with strict standards: The precision of laser cutting helps meet stringent industry standards.

3. Prototyping and Low-Volume Production

The quick turnaround time and flexibility of laser cut stencils make them ideal for:

- Rapid prototyping: Fast production allows for quick iterations in product development.

- High-mix, low-volume production: Easily accommodate frequent design changes and small production runs.

4. Consumer Electronics

The consumer electronics industry benefits from laser cut stencils in several ways:

- Miniaturization: Enables the production of smaller, more compact devices.

- Improved yield: The precision of laser cut stencils contributes to higher production yields, crucial in high-volume consumer electronics manufacturing.

Best Practices for Using Laser Cut SMT Stencils

To maximize the benefits of laser cut SMT stencils, consider the following best practices:

1. Proper Stencil Design

- Optimize aperture size and shape for different component types.

- Consider area ratio and aspect ratio guidelines for reliable paste release.

- Use step stencils or other advanced designs for mixed-technology boards.

2. Stencil Handling and Maintenance

- Handle stencils with care to avoid damage or deformation.

- Clean stencils thoroughly after each use to prevent clogging of apertures.

- Store stencils properly to maintain their flatness and prevent contamination.

3. Regular Inspection and Replacement

- Inspect stencils regularly for signs of wear or damage.

- Replace stencils when signs of degradation in print quality are observed.

- Keep track of stencil usage to anticipate replacement needs.

4. Optimize Printing Parameters

- Adjust squeegee pressure, speed, and angle for optimal paste deposition.

- Consider environmental factors such as temperature and humidity in the printing process.

5. Choose the Right Stencil Material

- Select appropriate stencil material based on the application requirements.

- Consider factors such as tensile strength, thermal expansion, and surface finish.

Future Trends in Laser Cut SMT Stencils

As technology continues to advance, we can expect to see further improvements in laser cut SMT stencils:

1. Even finer pitch capabilities: As component sizes continue to shrink, laser cutting technology will evolve to create even smaller and more precise apertures.

2. Advanced materials: Research into new stencil materials may lead to improved performance and longevity.

3. Integration with Industry 4.0: Expect to see more data-driven processes in stencil production and usage, potentially leading to predictive maintenance and optimized designs.

4. Sustainability improvements: Further advancements in laser technology may lead to even more energy-efficient and environmentally friendly production processes.

Conclusion

Laser cut SMT stencils have revolutionized the PCB assembly process, offering unparalleled precision, consistency, and flexibility. Their benefits extend from improved print quality and higher yields to faster turnaround times and environmental friendliness. As electronic devices continue to evolve, becoming smaller and more complex, the importance of high-quality stencils in the manufacturing process cannot be overstated.

The advantages of laser cut stencils make them the preferred choice for a wide range of applications, from high-density PCBs to medical and military electronics. By following best practices in design, handling, and maintenance, manufacturers can maximize the benefits of these advanced stencils.

As we look to the future, we can expect continued advancements in laser cutting technology, further enhancing the capabilities and performance of SMT stencils. This ongoing evolution will play a crucial role in enabling the next generation of electronic devices, ensuring that the electronics manufacturing industry can meet the ever-increasing demands for miniaturization, functionality, and reliability.

Frequently Asked Questions

1. What is the typical lifespan of a laser cut SMT stencil?

The lifespan of a laser cut SMT stencil can vary depending on several factors, including usage frequency, maintenance practices, and the complexity of the design. On average, a well-maintained laser cut stencil can last for 20,000 to 50,000 prints. However, some high-quality stencils used in less demanding applications may last even longer. Regular inspection and proper cleaning are crucial for maximizing the lifespan of the stencil.

2. Can laser cut stencils be used for both leaded and lead-free solder paste?

Yes, laser cut SMT stencils can be used for both leaded and lead-free solder paste applications. The high precision and smooth aperture walls of laser cut stencils make them suitable for various types of solder paste. However, it's important to note that lead-free solder pastes often require different printing parameters and may benefit from specific stencil designs or coatings to optimize performance.

3. How do laser cut stencils compare to nano-coated stencils?

Laser cut stencils and nano-coated stencils are not mutually exclusive. In fact, many laser cut stencils are also nano-coated to further enhance their performance. The laser cutting process provides the precision and consistency in aperture formation, while nano-coating improves the stencil's surface properties, enhancing solder paste release. The combination of laser cutting and nano-coating can offer superior performance, especially for challenging applications with fine-pitch components or difficult-to-print solder pastes.

4. Are there any limitations to the size of PCBs that can be accommodated by laser cut stencils?

While laser cut stencils offer excellent precision, there are some limitations to their maximum size. Typically, laser cut stencils are limited to around 24x24 inches (about 60x60 cm) due to the size constraints of most laser cutting machines[10]. For larger PCBs, manufacturers may need to use framed stencils or consider alternative methods like chemical etching, which can accommodate larger sizes. However, for most standard PCB sizes used in electronics manufacturing, laser cut stencils are more than adequate.

5. How does the cost of laser cut stencils compare to other stencil manufacturing methods?

Generally, laser cut stencils tend to be more expensive than chemically etched stencils, especially for larger sizes or simpler designs[10]. However, the higher cost is often justified by the superior quality, precision, and consistency offered by laser cut stencils. For high-volume production or applications requiring extreme precision, the improved yield and reduced defects can offset the higher initial cost. Additionally, the faster turnaround time of laser cutting can be valuable in prototyping or time-sensitive projects, potentially saving costs in the overall product development cycle.

Citations:

[1] https://www.soldertools.net/smt-stencil/

[2] https://rigidflexpcb.org/smt-stencil-and-laser-stencil/

[3] https://www.ipc.org/system/files/technical_resource/E6&S35_03.pdf

[4] https://stencillaser.lpkf.com/en/technology/about-stencil-manufacturing

[5] https://www.stencilsunlimited.com/blog/stencil-manufacturing-technologies/

[6] https://www.lpkf.com/en/industries-technologies/electronics-manufacturing/smt-stencils-and-micro-cut-parts

[7] https://stencillaser.lpkf.com/en/technology/benefits-laser-cutting-stencil

[8] https://stencillaser.lpkf.com/en/applications/smd-stencil

[9] https://hackaday.com/2015/04/03/cutting-smt-stencils-with-a-laser/

[10] https://www.linkedin.com/pulse/laser-cut-stencil-vs-etching-rayming-techonloy