Content Menu

● Understanding SMT PCB Production Lines

>> What is SMT?

>> Components of a Wholesale SMT PCB Production Line

● Benefits of Using a Wholesale SMT PCB Production Line

>> 1. Increased Production Speed

>> 2. Cost-Effectiveness

>> 3. Enhanced Quality and Reliability

>> 4. Flexibility and Scalability

>> 5. Improved Space Utilization

>> 6. Better Thermal Performance

>> 7. Environmental Benefits

>> 8. Streamlined Workflow

>> 9. Advanced Technology Integration

>> 10. Enhanced Safety Features

>> 11. Customization Capabilities

>> 12. Improved Supply Chain Management

>> 13. Long-Term Investment

>> 14. Competitive Advantage

● Conclusion

● FAQ

>> 1. What is the main advantage of using a wholesale SMT PCB production line?

>> 2. How does SMT technology improve PCB quality?

>> 3. Can a wholesale SMT PCB production line handle different types of components?

>> 4. What are the environmental benefits of using SMT technology?

>> 5. How does the size of SMT components benefit PCB design?

In the rapidly evolving world of electronics manufacturing, the demand for efficient, high-quality production processes has never been greater. One of the most significant advancements in this field is the adoption of wholesale SMT PCB production lines. These lines utilize Surface Mount Technology (SMT) to enhance the manufacturing of printed circuit boards (PCBs), which are essential components in virtually all electronic devices. This article explores the numerous benefits of using a wholesale SMT PCB production line, detailing how it can revolutionize production efficiency, quality, and cost-effectiveness.

Understanding SMT PCB Production Lines

What is SMT?

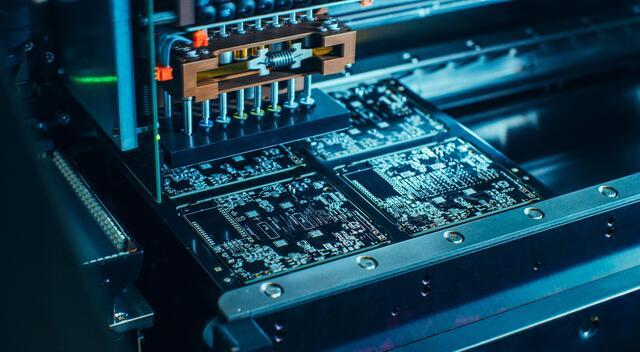

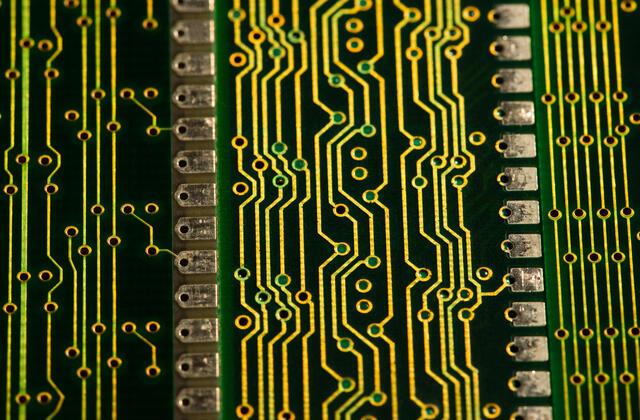

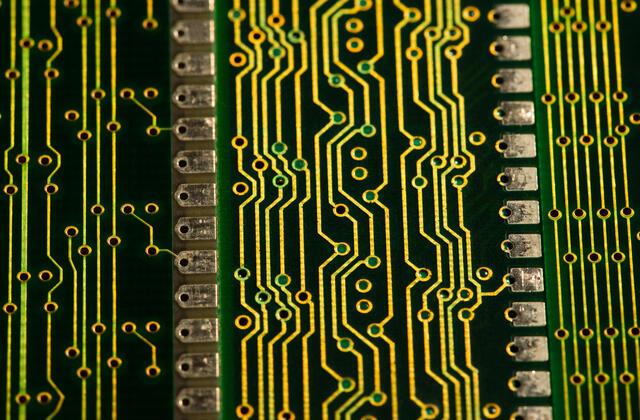

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of PCBs. This technology has largely replaced the older through-hole technology due to its numerous advantages, including reduced size, improved performance, and lower production costs.

Components of a Wholesale SMT PCB Production Line

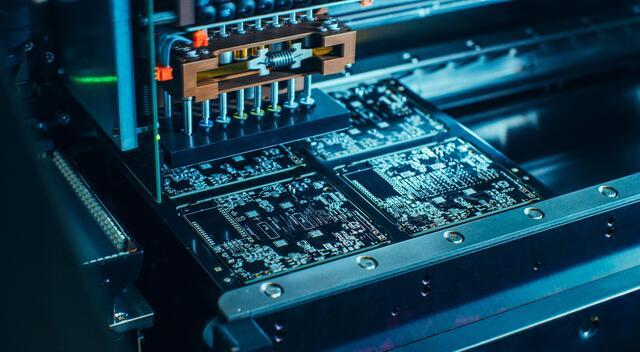

A typical wholesale SMT PCB production line consists of several key components:

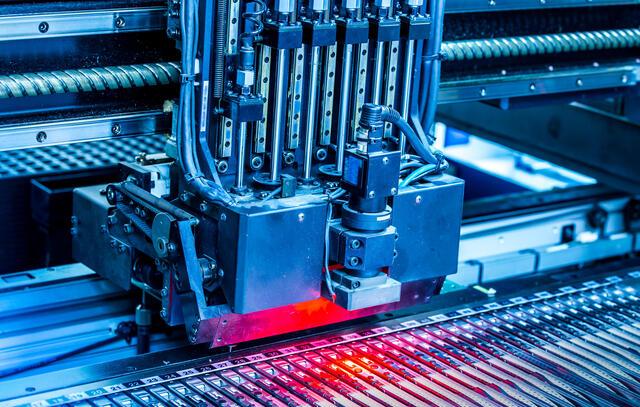

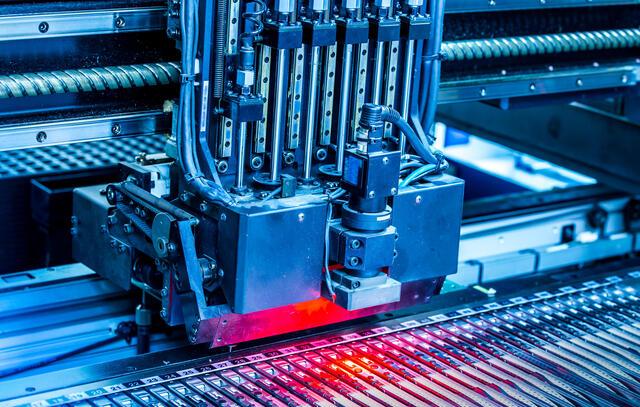

1. Pick and Place Machines: These machines are responsible for accurately placing components onto the PCB.

2. Solder Paste Printers: They apply solder paste to the PCB in preparation for component placement.

3. Reflow Ovens: These ovens heat the PCB to melt the solder, securing the components in place.

4. Automated Optical Inspection (AOI): This technology inspects the PCBs for defects after soldering.

5. Conveyor Systems: They transport PCBs through the various stages of production.

Benefits of Using a Wholesale SMT PCB Production Line

1. Increased Production Speed

One of the primary advantages of a wholesale SMT PCB production line is its ability to significantly increase production speed. Automation allows for rapid placement and soldering of components, enabling manufacturers to produce large volumes of PCBs in a shorter time frame. This efficiency is crucial in meeting the demands of a fast-paced market.

2. Cost-Effectiveness

Investing in a wholesale SMT PCB production line can lead to substantial cost savings. The automation of processes reduces labor costs and minimizes human error, which can lead to costly defects. Additionally, the ability to produce PCBs in bulk lowers the cost per unit, making it a financially viable option for manufacturers.

3. Enhanced Quality and Reliability

SMT technology provides improved quality and reliability compared to traditional methods. The precision of automated machines ensures that components are placed accurately, reducing the likelihood of defects. Furthermore, the use of AOI systems allows for real-time inspection, ensuring that any issues are identified and rectified promptly.

4. Flexibility and Scalability

Wholesale SMT PCB production lines are designed to be flexible and adaptable. They can handle a wide variety of components and PCB types, making them suitable for different production needs. This flexibility allows manufacturers to scale their operations up or down based on market demand, ensuring they can respond quickly to changes.

5. Improved Space Utilization

SMT components are generally smaller than their through-hole counterparts, allowing for more compact PCB designs. This reduction in size not only saves space on the PCB itself but also enables manufacturers to optimize their production facilities, making better use of available space.

6. Better Thermal Performance

SMT technology enhances the thermal performance of PCBs. The flat design of SMT components allows for better heat dissipation, which is critical in high-performance applications. This improved thermal management can lead to increased reliability and longevity of electronic devices.

7. Environmental Benefits

The shift to SMT technology can also have positive environmental impacts. The reduction in material waste, thanks to more efficient production processes, contributes to a lower environmental footprint. Additionally, the smaller size of SMT components often leads to less packaging waste.

8. Streamlined Workflow

A wholesale SMT PCB production line streamlines the entire manufacturing process. By integrating various stages of production—from solder paste application to component placement and inspection—manufacturers can achieve a more cohesive workflow. This integration minimizes delays and enhances overall productivity.

9. Advanced Technology Integration

Modern wholesale SMT PCB production lines often incorporate advanced technologies such as Industry 4.0 principles, including IoT connectivity and data analytics. This integration allows manufacturers to monitor production in real-time, optimize processes, and predict maintenance needs, further enhancing efficiency and reducing downtime.

10. Enhanced Safety Features

With automation comes improved safety in the workplace. Automated systems reduce the need for manual handling of components, which can be hazardous. Additionally, many modern SMT production lines are equipped with safety features that protect workers from potential accidents, creating a safer working environment.

11. Customization Capabilities

Wholesale SMT PCB production lines can be tailored to meet specific manufacturing needs. This customization allows manufacturers to produce specialized PCBs for niche markets or unique applications, providing a competitive edge in the industry.

12. Improved Supply Chain Management

By utilizing a wholesale SMT PCB production line, manufacturers can enhance their supply chain management. The ability to produce PCBs in-house reduces reliance on external suppliers, leading to better control over inventory and production schedules. This control can result in faster turnaround times and improved customer satisfaction.

13. Long-Term Investment

Investing in a wholesale SMT PCB production line is a long-term investment that can yield significant returns. The initial costs may be high, but the benefits of increased efficiency, reduced labor costs, and improved product quality can lead to substantial savings over time.

14. Competitive Advantage

In a highly competitive market, having a wholesale SMT PCB production line can provide a significant advantage. The ability to produce high-quality PCBs quickly and cost-effectively allows manufacturers to respond to market demands and stay ahead of competitors.

Conclusion

In conclusion, the adoption of a wholesale SMT PCB production line offers numerous benefits that can significantly enhance the efficiency, quality, and cost-effectiveness of electronics manufacturing. From increased production speed and cost savings to improved quality and flexibility, these production lines represent a strategic investment for manufacturers looking to stay competitive in a rapidly changing market. As technology continues to advance, the importance of efficient and reliable production processes will only grow, making wholesale SMT PCB production lines an essential component of modern electronics manufacturing.

FAQ

1. What is the main advantage of using a wholesale SMT PCB production line?

The main advantage is the increased production speed and efficiency, allowing manufacturers to produce large volumes of PCBs quickly and cost-effectively.

2. How does SMT technology improve PCB quality?

SMT technology improves quality through precise component placement and real-time inspection systems, reducing the likelihood of defects.

3. Can a wholesale SMT PCB production line handle different types of components?

Yes, these production lines are designed to be flexible and can accommodate a wide variety of components and PCB types.

4. What are the environmental benefits of using SMT technology?

SMT technology reduces material waste and packaging waste, contributing to a lower environmental footprint in electronics manufacturing.

5. How does the size of SMT components benefit PCB design?

The smaller size of SMT components allows for more compact PCB designs, optimizing space utilization in both the PCB and the production facility.