Content Menu

● Understanding AOI in SMT Assembly

>> What is AOI?

>> The Role of AOI in SMT Processing

● Benefits of Integrating AOI in SMT Assembly Lines

>> 1. Enhanced Quality Control

>> 2. Increased Production Efficiency

>> 3. Cost Reduction

>> 4. Data Collection and Analysis

>> 5. Flexibility and Adaptability

>> 6. Non-Destructive Testing

>> 7. Improved Traceability

>> 8. Reduction of Human Error

>> 9. Integration with Other Technologies

>> 10. Support for Industry 4.0 Initiatives

● Conclusion

● FAQ

>> 1. What types of defects can AOI detect in SMT assembly?

>> 2. How does AOI improve production efficiency?

>> 3. Is AOI a cost-effective solution for manufacturers?

>> 4. Can AOI systems be integrated into existing SMT assembly lines?

>> 5. What is the significance of data collection in AOI?

Automated Optical Inspection (AOI) has become a crucial component in the manufacturing process of Surface Mount Technology (SMT) assembly lines. As the demand for high-quality electronic products continues to rise, integrating AOI systems into SMT processes offers numerous benefits that enhance production efficiency, reduce costs, and improve product quality. This article explores the various advantages of AOI in SMT assembly lines, providing insights into its role, functionality, and impact on the manufacturing landscape.

Understanding AOI in SMT Assembly

What is AOI?

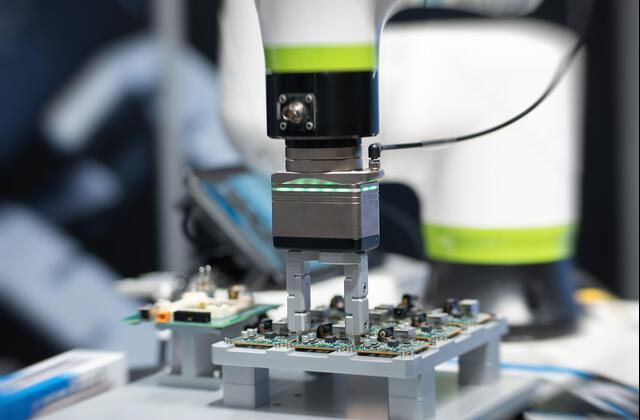

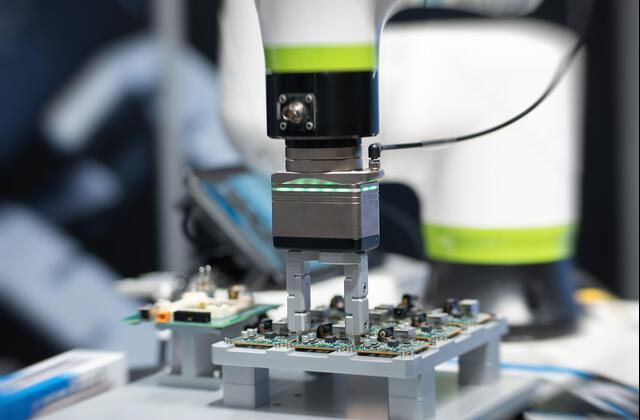

Automated Optical Inspection (AOI) is a technology used to inspect printed circuit boards (PCBs) and electronic assemblies for defects. It employs high-resolution cameras and sophisticated software algorithms to analyze the physical characteristics of components and solder joints. AOI systems can be integrated at various stages of the SMT assembly process, including post-solder paste application, after component placement, and before final assembly.

The Role of AOI in SMT Processing

The primary role of AOI in SMT processing is to ensure the quality and reliability of electronic assemblies. By detecting defects early in the production process, AOI helps manufacturers avoid costly rework and scrap, ultimately leading to improved yield rates and customer satisfaction.

Benefits of Integrating AOI in SMT Assembly Lines

1. Enhanced Quality Control

One of the most significant benefits of integrating AOI in SMT assembly lines is the enhancement of quality control. AOI systems can detect a wide range of defects, including:

- Soldering defects: Insufficient solder, excessive solder, and solder bridging.

- Component placement errors: Misalignment, missing components, and incorrect component types.

- Surface defects: Scratches, discoloration, and other cosmetic issues.

By identifying these defects early, manufacturers can take corrective actions before the products reach the final stages of production, ensuring that only high-quality assemblies are shipped to customers.

2. Increased Production Efficiency

Integrating AOI into the SMT assembly line significantly increases production efficiency. Traditional manual inspection methods are time-consuming and prone to human error. AOI systems, on the other hand, can perform inspections at high speeds, allowing for real-time monitoring of the production process. This rapid inspection capability enables manufacturers to maintain a steady workflow, reducing downtime and increasing throughput.

3. Cost Reduction

The implementation of AOI technology can lead to substantial cost savings for manufacturers. By catching defects early in the production process, AOI reduces the need for rework and scrap, which can be costly. Additionally, the automation of inspection processes minimizes labor costs associated with manual inspections. Over time, these savings can significantly impact the overall profitability of the manufacturing operation.

4. Data Collection and Analysis

AOI systems are equipped with advanced data collection and analysis capabilities. They can generate detailed reports on defect types, frequencies, and trends, providing valuable insights into the manufacturing process. This data can be used to identify recurring issues, optimize production parameters, and implement continuous improvement initiatives. By leveraging data analytics, manufacturers can enhance their quality control processes and make informed decisions to improve overall efficiency.

5. Flexibility and Adaptability

Modern AOI systems are designed to be flexible and adaptable to various production environments. They can be easily integrated into existing SMT assembly lines and configured to inspect different types of components and assemblies. This adaptability allows manufacturers to respond quickly to changing market demands and production requirements, ensuring that they remain competitive in a rapidly evolving industry.

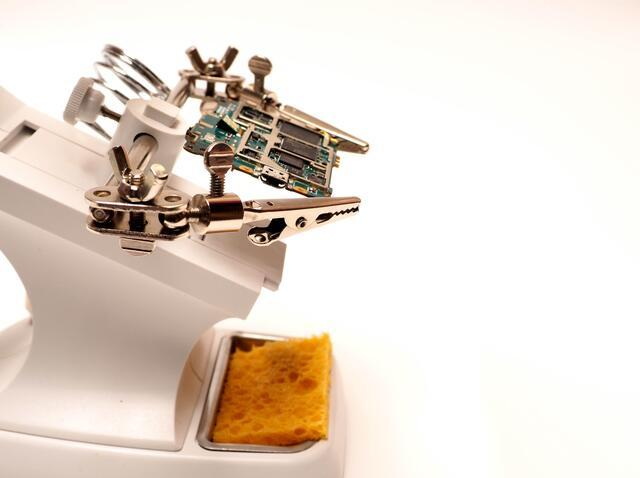

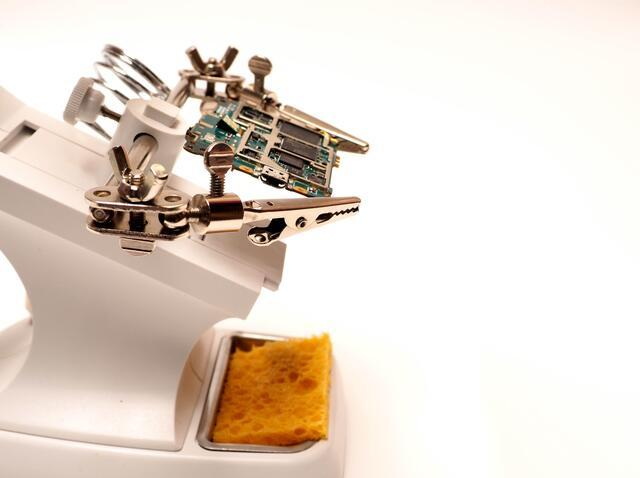

6. Non-Destructive Testing

AOI is a non-destructive testing method, meaning it does not damage the components or assemblies being inspected. This is particularly important in the electronics industry, where delicate components can be easily damaged during inspection. By using AOI, manufacturers can ensure that their products remain intact while still receiving thorough inspections.

7. Improved Traceability

Integrating AOI into the SMT assembly line enhances traceability throughout the manufacturing process. Each inspection can be logged and tracked, providing a comprehensive history of the product's quality control journey. This traceability is essential for compliance with industry standards and regulations, as well as for addressing customer concerns regarding product quality.

8. Reduction of Human Error

Human error is a significant factor in quality control processes, especially in manual inspections. AOI systems eliminate much of this risk by providing consistent and repeatable inspection results. This reliability not only improves the overall quality of the products but also builds trust with customers who expect high standards in electronic manufacturing.

9. Integration with Other Technologies

AOI can be integrated with other inspection technologies, such as X-ray inspection (AXI) and in-circuit testing (ICT). This multi-faceted approach to quality control allows manufacturers to cover a broader range of potential defects and ensures a more comprehensive inspection process. By combining these technologies, manufacturers can achieve higher levels of quality assurance and reliability in their products.

10. Support for Industry 4.0 Initiatives

As the manufacturing industry moves towards Industry 4.0, integrating AOI systems supports the transition to smart factories. AOI systems can be connected to the Internet of Things (IoT), allowing for real-time data sharing and analysis. This connectivity enables manufacturers to monitor production processes remotely, optimize operations, and respond quickly to any issues that arise.

Conclusion

The integration of Automated Optical Inspection (AOI) in SMT assembly lines offers numerous benefits that significantly enhance the quality, efficiency, and cost-effectiveness of electronic manufacturing. By detecting defects early, increasing production efficiency, and providing valuable data insights, AOI systems play a vital role in ensuring the reliability of electronic products. As technology continues to advance, the adoption of AOI will likely become even more prevalent, further transforming the landscape of SMT assembly.

FAQ

1. What types of defects can AOI detect in SMT assembly?

AOI can detect various defects, including soldering issues (insufficient or excessive solder), component placement errors (misalignment or missing components), and surface defects (scratches or discoloration).

2. How does AOI improve production efficiency?

AOI improves production efficiency by performing inspections at high speeds, allowing for real-time monitoring of the production process and reducing downtime associated with manual inspections.

3. Is AOI a cost-effective solution for manufacturers?

Yes, AOI is cost-effective as it reduces the need for rework and scrap, minimizes labor costs associated with manual inspections, and ultimately enhances overall profitability.

4. Can AOI systems be integrated into existing SMT assembly lines?

Yes, modern AOI systems are designed to be flexible and can be easily integrated into existing SMT assembly lines, adapting to various production environments.

5. What is the significance of data collection in AOI?

Data collection in AOI provides valuable insights into defect types and trends, enabling manufacturers to identify recurring issues, optimize production parameters, and implement continuous improvement initiatives.