Content Menu

● Understanding Universal SMT Production Lines

● Key Components of a Universal SMT Production Line

● Benefits of Using a Universal SMT Production Line

>> 1. Increased Production Efficiency

>> 2. Flexibility in Manufacturing

>> 3. Cost Savings

>> 4. Improved Product Quality

>> 5. Smaller and Lighter Products

>> 6. Enhanced Performance

>> 7. Scalability

>> 8. Environmentally Friendly Manufacturing

● Challenges Associated with Universal SMT Production Lines

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does a universal SMT production line improve efficiency?

>> 3. What are some key components of an SMT production line?

>> 4. What advantages does SMT offer over traditional methods?

>> 5. Are there any challenges associated with implementing an SMT production line?

● Citations:

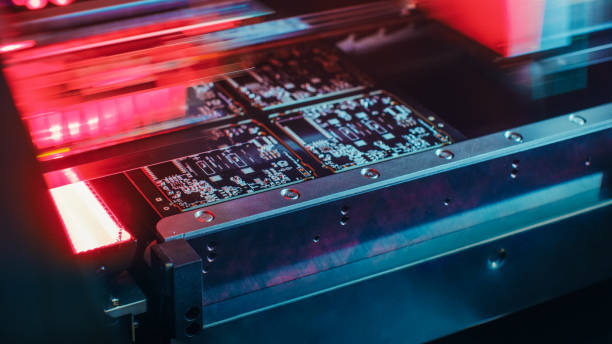

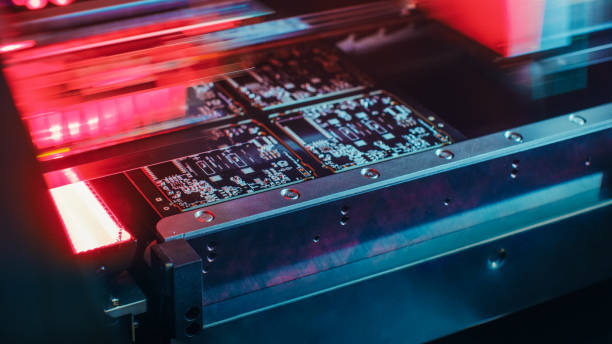

Surface Mount Technology (SMT) has transformed the landscape of electronics manufacturing, enabling companies to produce smaller, more efficient electronic devices. A universal SMT production line is designed to accommodate a wide variety of components and configurations, making it an invaluable asset for manufacturers. This article explores the numerous benefits of a universal SMT production line, detailing its components, operational efficiencies, and long-term advantages.

Understanding Universal SMT Production Lines

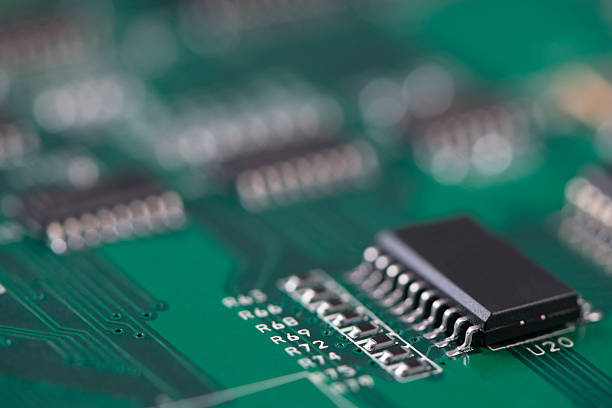

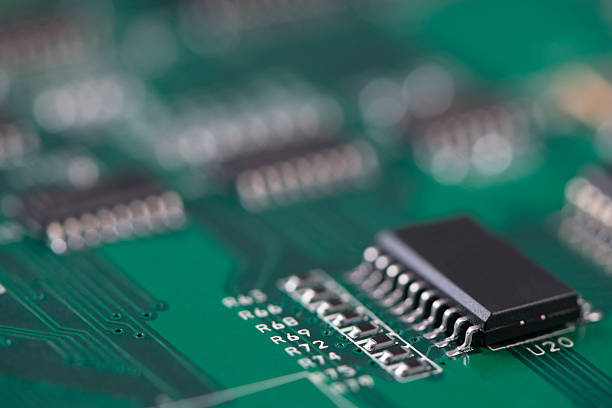

A universal SMT production line is a highly automated assembly system that allows for the placement of surface-mounted components onto printed circuit boards (PCBs). Unlike traditional through-hole technology, where components are inserted into drilled holes, SMT enables components to be mounted directly on the surface of the PCB. This method not only reduces manufacturing time but also enhances the overall quality and reliability of electronic products.

Key Components of a Universal SMT Production Line

Universal SMT production lines comprise several critical components that work in tandem to ensure efficient assembly:

- Solder Paste Printer: This machine applies solder paste to the PCB, which serves as an adhesive for the components.

- Pick-and-Place Machine: These machines are responsible for accurately placing components onto the soldered areas of the PCB.

- Reflow Oven: After placement, PCBs pass through a reflow oven where heat is applied to melt the solder paste, creating permanent connections between the components and the board.

- Inspection Systems: Automated Optical Inspection (AOI) systems check for defects in component placement and solder joints.

- Conveyor Systems: These transport PCBs between different stages of production, ensuring a smooth workflow.

Benefits of Using a Universal SMT Production Line

The adoption of a universal SMT production line offers numerous advantages:

1. Increased Production Efficiency

Universal SMT production lines significantly enhance production efficiency. The automation involved in SMT processes reduces human error and speeds up assembly times. With machines capable of placing thousands of components per hour, manufacturers can produce larger quantities in less time, meeting market demands more effectively[1][12].

2. Flexibility in Manufacturing

A universal SMT line can easily adapt to various component types and sizes. This flexibility allows manufacturers to switch between different product lines with minimal downtime, making it ideal for environments with rapidly changing product requirements[1][12].

3. Cost Savings

While the initial investment in advanced SMT equipment may be substantial, the long-term cost savings are significant. Reduced labor costs due to automation, lower material waste from precise component placement, and fewer defects that require rework all contribute to a lower overall cost of manufacturing[1][12][24].

4. Improved Product Quality

The precision offered by universal SMT equipment ensures high-quality assembly with fewer defects. Automated inspection systems quickly identify issues during various stages of production, ensuring that only high-quality products reach consumers[1][12][24].

5. Smaller and Lighter Products

SMT allows for smaller component sizes compared to traditional methods. This reduction in size enables manufacturers to design compact devices that are lighter and more portable. As consumer electronics trend towards miniaturization, universal SMT production lines provide a necessary advantage in meeting these market demands[1][12][24].

6. Enhanced Performance

Components mounted using SMT have shorter electrical paths, which can lead to improved signal integrity and reduced electromagnetic interference (EMI). This results in devices that operate more efficiently and reliably[1][12][24].

7. Scalability

As demand fluctuates, manufacturers need production lines that can scale accordingly. Universal SMT production lines can be easily adjusted to accommodate changes in product volume or design specifications, ensuring that manufacturers remain competitive in a fast-paced market[1][12][24].

8. Environmentally Friendly Manufacturing

SMT processes generally produce less waste compared to traditional methods due to their precision and efficiency. Additionally, many SMT components are designed with environmental considerations in mind, such as lead-free solder options[1][12][24].

Challenges Associated with Universal SMT Production Lines

While there are numerous benefits associated with universal SMT production lines, there are also challenges that manufacturers must consider:

- High Initial Investment: The cost of setting up an advanced SMT line can be significant. Manufacturers must weigh this initial investment against potential long-term savings.

- Need for Skilled Personnel: Operating sophisticated machinery requires skilled technicians who can manage equipment and troubleshoot issues as they arise.

- Regular Maintenance Requirements: To maintain optimal performance levels, regular maintenance of machinery is necessary.

Conclusion

In conclusion, a universal SMT production line offers significant advantages that can enhance productivity, reduce costs, and improve product quality in electronics manufacturing. As technology continues to advance and consumer demands evolve towards smaller and more efficient devices, investing in universal SMT equipment will become increasingly crucial for manufacturers seeking to maintain competitiveness in the market.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) refers to a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs) instead of being inserted into drilled holes.

2. How does a universal SMT production line improve efficiency?

A universal SMT production line improves efficiency through automation, allowing machines to place thousands of components per hour while minimizing human error and speeding up assembly times.

3. What are some key components of an SMT production line?

Key components include solder paste printers, pick-and-place machines, reflow ovens, inspection systems (like AOI), and conveyor systems.

4. What advantages does SMT offer over traditional methods?

SMT offers several advantages including reduced size and weight of devices, increased manufacturing speed, improved performance due to shorter electrical paths, and enhanced reliability.

5. Are there any challenges associated with implementing an SMT production line?

Challenges include high initial investment costs, the need for skilled technical personnel to operate machinery effectively, and regular maintenance requirements for optimal performance.

Citations:

[1] https://www.hct-smt.com/blog/the-ultimate-guide-to-universal-smt-equipment

[2] https://www.smtfactory.com/The-Key-Components-of-An-Efficient-SMT-Production-Line-for-PCB-Assembly-id48363586.html

[3] https://www.macrofab.com/blog/smt-assembly-vs-through-hole/

[4] https://www.smtfactory.com/Understanding-the-Full-Form-and-Meaning-of-SMT-Line-id48017676.html

[5] https://mpe.researchmfg.com/smt-qa/

[6] https://www.pcbasic.com/blog/smt_production_line.html

[7] https://smtmachineline.com/smt-line-solution/

[8] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[9] https://www.wevolver.com/article/smt-process

[10] https://www.neodensmt.com/news/what-are-the-smt-machine-production-line-45479151.html

[11] https://www.scspcba.com/cn/company-news/smt-basic-process-15-question-you-need-to-know.html

[12] https://www.gssmt-parts.com/what-are-the-key-benefits-of-an-smt-production-line.html

[13] https://www.smtfactory.com/Essential-Steps-for-SMT-Production-Line-Setup-id49117676.html

[14] https://www.reddit.com/r/mechanical_gifs/comments/bd1hl4/universal_instruments_smt_line_at_patton/

[15] https://www.smtfactory.com/news/Universal-SMT-Line.html

[16] https://www.smtfactory.com/Elevate-Your-Manufacturing-with-Advanced-SMT-Line-Equipment-id46017676.html

[17] https://www.eevblog.com/forum/manufacture/smt-production-line-manual-vs-automatic/25/

[18] https://chengyuansmt.com/blog/understanding-the-key-benefits-of-universal-smd-placement-and/

[19] https://www.uic.com/smt-hautes-leverages-universals-fuzion-for-high-volume-production-in-north-america/

[20] https://www.hayawin.com/resources/a-guide-to-smt-machines-what-they-are-and-how-to-choose.html

[21] https://www.linkedin.com/pulse/advantages-smt-manufacturing-practical-cost-effective-nyn3c

[22] https://www.smtfactory.com/smt-production-lines.html

[23] https://levisonenterprises.com/your-surface-mount-technology-questions-answered/

[24] https://www.hct-smt.com/blog/the-ultimate-guide-to-universal-smt-equipment

[25] https://www.xlin-smt.com/news/what-equipment-is-included-in-a-complete-smt-production-line/

[26] https://www.pcbcart.com/article/content/qa-about-smt-assembly.html

[27] https://www.all-smt.com/support-center/faq/

[28] https://versae.com/smt-assembly-faq/

[29] https://www.viasion.com/blog/smt-assembly-introduction-applications-steps-common-errors/

[30] https://help.archsys.io/hc/en-us/articles/360052554391-How-SMT-Manufacturers-Analyze-Time-and-Productivity-with-Line-Utilization

[31] https://www.macrofab.com/blog/smt-assembly-vs-through-hole/

[32] https://www.nextpcb.com/tech-center/smt-assembly-questions-and-answers

[33] https://lugsdirect.com/PDF%20Documents/Precautions-when-using-SMT.pdf

[34] https://www.reddit.com/r/AskEngineers/comments/h9t2ub/question_for_engineers_experienced_with_surface/

[35] https://www.smthelp.com/methods-and-measures-to-improve-the-production-efficiency-of-smt-production-line