Content Menu

● Understanding SMT and THT

>> Surface Mount Technology (SMT)

>> Through-Hole Technology (THT)

● Advantages of Combining SMT and THT

>> 1. Optimized Component Selection

>> 2. Enhanced Reliability

>> 3. Versatility in Design

>> 4. Balanced Manufacturing Process

>> 5. Improved Thermal Management

● Challenges and Considerations

>> Manufacturing Complexity

>> Design Considerations

>> Quality Control

● Best Practices for Mixed Assembly

>> 1. Strategic Component Selection

>> 2. Optimized PCB Design

>> 3. Process Optimization

>> 4. Quality Assurance

● Applications Benefiting from Mixed Assembly

>> Aerospace and Defense

>> Industrial Control Systems

>> Automotive Electronics

>> Medical Devices

>> Telecommunications Equipment

● Future Trends in Mixed Assembly

>> Miniaturization and Integration

>> Advanced Materials

>> Automation and Industry 4.0

>> Sustainability and Recyclability

● Conclusion

● FAQ

>> 1. What is the main difference between SMT and THT assembly?

>> 2. When should I choose mixed assembly over pure SMT or THT?

>> 3. How does mixed assembly affect the manufacturing process?

>> 4. Are there any specific design considerations for mixed assembly PCBs?

>> 5. How does mixed assembly impact the cost of PCB production?

● Citations:

In the ever-evolving world of electronics manufacturing, printed circuit board (PCB) assembly techniques play a crucial role in determining the efficiency, reliability, and overall performance of electronic devices. Two primary methods have dominated the industry: Surface Mount Technology (SMT) and Through-Hole Technology (THT). While each has its own merits, combining these technologies in a mixed assembly approach offers unique advantages that cater to the diverse needs of modern electronics. This article explores the benefits of integrating SMT and THT in PCB assembly, highlighting how this hybrid approach maximizes the strengths of both technologies.

Understanding SMT and THT

Before delving into the advantages of combining these technologies, it's essential to understand the fundamental differences between SMT and THT PCB assembly methods.

Surface Mount Technology (SMT)

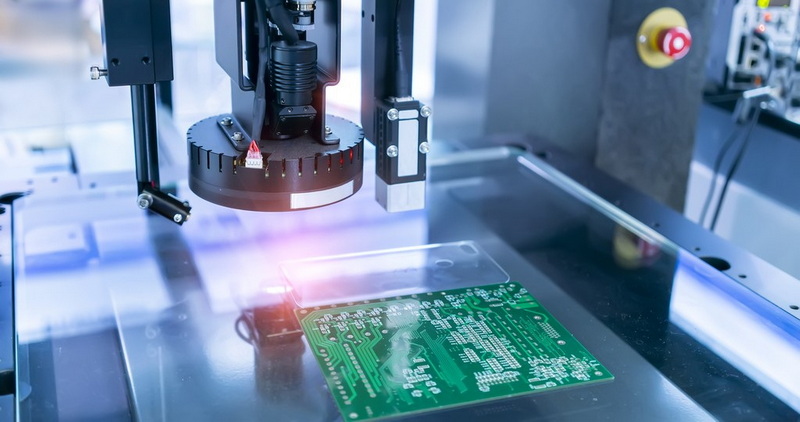

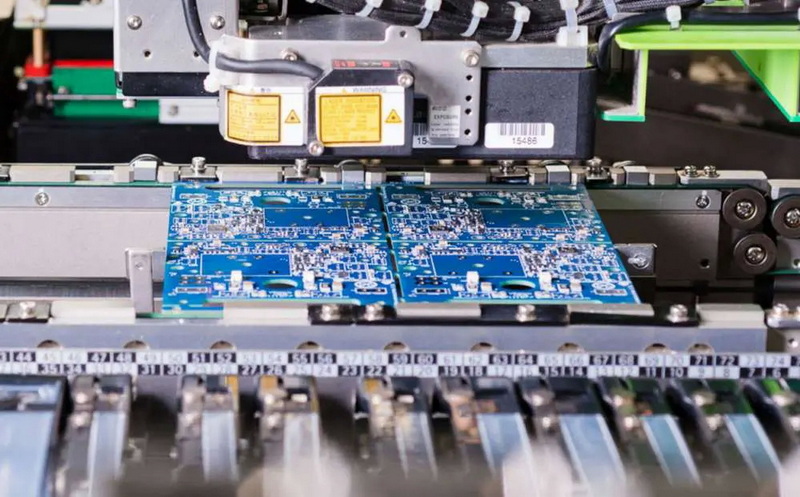

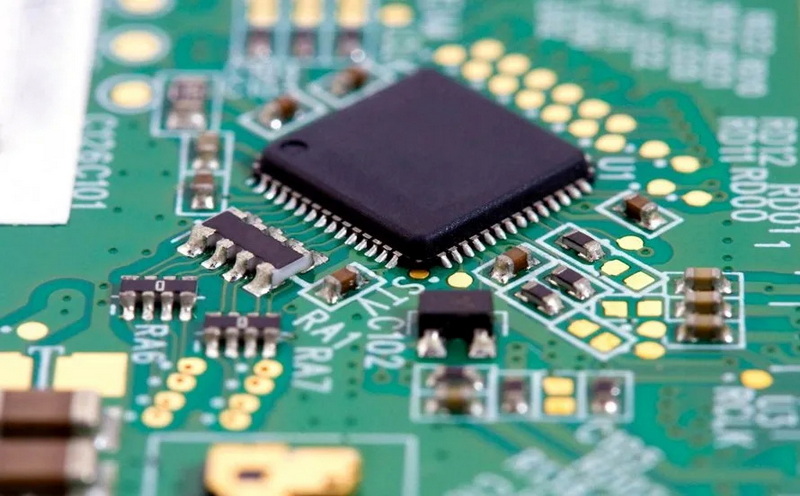

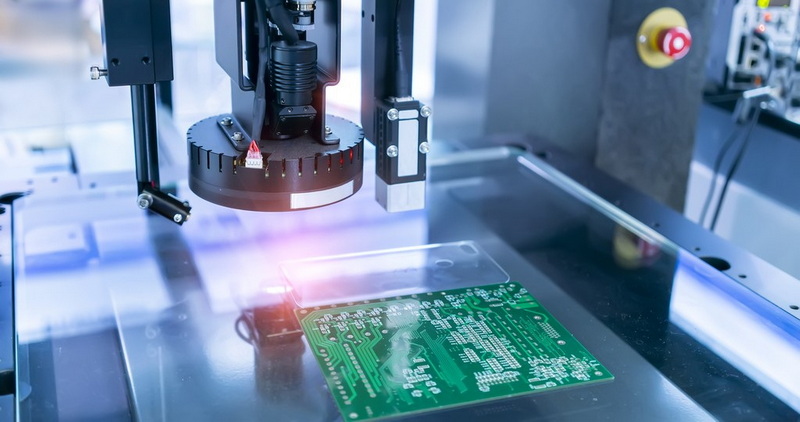

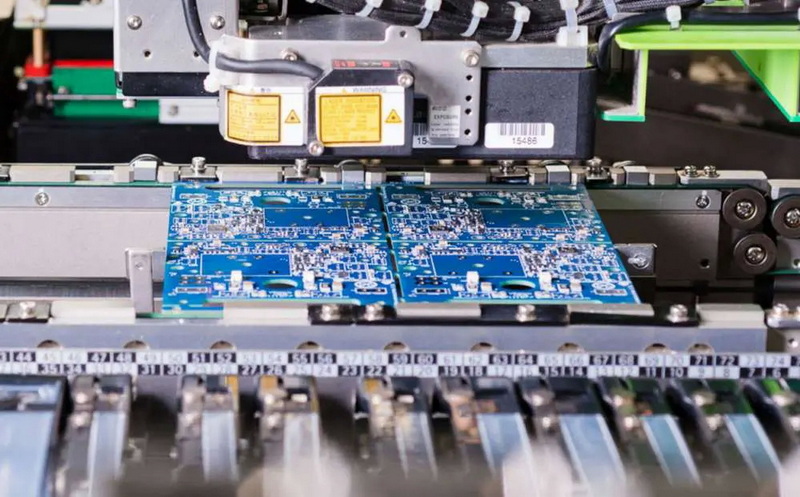

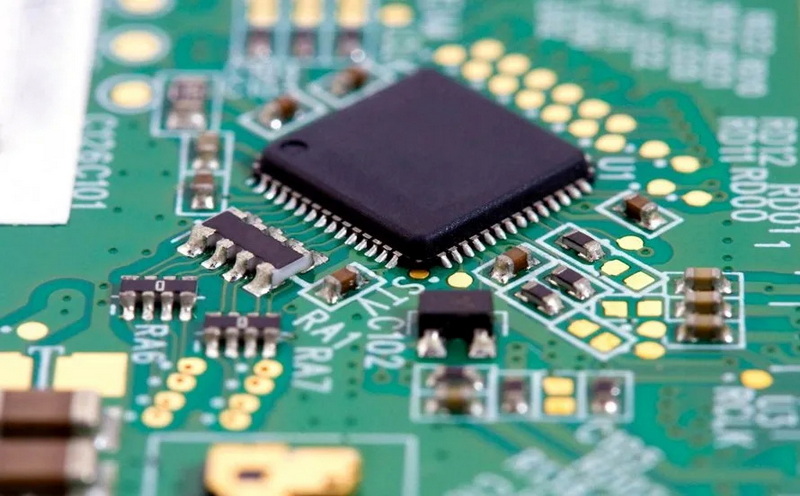

SMT involves mounting electronic components directly onto the surface of a PCB. Components used in SMT, known as surface mount devices (SMDs), are typically smaller and have flat contacts or short leads that are soldered directly onto pads on the PCB surface[5]. The SMT assembly process is highly automated, utilizing pick-and-place machines to position components precisely on the board before they are soldered in place using reflow ovens[3].

Through-Hole Technology (THT)

THT, on the other hand, requires components with leads to be inserted through pre-drilled holes in the PCB. These leads are then soldered on the opposite side of the board, creating a strong mechanical bond[7]. THT assembly can be performed using wave soldering machines or manual soldering techniques, depending on the production volume and specific requirements of the project[9].

Advantages of Combining SMT and THT

The integration of SMT and THT in PCB assembly, often referred to as mixed assembly, offers several significant advantages that address the limitations of using either technology exclusively.

1. Optimized Component Selection

By combining SMT and THT, manufacturers can select the most appropriate components for each function within a circuit. This flexibility allows for:

- Improved Performance: Some components perform better or are only available in through-hole packages. Integrating these with SMT components ensures optimal circuit performance without compromising on the benefits of surface mount technology[2].

- Cost-Effective Solutions: Manufacturers can choose between SMT and THT components based on cost, availability, and performance requirements, optimizing the overall cost of the assembly[1].

2. Enhanced Reliability

Mixed assembly leverages the strengths of both technologies to create more reliable PCBs:

- Robust Mechanical Connections: THT components provide stronger mechanical bonds, making them ideal for parts that may be subjected to physical stress or frequent handling[7].

- High-Density Layouts: SMT allows for high-density component placement, reducing signal path lengths and improving signal integrity[5].

3. Versatility in Design

The combination of SMT and THT offers greater design flexibility:

- Complex Circuits: Mixed assembly enables the creation of more complex circuits that require both high-density SMT components and specialized THT parts[9].

- Dual-Sided Assembly: While SMT components can be placed on both sides of a PCB, THT components can be strategically used where necessary, maximizing board space utilization[2].

4. Balanced Manufacturing Process

Integrating SMT and THT can lead to a more balanced and efficient manufacturing process:

- Optimized Production Flow: By strategically combining automated SMT placement with manual or semi-automated THT insertion, manufacturers can optimize their production line for both speed and precision[3].

- Flexibility in Production Volume: Mixed assembly allows for greater flexibility in production volumes, catering to both high-volume automated production and low-volume or prototype runs[9].

5. Improved Thermal Management

The combination of SMT and THT can contribute to better thermal management in PCB assemblies:

- Heat Dissipation: THT components often have better heat dissipation properties, which can be crucial for high-power applications[1].

- Thermal Relief: Strategic placement of THT components can provide thermal relief in designs where heat management is critical[5].

Challenges and Considerations

While combining SMT and THT offers numerous advantages, it also presents some challenges that need to be addressed:

Manufacturing Complexity

Mixed assembly requires careful planning and execution:

- Process Sequencing: Determining the optimal sequence for SMT and THT processes is crucial to avoid damaging components or compromising solder joints[9].

- Equipment Requirements: Manufacturers need to have both SMT and THT equipment, which can increase initial investment costs.

Design Considerations

Designers must carefully consider the placement of SMT and THT components:

- Layout Optimization: Balancing the placement of SMT and THT components to maximize board space and minimize signal interference requires skilled PCB design[2].

- Thermal Considerations: The different thermal characteristics of SMT and THT components must be accounted for in the design phase to ensure proper heat management[5].

Quality Control

Mixed assembly introduces additional quality control challenges:

- Inspection Techniques: Different inspection methods may be required for SMT and THT components, potentially complicating the quality assurance process[3].

- Defect Analysis: Identifying and addressing defects in mixed assemblies may require a broader range of expertise and tools.

Best Practices for Mixed Assembly

To maximize the benefits of combining SMT and THT in PCB assembly, consider the following best practices:

1. Strategic Component Selection

Carefully evaluate each component's requirements to determine whether SMT or THT is more appropriate:

- Use SMT for high-density, low-power components that require minimal mechanical stress resistance.

- Opt for THT for high-power components, connectors subject to frequent mating/unmating, or components requiring superior mechanical strength[7].

2. Optimized PCB Design

Design the PCB layout with mixed assembly in mind:

- Group SMT and THT components logically to streamline the assembly process.

- Consider the thermal requirements of both SMT and THT components when planning component placement[5].

3. Process Optimization

Develop an efficient assembly process that minimizes the risk of damage to components:

- Typically, perform SMT assembly first, followed by THT assembly to avoid exposing SMT components to additional heat during wave soldering[9].

- Use selective soldering techniques for THT components when possible to minimize thermal stress on nearby SMT components.

4. Quality Assurance

Implement comprehensive quality control measures:

- Utilize automated optical inspection (AOI) for SMT components and X-ray inspection for THT connections.

- Develop testing protocols that address the unique characteristics of both SMT and THT assemblies.

Applications Benefiting from Mixed Assembly

Several industries and applications particularly benefit from the advantages of combining SMT and THT in PCB assembly:

Aerospace and Defense

The aerospace and defense sectors often require PCBs that combine the high reliability of THT components with the compact size and advanced functionality of SMT devices[2]. Mixed assembly allows for the creation of robust, high-performance electronics that can withstand extreme conditions while maintaining compact form factors.

Industrial Control Systems

Industrial control systems frequently need a mix of high-density processing components (SMT) and rugged, high-power components (THT) to handle diverse operational requirements[9]. Mixed assembly enables the integration of advanced control circuitry with robust power handling and interface components.

Automotive Electronics

The automotive industry benefits from mixed assembly by combining high-density SMT components for advanced driver assistance systems (ADAS) and infotainment with robust THT components for power management and sensor interfaces[2]. This approach allows for the creation of reliable, feature-rich automotive electronics that can withstand the harsh environment of a vehicle.

Medical Devices

Medical devices often require a combination of high-precision SMT components for data processing and signal conditioning with reliable THT components for power supplies and patient interfaces[9]. Mixed assembly facilitates the development of compact, reliable medical devices that meet stringent regulatory requirements.

Telecommunications Equipment

Telecommunications infrastructure equipment benefits from mixed assembly by integrating high-speed SMT components for data processing with robust THT connectors and power components[2]. This combination allows for the creation of high-performance, reliable communication systems that can handle the demands of modern networks.

Future Trends in Mixed Assembly

As technology continues to evolve, several trends are shaping the future of mixed SMT and THT assembly:

Miniaturization and Integration

The ongoing trend towards smaller, more integrated devices is driving the development of new component packages and assembly techniques. While this trend generally favors SMT, there will likely be continued demand for mixed assembly solutions that can incorporate specialized THT components into increasingly compact designs.

Advanced Materials

The development of new PCB materials and component packages may influence the balance between SMT and THT in mixed assemblies. Materials with improved thermal properties or enhanced mechanical strength could potentially expand the application range of SMT components, reducing the need for THT in some applications.

Automation and Industry 4.0

Advancements in automation and the adoption of Industry 4.0 principles are likely to impact mixed assembly processes. Improved robotics and machine learning algorithms may enhance the efficiency and precision of THT component placement, potentially reducing the cost differential between SMT and THT assembly.

Sustainability and Recyclability

As environmental concerns become increasingly important, the recyclability and sustainability of electronic assemblies may influence component and assembly method choices. This could lead to innovations in both SMT and THT technologies aimed at improving the eco-friendliness of PCB assemblies.

Conclusion

The combination of Surface Mount Technology (SMT) and Through-Hole Technology (THT) in PCB assembly offers a powerful approach to electronics manufacturing that capitalizes on the strengths of both methodologies. By integrating these technologies, manufacturers can create PCBs that are not only compact and high-performance but also robust and versatile.

Mixed assembly allows for optimized component selection, enhanced reliability, greater design flexibility, and improved thermal management. While it does present some challenges in terms of manufacturing complexity and quality control, these can be effectively managed through careful planning and the implementation of best practices.

As the electronics industry continues to evolve, the ability to leverage both SMT and THT in PCB assembly will remain a valuable tool for manufacturers. This approach enables the creation of innovative products that meet the diverse and demanding requirements of modern electronics across various industries, from aerospace and automotive to medical devices and telecommunications.

The future of mixed assembly looks promising, with ongoing advancements in materials, automation, and sustainability likely to further enhance its capabilities and applications. As such, the integration of SMT and THT is expected to play a crucial role in shaping the next generation of electronic devices, ensuring that they are not only more powerful and efficient but also more reliable and adaptable to the changing needs of consumers and industries alike.

FAQ

1. What is the main difference between SMT and THT assembly?

SMT (Surface Mount Technology) involves mounting components directly onto the surface of the PCB, while THT (Through-Hole Technology) requires components to be inserted through holes in the board and soldered on the opposite side[1][7]. SMT allows for higher component density and faster assembly, while THT provides stronger mechanical connections.

2. When should I choose mixed assembly over pure SMT or THT?

Mixed assembly is ideal when your PCB design requires both high-density component placement and robust mechanical connections. It's particularly useful for projects that need a combination of miniaturized SMT components for advanced functionality and larger THT components for power handling or durability[2][9].

3. How does mixed assembly affect the manufacturing process?

Mixed assembly typically involves a two-stage process: SMT components are usually placed and soldered first using reflow soldering, followed by the insertion and soldering of THT components, often using wave or selective soldering techniques[9]. This can increase manufacturing complexity but offers greater flexibility in component selection and board design.

4. Are there any specific design considerations for mixed assembly PCBs?

Yes, designers must carefully consider component placement to optimize both SMT and THT processes. This includes grouping similar components, managing thermal requirements, and ensuring adequate space for both types of components. Additionally, the PCB layout should facilitate efficient assembly and testing procedures for both SMT and THT parts[2][5].

5. How does mixed assembly impact the cost of PCB production?

The cost impact of mixed assembly can vary. While it may increase initial setup costs due to the need for both SMT and THT equipment, it can potentially reduce overall costs by allowing for more optimal component selection. For low to medium volume production, mixed assembly can offer a cost-effective balance between the efficiency of SMT and the robustness of THT[1][9].

Citations:

[1] https://www.neodensmt.com/news/advantages-and-disadvantages-of-tht-pcb-assemb-68736412.html

[2] https://www.pcbx.com/article/What-is-the-Difference-Between-SMT-and-THT

[3] https://www.wellpcb.com/blog/pcb-assembly/smt-vs-tht-pcb-assembly/

[4] https://leadsintec.com/pcb-assembly-technology-comparison-smt-vs-tht/

[5] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[6] https://unitcircuits.com/smt-vs-smd-vs-tht-a-comprehensive-guide-to-pcb-assembly-techniques/

[7] https://www.wevolver.com/article/smt-vs-smd-vs-tht-a-comprehensive-guide-to-electronics-assembly-techniques

[8] https://www.rushpcb.co.uk/surface-mount-technology-smt-vs-through-hole-tht-explained/

[9] https://www.pcbgogo.com/knowledge-center/Mixed_Assembly_Advantages.html