Content Menu

● Introduction

● Understanding SMT Components

>> Types of SMT Components

>> Common SMT Component Packages

● Advantages of SMT Components

>> Increased Density

>> Improved Performance

>> Cost Efficiency

>> Enhanced Reliability

● Applications of SMT Components

>> Consumer Electronics

>> Automotive Industry

>> Telecommunications

>> Medical Devices

>> Industrial Automation

● Future Trends in SMT Technology

>> Miniaturization

>> Advanced Materials

>> Automation and AI Integration

>> Sustainability Initiatives

● Conclusion

● FAQ

>> 1. What is the difference between SMT and through-hole technology?

>> 2. Why are SMT components preferred over traditional ones?

>> 3. What types of products commonly use SMT components?

>> 4. How do you solder SMT components?

>> 5. What future trends should we expect in SMT technology?

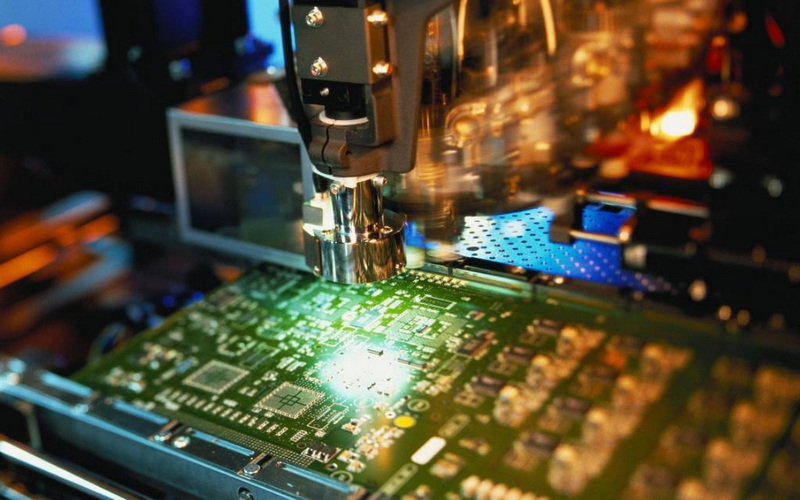

Introduction

Surface Mount Technology (SMT) is a method used for producing electronic circuits in which the components are mounted directly onto the surface of printed circuit boards (PCBs). SMT components are crucial in modern electronics, enabling the miniaturization of devices and improving manufacturing efficiency. This article will explore what SMT components are, their types, advantages, applications, and future trends in the industry.

Understanding SMT Components

SMT components differ from traditional through-hole components in several ways. They are typically smaller, lighter, and designed to be soldered directly onto the PCB surface. This technology has revolutionized the electronics industry by allowing for higher density circuit designs and more efficient production processes.

Types of SMT Components

SMT components can be classified into several categories based on their functionality and design:

- Passive Components: These include resistors, capacitors, and inductors that do not require a power source to operate. They play critical roles in controlling electrical signals within a circuit.

- Active Components: These components require a power source to function. Examples include integrated circuits (ICs), transistors, and diodes. Active components are essential for signal amplification and processing.

- Electromechanical Components: These include connectors, switches, and relays that facilitate the connection between different parts of an electronic system.

- Optoelectronic Components: This category includes light-emitting diodes (LEDs) and photodetectors that convert electrical signals into light or vice versa.

Common SMT Component Packages

SMT components come in various package types designed for specific applications. Some of the most common packages include:

- Chip Resistors: Small resistors used for current limiting and voltage division.

- Chip Capacitors: Used for filtering and energy storage in circuits.

- Ball Grid Array (BGA): A type of IC package with solder balls arranged in a grid pattern on the underside, allowing for high-density connections.

- Quad Flat Package (QFP): A square or rectangular package with leads on all four sides, commonly used for microcontrollers and processors.

- Surface-Mount Device (SMD): General term for any component designed for surface mounting, including both passive and active components.

Advantages of SMT Components

The adoption of SMT components offers several significant advantages over traditional through-hole technology:

Increased Density

SMT allows for higher component density on PCBs. This is particularly important in modern electronics where space is limited. By using smaller components that can be placed closer together, manufacturers can create more compact devices without sacrificing performance.

Improved Performance

SMT components typically have shorter lead lengths compared to through-hole components. This reduces inductance and resistance, leading to improved electrical performance. Additionally, SMT allows for better thermal management due to the efficient heat dissipation characteristics of flat-mounted components.

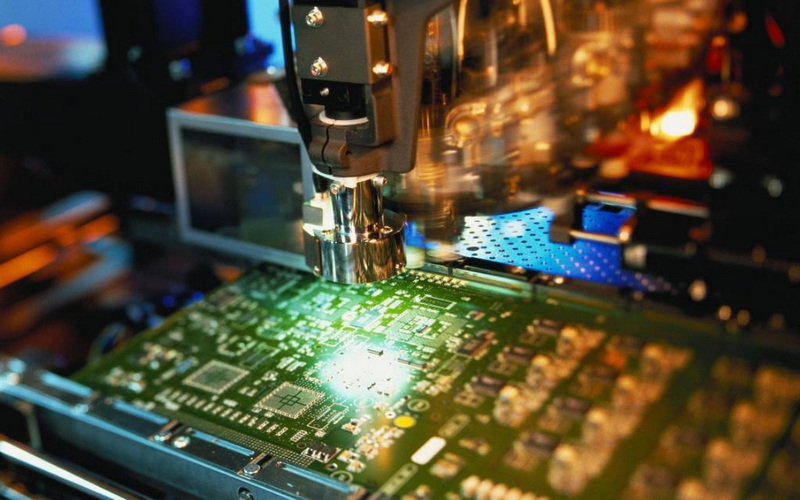

Cost Efficiency

Manufacturing processes involving SMT are generally more cost-effective. Automated assembly techniques reduce labor costs and increase production speed. Furthermore, because SMT components are smaller, they often require less material, contributing to lower overall production costs.

Enhanced Reliability

The soldering process used in SMT creates a more robust connection between the component and PCB compared to through-hole soldering. This results in improved reliability and durability of electronic devices under various environmental conditions.

Applications of SMT Components

SMT components are widely used across various industries due to their versatility and efficiency. Some notable applications include:

Consumer Electronics

From smartphones to laptops, consumer electronics rely heavily on SMT technology. The compact size of SMT components allows manufacturers to create thinner devices with enhanced functionality.

Automotive Industry

The automotive sector uses SMT components in control systems, infotainment systems, and safety features such as airbags and anti-lock braking systems. The reliability of SMT technology is crucial in ensuring safety and performance in vehicles.

Telecommunications

In telecommunications equipment, such as routers and switches, SMT components help manage high-speed data transmission effectively. Their small size allows for dense packing in networking hardware.

Medical Devices

Medical devices often require compact designs with high reliability. SMT technology is used in various medical applications, including diagnostic equipment, imaging systems, and wearable health monitors.

Industrial Automation

SMT components play a vital role in industrial automation systems by enabling precise control over machinery and processes. They are found in programmable logic controllers (PLCs), sensors, and actuators.

Future Trends in SMT Technology

As technology evolves, so does the landscape of SMT components. Several trends are shaping the future of this industry:

Miniaturization

The demand for smaller electronic devices continues to grow. Manufacturers are focusing on developing even smaller SMT components while maintaining or improving their performance characteristics.

Advanced Materials

Innovations in materials science are leading to the development of new substrates and solder materials that enhance the performance of SMT components. These materials can improve thermal conductivity and reduce environmental impact.

Automation and AI Integration

The integration of automation and artificial intelligence into manufacturing processes is expected to streamline production further. AI can optimize assembly lines by predicting failures and enhancing quality control measures.

Sustainability Initiatives

With increasing awareness about environmental issues, manufacturers are exploring sustainable practices within the SMT industry. This includes reducing waste during production and developing recyclable materials for component packaging.

Conclusion

SMT components have become indispensable in modern electronics due to their numerous advantages over traditional technologies. Their ability to enable miniaturization while maintaining performance makes them ideal for a wide range of applications across various industries. As technology continues to advance, we can expect further innovations that will enhance the capabilities of SMT components while promoting sustainability within the industry.

FAQ

1. What is the difference between SMT and through-hole technology?

SMT involves mounting components directly onto the surface of PCBs without drilling holes, while through-hole technology requires inserting leads into holes on the PCB before soldering them on the opposite side.

2. Why are SMT components preferred over traditional ones?

SMT components offer advantages such as increased density, improved electrical performance, cost efficiency due to automated manufacturing processes, and enhanced reliability through better solder connections.

3. What types of products commonly use SMT components?

SMT components are widely used in consumer electronics like smartphones and laptops, automotive systems, telecommunications equipment, medical devices, and industrial automation systems.

4. How do you solder SMT components?

Soldering SMT components typically involves using a reflow oven or hot air tool to melt solder paste applied to component pads on the PCB before placing the component on top.

5. What future trends should we expect in SMT technology?

Future trends include miniaturization of components, advancements in materials science for better performance, increased automation with AI integration in manufacturing processes, and sustainability initiatives aimed at reducing environmental impact.