Content Menu

● Introduction

● Understanding SMT Components

>> Types of SMT Components

● Double-Sided SMT Assembly

>> The Importance of Automation

● Advantages of Double-Sided SMT

● Challenges in Double-Sided SMT

● Technical Considerations for Double-Sided SMT

● Cost Implications of Double-Sided SMT

● Innovations in SMT Equipment

● Environmental Impact of SMT Technology

● The Role of SMT in Modern Electronics

● Future Trends in SMT Technology

● Conclusion

● FAQ

>> 1. What are the main benefits of using SMT components on both sides of a PCB?

>> 2. How does double-sided SMT assembly differ from single-sided assembly?

>> 3. What are the common challenges faced in double-sided SMT assembly?

>> 4. Can all types of components be used in double-sided SMT assembly?

>> 5. What future advancements are expected in SMT technology?

● Citations:

Introduction

Surface Mount Technology (SMT) has revolutionized the electronics industry, enabling manufacturers to create smaller, more efficient devices. The ability to mount components on both sides of a printed circuit board (PCB) is a significant advancement that maximizes space and enhances functionality. This article delves into the intricacies of SMT components on both sides of a PCB, exploring their advantages, challenges, and future trends in the industry.

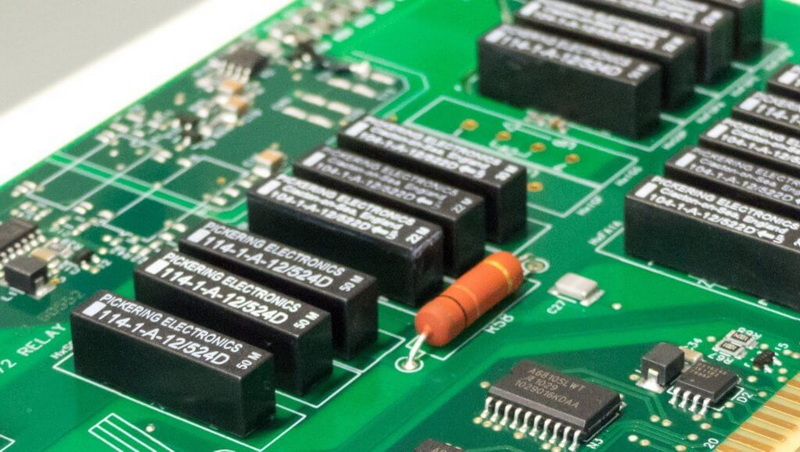

Understanding SMT Components

SMT components are electronic parts that are mounted directly onto the surface of a PCB. Unlike traditional through-hole components, SMT components do not require holes to be drilled into the board, allowing for a more compact design. Common types of SMT components include:

- Resistors

- Capacitors

- Diodes

- Integrated Circuits (ICs)

- Inductors

- Transformers

The primary advantage of using SMT components is their ability to save space and reduce the overall weight of the PCB. This is particularly beneficial for modern electronic devices where miniaturization is crucial. Additionally, SMT components can be automated in assembly processes, leading to higher production speeds and reduced labor costs.

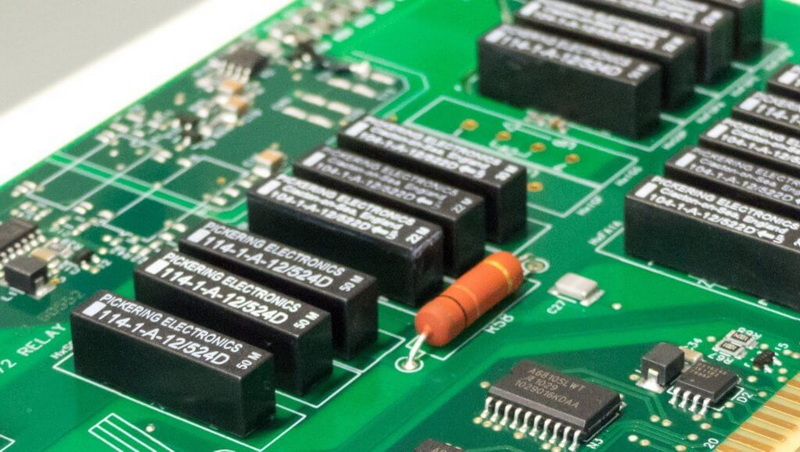

Types of SMT Components

Understanding the various types of SMT components is essential for effective PCB design. Each component type serves a unique function:

- Resistors: Used to control current flow within circuits.

- Capacitors: Store and release electrical energy as needed.

- Diodes: Allow current to flow in one direction only, protecting circuits from reverse polarity.

- Integrated Circuits (ICs): Combine multiple functions into a single chip, reducing space and improving performance.

- Inductors: Store energy in a magnetic field when electrical current flows through them.

- Transformers: Transfer electrical energy between two or more circuits through electromagnetic induction.

These components can vary significantly in size and form factor, with some being very small (like 0201 packages) while others can be larger (like power ICs). The choice of components impacts both the performance and manufacturability of the PCB.

Double-Sided SMT Assembly

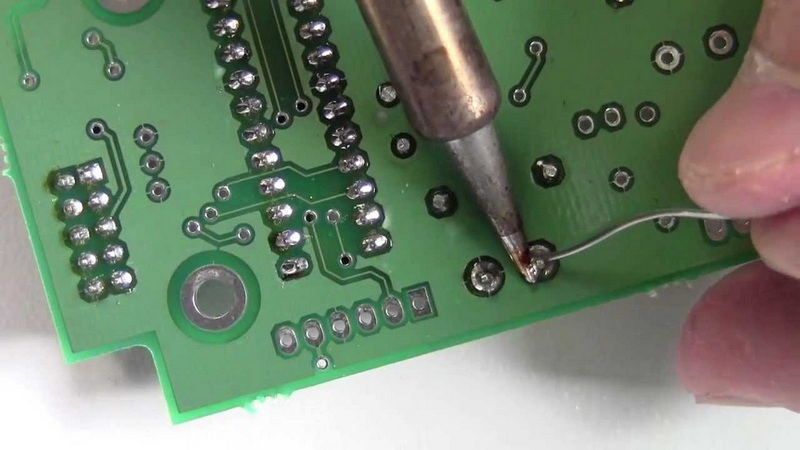

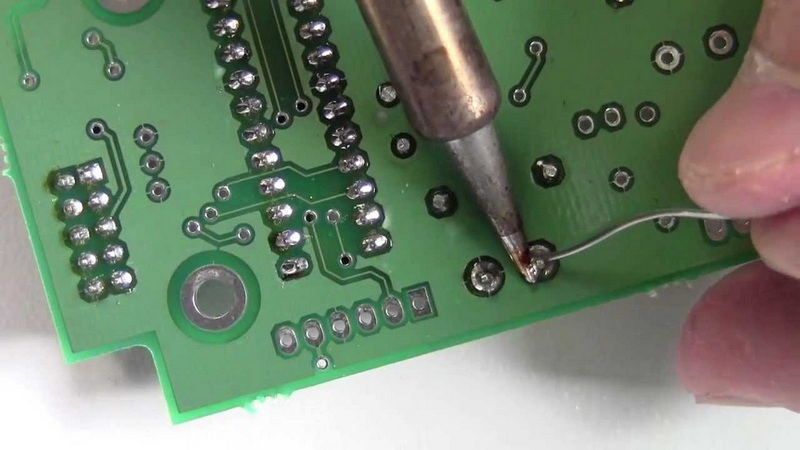

Double-sided SMT assembly involves placing components on both sides of the PCB. This process effectively doubles the available space for components, allowing for more complex and feature-rich designs. The assembly process typically includes several key steps:

1. Solder Paste Application: Solder paste is applied to both sides of the PCB using a stencil.

2. Component Placement: A pick-and-place machine positions the SMT components onto the board with high precision.

3. Reflow Soldering: The board is heated in a controlled manner to melt the solder paste, securing the components in place.

4. Flipping and Repeating: After soldering one side, the board is flipped to place components on the other side and undergoes another round of reflow soldering.

5. Inspection and Testing: After assembly, PCBs are inspected for defects using automated optical inspection (AOI) systems or X-ray inspection for hidden solder joints.

This method allows manufacturers to achieve high-density assemblies that are essential for compact electronic devices.

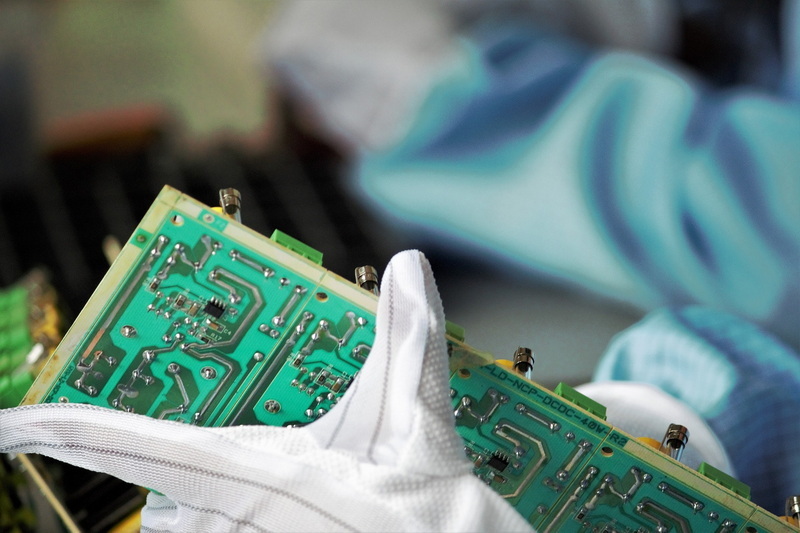

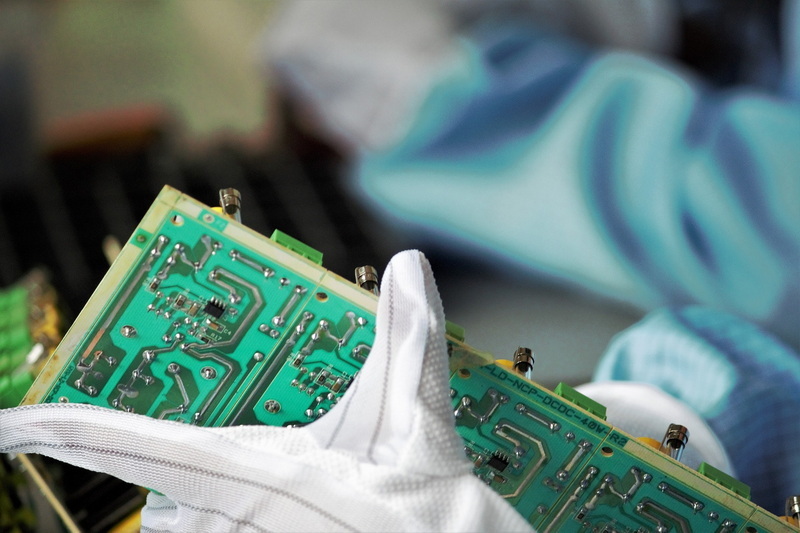

The Importance of Automation

Automation plays a crucial role in double-sided SMT assembly. Automated equipment, such as pick-and-place machines and reflow ovens, enhances precision and efficiency in manufacturing processes. Automation reduces human error, increases production speed, and allows for consistent quality control throughout the assembly process.

Advantages of Double-Sided SMT

The utilization of double-sided SMT offers numerous advantages:

- Space Efficiency: By placing components on both sides of the PCB, designers can maximize available space, which is critical in compact devices like smartphones and wearables.

- Enhanced Functionality: With more space for components, designers can incorporate advanced features and functionalities into their products without increasing the overall size.

- Cost Savings: By reducing the number of PCBs needed for complex designs, manufacturers can lower material costs and streamline production processes.

- Improved Performance: Double-sided assemblies often lead to better electrical performance due to shorter trace lengths and reduced signal interference.

- Design Flexibility: Designers have greater freedom to innovate with circuit layouts when utilizing both sides of a PCB.

Challenges in Double-Sided SMT

Despite its advantages, double-sided SMT presents several challenges:

- Alignment Precision: Ensuring accurate alignment and soldering of components on both sides requires sophisticated machinery and skilled operators. Misalignment can lead to defects that affect performance.

- Thermal Management: The increased density of components can lead to overheating issues if not managed properly. Effective thermal management strategies must be implemented to prevent heat buildup that could damage sensitive components.

- Cost Implications: The complexity of double-sided assembly can result in higher manufacturing costs due to advanced equipment requirements and longer production times. Manufacturers must balance these costs against potential savings from reduced material usage.

- Design Complexity: Designing PCBs for double-sided assembly requires careful planning to avoid interference between components on opposite sides. This complexity may increase design time and necessitate advanced simulation tools during development.

Designers must carefully consider these factors when opting for double-sided SMT in their projects.

Technical Considerations for Double-Sided SMT

When designing a PCB for double-sided SMT, several technical considerations must be taken into account:

- Layout Planning: The layout must be meticulously planned to avoid interference between components on opposite sides. This includes careful routing of traces to prevent short circuits and signal interference.

- Thermal Management: Effective thermal management strategies must be implemented, such as using thermal vias or heat sinks to dissipate heat generated by high-power components.

- Component Selection: Not all components are suitable for double-sided assembly. Designers should consider size, weight, and potential interference when selecting parts for each side of the PCB.

- Solder Mask Design: Proper solder mask design is crucial to prevent solder bridging between pads on opposite sides during reflow soldering processes.

Cost Implications of Double-Sided SMT

While double-sided SMT offers numerous benefits, it also comes with cost implications. The increased complexity can lead to higher manufacturing costs due to:

- Advanced equipment requirements

- Longer production times

- Increased labor costs associated with quality control

However, these costs can often be offset by the reduced need for multiple PCBs and enhanced functionality within a single board design. Manufacturers may also benefit from economies of scale as they optimize their production processes over time.

Innovations in SMT Equipment

Recent advancements in SMT equipment have significantly improved assembly efficiency and accuracy:

- High-Speed Pick-and-Place Machines: Modern machines can place thousands of components per hour with high precision, minimizing errors during assembly. These machines often utilize vision systems that allow them to identify component orientation automatically.

- Advanced Reflow Ovens: New reflow ovens provide better temperature control, ensuring consistent soldering quality across both sides of the PCB. Features like nitrogen atmospheres help reduce oxidation during soldering processes.

- Automated Inspection Systems: Advanced inspection technologies such as AOI and X-ray systems help identify defects early in the production process, reducing waste and ensuring high-quality output.

These innovations are driving improvements in production speed and product reliability while enabling manufacturers to meet increasing consumer demands for smaller yet more powerful devices.

Environmental Impact of SMT Technology

The shift towards SMT technology, particularly double-sided assembly, also has implications for sustainability. By reducing the size and weight of PCBs, SMT contributes to more energy-efficient electronic devices. Smaller devices typically consume less power during operation and transport, leading to lower carbon footprints throughout their lifecycle.

However, manufacturers must manage resource-intensive processes carefully to minimize environmental impact. As sustainability becomes a priority in electronics manufacturing, innovations aimed at reducing waste and energy consumption will likely emerge in SMT technology. Efforts such as recycling programs for electronic waste or adopting greener materials will become increasingly important as regulations tighten globally.

The Role of SMT in Modern Electronics

SMT technology is integral to modern electronics development. It enables manufacturers to produce smaller, faster, and more powerful devices across various applications:

- Consumer electronics

- Medical devices

- Automotive systems

- Industrial automation

In consumer electronics, products like smartphones rely heavily on compact designs enabled by double-sided SMT assemblies. In medical devices, precision is paramount; hence double-sided assemblies allow complex circuitry within small form factors necessary for portable diagnostic tools or implantable devices.

As demand for miniaturization continues to grow across all sectors—driven by consumer preferences for lightweight gadgets—SMT will remain a critical component in electronic manufacturing processes moving forward.

Future Trends in SMT Technology

Looking ahead, several trends are expected to shape the future of SMT technology:

- Automation Integration: The increasing use of automation will enhance efficiency while reducing labor costs in assembly processes. Automated systems will likely incorporate machine learning algorithms that improve over time based on data collected during production runs.

- Advanced Materials Development: Innovations in materials science will lead to new solder pastes and adhesives that improve performance and reliability under various operating conditions—especially important as electronic devices become more complex with higher power demands.

- Artificial Intelligence Applications: AI integration into design and assembly processes will enhance precision and adaptability in manufacturing operations by predicting potential failures before they occur or optimizing layouts based on real-time feedback from production lines.

These advancements will likely drive further innovation within the electronics industry as manufacturers seek competitive advantages through improved efficiency and product quality while addressing sustainability concerns effectively along their supply chains.

Conclusion

In summary, SMT components on both sides of a PCB offer significant advantages regarding space efficiency and performance enhancement while presenting unique challenges that require careful management throughout design phases until final production stages are complete successfully without compromising quality standards expected by end-users globally across various applications ranging from consumer electronics all way through industrial automation sectors where reliability matters most critically due high stakes involved often associated these industries' operations daily basis!

FAQ

1. What are the main benefits of using SMT components on both sides of a PCB?

The primary benefits include increased space efficiency and improved performance by allowing more components to fit into a smaller area without compromising functionality.

2. How does double-sided SMT assembly differ from single-sided assembly?

Double-sided SMT assembly involves placing components on both sides of the PCB while single-sided assembly only uses one side. This increases complexity but allows for greater component density.

3. What are the common challenges faced in double-sided SMT assembly?

Common challenges include ensuring proper alignment during soldering processes, managing thermal issues due to high component density, and controlling increased manufacturing costs associated with complexity.

4. Can all types of components be used in double-sided SMT assembly?

Not all components are suitable; designers must consider factors like size, weight, and potential interference between parts when selecting components for each side of the PCB.

5. What future advancements are expected in SMT technology?

Future advancements may include enhanced automation techniques, new materials that improve reliability and performance as well as AI-driven processes that optimize design and manufacturing efficiency.

Citations:

[1] https://www.pcb-hero.com/blogs/lisas-column/how-does-double-sided-smt-assembly-work

[2] https://compileiot.online/how-does-double-sided-smt-assembly-work/

[3] https://www.reddit.com/r/PrintedCircuitBoard/comments/1b41f5x/how_are_surface_mount_parts_soldered_to_both/

[4] https://resources.altium.com/p/best-design-practices-double-sided-pcb-soldering-smd-parts

[5] https://www.pcbgogo.com/Article/How_does_double_sided_SMT_assembly_work_.html