Content Menu

● Introduction

● What Are PCB SMT Components?

>> Types of SMT Components

>> Additional SMT Component Types

● Importance of PCB SMT Components in Electronics

>> Enhanced Miniaturization

>> Improved Electrical Performance

>> Higher Assembly Efficiency

>> Enhanced Thermal Performance

>> Cost-Effectiveness

>> Versatility

>> Reliability

● The SMT Assembly Process

● Challenges Associated with SMT Components

● Future Trends in SMT Technology

● Applications of PCB SMT Components

● Conclusion

● FAQ

>> 1. What is the main advantage of using SMT over through-hole technology?

>> 2. Can SMT components be used in high-power applications?

>> 3. Are there any limitations to using SMT components?

>> 4. How does SMT improve manufacturing efficiency?

>> 5. What types of devices benefit most from SMT?

● Citations:

Introduction

Printed Circuit Boards (PCBs) serve as the backbone of modern electronic devices, providing essential support and connectivity for various electronic components. Among the numerous technologies used in PCB assembly, Surface Mount Technology (SMT) stands out for its efficiency and effectiveness. This article delves into what PCB SMT components are, their significance in the electronics industry, and why they are considered essential.

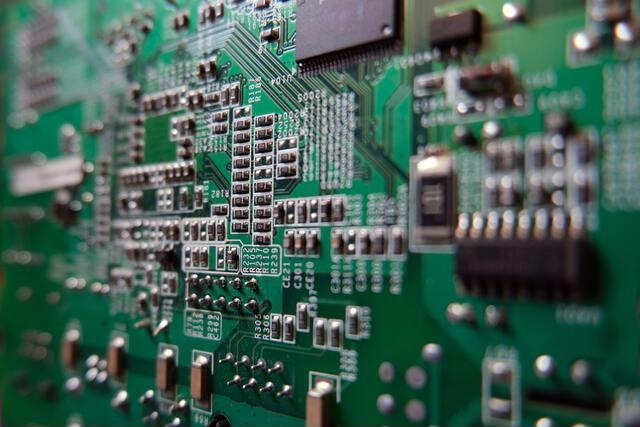

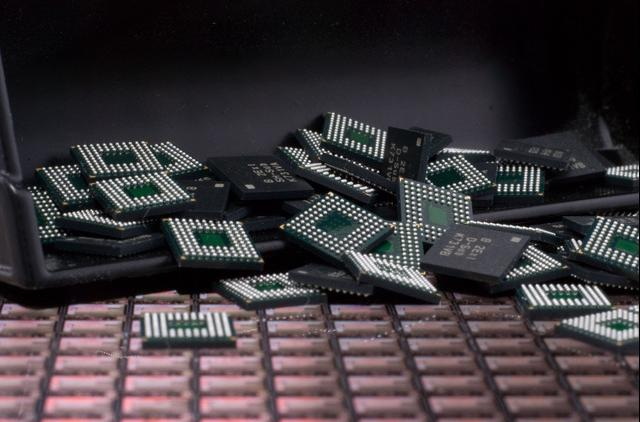

What Are PCB SMT Components?

PCB SMT components are electronic components that are mounted directly onto the surface of a PCB using Surface Mount Technology. Unlike traditional through-hole components, which require leads to be inserted into drilled holes on the PCB, SMT components are soldered directly onto the board's surface. This method allows for more compact and efficient designs, as components can be placed on both sides of the PCB and closer together.

Types of SMT Components

- Resistors: The most common type of SMT component, used to control the flow of electric current in a circuit.

- Capacitors: These components store and release electrical energy, playing a crucial role in filtering and stabilizing voltage.

- Integrated Circuits (ICs): ICs are complex components that can perform a variety of functions, from simple logic operations to complex processing tasks.

- Diodes: These components allow current to flow in one direction, providing protection and rectification in circuits.

- Transistors: Used for amplifying or switching electronic signals, transistors are fundamental components in many electronic devices.

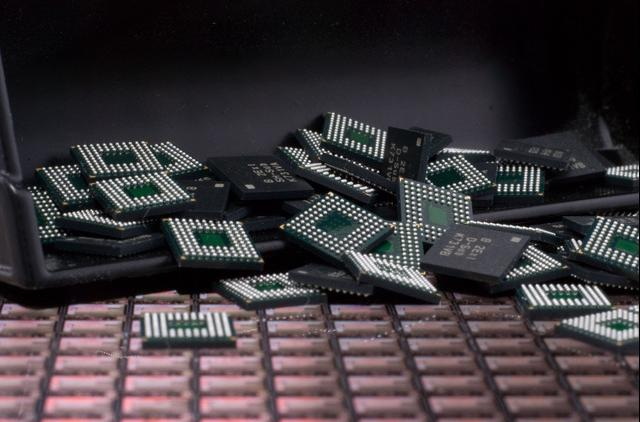

Additional SMT Component Types

Beyond the basic categories mentioned above, several other types of SMT components play crucial roles in various applications:

- Inductors: These components store energy in a magnetic field when electrical current passes through them. They are often used in filtering applications and power supplies.

- Connectors: SMT connectors allow for easy connection between different PCBs or between a PCB and external devices. They facilitate modular design approaches.

- Sensors: Many modern devices incorporate SMT sensors that detect environmental changes, such as temperature or light levels. These sensors are vital for applications ranging from smartphones to industrial automation.

Importance of PCB SMT Components in Electronics

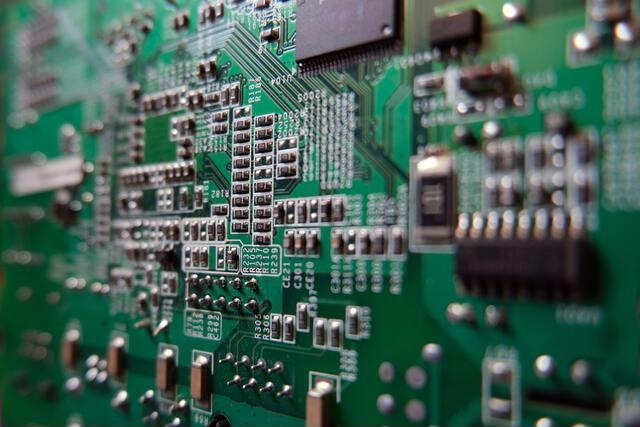

Enhanced Miniaturization

SMT allows for the creation of smaller and more compact electronic devices. By eliminating the need for drilled holes, SMT enables higher component density on PCBs, which is essential for modern gadgets where space is at a premium. This miniaturization is particularly beneficial in applications such as smartphones, tablets, and wearable technology.

Improved Electrical Performance

The shorter signal paths and reduced parasitic capacitance and inductance in SMT designs lead to improved signal integrity and electrical performance. This is particularly important in high-frequency applications where signal loss can be a significant issue. The ability to place components closer together helps maintain signal quality over longer distances.

Higher Assembly Efficiency

SMT supports automated assembly processes, significantly increasing production efficiency. Automated pick-and-place machines can rapidly position components on the PCB, reducing labor costs and minimizing the risk of human error. This automation streamlines the manufacturing process, allowing for faster turnaround times and higher output rates.

Enhanced Thermal Performance

SMT components can be mounted directly on the PCB surface, allowing for efficient heat transfer and dissipation. This results in better thermal management, which is crucial for maintaining the reliability and longevity of electronic devices. Proper thermal performance ensures that devices operate within safe temperature ranges, reducing the risk of failure.

Cost-Effectiveness

The automation of SMT processes not only speeds up production but also reduces costs associated with manual labor. This cost-effectiveness makes SMT a preferred choice for large-scale manufacturing. By minimizing material waste and optimizing assembly processes, manufacturers can achieve significant savings.

Versatility

SMT is versatile and can accommodate a wide range of components, from simple resistors to complex integrated circuits. This versatility allows for the design of multifunctional and sophisticated electronic devices. Manufacturers can easily adapt their designs to incorporate new technologies without extensive redesign efforts.

Reliability

The direct mounting of components on the PCB surface reduces the risk of mechanical failure, enhancing the overall reliability of electronic devices. This is particularly important in applications where device failure can have serious consequences, such as medical equipment or automotive systems.

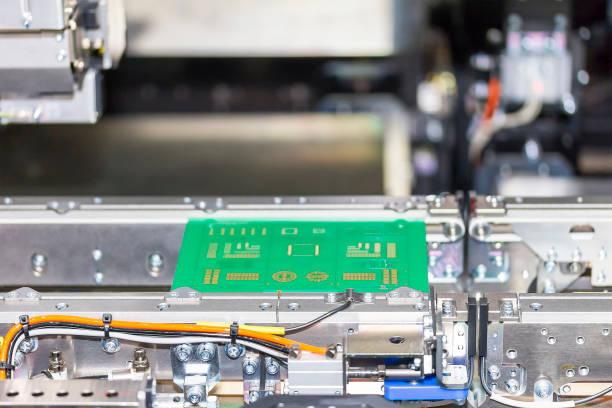

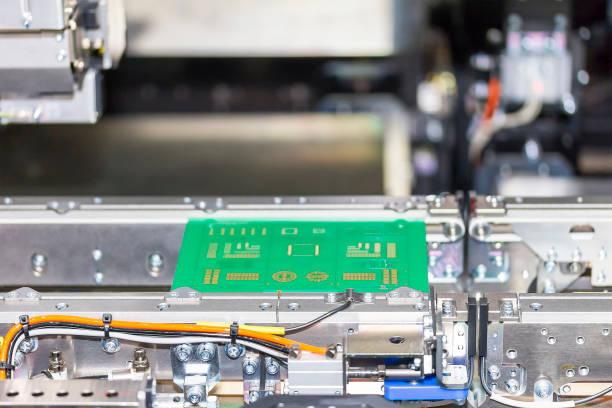

The SMT Assembly Process

The assembly process for SMT involves several key steps:

1. Solder Paste Application: A solder paste—a mixture of solder alloy particles and flux—is applied to specific areas on the PCB where components will be placed.

2. Component Placement: Using automated pick-and-place machines, SMT components are positioned accurately on the solder paste-covered pads.

3. Reflow Soldering: The assembled PCB is passed through a reflow oven where heat melts the solder paste, creating strong electrical connections between the components and the PCB.

4. Inspection: After soldering, PCBs undergo inspection processes to ensure that all components are correctly placed and soldered.

5. Testing: Post-assembly testing is critical to verify that all circuits function as intended before final packaging.

This streamlined assembly process contributes to higher production rates while maintaining quality standards.

Challenges Associated with SMT Components

While SMT offers numerous advantages, it also presents certain challenges:

- Handling Difficulty: The smaller size of SMT components makes them more challenging to handle manually during prototyping or repairs.

- Limited Component Availability: Not all electronic components are available in SMT packages; some may still require through-hole mounting due to their size or functionality.

- Repair Complexity: Repairing or replacing SMT components can be more complex than through-hole components due to their size and placement.

Despite these challenges, advancements in technology continue to improve handling techniques and repair methods for SMT components.

Future Trends in SMT Technology

As technology evolves, several trends are likely to shape the future of SMT:

- Increased Automation: Continued advancements in robotics and AI will further enhance automated assembly processes.

- Higher Frequencies: As demand grows for high-frequency applications such as 5G technology, SMT will adapt to accommodate these needs with specialized components designed for minimal signal loss.

- Sustainability Practices: Manufacturers will increasingly focus on sustainable practices within SMT processes to reduce environmental impact while maintaining efficiency.

- Integration with IoT Devices: As Internet of Things (IoT) devices proliferate, there will be an increasing need for compact yet powerful PCBs that utilize advanced SMT techniques to support connectivity features without sacrificing performance.

- Advanced Materials: Research into new materials that improve thermal conductivity or reduce weight will lead to innovations in component design that enhance overall device performance.

Applications of PCB SMT Components

PCB SMT components find application across various industries due to their versatility:

- Consumer Electronics: Smartphones, tablets, laptops, and smartwatches heavily rely on SMT technology for compactness and functionality.

- Automotive Industry: Modern vehicles utilize numerous electronic systems—ranging from engine control units (ECUs) to infotainment systems—that benefit from reliable SMT assemblies.

- Medical Devices: Precision instruments such as diagnostic equipment rely on high-density PCBs with SMT components for accurate readings and reliable operation under stringent conditions.

- Telecommunications: High-speed communication devices require efficient signal processing capabilities provided by advanced ICs mounted using SMT methods.

- Industrial Automation: Robotics and control systems utilize PCBs with high-density layouts enabled by SMT technology to manage complex tasks efficiently.

Conclusion

In conclusion, PCB SMT components are a cornerstone of modern electronics, offering numerous advantages in terms of size, performance, manufacturing efficiency, and versatility across various applications. Their ability to facilitate compact designs while enhancing electrical performance makes them indispensable in today's fast-paced technological landscape. As technology continues to advance alongside growing demands for smaller yet more powerful devices, the role of SMT in the electronics industry is likely to grow even more significant.

FAQ

1. What is the main advantage of using SMT over through-hole technology?

The main advantage of SMT over through-hole technology is its ability to create more compact and efficient designs. SMT allows for higher component density and supports automated assembly processes that can reduce production costs while improving performance.

2. Can SMT components be used in high-power applications?

Yes, SMT components can be used in high-power applications; however, it is essential to ensure proper thermal management through methods such as heat sinks or thermal vias to dissipate heat effectively.

3. Are there any limitations to using SMT components?

One limitation is that their smaller size can make them more challenging to handle manually during assembly or repairs. Additionally, not all electronic components are available in SMT packages; thus a combination with through-hole components may be necessary.

4. How does SMT improve manufacturing efficiency?

SMT improves manufacturing efficiency by enabling automated assembly processes where pick-and-place machines quickly position components on PCBs—this reduces labor costs while minimizing human error risks during assembly.

5. What types of devices benefit most from SMT?

Devices requiring compact designs—such as smartphones, laptops, and wearable technology—benefit most from SMT due to its ability to place components on both sides of PCBs while achieving higher component density.

Citations:

[1] https://www.jt-int.com/pcb-smt-a-revolution-in-electronics-manufacturing/

[2] https://levisonenterprises.com/5-advantages-to-using-smt/

[3] https://www.pcbonline.com/blog/pcb-smt-components.html

[4] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[5] https://vicoimaging.com/smd-and-smt-comprehensive-guide/

[6] https://www.raypcb.com/smt-pcb/

[7] https://jlcpcb.com/blog/the-characteristics-of-surface-mount-technology