Content Menu

● Introduction to SMT Reel Storage

● Common Mistakes in SMT Reel Storage

>> Inefficient Storage Systems

>> Lack of Environmental Control

>> Inadequate Component Protection

>> Poor Inventory Management

>> Insufficient Security Measures

● Best Practices for SMT Reel Storage

>> Smart Storage Solutions

>> Automated Storage and Retrieval Systems (ASRS)

>> Environmental Control and Component Protection

>> Inventory Management and Security

>> Scalability and Flexibility

● Technological Innovations in SMT Reel Storage

>> Additional Insights on Technological Innovations

● Industry Trends and Future Directions

>> Future of SMT Reel Storage

● Conclusion

● Frequently Asked Questions

>> 1. What are the benefits of using Automated Storage and Retrieval Systems (ASRS) for SMT reel storage?

>> 2. How can environmental factors affect stored electronic components?

>> 3. What are the key features of smart SMT reel storage solutions?

>> 4. Why is proper packaging important for long-term storage of electronic components?

>> 5. How can companies ensure efficient kitting processes for SMT reels?

Effective SMT component reel storage is crucial for maintaining the integrity of electronic components and ensuring efficient production processes. However, several common mistakes can lead to inefficiencies, component damage, and increased costs. This article will explore these mistakes and provide insights into best practices for SMT reel storage.

Introduction to SMT Reel Storage

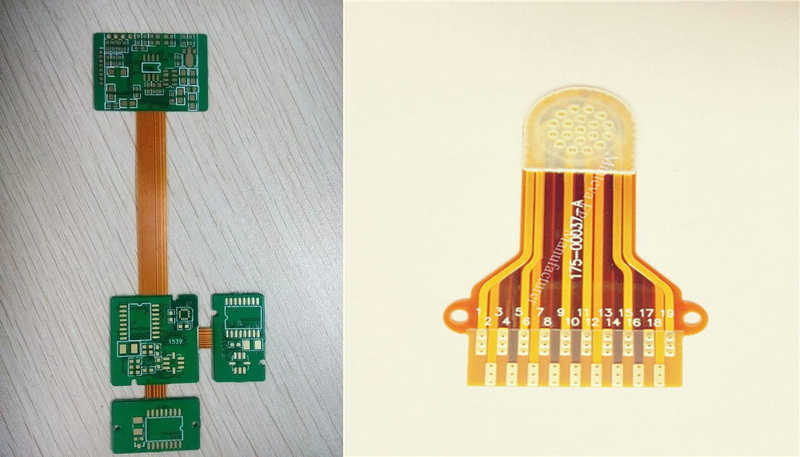

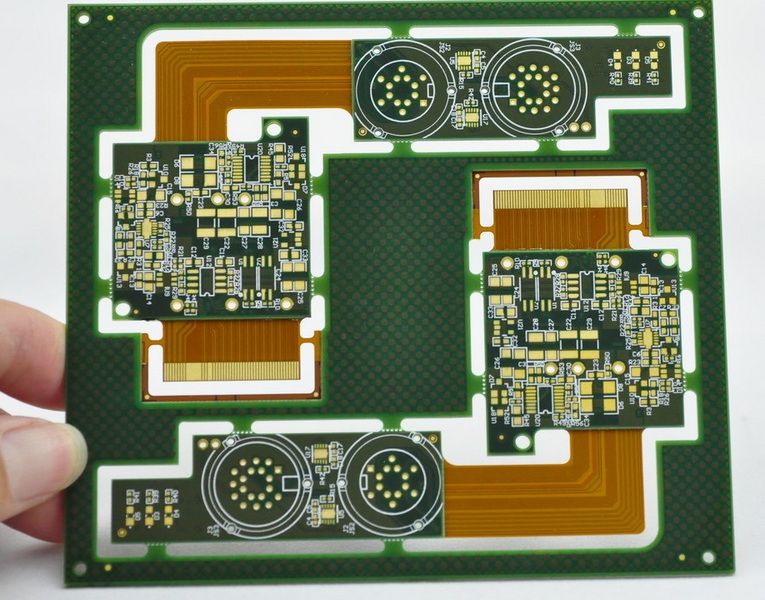

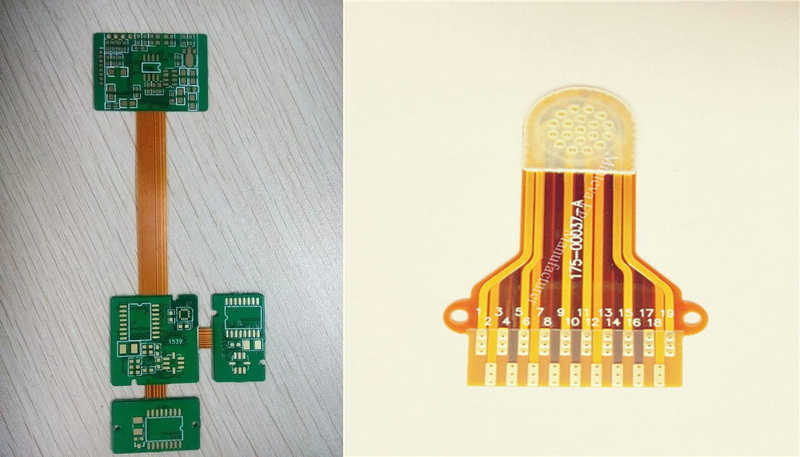

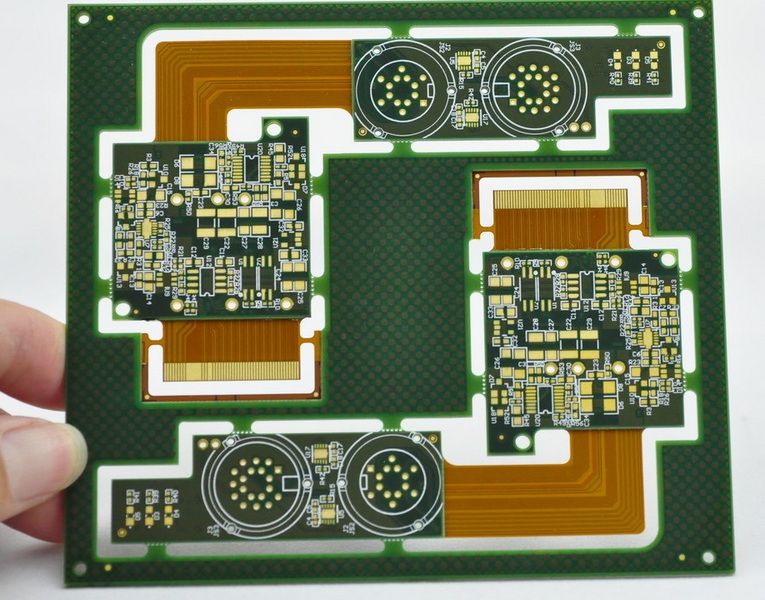

SMT reels are used to store and dispense surface mount components during the assembly process. They help keep components organized and allow them to be easily picked up and placed onto a PCB by a pick and place machine. The size and capacity of an SMT reel can vary depending on the type and size of the components it is used to hold. Proper maintenance and handling of SMT reels are essential to prevent damage to the components and ensure they are correctly positioned on the PCB.

Common Mistakes in SMT Reel Storage

Inefficient Storage Systems

One of the most common mistakes is using inefficient storage systems. Traditional manual storage methods can be time-consuming and prone to errors, leading to bottlenecks on the shop floor and reduced productivity. For instance, manual picking operations can take up to five minutes per line item, and returning each reel to the warehouse can also take several minutes. This inefficiency can be addressed by implementing smart storage solutions like integrated RFID smart shelves or Automated Storage and Retrieval Systems (ASRS). These systems not only optimize space but also provide quick access to components, reducing search times and improving overall efficiency.

Lack of Environmental Control

Another critical mistake is failing to control the storage environment. Electronic components are sensitive to environmental factors such as high humidity, extreme temperatures, aerosols, and oxidizing gases. Storing components in an uncontrolled environment can lead to damage and reduce their lifespan. Ideal storage conditions should maintain a relative humidity below 60% and stable temperatures, often found in air-conditioned environments. High-quality SMT reel storage systems often include climate control features that regulate temperature and humidity levels, ensuring that components remain in optimal condition.

Inadequate Component Protection

Not providing adequate protection against electrostatic discharge (ESD) and moisture is another common error. Components should be stored in antistatic bags or vacuum-sealed packaging with desiccants to prevent moisture absorption and ESD damage. Proper packaging also includes clear labeling with part numbers and storage dates to ensure components are used before they expire. Advanced storage systems often include built-in ESD protection measures to safeguard sensitive electronic components.

Poor Inventory Management

Poor inventory management can lead to using expired or damaged components, resulting in defective products and costly rework. Implementing systems that track inventory levels, lot numbers, and expiration dates can help ensure that components are used in the correct order. Automated storage systems typically integrate with inventory management software, providing real-time tracking of component quantities and usage history.

Insufficient Security Measures

Lastly, insufficient security measures can lead to theft, tampering, or mishandling of valuable components. Implementing access controls and secure storage systems can prevent these issues. Many modern SMT reel storage systems include access control features to restrict unauthorized access to valuable components.

Best Practices for SMT Reel Storage

Smart Storage Solutions

Using smart storage solutions like Inovaxe's Smart Storage Solutions can significantly improve efficiency. These systems allow for dense storage, quick access to components, and integration with inventory management systems. They can reduce kitting time from hours to minutes and provide a return on investment within a few months.

Automated Storage and Retrieval Systems (ASRS)

ASRS systems offer several benefits, including space optimization, improved inventory management, enhanced productivity, and reduced risk of contamination. They can be programmed to follow the "First In, First Out" (FIFO) method, ensuring older components are used before newer ones. This is particularly important for industries where component aging or expiration is a concern.

Environmental Control and Component Protection

Maintaining a controlled environment with stable humidity and temperature conditions is essential. Components should be stored in protective packaging to prevent damage from moisture and ESD. High-quality storage systems often include features like temperature control, humidity regulation, and ESD protection to maintain component integrity.

Inventory Management and Security

Implementing robust inventory management systems and security measures can prevent errors and unauthorized access. This includes tracking inventory levels, using access controls, and ensuring components are properly labeled and stored. Integration with manufacturing systems like MES and ERP can further enhance automation and efficiency.

Scalability and Flexibility

High-quality SMT reel storage systems are modular and scalable, allowing for easy expansion as storage needs increase. This scalability is a cost-effective solution in the long run, as it eliminates the need for complete system replacements as the business grows. These systems can accommodate various reel sizes and offer customizable storage options for other component types.

Technological Innovations in SMT Reel Storage

The integration of AI and IoT technologies into SMT reel storage systems is revolutionizing inventory management by providing real-time tracking and predictive analytics. These technologies help optimize production cycles and reduce downtime by identifying potential issues before they disrupt production. Cloud-based inventory management systems allow for centralized data access, enabling seamless collaboration across different locations and facilitating agile manufacturing practices.

Moreover, the use of AI can help in predictive maintenance of storage systems, ensuring that any potential failures are addressed before they occur. This proactive approach can significantly reduce maintenance costs and improve overall system reliability.

Additional Insights on Technological Innovations

The integration of AI and IoT technologies into SMT reel storage systems is not only enhancing inventory management but also transforming the way components are tracked and maintained throughout the production cycle. Predictive analytics can help identify potential stockouts or component failures before they occur, allowing for proactive measures to be taken. This level of foresight can significantly reduce downtime and improve overall production efficiency.

Moreover, the use of cloud-based inventory management systems facilitates real-time data access across different locations, enabling agile manufacturing practices and seamless collaboration among teams. This centralized approach ensures that all stakeholders have the most current information, reducing errors and improving decision-making.

Industry Trends and Future Directions

As manufacturing moves towards greater automation and Industry 4.0 principles, choosing an SMT reel storage system that aligns with these trends is crucial. Systems that integrate with AGVs for material transport and are compatible with robotic picking systems will future-proof investments and enhance factory efficiency. The emphasis on sustainability is driving the adoption of eco-friendly storage solutions that optimize space, reduce waste, and use energy-efficient technologies, aligning operations with global sustainability goals.

Future of SMT Reel Storage

As the electronics industry continues to evolve, the demand for more efficient, sustainable, and intelligent storage solutions will grow. Future SMT reel storage systems will likely incorporate more advanced automation technologies, such as robotics and machine learning algorithms, to further optimize storage and retrieval processes. These systems will not only enhance productivity but also contribute to environmental sustainability by optimizing space and reducing energy consumption.

In conclusion, the future of SMT reel storage is closely tied to technological innovation and sustainability. By embracing these trends, manufacturers can ensure that their storage systems are not only efficient but also aligned with global environmental goals.

Conclusion

Effective SMT component reel storage is vital for maintaining component integrity and ensuring efficient production processes. Avoiding common mistakes such as inefficient storage systems, lack of environmental control, inadequate component protection, poor inventory management, and insufficient security measures can significantly improve productivity and reduce costs. Implementing smart storage solutions, maintaining a controlled environment, and ensuring robust inventory management are key strategies for optimizing SMT reel storage.

Frequently Asked Questions

1. What are the benefits of using Automated Storage and Retrieval Systems (ASRS) for SMT reel storage?

ASRS systems offer several benefits, including space optimization, improved inventory management, enhanced productivity, reduced risk of contamination, and security features. They can also be programmed to follow the FIFO method and integrate with quality control processes.

2. How can environmental factors affect stored electronic components?

Environmental factors such as high humidity, extreme temperatures, aerosols, and oxidizing gases can damage electronic components. Ideal storage conditions should maintain a relative humidity below 60% and stable temperatures to prevent component degradation.

3. What are the key features of smart SMT reel storage solutions?

Smart storage solutions typically include features such as adjustable shelving, ESD protection, climate control, labeling and identification, and security features. They can also integrate with inventory management systems to improve efficiency and reduce errors.

4. Why is proper packaging important for long-term storage of electronic components?

Proper packaging is crucial for preventing environmental contamination and ensuring components remain usable over time. Components should be stored in antistatic bags or vacuum-sealed packaging with desiccants to prevent moisture absorption and ESD damage.

5. How can companies ensure efficient kitting processes for SMT reels?

Efficient kitting involves verifying inventory, sorting and organizing components, packaging and labeling them correctly, and storing them securely. Implementing smart storage solutions can significantly reduce kitting time and improve overall efficiency by integrating with inventory management systems.