Content Menu

● Understanding SMT Stencil Cleaners

>> Composition of SMT Stencil Cleaners

>> Types of SMT Stencils

● Safety Considerations

>> Compatibility with Stencil Materials

>> Environmental Impact

>> Health and Safety Precautions

● Application Methods

>> Manual Cleaning

>> Automated Cleaning Systems

>> Rinsing and Drying

● Best Practices for Using SMT Stencil Cleaners

>> Regular Cleaning Schedule

>> Use the Right Cleaner for the Job

>> Monitor Cleaning Performance

>> Train Staff on Proper Cleaning Techniques

>> Evaluate Cleaner Effectiveness

● Case Studies and User Testimonials

>> Case Study 1: Automotive Electronics Manufacturer

>> Case Study 2: Consumer Electronics Company

>> User Testimonials

● Conclusion

● FAQ

>> 1. What types of stencils can SMT stencil cleaners be used on?

>> 2. Are SMT stencil cleaners environmentally friendly?

>> 3. What safety precautions should be taken when using SMT stencil cleaners?

>> 4. How should SMT stencil cleaners be applied?

>> 5. Is rinsing necessary after using SMT stencil cleaners?

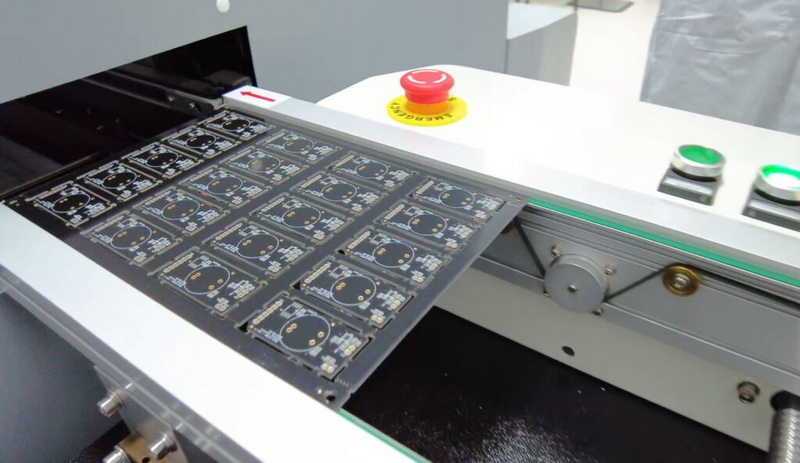

In the world of surface mount technology (SMT), maintaining the cleanliness of stencils is crucial for ensuring high-quality soldering and assembly processes. One of the key components in this maintenance is the SMT stencil cleaner. This article explores the safety and effectiveness of SMT stencil cleaners on various types of stencils, providing insights into their composition, application methods, and best practices.

Understanding SMT Stencil Cleaners

SMT stencil cleaners are specialized cleaning agents designed to remove solder paste, flux residues, and other contaminants from stencils used in the SMT process. These cleaners come in various forms, including sprays, wipes, and liquids, and are formulated to be effective while minimizing damage to the stencils.

Composition of SMT Stencil Cleaners

Most SMT stencil cleaners are composed of solvents, surfactants, and other additives that enhance their cleaning capabilities. Common ingredients include:

- Solvents: These are the primary cleaning agents that dissolve contaminants. They can be water-based or solvent-based, with water-based cleaners often being preferred for their lower environmental impact.

- Surfactants: These compounds help to break down the surface tension of contaminants, allowing for easier removal.

- Additives: Some cleaners include additives that provide additional benefits, such as anti-static properties or enhanced drying times.

Types of SMT Stencils

SMT stencils can be made from various materials, including stainless steel, nickel, and polymer. Each material has its own characteristics and cleaning requirements:

- Stainless Steel Stencils: These are durable and resistant to corrosion, making them suitable for repeated use. Most SMT stencil cleaners are safe for stainless steel.

- Nickel Stencils: Nickel stencils are also robust but can be more sensitive to certain chemicals. It's essential to choose a cleaner that is compatible with nickel.

- Polymer Stencils: These are lightweight and flexible but may be more susceptible to damage from harsh chemicals. Water-based SMT stencil cleaners are often recommended for polymer stencils.

Safety Considerations

When using SMT stencil cleaners, safety is a paramount concern. Here are some key points to consider:

Compatibility with Stencil Materials

Not all SMT stencil cleaners are suitable for every type of stencil material. It's crucial to check the manufacturer's recommendations to ensure compatibility. For instance, some solvent-based cleaners may damage polymer stencils, while water-based cleaners are generally safer.

Environmental Impact

Many modern SMT stencil cleaners are formulated to be environmentally friendly, containing no volatile organic compounds (VOCs) or hazardous air pollutants (HAPs). This not only makes them safer for users but also reduces their environmental footprint.

Health and Safety Precautions

When using any cleaning agent, including SMT stencil cleaners, it's essential to follow safety guidelines:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, such as gloves and safety goggles, to protect against skin and eye contact.

- Ventilation: Ensure that the cleaning area is well-ventilated to avoid inhaling fumes.

- Storage: Store cleaners in a cool, dry place away from direct sunlight and heat sources.

Application Methods

The effectiveness of SMT stencil cleaners largely depends on the application method. Here are some common techniques:

Manual Cleaning

For small batches or occasional cleaning, manual cleaning with wipes or sprays is often sufficient. This method involves applying the cleaner directly to the stencil and wiping it with a lint-free cloth. Manual cleaning allows for precise control over the amount of cleaner used and can be effective for removing stubborn residues.

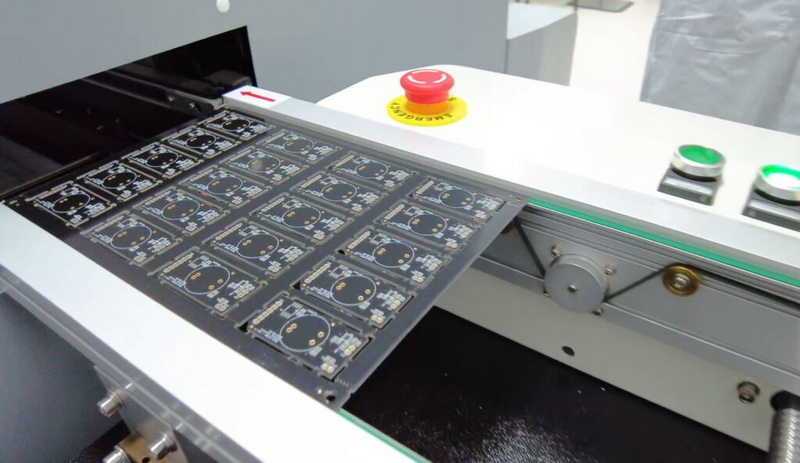

Automated Cleaning Systems

For larger production environments, automated cleaning systems can enhance efficiency. These systems often use ultrasonic cleaning or spray cleaning methods to ensure thorough cleaning without damaging the stencils. Automated systems can handle multiple stencils simultaneously, significantly reducing downtime and labor costs.

Rinsing and Drying

After cleaning, it's essential to rinse the stencil with clean water (if applicable) and dry it properly to prevent any residue from affecting the next printing process. Proper drying techniques, such as using air blowers or drying ovens, can help ensure that no moisture remains on the stencil, which could lead to solder paste defects.

Best Practices for Using SMT Stencil Cleaners

To maximize the effectiveness of SMT stencil cleaners and ensure the longevity of stencils, consider the following best practices:

Regular Cleaning Schedule

Establishing a regular cleaning schedule is vital for maintaining stencil quality. Depending on the production volume and type of solder paste used, stencils may need to be cleaned after every few prints or at the end of each production run. Regular cleaning helps prevent the buildup of residues that can affect print quality.

Use the Right Cleaner for the Job

Selecting the appropriate SMT stencil cleaner based on the stencil material and the type of contaminants is crucial. For example, a water-based cleaner may be ideal for polymer stencils, while a solvent-based cleaner might be more effective for stainless steel stencils with heavy flux residues.

Monitor Cleaning Performance

Keep track of the cleaning performance by inspecting stencils after cleaning. Look for any remaining residues or signs of damage. If stencils are not coming out clean, it may be necessary to adjust the cleaning method or switch to a more effective cleaner.

Train Staff on Proper Cleaning Techniques

Ensure that all personnel involved in the cleaning process are trained on the proper techniques and safety protocols. This training should include information on the types of cleaners used, application methods, and safety precautions to minimize risks.

Evaluate Cleaner Effectiveness

Periodically evaluate the effectiveness of the SMT stencil cleaners being used. This can involve testing different brands or formulations to determine which provides the best cleaning results without damaging the stencils.

Case Studies and User Testimonials

Case Study 1: Automotive Electronics Manufacturer

An automotive electronics manufacturer faced challenges with solder paste residues on their stainless steel stencils, leading to defects in their products. After switching to a high-performance water-based SMT stencil cleaner, they reported a significant reduction in defects and improved print quality. The cleaner was easy to use and safe for their stainless steel stencils, leading to increased production efficiency.

Case Study 2: Consumer Electronics Company

A consumer electronics company using polymer stencils struggled with residue buildup that affected their production line. They implemented an automated cleaning system with a specialized SMT stencil cleaner designed for polymer materials. The results were impressive, with a noticeable improvement in stencil cleanliness and a reduction in downtime for cleaning.

User Testimonials

- John D., SMT Technician: "Switching to a water-based SMT stencil cleaner has made a huge difference in our production. It's safe for our stencils and does an excellent job of removing solder paste."

- Lisa M., Production Manager: "We invested in an automated cleaning system, and it has paid off. Our stencils are cleaner than ever, and we've seen a drop in defects."

Conclusion

In conclusion, SMT stencil cleaners are generally safe for use on all types of stencils, provided that the correct cleaner is chosen based on the stencil material. Water-based cleaners are often the safest option, especially for sensitive materials like polymers. By following proper safety protocols and application methods, users can ensure effective cleaning while maintaining the integrity of their stencils. Regular cleaning, the right choice of cleaner, and proper training are essential for achieving optimal results in the SMT process.

FAQ

1. What types of stencils can SMT stencil cleaners be used on?

SMT stencil cleaners can be used on stainless steel, nickel, and polymer stencils, but it's essential to choose a cleaner compatible with the specific material.

2. Are SMT stencil cleaners environmentally friendly?

Many SMT stencil cleaners are formulated to be environmentally friendly, containing no VOCs or HAPs, making them safer for both users and the environment.

3. What safety precautions should be taken when using SMT stencil cleaners?

Users should wear PPE, ensure proper ventilation, and store cleaners safely to avoid health risks.

4. How should SMT stencil cleaners be applied?

SMT stencil cleaners can be applied manually with wipes or sprays, or through automated cleaning systems for larger production needs.

5. Is rinsing necessary after using SMT stencil cleaners?

Rinsing is recommended, especially for water-based cleaners, to remove any residue before the stencil is reused.